Abstract

The extraordinary responsiveness and large diversity of self-assembled structures of liquid crystals are well documented and they have been extensively used in devices like displays. For long, this application route strongly influenced academic research, which frequently focused on the performance of liquid crystals in display-like geometries, typically between flat, rigid substrates of glass or similar solids. Today a new trend is clearly visible, where liquid crystals confined within curved, often soft and flexible, interfaces are in focus. Innovation in microfluidic technology has opened for high-throughput production of liquid crystal droplets or shells with exquisite monodispersity, and modern characterization methods allow detailed analysis of complex director arrangements. The introduction of electrospinning in liquid crystal research has enabled encapsulation in optically transparent polymeric cylinders with very small radius, allowing studies of confinement effects that were not easily accessible before. It also opened the prospect of functionalizing textile fibers with liquid crystals in the core, triggering activities that target wearable devices with true textile form factor for seamless integration in clothing. Together, these developments have brought issues center stage that might previously have been considered esoteric, like the interaction of topological defects on spherical surfaces, saddle-splay curvature-induced spontaneous chiral symmetry breaking, or the non-trivial shape changes of curved liquid crystal elastomers with non-uniform director fields that undergo a phase transition to an isotropic state. The new research thrusts are motivated equally by the intriguing soft matter physics showcased by liquid crystals in these unconventional geometries, and by the many novel application opportunities that arise when we can reproducibly manufacture these systems on a commercial scale. This review attempts to summarize the current understanding of liquid crystals in spherical and cylindrical geometry, the state of the art of producing such samples, as well as the perspectives for innovative applications that have been put forward.

Original content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

Liquid crystals present phenomena that no other materials can reproduce. They uniquely combine the long-range order that we know from solid crystals with the mobility and flexibility of fluid phases. The fact that they are liquid allows them to easily change shape, accommodating very different boundaries from the standard flat and rigid confining substrates typically used when studying or applying liquid crystals (LCs) in display-like geometries. Curved confinement can trigger fascinating effects, since curvature of the sample boundary, in case of sufficiently strong anchoring of the LC alignment direction at the boundary, is transmitted into the bulk in form of deformation of the orientational field. In many cases topological defects and sometimes also dislocations form, often with beautiful as well as informative consequences. In fact, the nanoscopic response of a smectic LC to the macroscopic curvature of a droplet (the droplet becomes 'stepped') was instrumental to Grandjean's experiments leading up to the identification of the molecular organization in smectics, and Mauguin's experiments of liquid crystal flow through capillary tubes demonstrated the surprising result that the viscosity could be lower in the nematic than in the isotropic phase [1].

As these classic experiments took place at the dawn of the 20th century, one might think that the mysteries of droplets, cylinders and other curved geometries for studying LCs would by now be elucidated and the research field exhausted. This is very far from the case. With the considerable advances in understanding of LCs that have developed during their first 128 years in human awareness (the first report of liquid crystals, by Reinitzer, dates from 1888 [2]) the enormous complexity and beauty of these states of matter has become apparent, continuously leading to new stimulating mysteries and providing many good reasons to revisit the classic experiments. Modern theoretical knowledge allow a deeper analysis of the behavior of LCs with curved boundaries, and the experimental equipment has developed to such an extent that today investigations that Mauguin and Grandjean could not dream of are possible.

Beyond superior imaging equipment, we now also have methods for producing LC samples with curved geometries with unprecedented control. The key development in this respect is the advent of microfluidics, which not only allows rapid production of thousands of identical LC droplets with extraordinary monodispersity, but even the 'excavation' of the droplet, by including a droplet of isotropic liquid inside it, thus creating a thin shell of LC. With shells we have obtained a truly fascinating new configuration for studying LCs, with two closely spaced curved interfaces, with positive curvature on one side and negative on the other. Another powerful technique is electrospinning, which allows us to prepare LC samples in a geometry that fundamentally is cylindrical with very small radius (on the order of a micron), but which can also be modulated into a beads-on-a-string type morphology, if desired.

This review is motivated by the many new opportunities that are now available for studying LCs in the shape of drops, shells or fibers, and the intriguing behavior that different LC phases grant us with when subjected to these sample geometries. These new configurations are intriguing not only from a fundamental science point of view, but they can be very interesting also in an applied perspective. Recent research has demonstrated application potential in sensors, actuators, photonics and even security. We believe that such cross-fertilization opportunities render the systems that we discuss interesting also outside the LC community. Even without a focus on applications, researchers working with microfluidics of isotropic liquids may find the new opportunities arising by incorporating LCs stimulating. The electrospinning and fiber technology research community will find that the responsiveness that LCs can add to textile and other fibers open many new opportunities.

Therefore, we begin the review with a brief introduction to the liquid crystalline states of matter and the terminology used to describe them in section 2, directed at researchers curious in the topic but without the LC background. Section 3 is devoted to shells and droplets of LCs, where we also provide a brief introduction to microfluidics in section 3.1, limiting ourselves to the key issues relevant for LC work. In the rest of section 3 we discuss the technicalities of producing and tuning LC droplets and shells in section 3.2, moving to the intriguing physics related to the topological defects that arise when preparing droplets or shells of LC in section 3.3, and then to two application opportunities, in LC elastomer actuators (section 3.4) and in photonics (section 3.5), respectively. The section ends with a brief discussion in section 3.6 of the very recent addition of LC droplet swimmers and active LCs in shell geometry.

