Construction dewatering

- 1. Construction Equipments - A project report on Construction Dewatering…

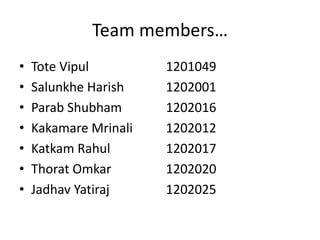

- 2. Team members… • Tote Vipul • Salunkhe Harish • Parab Shubham • Kakamare Mrinali • Katkam Rahul • Thorat Omkar • Jadhav Yatiraj 1201049 1202001 1202016 1202012 1202017 1202020 1202025

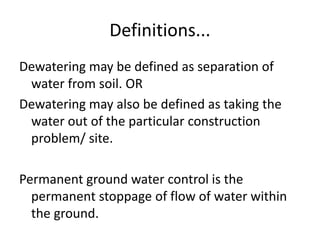

- 3. Definitions... Dewatering may be defined as separation of water from soil. OR Dewatering may also be defined as taking the water out of the particular construction problem/ site. Permanent ground water control is the permanent stoppage of flow of water within the ground.

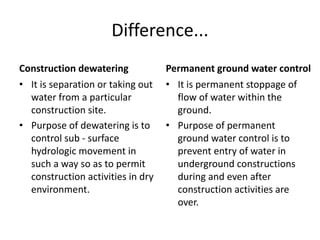

- 4. Difference... Construction dewatering • It is separation or taking out water from a particular construction site. • Purpose of dewatering is to control sub - surface hydrologic movement in such a way so as to permit construction activities in dry environment. Permanent ground water control • It is permanent stoppage of flow of water within the ground. • Purpose of permanent ground water control is to prevent entry of water in underground constructions during and even after construction activities are over.

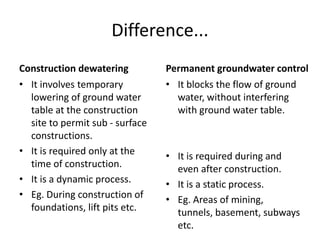

- 5. Difference... Construction dewatering • It involves temporary lowering of ground water table at the construction site to permit sub - surface constructions. • It is required only at the time of construction. • It is a dynamic process. • Eg. During construction of foundations, lift pits etc. Permanent groundwater control • It blocks the flow of ground water, without interfering with ground water table. • It is required during and even after construction. • It is a static process. • Eg. Areas of mining, tunnels, basement, subways etc.

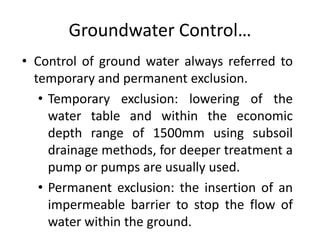

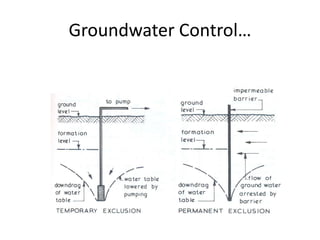

- 6. Groundwater Control… • Control of ground water always referred to temporary and permanent exclusion. • Temporary exclusion: lowering of the water table and within the economic depth range of 1500mm using subsoil drainage methods, for deeper treatment a pump or pumps are usually used. • Permanent exclusion: the insertion of an impermeable barrier to stop the flow of water within the ground.

- 8. Groundwater Control… • Water can be classified by its relative position to or within the ground.

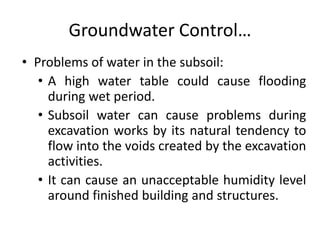

- 9. Groundwater Control… • Problems of water in the subsoil: • A high water table could cause flooding during wet period. • Subsoil water can cause problems during excavation works by its natural tendency to flow into the voids created by the excavation activities. • It can cause an unacceptable humidity level around finished building and structures.

