Bulk carrier

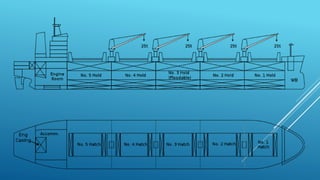

- 4. Bulk Carrier A bulk carrier, bulk freighter, or bulker is a merchant ship specially designed to transport unpackaged bulk cargo, such as grains, coal, ore, and cement in its cargo holds. Since the first specialized bulk carrier was built in 1852, economic forces have fuelled the development of these ships, causing them to grow in size and sophistication. Today's bulkers are specially designed to maximize capacity, safety, efficiency, and durability. Today, bulkers make up 15% - 17% of the world's merchant fleets and range in size from single-hold mini- bulkers to mammoth ore ships able to carry 400,000 metric tons of deadweight (DWT). A number of specialized designs exist: some can unload their own cargo, some depend on port facilities for unloading, and some even package the cargo as it is loaded. Over half of all bulkers have Greek, Japanese, or Chinese owners and more than a quarter are registered in Panama. Korea is the largest single builder of bulkers, and 82% of these ships were built in Asia. Bulk cargo can be very dense, corrosive, or abrasive. This can present safety problems: cargo shifting, spontaneous combustion, and cargo saturation can threaten a ship. The use of ships that are old and have corrosion problems has been linked to a spate of bulker sinkings in the 1990s, as have the bulker's large hatchways, important for efficient cargo handling. New international regulations have since been introduced to improve ship design and inspection, and to streamline the process of abandoning ship.

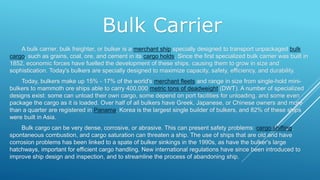

- 5. Size Categories Major Bulk Carrier Size Categories

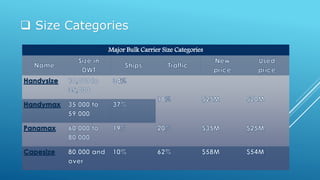

- 6. CATEGORIES AS PER REGIONS Categories occur in regional trade, such as Kamsarmax, Seawaymax, Setouchmax, Dunkirkmax, and Newcastlemax also appear in regional trade. "Kamsarmax" : Maximum length overall 229 meters refers to a new type of ships, larger than panamax, that are suitable for berthing at the Port of Kamsar (Republic of Guinea), where the major loading terminal of bauxite is restricted to vessels not more than 229 meters. "Newcastlemax" : Maximum beam 50 meters, and maximum length overall of 300 meters Refers to the largest vessel able to enter the port of Newcastle, Australia at about 185,000 DWT "Setouchmax" : About 203,000 DWT, being the largest vessels able to navigate the Setouch Sea, Japan "Seawaymax" : LOA 226 m max / 7.92 m draft. Refers to the largest vessel that can pass through the canal locks of the St Lawrence Seaway (Great lakes, Canada) "Malaccamax" : LOA 330 m / 20 m draft / 300,000 DWT, Refers to the largest vessel that can pass through the Straits of Malacca. "Dunkirkmax" : Maximum allowable beam = 45 m / LOA 289 m. max (175,000 DWT approx.) for the eastern harbor lock in the Port of Dunkirk (France)

- 7. GENERAL TYPES General Bulk Carrier Types Illustration Description Geared bulk carriers are typically in the handysize to handymax size range although there are a small number of geared panamax vessels, like all bulkers they feature a series of holds covered by prominent hatch covers. They have cranes, derricks or conveyors that allow them to load or discharge cargo in ports without shore-based equipment. This gives geared bulkers flexibility in the cargoes they can carry and the routes they can travel. Combined carriers are designed to transport both liquid and dry bulk cargoes. If both are carried simultaneously, they are segregated in separate holds and tanks. Combined carriers require special design and are expensive. They were prevalent in the 1970s, but their numbers have dwindled since 1990. Gearless carriers are bulkers without cranes or conveyors. These ships depend on shore-based equipment at their ports of call for loading and discharging. They range across all sizes, the larger bulk carriers (VLOCs) can only dock at the largest ports, some of these are designed with a single port-to-port trade in mind. The use of gearless bulkers avoids the costs of installing, operating, and maintaining cranes.

