Tamarind varieties and processing

- 1. TAMARIND – VARIETIES & POST HARVEST TECHNOLOGY AND PROCESSING BY R.JOTHI LAKSHMI

- 2. FACTS ABOUT TAMARIND • Tamarindus indica L • “Tamare – hindi” / “Tamarhindi” - arabic word – Indian dates • ‘Amlika’ in Sanskrit – sour taste • Monotypic genus Tamarindus • Origin : Eastern Tropical Africa • India largest producer & only country to produce it commercially • 30:40:30% pulp: seed: fibre • Protogynous, entamophillous, highly cross pollinated crop •

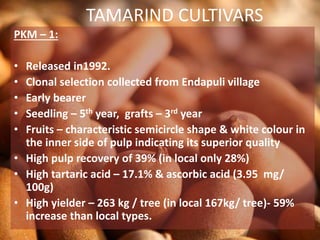

- 3. TAMARIND CULTIVARS PKM – 1: • Released in1992. • Clonal selection collected from Endapuli village • Early bearer • Seedling – 5th year, grafts – 3rd year • Fruits – characteristic semicircle shape & white colour in the inner side of pulp indicating its superior quality • High pulp recovery of 39% (in local only 28%) • High tartaric acid – 17.1% & ascorbic acid (3.95 mg/ 100g) • High yielder – 263 kg / tree (in local 167kg/ tree)- 59% increase than local types.

- 4. URIGAM: • Superior local genotype located near Urigam, near Thenkanikottai in Dharmapuri district • Seedling – 6-8 years, grafts-4th year • Short , branches like an umbrella • Pods lengthy, fleshy & tasty • Characteristic- flat, inward ‘C’ shaped curve • Late flowering in march, ready for harvest by July • Each fruit weighs 150- 200g. Seed content- 10- 12/pod

- 5. Prathithan: • High yielder released from FRS, Aurangabad, Maharashtra DTS -1 : • UAS, Dharwad • Sweet red type Yogeswari: • Forest dept, Karnataka. • Red pulp selection.

- 6. Other local selection are 1. Cumbum selection: Selection made at Cumbum in Madurai Dt 2. Rahuri selection from MH 3. Karur urigam tamarind from Karur, TN 4. Kangadevanapalli tamarind 5. Dever ullimangalam tamarind

- 7. CLASSIFICATION OF TAMARIND Colour • Red • Black • brown Taste • Sour: prathisthan, PKM – 1 • Sweet: Thailand type • Red var peferred – acid free &sweet, pink & brown var – sour Place of identification • Urigam • cumbam • Karur etc., Place of origin (a) EI var:long pods(6-12 seeds/tree) (b) WI var: short pods(1- 4 seeds/ tree)

- 8. POST- HARVEST TECHNOLOGY • Pulp is freed from fiber and seed and is mixed with about 10% salt and beaten down with mallets, so as to exclude air • It is then packed into gunny bags, lined with palm- leaf matting • Pulp with fiber & seed also common in the market • Another process- salted pulp- trodden into a mass & made into balls, exposed to the sun & dew for about a week • Balls steamed for a short time before being exposed to the sun & dew • Pulp- light brownish red, but darkens with time during storage

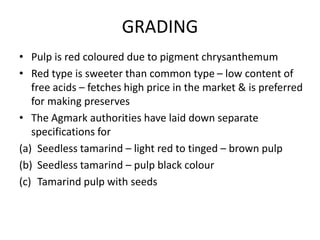

- 9. GRADING • Pulp is red coloured due to pigment chrysanthemum • Red type is sweeter than common type – low content of free acids – fetches high price in the market & is preferred for making preserves • The Agmark authorities have laid down separate specifications for (a) Seedless tamarind – light red to tinged – brown pulp (b) Seedless tamarind – pulp black colour (c) Tamarind pulp with seeds

- 10. PROCEESED PRODUCTS OF TAMARIND TAMARIND PULP: • Ripe fruit contains 55%tamarind pulp, 33% seed 12%fiber.

- 11. CONTENT AMOUNT Moisture 18.2% Free acid (tartaric acid) 9.8% Combined acid 6.7% Total sugars as invert sugar 38.2% Protein 2.8% Pectin 2.8% Cellulose residue (fiber) 19.4% Mineral matter 2.8% calcium 0.17% Phosphorus 0.11% Iron 0.011% Calorific value 83 calories / 100g Vit A 100 I.U./100 g niacin 0.2 mg/ 100g Tamarind pulp contains

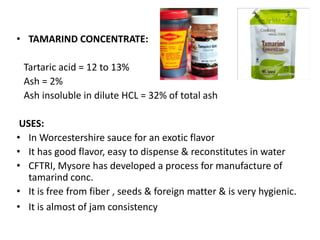

- 12. • TAMARIND CONCENTRATE: Tartaric acid = 12 to 13% Ash = 2% Ash insoluble in dilute HCL = 32% of total ash USES: • In Worcestershire sauce for an exotic flavor • It has good flavor, easy to dispense & reconstitutes in water • CFTRI, Mysore has developed a process for manufacture of tamarind conc. • It is free from fiber , seeds & foreign matter & is very hygienic. • It is almost of jam consistency