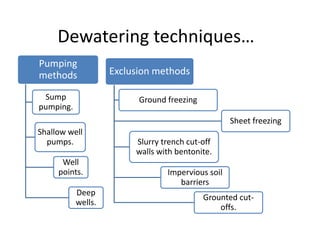

- 10. Dewatering techniques… Pumping methods Sump pumping. Shallow well pumps. Well points. Deep wells. Exclusion methods Ground freezing Sheet freezing Slurry trench cut-off walls with bentonite. Impervious soil barriers Grounted cut- offs.

- 11. Construction Dewatering… Sump and Sump pumping. • Water is collected in deeper part of excavations (called sumps) and pumped away.

- 12. Sump and Sump pumping… ADVANTAGES- • Simple and cheap method of dewatering. DISADVANTAGES- • The sump takes up space within the excavation. • Can lead to water pollution problems silt- laden water.

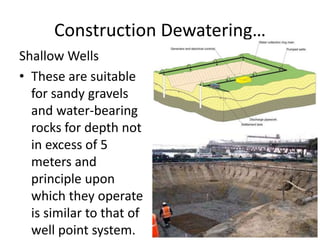

- 13. Construction Dewatering… Shallow Wells • These are suitable for sandy gravels and water-bearing rocks for depth not in excess of 5 meters and principle upon which they operate is similar to that of well point system.

- 14. Shallow Wells ADVANTAGES • It is used to extract large quantities of water from a single hole. DISADVANTAGES • The limiting depth to which this method is employed is about 8 m.

- 15. Construction Dewatering… Well point system. • A line or ring of small diameter shallow wells (called well points) installed at close spacing (1 to 3 m centres) around the excavation. • Commonly used for dewatering of pipeline trenches.

- 16. Well point system ADVANTAGES- • Can be very flexible and effective method of dewatering in sands or sands and gravel. DISADVANTAGES- • Drawdown limited to 5 to 6 m below level of pump due to suction lift limits.

- 17. Construction Dewatering… Deep wells system • Wells are drilled at wide spacing (10 to 60 m between wells) to form a ring around the outside of the excavation • An electric submersible pump is installed in each well.

- 18. Deep wells system ADVANTAGES • Effective in a wide range of ground conditions, sands, gravels, fissured rocks. DISADVANTAGES- • Drawdown limited only by wells depth and soil stratification.

- 19. Permanent groundwater Control… • Ground Freezing Techniques • Slurry Trench Walls • Steel sheet Piling • Thin Grouted Membranes • Contiguous Piling • Diaphragm Wall • Precast Concrete Diaphragm Walls • Grouting Methods

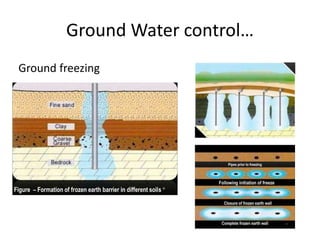

- 20. Ground Water control… Ground freezing

- 21. Ground freezing…

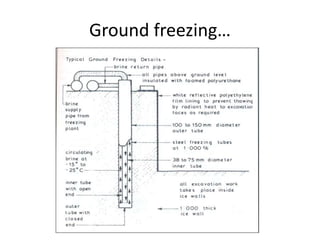

- 22. Permanent groundwater Control… Ground Freezing • Principle: To change the water in the soil into a solid wall of ice. • Seepage into a excavation or shaft can be prevented by freezing the surrounding soil. However, freezing is expensive and requires expert design, installation, and operation.

- 23. Permanent groundwater Control… Ground Freezing Techniques • Suitable for all types of saturated soils and rock and for soils with a moisture content in excess of 8% of the voids. • The basic principle is to insert into the ground a series of freezing tubes to form an ice wall thus creating an impermeable barrier. • Takes time to develop and the initial costs are high.

- 24. Permanent groundwater Control… Ground Freezing Techniques • The freezing tubes can be installed vertically for conventional excavations and horizontally for tunneling works. • Normally using magnesium chloride and calcium chloride with a temperature of -15 to -25 degree Celsius which takes 10 to 17 days to form an ice wall 1m thick. • Liquid nitrogen could be used as the freezing medium to reduce the initial freezing period if the extra cost can be justified.

- 25. Ground freezing ADVANTAGES • Ground freezing is an extremely versatile method for temporary ground improvement or cutoff. • It is applicable to the entire range of soils, provided that the soil is near saturation or completely saturated. • It is also applicable to difficult ground conditions including large boulders and cobbles, or debris-rich non-engineered fills.