Cylindrical confinement of LCs is the topic of section 4. We first give a general overview, summarizing seminal work on LCs filled into glass capillaries or in narrow Anopore or Nucleopore membranes. We then give a general introduction to the electrospinning technique in section 4.2, focusing on the specific challenge of incorporating LCs within polymer fibers in section 4.3. Finally, we move on to application opportunities of LC fibers in section 4.4. We end the article with an outlook in section 5.

2. The liquid crystalline states of matter

The long-range order in arrangement of molecules, molecule aggregates or particles that make up the LC phase gives it anisotropic macroscopic properties, like birefringence, direction-dependent viscosity and the ability to rearrange its internal structure in response to electromagnetic fields. Reflecting the unique combination of anisotropy with fluidity, LCs are sometimes referred to as anisotropic liquids. Many LCs are colloids, the phase building blocks then being nanoparticles or aggregates of amphiphilic molecules in an isotropic solvent (frequently water). This group constitutes the broad class of lyotropic LCs. The phase diagram of lyotropic LCs depends primarily on the volume fraction of the disperse phase.

Because the vast majority of studies of LC drops, shells and fibers were not done with lyotropics but rather with thermotropic LCs, we will focus mainly on the latter class in this review. Here no solvent is needed, and the phase is homogeneous down to the molecular scale, rather than colloidal. The molecules making up a thermotropic LC are called mesogens, as they generate mesophases (from Greek  = intermediate), an alternative name for liquid crystal phase. An LC-forming compound is sometimes called mesogenic, but most often it is simply referred to as a liquid crystal. This somewhat careless terminology can be confusing for the newcomer, who may have difficulties to tell LC phases apart from LC materials, in particular since the latter exhibit crystalline solid states at low temperatures and isotropic liquid states at high temperatures.

= intermediate), an alternative name for liquid crystal phase. An LC-forming compound is sometimes called mesogenic, but most often it is simply referred to as a liquid crystal. This somewhat careless terminology can be confusing for the newcomer, who may have difficulties to tell LC phases apart from LC materials, in particular since the latter exhibit crystalline solid states at low temperatures and isotropic liquid states at high temperatures.

Indeed, the phase diagram of thermotropics depends primarily on temperature (pressure is also relevant, but for practical reasons most experiments are done at atmospheric pressure), a fact that is reflected in the name of this LC class. While ordinary materials melt directly from the crystalline solid into the isotropic liquid state, LCs exhibit at least two transitions separating these states: first the crystal melts into a liquid crystalline state, then there may be transitions between different LC phases, before the highest-temperature LC phase is replaced by the isotropic liquid state at the clearing point. The latter name reflects the fact that a bulk LC without control of its alignment scatters light, in contrast to the behavior in the isotropic phase of the same material, where it becomes transparent and clear. In case of mixtures between multiple mesogens (sometimes also involving non-mesogenic constituents), also the mixture composition becomes a key parameter in determining the phase diagram.

A large number of thermotropic LC phases have been identified over the years. In this review we will only deal with a small selection that we consider the most important for the field that we cover: the nematic, in its non-chiral and chiral versions (the latter often called cholesteric), and the smectic phases SmA and SmC. In the following subsections each phase is introduced in some detail, and thereafter we will say a few words about the peculiar behavior of LC rubbers, or elastomers (LCEs).

2.1. Thermotropic nematics

The least ordered thermotropic LC phase is called nematic (abbreviated N), and it is characterized by long-range order in orientation of the molecules (which evidently must be anisometric, e.g. rod- or disc-shaped) but no long-range positional order, see figure 1. In terms of positional order the N phase is similar to an ordinary liquid, with only short-range positional order and no periodic lattice, no grains and no grain boundaries. Indeed, nematics typically flow easily, making them an ideal candidate for exploring liquid crystalline drops, shells or fibers. To describe the long-range orientational order and analyze how it gives rise to the anisotropic physical properties, one introduces the director, abbreviated  . It indicates the direction along which the molecules tend to align, thus the principal symmetry axis of the phase. Because there are equally many molecules 'pointing upwards' as are 'pointing downwards' in an averaging ensemble, +

. It indicates the direction along which the molecules tend to align, thus the principal symmetry axis of the phase. Because there are equally many molecules 'pointing upwards' as are 'pointing downwards' in an averaging ensemble, + and -

and - are indistinguishable. This is often expressed by the director sign invariance, formalized as

are indistinguishable. This is often expressed by the director sign invariance, formalized as  . More specifically, the director can be said to be a signless pseudovector.

. More specifically, the director can be said to be a signless pseudovector.

Figure 1. Cartoon of the order in a nematic phase of rod-like mesogens (left), aligning on the average along the director  , without any long-range positional order. The right drawing illustrates the parameters required for calculating the orientational order parameter according to (1). The polar angle β expresses the deviation of a certain molecule from

, without any long-range positional order. The right drawing illustrates the parameters required for calculating the orientational order parameter according to (1). The polar angle β expresses the deviation of a certain molecule from  and the azimuthal angle φ defines the deviation direction. The variable φ does not appear explicitly in (1) but it is implicit in the pointed brackets, which express averaging over all three space dimensions.

and the azimuthal angle φ defines the deviation direction. The variable φ does not appear explicitly in (1) but it is implicit in the pointed brackets, which express averaging over all three space dimensions.

Download figure:

Standard image High-resolution image2.1.1. The nematic order parameter.

The long-range orientational order of LCs is quantified by an orientational order parameter (also called nematic order parameter) that in 3D takes the form:

The angle β describes the deviation in orientation away from  of a particular molecule in the averaging ensemble, see figure 1. The pointed brackets here express averaging over 3D space, thus integrating over the angles β and φ, defined in figure 1.

of a particular molecule in the averaging ensemble, see figure 1. The pointed brackets here express averaging over 3D space, thus integrating over the angles β and φ, defined in figure 1.