- 13. SIMMERING OF FRUITS PASSING COOKED MASS THROUGH MOTORISED PULPER (removes all residual seed, fiber& cellulosic material) VACUUM CONC OF THIS SOFT HOMOGENISED PULP (OR) COMPRESSING IT INTO MOULDS BLOCKS LIKE CHEESE, CERTAIN AMT OF CLEANING (removes fiber, husk & seed)

- 14. Tamarind pulp powder • Prepared in hygienic powder form • Packed in HDPE pockets or unit-packing from 250g

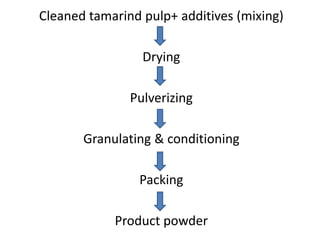

- 15. Cleaned tamarind pulp+ additives (mixing) Drying Pulverizing Granulating & conditioning Packing Product powder

- 16. Tamarind Beverages • Cooling beverages from tamarind pulp are prepared.

- 17. Tamarind seed kernel powder • Source of starch – cheaper than corn starch • used as a good creaming agent for the conc. of rubber latex. • As a conditioner and stabilizer of soil for brick making • As ‘jellose’ – it forms ‘gel’ with sugar and water at specific pH. ( jellose is a veg. polysaccharide composed of glucose, xylose & galactose. Used as thickening agent ,as a stabilizer and as a gelling agent similarly as pectin. But it is not a true pectin due to the absence of glacturonic acid)

- 18. Tamarind candy Selection of the tamarind fruit Peeling Pouring the boiling sugar syrup (620 c) (boiling sugar – 3parts of water+ 1part of water) Soaking for 3 davs Draining

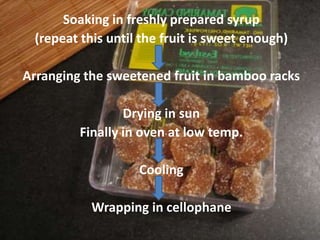

- 19. Soaking in freshly prepared syrup (repeat this until the fruit is sweet enough) Arranging the sweetened fruit in bamboo racks Drying in sun Finally in oven at low temp. Cooling Wrapping in cellophane

- 20. Tamarind jam Selection of ripe fruits Shelling Boiling the pulp for 10 minutes Draining Separating from seeds Adding 2 cups of sugars for 1 cup of pulp

- 21. Cooking with constant stirring till thick constancy Cooling Packing in sterilized jar sealing

- 22. Tamarind pickle Selection of tamarind fruit Soaking in water for 12 hrs Separation of pulp Adding sugar to pulp(1:1) Boiling and stirring the mixture Adding the spice mixture (spice mix- coriander, cumin seed, black cumin, cloves, cardamom, cinnamon, chilies, salt, mustard oil, black pepper)

- 23. Ground to paste Add to boiling tamarind Packed in sterilized glass jar sealing

- 24. Tamarind syrup Boiling immature tamarind fruit pulp Straining thru cheese cloth Add ½ tsp of baking soda for 1cup of juice Boil the mixture to ½ the original quantities Removing the scum Straining the juice

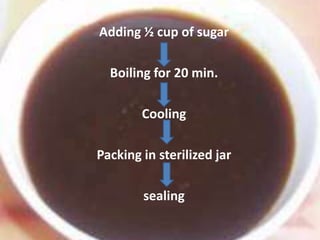

- 25. Adding ½ cup of sugar Boiling for 20 min. Cooling Packing in sterilized jar sealing

- 27. Integrated process for the manufacture of Tartarates, Pectin and Alcohol • Since pulp contains pectin, an integrated scheme has been worked out at CFTRI – pectin, tartarates and ethanol from it. Pulp repeatedly extracted with boiling water Filltered extract cooled potassium bitartarate seperates Supernant is conc under vacuum

- 28. Pectin seperated by adding alcohol Filtrate treated with lime to precipitate calcium tartarate Remaining sugars – fermented with yeast - alcohol recovered • For isolating tartaric acid use of green pods is suggested, as they contain most of the acid in free form.

- 29. REFERENCES • Minor Spices & condiments crop management and post harvest technology J.S. Pruthi pg 420 -423 • Spices – horticultural series- 5 EV.Nybe, M.Mini Raj, K.V.Peter, 2007. • TNAU Agri portal - Post harvest Technology

Editor's Notes

- #13: Worcester sauce is a fermented liquid complement of British origin from Worcester based on an older Greco roman sauce. Ingredients – barley malt vinegar, spirit vinegar, sugar, salt, anchovies, tamarind extract, onion, garlic and spice. – ingredient of Mexican beer cocktail. Reconstitutes – dried to original state by adding water

- #14: SIMMERING – STAYING JUST BELOW BOILING POINT AT WHILE BUBBLING GENTLY

- #21: Shelling – removing the shell of the pod

- #25: Scum – a layer of dirt or froth on the surface of liquid