- 26. Ground freezing DISADVANTAGES • Ground freezing is a highly energy intensive process, requiring refrigeration of massive quantities of soil over extended periods of time, which is very expensive.

- 27. Ground freezing DISADVANTAGES • Ground freezing requires plenty of monitoring: brine temperatures, soil temperatures, deflections of adjacent or nearby structures, heaving and settlement at the ground surface, groundwater salinity, pressures within freeze pipes (leak detection), frozen wall thickness, and the location and dimensions of possible windows within the frozen wall, among other site specific measurements.

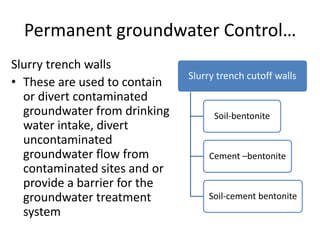

- 28. Permanent groundwater Control… Slurry trench walls • These are used to contain or divert contaminated groundwater from drinking water intake, divert uncontaminated groundwater flow from contaminated sites and or provide a barrier for the groundwater treatment system Slurry trench cutoff walls Soil-bentonite Cement –bentonite Soil-cement bentonite

- 29. Slurry trench wall ADVANTAGES • This is the only method that permits the visual inspection of key material. • Depth up to 200ft can be reached. DISADVANTAGES • Large excavation site, excavated soil storage, slurry mixing, material storage etc. • It is hard to ensure integrity of the wall.

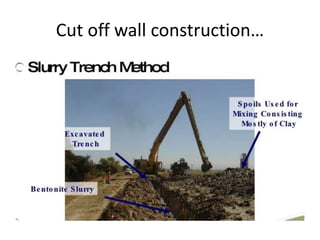

- 30. Permanent groundwater Control… Cutoff wall • Vertical barriers or “cutoff walls” are often used in geo-environmental engineering to control the spread of contaminants. • Cutoff curtains can be used to stop or minimize seepage into an excavation where the cutoff can be installed down to an impervious formation.

- 31. Cut off wall construction…

- 32. Permanent groundwater Control… Steel sheet piling • Steel sheet piles are long structural sections with a vertical interlocking system that creates a continuous wall. The walls are most often used to retain either soil or water.

- 33. Steel sheet piling ADVANTAGES • It is extremely light weight and makes it easier to lift and handle. • Steel sheeting is reusable and recyclable. • The pile length is easily adaptable and can be welded or bolted to make it work

- 34. Steel sheet piling DISADVANTAGES • It is extremely difficult to install steel sheeting in soil that is rocky or has large boulders. • Driving the sheets may cause neighborhood disturbance.

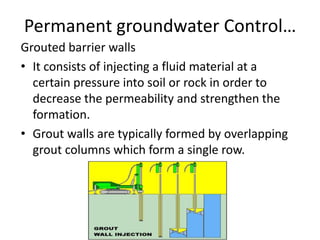

- 35. Permanent groundwater Control… Grouted barrier walls • It consists of injecting a fluid material at a certain pressure into soil or rock in order to decrease the permeability and strengthen the formation. • Grout walls are typically formed by overlapping grout columns which form a single row.

- 36. Grouted barrier walls ADVANTAGES • Depths greater than 200 ft can be achieved. • Little waste material is generated. DIS-ADVANTAGES • This configuration involves more cost. • Relatively high hydraulic conductivity values are obtained.

- 37. Permanent groundwater Control… Thin Grouted Membranes • Work as permanent curtain or cut-off non structural walls or barriers inserted in the ground to enclose the proposed excavation area. • Suitable for silts and sands and can be installed rapidly but they must be adequately supported by earth on both sides. • The only limitation is the depth to which the formers can be driven and extracted.

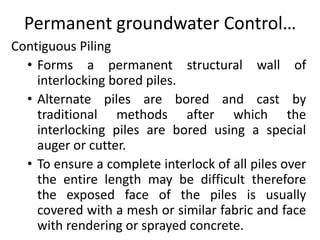

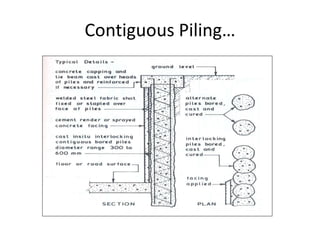

- 39. Permanent groundwater Control… Contiguous Piling • Forms a permanent structural wall of interlocking bored piles. • Alternate piles are bored and cast by traditional methods after which the interlocking piles are bored using a special auger or cutter. • To ensure a complete interlock of all piles over the entire length may be difficult therefore the exposed face of the piles is usually covered with a mesh or similar fabric and face with rendering or sprayed concrete.

