5S - Seiri, Seiton, Seiso, Seiketsu, Shitsuke

- 2. P X A C H Y S I R L Q U

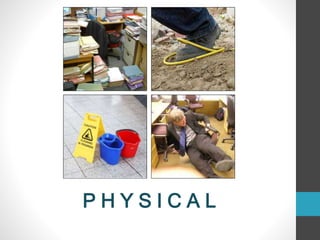

- 3. P H Y S I C A L

- 4. V C H W M C L I P E J A

- 5. C H E M I C A L

- 6. M H C T E I A B N L C A

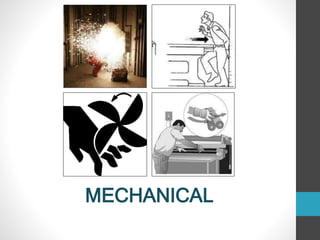

- 7. MECHANICAL

- 8. L E C M E T R H A C I D

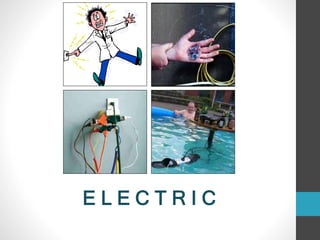

- 9. E L E C T R I C

- 14. D H A M E W I Y Z O S R R T A S Y D C H R D O E U N R U S Z H O G A N I

- 15. D H A M E W I Y Z O S R R T A S Y D C H R D O E U N R U S Z H O G A N I

- 18. Increased PRODUCTIVITY with 5S Richard Anthony M. Miranda

- 19. Seiri

- 20. SEITON •Separating the essential from the inessential. •Getting rid of all the different things you no longer need.

- 21. Seiton

- 22. SEITON •Setting and arranging items. •There must be a place for everything, and everything in its place.

- 23. Seiso

- 24. SEISO •Cleaning and maintaining the workplace. •Checking up for some malfunctions.

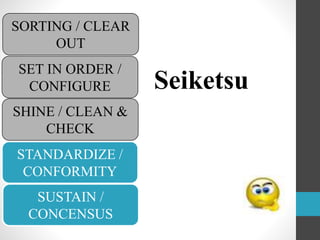

- 25. Seiketsu

- 26. SEIKETSU •Maintaining everything in order and according to its standards.

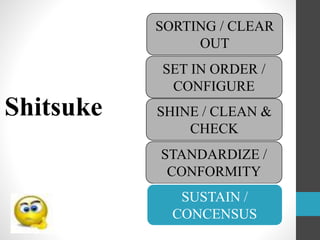

- 27. Shitsuke

- 28. SHITSUKE •Having the self-discipline to sustain what has been done and not fall back to the old, bad ways.

- 29. Benefits of 5S Improved Productivity Safety

- 30. SEIRI SORTING / CLEAR OUT SET IN ORDER / CONFIGURE SHINE / CLEAN & CHECK STANDARDIZE / CONFORMITY SUSTAIN / CONCENSUS

- 31. Seiton SORTING / CLEAR OUT SET IN ORDER / CONFIGURE SHINE / CLEAN & CHECK STANDARDIZE / CONFORMITY SUSTAIN / CONCENSUS

- 32. Seiso SORTING / CLEAR OUT SET IN ORDER / CONFIGURE SHINE / CLEAN & CHECK STANDARDIZE / CONFORMITY SUSTAIN / CONCENSUS

- 33. Seiketsu SORTING / CLEAR OUT SET IN ORDER / CONFIGURE SHINE / CLEAN & CHECK STANDARDIZE / CONFORMITY SUSTAIN / CONCENSUS

- 34. Shitsuke SORTING / CLEAR OUT SET IN ORDER / CONFIGURE SHINE / CLEAN & CHECK STANDARDIZE / CONFORMITY SUSTAIN / CONCENSUS

- 35. ACTIVITY

- 36. Short Quiz

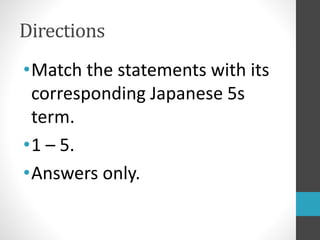

- 37. Directions •Match the statements with its corresponding Japanese 5s term. •1 – 5. •Answers only.

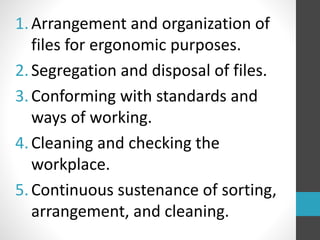

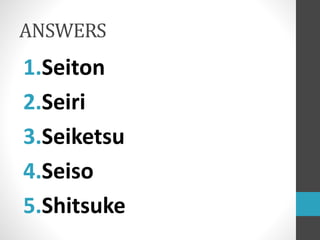

- 38. 1.Arrangement and organization of files for ergonomic purposes. 2.Segregation and disposal of files. 3.Conforming with standards and ways of working. 4.Cleaning and checking the workplace. 5.Continuous sustenance of sorting, arrangement, and cleaning.

- 40. Assignment 1.Give three (3) real-life applications for all five terms in 5s. 2.What is ergonomics? Write your answers in your notebook.

- 41. Thank you for listening!

- 42. Very good! You’ve been listening! 2s 1 1 1 1 1

- 43. See, I’m a Genius! 3s 1 1 1 1 1

- 44. Yes! May Tama Ka! 4s 1 1 1 1 1

- 45. Splendid work! 5s 1 1 1 1 1

- 46. Wow, nakatsamba! ac 1 1 1 1 1

- 47. UHHHH, I really don’t know 1s

- 48. Wait ….. research ko muna ang sagot 1s 2s

- 49. Think…think… think… 1s 2s 3s

- 50. WRONG ANSWER 1s 2s 3s 4s

Editor's Notes

- #15: Dirty Hazardous Messy Unorganized Chaos

- #16: Dirty Hazardous Messy Unorganized Chaos

- #17: Dirty Hazardous Messy Unorganized Chaos

- #23: Can also be translated as "set in order", "straighten", or "streamline" Arrange all necessary items so they can be easily selected for use Prevent loss and waste of time Make it easy to find and pick up necessary items Ensure first-come-first-served basis Make workflow smooth and easy All above work should be done on regular basis

- #25: Can also be translated as "sweep", "sanitize", or "scrub" Clean your workplace completely Use cleaning as inspection Prevent machinery and equipment deterioration Keep workplace safe and easy to work Keep work place clean and pleasing to work in When in place anyone not familiar to the environment must be able to detect problems in 5 seconds within 50 feet.

- #27: Standardize the best practices in the work area. Maintain high standards and workplace organization at all times. Maintain orderliness. Maintain everything in order and according to its standard. Everything in its right place. Every process has a standard.

- #29: To keep in working order Also translates as "do without being told" Perform regular audits Training and Discipline Training is goal oriented process. Its resulting feedback is necessary monthly

- #39: SEITON – arrangement and organization of files for ergonomic purposes. SEIRI – segregation and disposal of files. SEIKETSU – conforming with standards and ways of working. SEISO – cleaning and checking the workplace. SHITSUKE – set of values for continuous sustenance of sorting, arrangement, and cleaning.

- #40: SEITON – arrangement and organization of files for ergonomic purposes. SEIRI – segregation and disposal of files. SEIKETSU – conforming with standards and ways of working. SEISO – cleaning and checking the workplace. SHITSUKE – set of values for continuous sustenance of sorting, arrangement, and cleaning.