In 3D, the order parameter (1) is zero for total disorder, whereas for complete orientational order, S = 1. The isotropic-nematic transition in thermotropics is first-order, i.e. S jumps discretely at the phase transition from zero to a non-zero value, typically around S = 0.4. On further cooling, S increases, initially fast but rapidly approaching saturation around S = 0.6–0.7.

2.1.2. Optical anisotropy and the terminology for describing LC orientation.

The mesogen anisometry together with the long-range orientational order generally render LCs optically anisotropic, i.e. their refractive index  parallel to

parallel to  is different from that perpendicular to the director,

is different from that perpendicular to the director,  . The director defines the optic axis. The magnitude of optical anisotropy, the birefringence, is defined as

. The director defines the optic axis. The magnitude of optical anisotropy, the birefringence, is defined as  . Consequently, if

. Consequently, if  is the maximum refractive index,

is the maximum refractive index,  and we call the LC positive uniaxial (normal case for rod-shaped mesogens). Light passing through the sample will experience

and we call the LC positive uniaxial (normal case for rod-shaped mesogens). Light passing through the sample will experience  as the ordinary refractive index no, while the extraordinary index ne varies depending on the direction of light propagation,

as the ordinary refractive index no, while the extraordinary index ne varies depending on the direction of light propagation,  being the limiting value.

being the limiting value.

Like any birefringent material, LCs can affect the polarization  of light, changing it continuously between linear, elliptical and circular as well as changing the main oscillation direction or reversing rotation handedness. The effect disappears, however, if the light propagates along

of light, changing it continuously between linear, elliptical and circular as well as changing the main oscillation direction or reversing rotation handedness. The effect disappears, however, if the light propagates along  , because a birefringent material appears isotropic to light traveling along the optic axis: since light is a transverse wave,

, because a birefringent material appears isotropic to light traveling along the optic axis: since light is a transverse wave,  is then by necessity perpendicular to the optic axis, hence the light experiences only no. An LC sample that is prepared such that the director is perpendicular to its boundary is called homeotropic, a name that reflects the 'isotropic-like' appearance for light entering the sample at normal incidence, along the director. If a flat homeotropic LC sample is placed between crossed polarizers during observation and if the alignment persists throughout the sample (also the other boundary must thus be homeotropic), it appears black. When working with curved samples, like those considered in this review, the meaning of the term 'homeotropic' as director perpendicular to the boundary is carried over. Note, however, that the curvature then means that light will generally not enter the sample along the director, and the curved sample will thus not (except in certain points) appear black.

is then by necessity perpendicular to the optic axis, hence the light experiences only no. An LC sample that is prepared such that the director is perpendicular to its boundary is called homeotropic, a name that reflects the 'isotropic-like' appearance for light entering the sample at normal incidence, along the director. If a flat homeotropic LC sample is placed between crossed polarizers during observation and if the alignment persists throughout the sample (also the other boundary must thus be homeotropic), it appears black. When working with curved samples, like those considered in this review, the meaning of the term 'homeotropic' as director perpendicular to the boundary is carried over. Note, however, that the curvature then means that light will generally not enter the sample along the director, and the curved sample will thus not (except in certain points) appear black.

The geometry orthogonal to homeotropic, where  is in the plane of the sample boundary, is called planar. If the sample is flat and if also the opposite boundary promotes the same planar alignment, such that

is in the plane of the sample boundary, is called planar. If the sample is flat and if also the opposite boundary promotes the same planar alignment, such that  is uniform throughout the sample, the full birefringence

is uniform throughout the sample, the full birefringence  is experienced by light entering at normal incidence. Inside the LC the light is split up into two eigenmodes with polarization perpendicular and parallel to

is experienced by light entering at normal incidence. Inside the LC the light is split up into two eigenmodes with polarization perpendicular and parallel to  , respectively, experiencing the refractive indices

, respectively, experiencing the refractive indices  and

and  . Homeotropic and planar anchoring are the two limiting cases of anchoring, but the anchoring conditions can often promote an arbitrary tilt of

. Homeotropic and planar anchoring are the two limiting cases of anchoring, but the anchoring conditions can often promote an arbitrary tilt of  out of the interfacial plane. A tilt of 0° corresponds to planar alignment, a tilt of 90° is homeotropic, whereas we here refer to anchoring with any other inclination simply as tilted.

out of the interfacial plane. A tilt of 0° corresponds to planar alignment, a tilt of 90° is homeotropic, whereas we here refer to anchoring with any other inclination simply as tilted.

For curved samples the situation is again more complex. As for the term 'homeotropic', the terms 'planar' and 'tilted' are carried over in the sense of how  is oriented with respect to the sample boundary. A planar interface thus has the director in the boundary plane, regardless of how this curves. This means that, across the surface of a planar-aligned curved sample,

is oriented with respect to the sample boundary. A planar interface thus has the director in the boundary plane, regardless of how this curves. This means that, across the surface of a planar-aligned curved sample,  and thus the optic axis change direction with respect to the light propagation. The resulting optical behavior is very different compared to a planar flat sample. We refer the reader to an optics textbook for a deeper analysis, here settling by pointing out that the effective birefringence in most points is lower than for a flat planar sample, the difference depending on the inclination of

and thus the optic axis change direction with respect to the light propagation. The resulting optical behavior is very different compared to a planar flat sample. We refer the reader to an optics textbook for a deeper analysis, here settling by pointing out that the effective birefringence in most points is lower than for a flat planar sample, the difference depending on the inclination of  in each point. The reduction in

in each point. The reduction in  is partially compensated by an increased length of light passage through the curving LC. For a shell, moreover, we frequently have top and bottom surfaces and—as discussed in section 3.3—both contribute to the birefringence, even if only one of them is in focus.

is partially compensated by an increased length of light passage through the curving LC. For a shell, moreover, we frequently have top and bottom surfaces and—as discussed in section 3.3—both contribute to the birefringence, even if only one of them is in focus.

