Outdoor Live Tank SF6 Gas Circuit Breaker - Rockwill Brand

<< The professional manufacturer of Outdoor and Indoor SF6 gas circuit breaker >>

----------------------------------------------------------------------------------------------

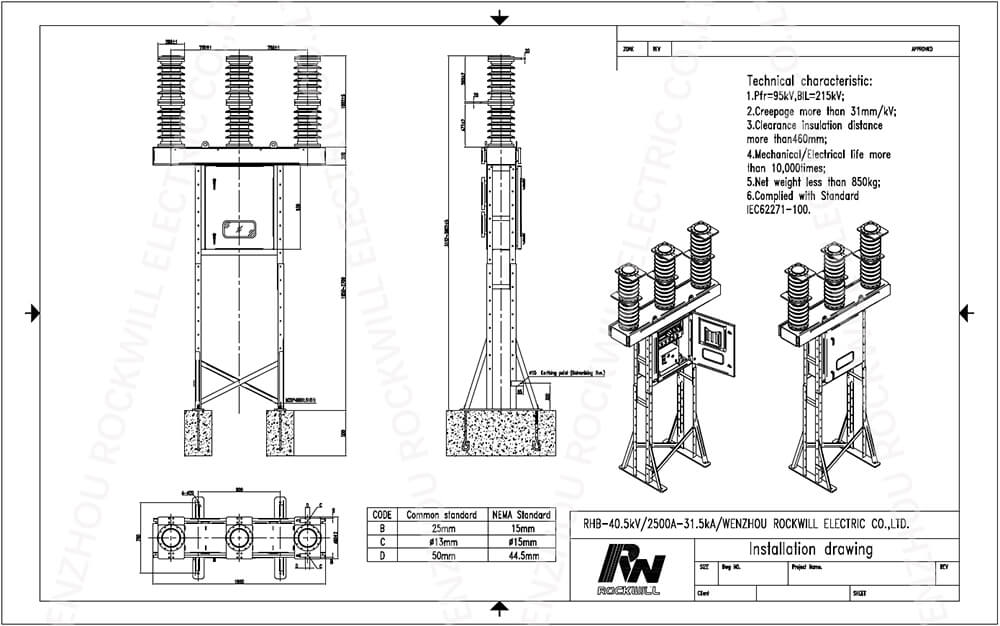

RHB-40.5 type medium voltage live tank sf6 gas circuit-breakers for outdoor installation use sulphur hexafluoride gas (SF6) to extinguish the electric arc and as the insulating medium.

Breaking in SF6 gas takes place without current chopping or generation of overvoltages.

These characteristics guarantee a long electrical life for the circuit-breaker and limited dynamic, di-electric and thermal stresses on the installation.

The GSH (MH) type of stored energy and free release mechanical operating mechanism allows opening and closing operations through local and remote control.

The operating mechanism, the activating kinematics of the moving contacts and the anti-condensation heater are located inside a tight metal enclosure which also acts as the support for the poles.

The above-mentioned structure is supported by a frame made of telescopic metal sections which allow the height of the circuit-breaker terminal to be adapted from 2800 mm to 3700 mm.

The metal enclosure has IP 54(*) degree of protection and is fitted with a tight door with an inspection window.

The circuit-breaker is compact and ensures a high level of sturdiness and excellent mechanical reliability.

The enclosure is made out of a steel plate with adequate surface protection by a special metalising and painting process. The support structures are hot dip galvanised.

Fields of application of RHB-40.5 type medium voltage live tank sf6 gas circuit-breakers

RHB-40.5 type medium voltage live tank sf6 gas circuit-breakers are used in power distribution for control and protection of lines and for control and protection of transformers, rectifier units, capacitor banks, etc.

Due to the SF6 autopuffer breaking technique, the RHB-40.5 circuit-breakers do not generate overvoltage during switching, and are therefore also highly suitable for retrofitting, upgrading and enlarging older installations where the insulating materials of the cables and apparatus may have already been stressed during service.

Service environment of RHB-40.5 type medium voltage live tank sf6 gas circuit-breakers

1. Altitude: no more than 2500 meters; high prototype 4000 meters;

2. Ambient temperature: -30 ℃ — + 40 ℃ (special requirements -40 ℃ — + 40 ℃);

3. Relative humidity: daily average is not greater than 95%, monthly average is not greater than 90% (25 ° C);

4. Wind speed: no more than 35 meters / second;

5. Where there is no flammable substance, explosion hazard, chemical corrosion and severe vibration.

Standards and approvals

The RHB-40.5 circuit-breakers comply with the IEC 62271-100 standard as well as of other major industrialised countries.

They have undergone the tests indicated below andensure service safety and reliability of the apparatus in allinstallations.

