Process planning (lesson 1)

- 1. PROCESS PLANNING Presented by: Prof.Dr.P.T. SRINIVASAN 1

- 2. Process planning Begins with Product Selection 2

- 3. Product Selection • is a strategic decision i.e. long term decisions • decisions like technology to be used, capacity of the production system, location of the facility, organization of the production function, planning, and control systems depend on this 3

- 4. Product Selection involves other functional areas like marketing, research and development, and the top management 4

- 5. Product Selection • The process of selecting a product is highly integrative • Product function, cost, quality and reliability are other inputs to product selection 5

- 6. Product Selection Organizations try to get synergistic results by exploiting the following factors: 1. Familiarity with similar products / services 2. Familiarity with the same or similar production process 3. Familiarity with the same or similar market segments 4. Familiarity with the same or similar 6 distribution channels

- 7. Product Development Development effort improves the performance of the product, adds options and additional features Also adds variants to the basic product Development starts after research has established an idea that has been examined, evaluated and refined 7

- 8. Product Design includesdimensional specifications, specifications regarding capacity, horse power, speed, colour etc. 8 PM / L 1 / S 8

- 9. Product Variety There are two distinctly different priorities that can affect the design of a product or service 1. Standardization 2. Modularization 9

- 10. Standardization Higher the standardization, the greater will be the ease in producing It reduces variety in the product Ensures better use of productive facilities It reduces unit costs 10

- 11. Advantages of Standardization Simplifies operational procedures Raw materials can be purchased in bulk at reduced price Enables steady flow of materials through work centres Reduces the number of production set-ups 11

- 12. Advantages of Standardization Reduces the total inventory of raw materials, work-in-process, and finished goods Provides economies of scales due to high volume of production 12

- 13. Modularization Used to obtain variety and yet hold down the cost Modules are interchangeable and each different combination gives a new variety of the product Design simplification without compromise on quality can reduce production costs 13

- 14. Key Elements in Product Design Function Cost Quality Reliability Appearance Environmental impact 14

- 15. FromProduct Design Stage let us now move on to Process Planning 15

- 16. Process – Meaning Processes are the essence of operations management. They transform inputs into outputs. More than products or technologies, the ability to do things well- processes – constitutes a firm’s competitive advantage. 16

- 17. Process Planning - Definition Planning in which the conditions necessary for transforming material from one state to another are determined. It determines how a work is to be done. Itconverts designs into workable instructions for manufacture, along with associated decisions on component purchase or fabrication and process and equipment selection. 17

- 18. Types of Processes Projects: It is one-of-a kind production of a product to customer order. BatchProduction: Batch production systems process many different jobs through the system in groups (or batches). Mass production(Line processes) : It produces large volumes of a standard product for a mass market. Continuousproduction: They are used for very high volume commodity products. 18

- 19. Project Batch Mass Continuous Product Unique Made to order Made to stock Commodity Customer Singly Few individuals Mass market Mass market Demand Infrequent Fluctuates Stable Very stable Volume Very low Low to med High Very high Variety Infinite Many, high Low Very low System Long-term Intermittent Flow lines Process industry Equipment Varied General Special Highly automated Type of work Contracts Fabrication Assembly Mix, treat, refine Skills Experts, Wide range Limited range Equipment craftspeople monitors Advantages Custom work, Flexibility, Efficiency, Highly efficient quality speed, low cost large capacity Disadv. Nonrepeating Costly, slow Capital invest. Difficult to change Example Construction Printing, bakery Autos, TV’s Paint, oil, food 19

- 20. Underlying Process Relationship Between Volume and Standardization Continuum 20

- 21. Process Planning • Process planning is a key element in project management that focuses on selecting resources for use in the execution and completion of a project • In a manufacturing setting, this aspect of planning also includes establishing the general sequence of steps that begin with the acquisition of materials and end with the creation of a finished product. 21

- 22. DECISION ON WHAT TO MAKE DEMAND FORECAST FUNCTIONAL DESIGN PRODUCT PRODUCTION DESIGN DESIGN DRAWING & SPECIFICATION OF WHAT TO MAKE PRODUCT ANALYSIS & ASSEMBLY CHARTS MAKE (OR) BUY DECISION PROCESS DESIGN PROCESS DECISION, SELECTION FROM ALTERNATIVE PROCESSES ROUTE / SPECIFICATION WORK PLACE & SHEET TOOL DESIGN 22 MANUFACTURE MODIFICATION OF PROCESS PLANSDUE TO LAYOUT, PLANING QUALITY PERFORMANCE AND M/C AVAILABILITY

- 23. Process Planning Make-or-buy decisions Process selection Capacity Planning Assembly Chart 23

- 24. Make-Or-Buy Decisions A firm’s Make-or-Buy choices should be based on the following considerations: 1. Cost (fixed cost + variable cost) make = Cost (fixed cost + Variable cost) buy 2. Available capacity 3. Quality considerations 4. Speed 5. Reliability 6. Expertise 24

- 25. Make-Or-Buy Decisions • Determination whether to produce a component part internally or to buy it from an outside supplier. This decision involves both qualitative and quantitative factors. Qualitative considerations include product quality and the necessity for long- run business relationships with subcontractors. Quantitative factors deal with cost. The quantitative effects of the make-or-buy decision are best seen through the Relevant Cost Approach • For example, assume a firm has prepared the following cost estimates for the manufacture of a subassembly component based on an annual production of 8000 units: 25 25