If light propagates perpendicular to a uniformly planar-aligned LC, the orientation that  has within the sample plane—which is then equal to the light's polarization plane—is also very important for the optical effect of the LC. For tilted alignment the same holds for the orientation of the projection of

has within the sample plane—which is then equal to the light's polarization plane—is also very important for the optical effect of the LC. For tilted alignment the same holds for the orientation of the projection of  onto this plane, which we here call

onto this plane, which we here call  . Whenever the light polarization

. Whenever the light polarization  is along or perpendicular to

is along or perpendicular to  (or

(or  ), one of the two eigenmodes has zero amplitude, and the effect of the birefringence is lost. Therefore, when a sample is observed between crossed polarizers and

), one of the two eigenmodes has zero amplitude, and the effect of the birefringence is lost. Therefore, when a sample is observed between crossed polarizers and  or

or  (or

(or  or

or  ), it appears black. For all other polarizations both components exist, the birefringence changes the polarization state, and the sample typically appears bright between crossed polarizers, see figure 2.

), it appears black. For all other polarizations both components exist, the birefringence changes the polarization state, and the sample typically appears bright between crossed polarizers, see figure 2.

Figure 2. The schlieren texture of a flat nematic sample with degenerate planar alignment prevailing uniformly from one substrate to the other, observed between crossed polarizers. The dashed lines are sketches of the director field variations within the sample. Two topological defects are highlighted with grey spots, the upper one with strength s = 1 and the lower with strength s = 1/2. The texture photo was previously shown in [3]. Reproduced with permission from [3].

Download figure:

Standard image High-resolution imagePlanar alignment means that the director is in the sample boundary plane, and tilted alignment that it has a component  in that plane, but the terms say nothing about which orientation in this plane

in that plane, but the terms say nothing about which orientation in this plane  or

or  should adopt. With a solid substrate a preferred orientation can often be induced, for instance by rubbing the substrate in a specific direction, but many planar- or tilted-aligning interfaces induce what is called 'degenerate planar/tilted alignment', giving no preference for any particular direction within the interface plane. In a nematic LC subject to such boundary conditions, the direction of

should adopt. With a solid substrate a preferred orientation can often be induced, for instance by rubbing the substrate in a specific direction, but many planar- or tilted-aligning interfaces induce what is called 'degenerate planar/tilted alignment', giving no preference for any particular direction within the interface plane. In a nematic LC subject to such boundary conditions, the direction of  /

/ in the interface plane can vary smoothly as a function of location. Since

in the interface plane can vary smoothly as a function of location. Since  defines the optic axis, this means that such a spatially varying director field

defines the optic axis, this means that such a spatially varying director field  is recognized in the polarizing microscope through a characteristic schlieren texture, named after the German word for streak. An example is shown in figure 2. Softly curving black 'brushes' appear, often emanating from crosses or cusps that are defects in the director field (see section 3.3). Along a black brush,

is recognized in the polarizing microscope through a characteristic schlieren texture, named after the German word for streak. An example is shown in figure 2. Softly curving black 'brushes' appear, often emanating from crosses or cusps that are defects in the director field (see section 3.3). Along a black brush,  is parallel to one of the polarizers.

is parallel to one of the polarizers.

2.1.3. The viscous flow properties of nematics.

While nematics normally can flow easily, it makes a great difference if the flow is along or perpendicular to  , and, for the latter case, it also makes a difference if the flow velocity gradient is along or perpendicular to

, and, for the latter case, it also makes a difference if the flow velocity gradient is along or perpendicular to  . These three situations, depicted by three orthogonal director orientations

. These three situations, depicted by three orthogonal director orientations  ,

,  and

and  in figure 3, were investigated by the Polish physicist Marian Mięsowicz [4], after whom the three corresponding viscosities,

in figure 3, were investigated by the Polish physicist Marian Mięsowicz [4], after whom the three corresponding viscosities,  ,

,  and

and  are now called the Mięsowicz viscosities. The lowest viscosity is

are now called the Mięsowicz viscosities. The lowest viscosity is  , when the flow is along the director, whereas the highest is

, when the flow is along the director, whereas the highest is  , measured when the director is perpendicular to the flow but parallel to the flow velocity gradient. The third director orientation,

, measured when the director is perpendicular to the flow but parallel to the flow velocity gradient. The third director orientation,  , perpendicular to both flow and gradient, results in an intermediate viscosity

, perpendicular to both flow and gradient, results in an intermediate viscosity  , generally much closer to

, generally much closer to  than to

than to  . The Mięsowicz viscosities are typically on the order of a Poise, or 1kg m−1 s−1 in SI units.

. The Mięsowicz viscosities are typically on the order of a Poise, or 1kg m−1 s−1 in SI units.