Type tests:

– Temperature rise test

– Di-electric test

– Short circuit test duties

– Short time current test

– Mechanical endurance test

Routine tests:

– Power frequency voltage with stand test

– Insulation test on auxiliary and control circuits

– Measurement of main circuit resistance

– Mechanical and electrical operation test

Service safety

The mechanical and electrical locking devices have been provided to prevent incorrect operations and to carry out inspection of the installations while guaranteeing maximum operator safety.

Structure

RHB-40.5 type circuit breaker is a porcelain column structure, with three phases separated, each has a gas-pressured arc extinguishing chamber, and the three-phase gas is connected through copper pipes. The circuit breaker is composed of a pillar porcelain bottle, a current transformer, an arc extinguishing chamber, an adsorber, a transmission box, a connecting rod, a chassis and a spring operating mechanism.

Porcelain sleeve

Porcelain sleeve is the supporting and insulating component of the main circuit of the circuit breaker and the power system. Because it is in communication with the circuit breaker shell, it is a part of the pressure vessel, so it has high strength and good air tightness.

The arc extinguishing chamber of the RHB-40.5 circuit breaker is mainly composed of static contacts, moving contacts, porcelain sleeves, cylinders and nozzles (see Figure 5). The porcelain sleeves and insulation rods form the ground insulation of the moving and static contacts. .

Adsorber

The adsorber is an aluminum alloy container. RHB-40.5 circuit breakers are each equipped with six, but three of them are placed in the gearbox and three are in the cooling cap. The F-03 molecular sieve is installed in the adsorber, and its role is to adsorb the water in the sulfur hexafluoride gas and the low fluoride formed by the decomposition of the arc.

Working principle

The breaking principle of RHB circuit-breakers is basedon compression and self-blast technique to obtain topperformances at all breaking current values, with minimumarc times, gradual arc extinction without chopping, and norestriking or switching overvoltages. This breaking technique-already widely appreciated and used in high voltage circuit-breakers, has been introduced into medium voltage with theHD4 series circuit-breakers for indoor installation.

Main contact separation

No electric arc is struck because the current flows through the arcing contacts. During its run downwards, the moving apparatus compresses the gas in the lower chamber. The compressed gas

flows from the lower to the upper chamber, thereby taking both the chambers to the same pressure.

Arcing contact separation

The current flows due to the electric arc which has struck between the arcing contacts. The gas cannot escape through the nozzle because the hole is still closed by the fixed arcing contact and cannot even escape through the inside of the arcing contact, because of the clogging effect of the electric arc.

– at low current values, the arc is extinguished when the current passes through its natural zero and the gas flows through the contacts. The low pressure level cannot chop the current and the modest amount of gas which “escapes” is sufficient to restore di-electric resistance between the two contacts, preventing restriking on the rising front of the recovery voltage.

– at high short-circuit values, the pressure wave generated by the electric arc closes the valve between the two chambers so that the circuit-breaker starts to operate as “pure self-blast”

apparatus. The pressure increases in the upper volume due to the gas heating and molecular dissociation due to the high temperature. The pressure increase is proportional to the arc current and ensures arc extinction during the first passage through zero current.

Circuit-breaker open

The arc has been extinguished, the self-generated pressure in the upper volume decreases because the gas is flowing through the contacts. The valve re-opens and a new jet of fresh gas flows in and “washes” the chamber. This means the apparatus is immediately ready to close and trip again up to its maximum breaking capacity.

1 Terminal

2 Insulating enclosure

3 Blasting nozzle

4 Moving arcing contact

5 Moving contact

6 Fixed arcing contact

7 Fixed contact

8 Insulating tie-rod

9 Cap with bursting valve (upon request)

Standard Equipment

1)GSH operating mechanism, complete with manualopening and closing push buttons, mechanical indicatorsfor circuit-breaker “open or closed” and for springs“charged or discharged”

2) Shunt opening release

3) Shunt closing release

4) Spring-charging geared motor

5) Lever for manual spring charging

6) Pressure switch with two levels (one per pole); suitable foroperation down to -25 0 C. For lower service temperatures,please contact us

7) Locking circuit for insufficient gas pressure (automaticopening with additional shunt opening release and lock inthe open position by means of closing circuit interruption)

8) Electrical contacts signalling: springs charged

9) Auxiliary contacts (13 NO + 13 NC) including those usedfor internal breaker-control circuit

10) Anti-condensation/heating circuit for low temperatureswith armoured anti-condensation heating elements andthermostat; solution provided for operation down to -25 0 C

11) The cabinet is fitted with cable gland plate for control,cables and with padlockable front door