- 8. GENERAL TYPES General Bulk Carrier Types Illustration Description Self-dischargers are bulkers with conveyor belts, or with the use of an excavator that is fitted on a traverse running over the vessel's entire hatch, and that is able to move sideways as well. This allows them to discharge their cargo quickly and efficiently. Lakers are the bulkers prominent on the Great Lakes, often identifiable by having a forward house which helps in transiting locks. Operating in fresh water, these ships suffer much less corrosion damage and have a much longer lifespan than saltwater ships.As of 2005, there were 98 lakers of 10,000 DWT or over. BIBO or "Bulk In, Bags Out" bulkers are equipped to bag cargo as it is unloaded. The CHL Innovator, shown in the photo, is a BIBO bulker. In one hour, this ship can unload 300 tons of bulk sugar and package it into 50 kg sacks.

- 9. LOADS, HULL STRUCTURE AND DESIGN

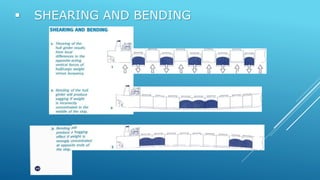

- 10. SHEARING AND BENDING

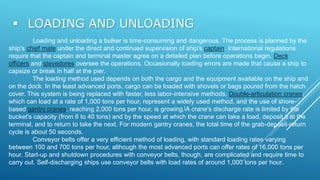

- 14. LOADING AND UNLOADING Loading and unloading a bulker is time-consuming and dangerous. The process is planned by the ship's chief mate under the direct and continued supervision of ship's captain. International regulations require that the captain and terminal master agree on a detailed plan before operations begin. Deck officers and stevedores oversee the operations. Occasionally loading errors are made that cause a ship to capsize or break in half at the pier. The loading method used depends on both the cargo and the equipment available on the ship and on the dock. In the least advanced ports, cargo can be loaded with shovels or bags poured from the hatch cover. This system is being replaced with faster, less labor-intensive methods. Double-articulation cranes, which can load at a rate of 1,000 tons per hour, represent a widely used method, and the use of shore- based gantry cranes, reaching 2,000 tons per hour, is growing.[A crane's discharge rate is limited by the bucket's capacity (from 6 to 40 tons) and by the speed at which the crane can take a load, deposit it at the terminal, and to return to take the next. For modern gantry cranes, the total time of the grab-deposit-return cycle is about 50 seconds. Conveyor belts offer a very efficient method of loading, with standard loading rates varying between 100 and 700 tons per hour, although the most advanced ports can offer rates of 16,000 tons per hour. Start-up and shutdown procedures with conveyor belts, though, are complicated and require time to carry out. Self-discharging ships use conveyor belts with load rates of around 1,000 tons per hour.

- 15. LOADING AND UNLOADING Once the cargo is discharged, the crew begins to clean the holds. This is particularly important if the next cargo is of a different type. The immense size of cargo holds and the tendency of cargoes to be physically irritating add to the difficulty of cleaning the holds. When the holds are clean, the process of loading begins. It is crucial to keep the cargo level during loading in order to maintain stability. As the hold is filled, machines such as excavators and bulldozers are often used to keep the cargo in check. Leveling is particularly important when the hold is only partly full, since cargo is more likely to shift. Extra precautions are taken, such as adding longitudinal divisions and securing wood atop the cargo. If a hold is full, a technique called tomming is used, which involves digging out a 6 feet (2 m) hole below the hatch cover and filling it with bagged cargo or weights.