Category:Pressure vessels

Vai alla navigazione

Vai alla ricerca

container designed to hold gases or liquids at a pressure substantially different from the ambient pressure | |||||

| Carica un file multimediale | |||||

| Sottoclasse di | |||||

|---|---|---|---|---|---|

| Parte di | |||||

| Materiale usato |

| ||||

| Consiste di |

| ||||

| |||||

Sottocategorie

Questa categoria contiene le 16 sottocategorie indicate di seguito, su un totale di 16.

A

B

C

- Cascade filling system (2 F)

- Circumferential stress (10 F)

D

- Diving cylinders (103 F)

E

G

H

- Pressure vessel heads (10 F)

O

- Oil receivers (1 F)

R

- Reactor pressure vessel (31 F)

Pagine nella categoria "Pressure vessels"

Questa categoria contiene un'unica pagina, indicata di seguito.

File nella categoria "Pressure vessels"

Questa categoria contiene 165 file, indicati di seguito, su un totale di 165.

-

De-Druckbehälter.ogg 2,0 s; 20 KB

-

2018 07 Poel IMG 3683.jpg 5 494 × 3 093; 12,61 MB

-

A Simple Well Water Control System.jpg 462 × 341; 29 KB

-

AHTS A501.jpg 2 976 × 3 968; 2,65 MB

-

Air blaster-008618838111803.jpg 600 × 600; 77 KB

-

Air cannon-008618838111803.png 592 × 483; 331 KB

-

Air Receiver - geograph.org.uk - 1752504.jpg 1 600 × 1 200; 626 KB

-

Aquabulle 4.jpg 1 000 × 663; 142 KB

-

Ballon de pressurisation.jpg 640 × 480; 152 KB

-

Batería de botellas industriales.jpg 2 560 × 1 920; 1,54 MB

-

Bellingham - Waypoint Park 01 - the Acid Ball.jpg 4 000 × 6 000; 14,02 MB

-

Bellingham - Waypoint Park 02.jpg 6 000 × 4 000; 10,14 MB

-

Biogasholder and flare.JPG 1 492 × 1 023; 144 KB

-

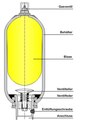

Blasensp.pdf 1 239 × 1 752; 220 KB

-

Blue Grass Chemical Agent-Destruction Pilot Plant Welders (33022039713).jpg 4 288 × 2 848; 3,01 MB

-

Bouteille air démarrage.JPG 2 272 × 1 704; 1,25 MB

-

Bridgman seal closed 01.svg 569 × 850; 8 KB

-

Bridgman seal closed 02.png 549 × 830; 6 KB

-

Burst air receiver at Bay Road - Anzac Highway(GN04228).jpg 3 264 × 2 448; 1,02 MB

-

Caisson hyperbare.jpg 640 × 480; 62 KB

-

Canned-air.jpg 1 821 × 1 662; 878 KB

-

Cercle mohr etat contraintes biaxiale.svg 589 × 1 054; 170 KB

-

Chiang-Mai Thailand Pressure-vessel-converted-to-a-safe-01.jpg 2 000 × 1 333; 2,12 MB

-

Copv tank close out prior to flight.png 1 721 × 995; 2,29 MB

-

December 2, 2012 - Colorful Freon tanks, ready for recycling. (8250066769).jpg 2 736 × 3 648; 3,29 MB

-

DESP categorie risque recipient sous pression gaz groupe 1.svg 462 × 410; 31 KB

-

DESP categorie risque recipient sous pression gaz groupe 2.svg 462 × 410; 31 KB

-

DESP categorie risque recipient sous pression liquides groupe 1.svg 462 × 410; 26 KB

-

DESP categorie risque recipient sous pression liquides groupe 2.svg 462 × 410; 25 KB

-

DESP categorie risque recipient sous pression production vapeur.svg 462 × 410; 29 KB