The circuit-breaker is supplied with asymmetrical terminalconnections on one side of the poles only and with 4 holesas per NEMA form 4 Standards. The lower terminal is turnedtowards the rear of the apparatus, the upper terminalsare provided as standard turned towards the front of theapparatus but, on request, it can be turned towards the rearof the apparatus

Equipment supplied on request

12) MCB for geared motor protection

13) Signalling lamps placed inside the cabinet, in a position visible from the inspection window on the door. A single solution with 4 lamps is provided for:

– signalling circuit-breaker closed (red lamp)

– signalling circuit-breaker open (green lamp)

– signalling springs charged (yellow lamp)

– signalling insufficient gas pressure (white/amber lamp)

14) Selector switch for local/remote control

15) Control switch for local ON/OFF electrical operation through shunt closing and opening releases

16) YU undervoltage release

17) Electrical signalling of YU undervoltage release energised (or de-energised)

18) Single-phase socket

19) Illumination lamp which automatically switches on by means of a limit switch when the door is opened

20) Telescope metal structure to vary mounting height and arrangement of CT/PT mounting

|

Circuit-breaker on column

|

RHB-12/24

|

RHB-36

|

RHB-40

|

|

Standards

|

IEC 62271-100

|

•

|

•

|

•

|

|

Rated voltage

|

Ur [kV]

|

12/24

|

36

|

40.5

|

|

Rated insulation voltage

|

Us [kV]

|

12/24

|

36

|

40.5

|

|

Withstand voltage at 50 Hz

|

Ud (1 min) [kV]

|

70 (dry) /

60 (wet)

|

95 (dry) /

80 (wet)

|

95 (dry) /

80 (wet)

|

|

Impulse withstand voltage

|

Up [kV]

|

125/150

|

200

|

200

|

|

Rated frequency

|

fr [Hz]

|

50-60

|

50-60

|

50-60

|

|

Rated normal current (400C)

|

lr [A]

|

1250

|

2500

|

1250

|

2500

|

1250

|

2500

|

|

Rated breaking capacity

|

Isc [kA]

|

25

|

25

|

25

|

25

|

25

|

25

|

|

31.5

|

31.5

|

31.5

|

31.5

|

31.5

|

31.5

|

|

Rated short-time

|

Ik [kA]

|

25

|

25

|

25

|

25

|

25

|

25

|

|

withstand current (3 s)

|

31.5

|

31.5

|

31.5

|

31.5

|

31.5

|

31.5

|

|

Making capacity

|

Ip [kA]

|

63

|

63

|

63

|

63

|

63

|

63

|

|

80

|

80

|

80

|

80

|

80

|

80

|

|

Operation sequence

|

[O-0, 3s-CO-15s-CO]

|

•

|

•

|

•

|

|

Opening time

|

[ms]

|

45+10

|

45+10

|

45+10

|

|

Arcing time

|

[ms]

|

10-15

|

10-15

|

10-15

|

|

Total breaking time

|

[ms]

|

55-60

|

55-60

|

55-60

|

|

Closing time

|

[ms]

|

75+10

|

75+10

|

75+10

|

|

Overall dimensions

|

on frame

|

3090 – 3840

|

3090 – 3840

|

3090 – 3840

|

|

H [mm]

|

|

L [mm]

|

900

|

900

|

900

|

|

P [mm]

|

686

|

686

|

686

|

|

Weight

|

[Kg]

|

900

|

900

|

900

|

|

SF6 gas absolute pressure

|

Rated service value [kPa]

|

380

|

380

|

550

|

|

Operating temperature (1)

|

[0C]

|

–25...+40

|

–25...+40

|

–25...+40

|

|

Tropicalisation

|

IEC: 60068-2-30, 721-2-1

|

•

|

•

|

•

|

|

Electromagnetic compatibility

|

IEC: 60694, 61000-6-2, 61000-6-4

|

•

|

•

|

•

|

|

Solar radiation

|

[W/m2]

|

1000

|

1000

|

1000

|

|

Presence of pollution

|

IEC 815 - table 1

|

Level III

|

Level III

|

Level III

|

|

Creepage distance

|

[cm/kV]

|

2.5

|

2.5

|

2.75

|

|

Ice coating

|

[mm]

|

10

|

10

|

10

|

|

Wind speed

|

[m/s]

|

34

|

34

|

34

|

|

Earthquake resistance

|

[g]

|

0.3

|

0.3

|

0.3

|

|

Static force on the terminals

|

Longitudinal [N]

|

750

|

750

|

750

|

|

Transversal [N]

|

500

|

500

|

500

|

|

Vertical [N]

|

750

|

750

|

750

|

|

(1) For lower operating temperatures, please consult us.

|

RHB-40.5 type medium voltage live tank sf6 gas circuit-breakers for outdoor installat…