- 40. Permanent groundwater Control… Contiguous Piling • Suitable for most types of subsoil and has the main advantages of being economical on small and confined sites; capable of being formed close to existing foundations and can be installed with the minimum of vibration and noise. • Suitable for structures such as basements, road underpasses and underground car parks.

- 42. Permanent groundwater Control… Diaphragm Wall • Are structural concrete walls which can be cast in-situ or using pre-cast concrete methods. • Suitable for most subsoil and their installation generates only a small amount of vibration and noise. • The high cost of these walls makes them uneconomic unless they can be incorporated into the finished structure. • Normally use for basements, underground carparks and similar structures.

- 43. Diaphragm Wall…

- 44. Permanent groundwater Control… Pre-cast Concrete Diaphragm Wall • Have some applications with in-situ concrete diaphragm walls. • Lack in design flexibility. • The panel or post panel units are installed in a trench filled with a special mixture of bentonite and cement with a retarder to control the setting time. • This mixtures ensures that the joints between the wall components are effectively sealed. • To provide stability, the panels of posts are tied to the retained earth with ground anchors.

- 45. Pre - cast diaphragm wall…

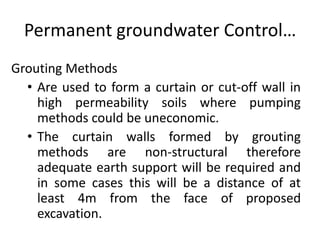

- 46. Permanent groundwater Control… Grouting Methods • Are used to form a curtain or cut-off wall in high permeability soils where pumping methods could be uneconomic. • The curtain walls formed by grouting methods are non-structural therefore adequate earth support will be required and in some cases this will be a distance of at least 4m from the face of proposed excavation.

- 47. Permanent groundwater Control… Grouting Methods • Grout mixtures are injected into the soil by pumping the grout at high pressure through special injection pipes inserted in the ground. • The pattern and spacing of the injection pipes will depend on the grout type and soil conditions. • Grout types: • Cement grouts • Chemical grouts • Resin grouts

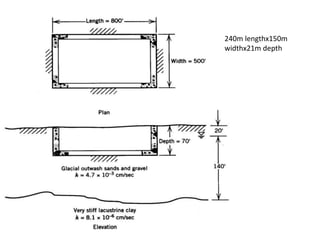

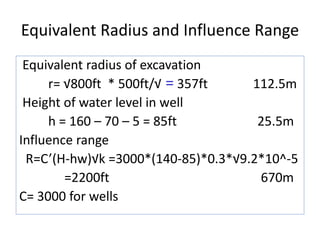

- 50. Equivalent Radius and Influence Range Equivalent radius of excavation r= √800ft * 500ft/√ = 357ft 112.5m Height of water level in well h = 160 – 70 – 5 = 85ft 25.5m Influence range R=C’(H-hw)√k =3000*(140-85)*0.3*√9.2*10^-5 =2200ft 670m C= 3000 for wells

- 51. Layout of deep wells

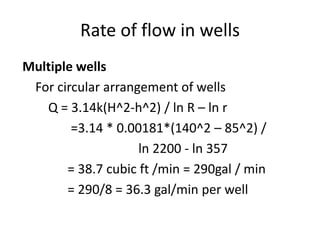

- 52. Rate of flow in wells Multiple wells For circular arrangement of wells Q = 3.14k(H^2-h^2) / ln R – ln r =3.14 * 0.00181*(140^2 – 85^2) / ln 2200 - ln 357 = 38.7 cubic ft /min = 290gal / min = 290/8 = 36.3 gal/min per well

- 53. Multiple Wells Deep wel l size: 4” dia. for 36.3 gal/min Header pipe: 4” dia. for 5*36.6 gal/min=181 gal/min Discharge pump: 4” dia. Pump for 290 gal/min