- 26. Contd…. • The supplier has offered the subassembly at a price of $16 each. Two-thirds of fixed factory overhead, which represents executive salaries, rent, depreciation, and taxes, continue regardless of the decision. Should the company buy or make the product? The key to the decision lies in the investigation of those relevant costs that change between the make or buy alternatives. Assuming that the productive capacity will be idle if not used to produce the subassembly, we can make the following analysis • he make-or-buy decision must be investigated in the broader perspective of available facilities. The alternatives are: (1) leaving facilities idle; (2) buying the parts and renting out idle facilities; or (3) buying the parts and using unused facilities for other products. 26 26

- 27. Make-Or-Buy Process •Stage 1 refers to the preparations phase, which entails creating a multi-disciplinary team, selecting the part, assembly or family of parts for analysis and briefing the team. •Stage 2 is concerned with data collection. 27

- 28. Contd…. Stage 3 • consists of data analysis using a spreadsheet which provides the following: • Final scores for in-house and for the supplier. The highest score indicates the best option. • Weighted gaps for each factor area, highlighting the strengths and weaknesses of this option. • A sensitivity analysis which tests the robustness of the final outcome. Stage 4 28 • consists of feeding back the results to the team.

- 29. CROSSOVER CHARTS It is a chart of costs at the possible volumes for more than one process. Fixed cost Variable cost Rs Rs R . s Process A Process B Process C R 110000 80,000 Fixed cost – Fixed cost – 75,000 Fixed cost – Process C Process B 29 V1(5000) V2 (15,000) Process A Volume

- 30. Break Even Analysis For a company to produce a new product, the initial investment in plant & equipment is estd. to be Rs.2000. Labour & material cost is approx. Rs.5 per unit. If the rafts can be sold at Rs.10 per unit, what volume of demand would be necessary to break-even? Fixed cost: Rs. 2000; variable cost: Rs.5 per unit; selling price: Rs.10 per unit. Then BEP is 2000/ 10-5 = 400 rafts. 30

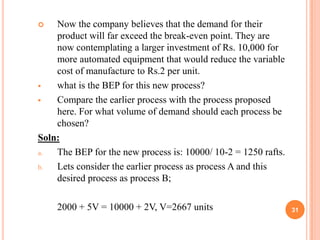

- 31. Now the company believes that the demand for their product will far exceed the break-even point. They are now contemplating a larger investment of Rs. 10,000 for more automated equipment that would reduce the variable cost of manufacture to Rs.2 per unit. what is the BEP for this new process? Compare the earlier process with the process proposed here. For what volume of demand should each process be chosen? Soln: a. The BEP for the new process is: 10000/ 10-2 = 1250 rafts. b. Lets consider the earlier process as process A and this desired process as process B; 2000 + 5V = 10000 + 2V, V=2667 units 31

- 32. The solution procedure for process selection consists of 4 steps: Formulate a total cost equation for each process considered. Calculate the point of indifference bet 2 alternatives by equating the total cost of each alternative and solve for V, which is the demand volume. Above the point of indifference, choose the alternative with the lowest variable cost. Below the point of indifference, choose the alternative with the lowest fixed cost. 32

- 33. Capacity Planning • Capacity planning is the process of determining the production capacity needed by an organization to meet the demands for its products. • A discrepancy between the capacity of an organization and the demands of its customers results in unfulfilled customers. 33

- 34. Process Analysis Itis the systematic examination of all aspects of a process to improve its operation. A basic tool for process analysis is the flowchart. 34

- 35. Flow Chart • Flow charts are easy-to-understand diagrams showing how steps in a process fit together. This makes them useful tools for communicating how processes work, and for clearly documenting how a particular job is done. Furthermore, the act of mapping a process out in flow chart format helps you clarify your understanding of the process, and helps you think about where the process can be improved. • A flow chart can therefore be used to: • (i)Define and analyze processes • (ii)Build a step-by-step picture of the process for analysis, • discussion, or communication and • (iii)Define, standardize or find areas for improvement in a process 35

- 36. Assembly Chart Assembly charts :gives pictorially step by step assembly sequence and what items to be assembled till finished product is produced. 36

- 37. Assembly Chart • Assembly chart gives a macro view of how materials and sub assembly are united to form a finished product. It is a starting point to understand the factory layout needs, equipments needs, training needs for any company to deliver a finished product / service 37

- 38. Parts of a Wind Mill Turbine 38

- 39. Example of an Assembly chart Blade 1 Hub 2 Tower SA-1 A-2 Generator 3 Rotor 4 A-5 Component/Assembly Operation Inspection A Windmill Turbine 39

- 40. Assembly Drawing-Blueprint Shows exploded view of product Head Neck End Cap Handle 40

- 41. Assembly Chart 41

- 42. Operation process chart • Operation Process chart represents the sequence of steps or tasks needed to complete a product and details how to build a product at each process. It includes what materials are needed, type of processes, product flow, time taken to process product through each step of flow and thus serves as a basis for examining and possibly improving the way the operation is carried out. 42

- 43. Process Re-engineering Process Re-engineering is a structured approach to process flow analysis used when major business changes are required as a result of: Major new products Quality improvement needed Better competitors Inadequate performance In short, it is the total redesign of a process. 43

- 44. Thank You 44