Figure 3. To define the three Mięsowicz viscosities,  ,

,  and

and  , one considers an experiment of flow of nematic liquid crystal through, e.g. a tube; the dashed arrows on the left indicate the flow velocity along the tube, as a function of location. The director

, one considers an experiment of flow of nematic liquid crystal through, e.g. a tube; the dashed arrows on the left indicate the flow velocity along the tube, as a function of location. The director  is blocked by an external magnetic field, giving three possible orthogonal director orientations,

is blocked by an external magnetic field, giving three possible orthogonal director orientations,  ,

,  and

and  , with respect to the flow direction, each giving rise to the respective Mięsowicz viscosity.

, with respect to the flow direction, each giving rise to the respective Mięsowicz viscosity.

Download figure:

Standard image High-resolution imageThe Mięsowicz viscosities constitute the first approximation for understanding the viscous flow of LCs. If we make no effort to control the director orientation during flow,  will align nearly parallel to the flow to minimize viscous losses. The minimum viscosity is actually obtained for a slight offset, as a more rigorous treatment shows [5]. Flow alignment can be important in the study of drops, shells and fibers of LCs, as the sample preparation always involves flow. If the samples are prepared with the material in its nematic phase, the viscosity anisotropy will lead to a relatively uniform alignment during the process. Note, however, that for smectics (see section 2.2) the minimum dissipation is not along

will align nearly parallel to the flow to minimize viscous losses. The minimum viscosity is actually obtained for a slight offset, as a more rigorous treatment shows [5]. Flow alignment can be important in the study of drops, shells and fibers of LCs, as the sample preparation always involves flow. If the samples are prepared with the material in its nematic phase, the viscosity anisotropy will lead to a relatively uniform alignment during the process. Note, however, that for smectics (see section 2.2) the minimum dissipation is not along  but along the smectic layers. Moreover, in many cases the LC is brought into an isotropic state during sample preparation, by heating or by adding a solvent.

but along the smectic layers. Moreover, in many cases the LC is brought into an isotropic state during sample preparation, by heating or by adding a solvent.

2.1.4. Liquid crystal elasticity and deformations in the director field.

Liquid crystals, with nematics forming the clearest example, exhibit a type of elasticity that is unique to this materials class. This 'nematic elasticity' is fundamentally different from solid or rubber elasticity, since in this case there is no restoring force arising in response to deformation of the sample shape, but instead a restoring torque that builds up in response to deformation of the director field  .

.

In the elastic ground state of an achiral nematic (ignoring thermally activated fluctuations [1]) the director field is uniform, i.e.  is a constant, independent of location. A deviation from the uniform field costs energy, and this is what gives rise to nematic elasticity. This energy is quantified in the Oseen–Frank theory, based on Oseen's groundwork in the 1920s and the refinement, and introduction of modern terminology, by Frank in 1958 [2]. In the bulk of a nematic, any generic deformation from uniform

is a constant, independent of location. A deviation from the uniform field costs energy, and this is what gives rise to nematic elasticity. This energy is quantified in the Oseen–Frank theory, based on Oseen's groundwork in the 1920s and the refinement, and introduction of modern terminology, by Frank in 1958 [2]. In the bulk of a nematic, any generic deformation from uniform  can be described as a linear combination of three elementary elastic deformations: splay, twist and bend. These three fundamental distortions, defined graphically in figure 4, are independent of each other, such that no combination of twist and/or splay can compensate for a bend etc. The total free energy Fb related to bulk elastic deformations of the director field can thus be calculated by integrating a bulk energy density fb, containing one term each for splay, twist and bend, over the volume of the sample (if S is not uniform within the volume considered, a fourth term, saddle-splay, to be discussed in a moment, must be included as well):

can be described as a linear combination of three elementary elastic deformations: splay, twist and bend. These three fundamental distortions, defined graphically in figure 4, are independent of each other, such that no combination of twist and/or splay can compensate for a bend etc. The total free energy Fb related to bulk elastic deformations of the director field can thus be calculated by integrating a bulk energy density fb, containing one term each for splay, twist and bend, over the volume of the sample (if S is not uniform within the volume considered, a fourth term, saddle-splay, to be discussed in a moment, must be included as well):

Figure 4. Graphical definitions of the three elementary director field deformations splay, twist and bend, together with their corresponding terms in the elastic free energy density and their respective elastic constants K1, K2 and K3.

Download figure:

Standard image High-resolution imageReflecting its character as a source, the splay term in (2b) contains the divergence of the director field ( ), whereas the terms representing the two rotational distortions twist and bend contain the curl (

), whereas the terms representing the two rotational distortions twist and bend contain the curl ( ). Because each term is squared, the bulk elastic constants, K1 for splay, K2 for twist and K3 for bend, must all be positive, otherwise there would be no finite energy minimum.

). Because each term is squared, the bulk elastic constants, K1 for splay, K2 for twist and K3 for bend, must all be positive, otherwise there would be no finite energy minimum.

When considering strongly confined LC samples such as drops, shells and fibers, one must also consider the influence from the bounding interfaces. There are two contributions to the interfacial energy. First, as with any interface, there is an energy term given by the product of interfacial tension and the bounding area. However, since this is an LC the interfacial tension may depend on how  is aligned with respect to the boundary. We say that

is aligned with respect to the boundary. We say that  is anchored in a certain preferred orientation at the interface. This terminology should not be interpreted too literally, however, as we may have anything from very strong to very weak anchoring. The balance between surface anchoring and bulk elasticity will be discussed for the case of droplets in section 3.3.1. The anchoring energy is quantified by a parameter W. A common expression for this contribution to the interfacial energy is the Rapini–Papoular energy density (an area density, thus J/m2) [6, 7]:

is anchored in a certain preferred orientation at the interface. This terminology should not be interpreted too literally, however, as we may have anything from very strong to very weak anchoring. The balance between surface anchoring and bulk elasticity will be discussed for the case of droplets in section 3.3.1. The anchoring energy is quantified by a parameter W. A common expression for this contribution to the interfacial energy is the Rapini–Papoular energy density (an area density, thus J/m2) [6, 7]:

where the unit vector  denotes the preferred orientation of the director at the interface, and we let the index 'a' stand for 'anchoring'.

denotes the preferred orientation of the director at the interface, and we let the index 'a' stand for 'anchoring'.