-

Diffuser Head.jpg 2 816 × 2 120; 463 KB

-

Dobor zbiornika do sprezarek.png 582 × 496; 22 KB

-

Druckbehaelter01.jpg 1 001 × 670; 133 KB

-

Druckbehaelter02.jpg 1 536 × 1 024; 416 KB

-

Dsm gas tank.jpg 1 024 × 683; 376 KB

-

DuraStor consortium Thermoplastic composite pressure vessels.png 500 × 333; 199 KB

-

Dust-Off 10oz.jpg 1 024 × 1 536; 779 KB

-

Enveloppe avec piquage zone interdiction soudures DESP.svg 1 527 × 1 608; 60 KB

-

Expansion tank (Ausdehnungsgefäß) bemalt als Minion - an Bord der Nordic.JPG 3 024 × 4 032; 3,14 MB

-

Face sealed isolation manifold on twin 12l steel cylinders PB128181.jpg 3 648 × 2 736; 2,32 MB

-

FAILED STEEL TANK - NARA - 17472515.jpg 4 853 × 6 179; 24,75 MB

-

FAILED STEEL TANK - NARA - 17472516.jpg 4 888 × 6 197; 23,97 MB

-

FAILED STEEL TANK - NARA - 17472517.jpg 4 853 × 6 179; 26,51 MB

-

Fig-4-Cluster-1-observations.gif 778 × 249; 80 KB

-

GALATHEE.jpg 1 948 × 2 960; 4,16 MB

-

Gas blending equipment cropped.jpg 855 × 972; 218 KB

-

Gas blending equipment.JPG 1 296 × 972; 223 KB

-

Gas burner on internal heat exchanger.jpg 640 × 895; 160 KB

-

Gas Duster blowing in PC.jpg 768 × 1 024; 165 KB

-

Gas tank transport tricycle - 苏DWG017.jpg 4 000 × 3 000; 4,04 MB

-

Glass Pressure Reactor.jpg 2 915 × 4 032; 2,05 MB

-

Haan, Mahnertmühle 1, hist. Geräte in der SO-Ecke des Geländes.jpg 3 647 × 2 645; 4,06 MB

-

HIPPOCAMPE.jpg 5 295 × 3 431; 4,62 MB

-

Hydrophore and pump at sunset.jpg 4 536 × 3 952; 8,36 MB

-

Hyperbaric oxygen cell testing pot cell mounting plate and end cover IMG 20201209 153924.jpg 5 120 × 3 840; 4,45 MB

-

Hyperbaric oxygen cell testing pot cell mounting plate and end cover IMG 20201209 153934.jpg 5 120 × 3 840; 4,58 MB

-

Hyperbaric oxygen cell testing pot interior view IMG 20201209 153908.jpg 5 120 × 3 840; 6,75 MB

-

Hyperbaric oxygen cell testing pot pressure gauge IMG 20201209 153847.jpg 5 120 × 3 840; 3,78 MB

-

Hyperbaric oxygen cell testing pot with cable connected IMG 20201209 153728.jpg 3 840 × 5 120; 3,95 MB

