Shoring

- 1. Building Construction Report On SHORING Siddharth Mathur A/2237/2010 Nandini Priya T. A/2270/2010

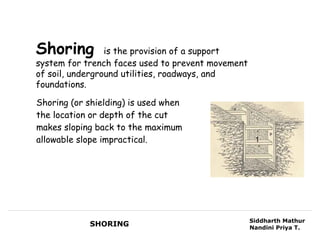

- 2. Shoring is the provision of a support system for trench faces used to prevent movement of soil, underground utilities, roadways, and foundations. Shoring (or shielding) is used when the location or depth of the cut makes sloping back to the maximum allowable slope impractical. 1 Siddharth Mathur SHORING Nandini Priya T.

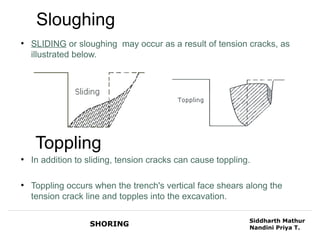

- 3. Sloughing ● SLIDING or sloughing may occur as a result of tension cracks, as illustrated below. Toppling ● In addition to sliding, tension cracks can cause toppling. ● Toppling occurs when the trench's vertical face shears along the tension crack line and topples into the excavation. Siddharth Mathur SHORING Nandini Priya T.

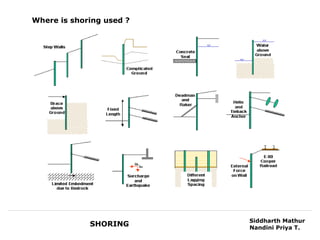

- 4. Where is shoring used ? Siddharth Mathur SHORING Nandini Priya T.

- 5. Shoring Types Shoring systems consist of posts, wales, struts, and sheeting. Three basic types of shoring are: Timber Hydraulic Pneumatic Siddharth Mathur SHORING Nandini Priya T.

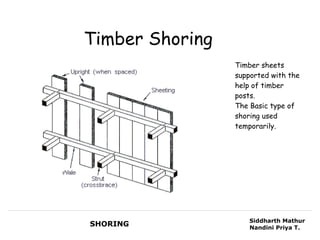

- 6. Timber Shoring Timber sheets supported with the help of timber posts. The Basic type of shoring used temporarily. Siddharth Mathur SHORING Nandini Priya T.

- 7. Hydraulic Shoring The trend today is toward the use of hydraulic shoring, a prefabricated strut and/or wale system manufactured of aluminum or steel. Hydraulic shoring provides a critical safety advantage over timber shoring because workers do not have to enter the trench to install or remove hydraulic shoring. Other advantages of most hydraulic systems are that they: Are light enough to be installed by one worker; Are gauge-regulated to ensure even distribution of pressure along the trench line; Can have their trench faces "preloaded" to use the soil's natural cohesion to prevent movement; and Can be adapted easily to various trench depths and widths. Siddharth Mathur SHORING Nandini Priya T.

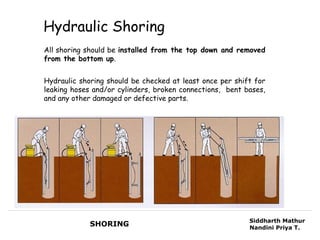

- 8. Hydraulic Shoring All shoring should be installed from the top down and removed from the bottom up. Hydraulic shoring should be checked at least once per shift for leaking hoses and/or cylinders, broken connections, bent bases, and any other damaged or defective parts. Siddharth Mathur SHORING Nandini Priya T.

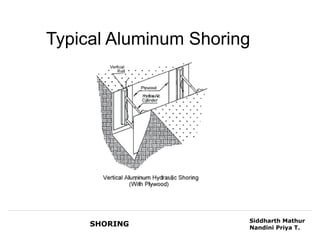

- 9. Typical Aluminum Shoring Siddharth Mathur SHORING Nandini Priya T.

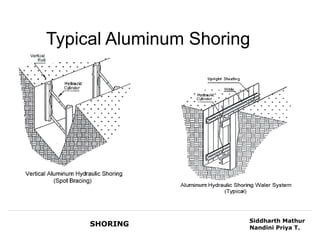

- 10. Typical Aluminum Shoring Siddharth Mathur SHORING Nandini Priya T.

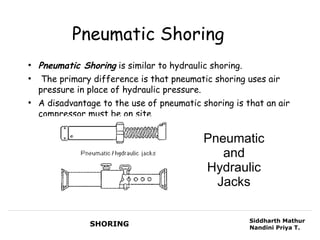

- 11. Pneumatic Shoring ● Pneumatic Shoring is similar to hydraulic shoring. ● The primary difference is that pneumatic shoring uses air pressure in place of hydraulic pressure. ● A disadvantage to the use of pneumatic shoring is that an air compressor must be on site. Pneumatic and Hydraulic Jacks Siddharth Mathur SHORING Nandini Priya T.

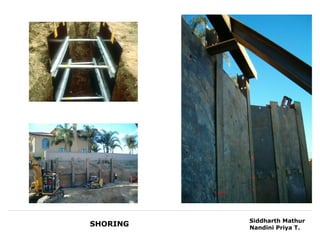

- 12. Siddharth Mathur SHORING Nandini Priya T.

- 13. Siddharth Mathur SHORING Nandini Priya T.