The second interfacial energy contribution is the just mentioned saddle-splay term, which actually is an elastic energy related to director field distortion in the Oseen–Frank theory. As the name suggests, the term, quantified by the saddle-splay constant K24, relates to a deformation of the director field such that  is normal to a saddle (or potato chip) surface [8]. Such surfaces have negative Gaussian curvature, i.e. their two principal curvatures have opposites signs; a saddle curves upwards along the horse but downwards across the horse. The corresponding energy density is a pure divergence (

is normal to a saddle (or potato chip) surface [8]. Such surfaces have negative Gaussian curvature, i.e. their two principal curvatures have opposites signs; a saddle curves upwards along the horse but downwards across the horse. The corresponding energy density is a pure divergence ( ) term:

) term:

This means that its volume integral, required to calculate the corresponding energy, can be converted into a surface integral via the divergence theorem (Gauss' theorem), provided that K24 is constant within the integration volume:

Note that the integrand in the last term in (5) is not f24, as defined in (4), which is a volume energy density, J/m3. Compiling the above, we can obtain the total free energy (in the absence of fields and for constant K24 within the sample volume) as [7]:

A key difference between the F24 term and the other contributions to the free energy is that F24 enters with negative sign. In other words, while any deformation described by Fb raises the free energy, as does any increase in interfacial area, captured by  , a saddle-splay deformation of the bounding interface actually decreases the energy if K24 > 0. This seems to be the case for all materials that have been experimentally studied so far with respect to saddle-splay deformation.

, a saddle-splay deformation of the bounding interface actually decreases the energy if K24 > 0. This seems to be the case for all materials that have been experimentally studied so far with respect to saddle-splay deformation.

Because the saddle-splay term in case of constant K24 does not influence the bulk energy far from boundaries it has often been ignored, as the sample size was reasonably large in many studies. Moreover, when the sample boundaries are flat, as in standard display-like devices, the F24 contribution vanishes entirely. In contrast, in our focus on small samples with strongly curved boundaries, where the interface influence can be considerable, the F24 contribution can play an important role. If K24 varies within the sample volume, which should be the case if the order parameter S is non-uniform, Gauss' theorem cannot be applied and the saddle-splay contribution must be treated as a bulk elastic energy. Such a situation is not as exotic as one might at first think; at temperatures near the clearing point a temperature gradient within the sample would lead to varying S and thus varying K24, but even at uniform temperature, S decreases in the close vicinity of a topological defect or an impurity. As droplets, shells and fibers frequently comprise topological defects, the saddle-splay term may need to be treated with its full bulk character2.

The four elastic constants are significant material parameters, with key relevance for understanding the behavior of strongly confined LCs. When the boundaries are strongly curved, as in the cases considered in this review, the boundary conditions often impose elastic distortions within the LC, thereby raising the free energy. The elastic constants have the dimension J/m = N, i.e. a force, with a magnitude typically in the pN range. Note that the saddle-splay energy density (4) contains no squared terms, hence the saddle-splay constant K24 can, in principle, take negative as well as positive signs, in contrast to the bulk elastic constants. For thermotropics, K1 and K2 often have about the same value whereas K3 is about twice that value. A commonly applied convenient approximation is  and K24 = 0, a simplification referred to as the 'one-constant approximation'.

and K24 = 0, a simplification referred to as the 'one-constant approximation'.

Since a spatial derivative yields an inverse length, each term in (2b) is proportional to 1/R2, where R is the characteristic length of the respective deformation. This is the pitch in case of a twist, the radius of curvature of a bend, and the distance to the 'source' of a splay deformation. Note that R is independent of location for a twist of constant magnitude, while, in contrast, the characteristic length of bend and splay is only defined once we have chosen a certain location. A bend or splay gets less apparent the further away from the center of curvature or 'source' that we are.

The 1/R2 dependence and the small magnitude of the elastic constants means that elastic deformations with large characteristic length cost very little energy, so little in fact that large-scale deformations are thermally generated in a bulk nematic LC in its ground state. This means that large-scale non-uniformities arise spontaneously in bulk LC samples, giving them a characteristic turbid character. A uniform  actually has higher free energy, which we may provide, e.g. by applying a magnetic field that aligns the LC [1].

actually has higher free energy, which we may provide, e.g. by applying a magnetic field that aligns the LC [1].

2.2. Thermotropic smectics

The defining characteristic of smectic LCs is a layered structure, see figure 5. The layering should not be understood too literally, however. While we often speak of 'layer boundaries' for practical purposes, these are mainly help concepts: there are no sharp layer boundaries in smectics, but rather a quasi-long-range electron density modulation along one direction [9]. In the smectic-A phase, abbreviated SmA, the density modulation is along the director, i.e.  is identical to the smectic layer normal

is identical to the smectic layer normal  . The modulation can, however, also develop along an arbitrary angle with respect to

. The modulation can, however, also develop along an arbitrary angle with respect to  , which means that the director tilts in the layers. The most imported tilted smectic is the smectic-C phase, SmC.