-

Hyundai nexo high pressure hydrogen tank safety.jpg 1 920 × 1 080; 104 KB

-

IMCA Calibration gas shoulder.svg 181 × 171; 5 KB

-

IMCA Carbon dioxide shoulder.svg 181 × 171; 5 KB

-

IMCA Heliox shoulder quartered.svg 181 × 171; 6 KB

-

IMCA Heliox shoulder.svg 181 × 171; 6 KB

-

IMCA Helium shoulder.svg 181 × 171; 5 KB

-

IMCA Nitrogen shoulder.svg 181 × 171; 5 KB

-

IMCA Nitrox shoulder quartered.svg 181 × 171; 6 KB

-

IMCA Nitrox shoulder.svg 181 × 171; 6 KB

-

IMCA Oxygen shoulder.svg 181 × 171; 5 KB

-

IMCA Trimix shoulder quartered.svg 181 × 171; 6 KB

-

IMCA Trimix shoulder.svg 181 × 171; 6 KB

-

Inspektionsoeffnung 0001.JPG 1 406 × 929; 116 KB

-

Inspektionsoeffnung 0002.JPG 1 800 × 1 350; 283 KB

-

Instalacja sprezonego powietrza.png 550 × 544; 49 KB

-

ISO 7000 - Ref-No 2979.svg 200 × 200; 659 byte

-

Kontenerji.jpg 1 135 × 820; 99 KB

-

KSC-20160201-PH KLS0002 0185 (24151677143).jpg 3 000 × 2 000; 3,84 MB

-

KSC-20160201-PH KLS0002 0188 (24660720022).jpg 3 000 × 2 000; 3,51 MB

-

KSC-20160201-PH KLS0002 0191 (24150380984).jpg 3 000 × 2 000; 3,59 MB

-

KSC-20160201-PH KLS0002 0195 (24150380394).jpg 3 000 × 2 000; 3,89 MB

-

KSC-20160201-PH KLS0002 0201 (24778592885).jpg 3 000 × 2 000; 3,73 MB

-

KSC-20160201-PH KLS0002 0202 (24410920799).jpg 3 000 × 2 000; 3,43 MB

-

KSC-20160201-PH KLS0002 0204 (24150430834).jpg 3 000 × 2 000; 3,84 MB

-

KSC-20160201-PH KLS0002 0207 (24150430084).jpg 3 000 × 2 000; 4,06 MB

-

KSC-20160201-PH KLS0002 0216 (24150429284).jpg 3 000 × 2 000; 4,07 MB

-

KSC-20160203-PH SWW0001 0001 (24430266079).jpg 3 000 × 2 000; 3,65 MB

-

KSC-20160203-PH SWW0001 0004 (24169764874).jpg 3 000 × 2 000; 3,58 MB

-

KSC-20160203-PH SWW0001 0010 (24502396780).jpg 3 000 × 2 000; 3,72 MB

-

KSC-20160203-PH SWW0001 0013 (24797929825).jpg 3 000 × 2 000; 3,51 MB

-

KSC-20160203-PH SWW0001 0022 (24771696146).jpg 3 000 × 2 000; 3,17 MB

-

KSC-20160203-PH SWW0001 0035 (24771697296).jpg 2 000 × 3 000; 3,85 MB

-

KSC-20160203-PH SWW0001 0055 (24704432641).jpg 3 000 × 2 000; 3,86 MB

-

KSC-20160203-PH SWW0001 0064 (24680082312).jpg 3 000 × 2 000; 3,91 MB

-

Left side cylinder valve for barrel seal manifold with blanking plug PB128179.jpg 3 648 × 2 736; 2,34 MB

-

LPG Bulk.jpg 4 970 × 3 168; 2,31 MB

-

MarmitaPapin.JPG 1 884 × 3 654; 2,24 MB

-

Modified Hanson steelwatertank.jpg 524 × 300; 20 KB

-

P1000204 - Flickr - Ronnie Garcia.jpg 960 × 1 280; 139 KB

-

Pipe couplings on a pressure tank under construction 2.jpg 4 925 × 3 283; 7,82 MB

-

Pipe couplings on a pressure tank under construction.jpg 4 925 × 3 283; 8 MB

-

Portrait of an unknown scientist - DPLA - fcb3927f61faa1b5a1d5985071bf69bb.jpg 6 175 × 8 097; 13,79 MB

-

Pressure tank and square D.jpg 2 355 × 2 700; 1,06 MB

-

Pressure tanks empty and in use.jpg 316 × 291; 11 KB

-

Pressure tanks under construction 2.jpg 4 201 × 3 283; 6,74 MB

-

Pressure tanks under construction 3.jpg 4 577 × 3 051; 10,2 MB

-

Pressure tanks under construction.jpg 4 378 × 3 283; 8,46 MB

-

Pressure Vessel for Australia.jpg 512 × 384; 53 KB

-

Pressure Vessel.jpg 1 200 × 1 600; 275 KB

-

PRESSURE VESSELS - 71 - 81 - 11I - DPLA - a3af679ff3a965dbb9f570cad9c7b31f.jpg 5 093 × 6 105; 20,94 MB