, which means that the director tilts in the layers. The most imported tilted smectic is the smectic-C phase, SmC.

Figure 5. Schematic 2D drawings of the two most important smectic phases. Mesogens are drawn as ellipses, layer boundaries with dashed lines. Due to the tilt in the SmC phase of  with respect to the layer normal

with respect to the layer normal  , by an angle θ, the layer thickness dC is smaller than the layer thickness dA in the SmA phase.

, by an angle θ, the layer thickness dC is smaller than the layer thickness dA in the SmA phase.

Download figure:

Standard image High-resolution imageThe SmC tilt angle, normally given the symbol θ, is generally temperature dependent, often approaching zero on heating towards a SmA phase, while it at lower temperatures may saturate in the range 20–30°. The exception is if the SmC phase follows on cooling directly from an N phase or from the isotropic liquid state; then θ is often large (around 45°) and close to temperature-independent. The same holds in case of a transition from a SmA phase with strong first-order character. There are several versions of the basic smectic-C-type structure, distinguished by different interlayer tilting direction correlation schemes (see e.g. [10]). In the fundamental SmC phase the tilt in adjacent layers is in the same direction.

The magnitude of tilt θ critically influences the free energy of a SmC phase, but the tilting direction has no impact on the energy. Any direction is thus equally good, yielding a range of degenerate SmC states that define a cone (the SmC tilt cone), with opening angle  and symmetry axis along

and symmetry axis along  . Basically, the smectic layer thickness is the projection of the average mesogen length on

. Basically, the smectic layer thickness is the projection of the average mesogen length on  (taking conformational disorder into account [10]), see figure 5(b).

(taking conformational disorder into account [10]), see figure 5(b).

The Oseen–Frank elasticity theory was developed for nematics but it can be extended to phases with partial positional order. One must then take into account the special restrictions imposed on  by the symmetry of each phase. Twist and bend are incompatible with the constant layer thickness in the SmA phase. In contrast, the phase is compatible with director splay, and rolling-up of SmA layers into a splayed director configuration frequently occurs.

by the symmetry of each phase. Twist and bend are incompatible with the constant layer thickness in the SmA phase. In contrast, the phase is compatible with director splay, and rolling-up of SmA layers into a splayed director configuration frequently occurs.

Although SmC is less symmetric than SmA it allows more fluctuations in  . Tilting gives a new freedom (tilt direction) that enables deformations which do not interfere with the layered structure. In fact, the projection of

. Tilting gives a new freedom (tilt direction) that enables deformations which do not interfere with the layered structure. In fact, the projection of  onto the layer plane (this projection is often called the C-director,

onto the layer plane (this projection is often called the C-director,  ) behaves similar to the ordinary director in the nematic. The characteristic texture of a quasi-homeotropic SmC sample therefore reminds of the schlieren texture of a planar-aligned nematic, the changing curvature of the schlieren reflecting variations in

) behaves similar to the ordinary director in the nematic. The characteristic texture of a quasi-homeotropic SmC sample therefore reminds of the schlieren texture of a planar-aligned nematic, the changing curvature of the schlieren reflecting variations in  . There are some important differences in terms of which topological defects (see section 3.3) can develop, however, because the sign invariance of the director,

. There are some important differences in terms of which topological defects (see section 3.3) can develop, however, because the sign invariance of the director,  , does not apply to the C-director (

, does not apply to the C-director (

-

- ). The director tilting directions for

). The director tilting directions for  and -

and - are opposite, hence they correspond to different physical states.

are opposite, hence they correspond to different physical states.

2.3. Cholesterics (chiral nematics)

In recognition of the first chiral nematic-forming compounds being cholesterol derivatives, we often use the term cholesteric as an alternative name for chiral nematic. The phase can consequently be abbreviated either Ch or N*, where the star signifies chirality. The key expression of chirality is a helical modulation of  in the N* ground state, see the schematic illustration in figure 6. The helix axis, often chosen as

in the N* ground state, see the schematic illustration in figure 6. The helix axis, often chosen as  , is perpendicular to

, is perpendicular to  . The period, generally referred to as pitch p, is defined as the distance over which

. The period, generally referred to as pitch p, is defined as the distance over which  makes a 2π rotation. Due to the director sign invariance the physical properties repeat along

makes a 2π rotation. Due to the director sign invariance the physical properties repeat along  with a period p/2.

with a period p/2.

Figure 6. In chiral nematics the director is modulated helically, with a pitch p, along an axis  that is everywhere perpendicular to

that is everywhere perpendicular to  . Reproduced from [11]. CC BY 3.0.

. Reproduced from [11]. CC BY 3.0.

Download figure:

Standard image High-resolution imageIn the ground state the pitch has a well-defined value p0, sometimes called the natural pitch. This helical ground state is incompatible with (2b), which models a non-chiral nematic and thus indicates that any twist would raise the free energy. But for a cholesteric phase a non-helical state raises the free energy, as would any helix pitch different from p0. The free energy density expression must therefore be modified, extending the achiral twist term slightly to express the spontaneous twist:

The added term  is the wave vector of the spontaneous cholesteric helix. If the tendency to twist is weak, q0 is small and the term in (7) does not significantly affect the elastic energy density. For strong spontaneous twist, however, typically with the pitch on the same order as the wavelength of visible light or smaller, the added term in (7) can have a considerable impact.

is the wave vector of the spontaneous cholesteric helix. If the tendency to twist is weak, q0 is small and the term in (7) does not significantly affect the elastic energy density. For strong spontaneous twist, however, typically with the pitch on the same order as the wavelength of visible light or smaller, the added term in (7) can have a considerable impact.