-

Pressurevessel.gif 270 × 180; 2 KB

-

PressureVesselBoundaryConditions.jpg 1 416 × 571; 123 KB

-

PressureVesselMaximalPrincipalStress.jpg 1 406 × 595; 300 KB

-

PressureVesselMesh.jpg 1 101 × 565; 172 KB

-

Pressurisation.jpg 637 × 1 063; 141 KB

-

Pressurized vessel horizontal.svg 71 × 71; 5 KB

-

Pressurized vessel vertical.svg 71 × 71; 5 KB

-

Recipiente cilindrico.png 137 × 244; 8 KB

-

Recipiente fasciato.png 210 × 171; 6 KB

-

Recipiente multistrato.png 237 × 187; 16 KB

-

Red Air Cannon.png 592 × 475; 291 KB

-

Regenerator1.jpg 1 600 × 1 200; 815 KB

-

Rezervoarji pri plinohramu v Ljubljani.jpg 1 128 × 808; 146 KB

-

Road–rail vehicle Terberg Zagro RR222 4x2.jpg 5 014 × 3 343; 8,46 MB

-

SK210-492.pdf 1 754 × 1 239; 277 KB

-

Steel 15l cylinder with boot and net and Aluminium 12l cylinder PB128188.jpg 2 736 × 3 648; 2,1 MB

-

Strain distribution vessel wall.png 484 × 494; 18 KB

-

Stress distribution vessel wall.png 640 × 568; 28 KB

-

Systém kompenzace objemu.png 789 × 689; 54 KB

-

Tec diver with sidemount tanks.JPG 355 × 490; 40 KB

-

Truck, with reactor vessel, breakdown on I-540.jpg 4 288 × 2 848; 2,96 MB

-

Tryckkärl bra 1.jpg 319 × 425; 43 KB

-

Tryckkärl bra 2.jpg 319 × 425; 43 KB

-

Vacuum Insulated Evaporator diagram-mr.svg 700 × 536; 63 KB

-

Vacuum Insulated Evaporator diagram.svg 700 × 536; 66 KB

-

Vacuum Insulated Evaporator photo.JPG 3 648 × 2 736; 4,65 MB

-

Vaso de pressao.jpg 600 × 372; 53 KB

-

Water well tank.JPG 1 704 × 2 352; 262 KB

-

Wülfrath, Klinik Aprath westl. Nr. 2, 800-Liter-Druckkessel.jpg 2 468 × 3 290; 3,03 MB

-

X-RayStandardization 010.jpg 6 023 × 4 809; 23,59 MB

-

X-RayStandardization 013.jpg 5 993 × 4 869; 23,94 MB

-

X-RayStandardization 035.jpg 5 978 × 4 824; 23,09 MB

-

X-RayStandardization 039.jpg 5 963 × 4 854; 23,63 MB

-

X14. Kocioł parowy stojący systemu Lachapella.jpg 1 406 × 2 186; 986 KB

-

Zabrze kopalnia Guido 34.jpg 5 184 × 3 456; 9,59 MB

-

Łódź-EC1 and one of exhibits (2).jpg 5 152 × 3 864; 2,34 MB

-

Емкость для порошка от автомобиля порошкового тушения АП-5.JPG 2 693 × 1 811; 721 KB

-

Подъем в барокамере на высоту 5000 м.jpg 3 586 × 2 391; 1,35 MB

-

Ресивер хладагента FP-LR-1,0.png 927 × 791; 724 KB

-

Ресивер хладагента FP-LR-100.png 408 × 1 505; 665 KB

-

液化炭酸ガスのタンク.jpg 988 × 1 348; 493 KB