Chirality has several important consequences for the physical properties of LC phases, sometimes related to the helical modulation, sometimes in general to the loss of mirror symmetry [12, 13]. Here we will restrict ourselves to discuss the effect of the helix on the optical properties of cholesterics, which is probably the most striking chirality expression. For more detailed information on chiral LCs, see, e.g. the book by Kitzerow and Bahr [13]. A good derivation of the optical properties of cholesterics can be found in a text by Priestly [14].

If p0 is short, on the order of 300 nm,  of the phase changes sign compared to the non-helical analog, and the helix axis

of the phase changes sign compared to the non-helical analog, and the helix axis  becomes the optic axis. Moreover, such a short-pitch cholesteric typically shows selective reflection of visible light incident along

becomes the optic axis. Moreover, such a short-pitch cholesteric typically shows selective reflection of visible light incident along  , turning the sample iridescently colored, the color depending on the viewing angle as well as on p0. In modern terminology, the cholesteric LC intrinsically exhibits a photonic band gap. The reflected light is circularly polarized with the same handedness as the helix, whereas the opposite handedness of circularly polarized light is transmitted.

, turning the sample iridescently colored, the color depending on the viewing angle as well as on p0. In modern terminology, the cholesteric LC intrinsically exhibits a photonic band gap. The reflected light is circularly polarized with the same handedness as the helix, whereas the opposite handedness of circularly polarized light is transmitted.

The helical modulation of  leads to a periodic modulation along the direction of light propagation of the refractive index, as long as the light does not enter perpendicular to

leads to a periodic modulation along the direction of light propagation of the refractive index, as long as the light does not enter perpendicular to  . Although the helix periodicity is p0 the optical periodicity along the helix axis is half of this, since already a 180° turn of

. Although the helix periodicity is p0 the optical periodicity along the helix axis is half of this, since already a 180° turn of  takes us back to an optically equivalent situation. We can apply Bragg's geometrical method (figure 7), well known from x-ray diffraction, to obtain an expression for the relation between the selectively reflected wavelength

takes us back to an optically equivalent situation. We can apply Bragg's geometrical method (figure 7), well known from x-ray diffraction, to obtain an expression for the relation between the selectively reflected wavelength  (as measured within the N* phase) and the viewing angle:

(as measured within the N* phase) and the viewing angle:

where m is an integer. For normal incidence (along  ) we can set m = 1 because only the fundamental reflection is present. Higher-order reflections would be the result of higher harmonics of the periodic structure but a sinusoidal modulation has no harmonics, only the fundamental. For oblique incidence the modulation is no longer perfectly sinusoidal since we are not following the helix, hence we then get weak higher-order reflections.

) we can set m = 1 because only the fundamental reflection is present. Higher-order reflections would be the result of higher harmonics of the periodic structure but a sinusoidal modulation has no harmonics, only the fundamental. For oblique incidence the modulation is no longer perfectly sinusoidal since we are not following the helix, hence we then get weak higher-order reflections.

Figure 7. The viewing angle dependence of the color of a cholesteric liquid crystal, summarized in the bottom cartoon, can be understood following a simple graphical procedure analogous to Bragg's law for x-ray diffraction, sketched at the top. Reproduced with permission from [3].

Download figure:

Standard image High-resolution imageSelective reflection occurs within a band of wavelengths that for normal incidence has the width  , where

, where  is the birefringence the sample would have had if the helix were unwound. The light wavelength in the N* phase is shortened with respect to the wavelength in vacuum by a factor equal to the average refractive index. For typical LCs this is about 1.5. Thus, if an N* phase appears green (∼550 nm wavelength in air) at normal incidence, the helix pitch must be around 370 nm.

is the birefringence the sample would have had if the helix were unwound. The light wavelength in the N* phase is shortened with respect to the wavelength in vacuum by a factor equal to the average refractive index. For typical LCs this is about 1.5. Thus, if an N* phase appears green (∼550 nm wavelength in air) at normal incidence, the helix pitch must be around 370 nm.

A decrease in the angle of incidence α of the light leads, according to (8), to a reduced wavelength of the selectively reflected light. This explains the observation that the color changes towards shorter wavelengths (from red to blue) if we tilt a cholesteric sample away from us, as schematically summarized in the lower part of figure 7. If the pitch is slightly too long to give selective reflection at normal incidence, we might start seeing colors under oblique incidence.

2.4. Liquid crystal elastomers

Liquid crystal elastomers (LCEs) comprise a unique class of materials due to their remarkable feature of dramatic shape change induced by a phase transition (usually the clearing transition). Experimental studies have reported up to ∼400% strain and stress of ∼10–100 kPa [15–17]. They are sometimes portrayed as artificial muscles although soft actuator is perhaps more appropriate; in his plenary talk at the ILCC 2002 (Edinburgh, UK) Pierre-Gilles de Gennes pointed out that LCEs are unlikely to match the force and speed of real biological muscles. Nevertheless, there are many interesting application scenarios, e.g. in soft robotics or other areas where shape change is required but ordinary rigid mechanics are not an option.

When you stretch a piece of rubber (the layman's term for elastomer) you are working against entropy. The polymer chains in the rubber, which cannot flow due to a limited amount of crosslinks, yet still have considerable conformational freedom, will adopt an isotropic random coil conformation in the ground state. As you stretch the rubber you reduce the number of accessible conformations, imposing the much reduced set in which the polymer is extended along the stretching direction. It is the entropic cost of this reduced conformational freedom that provides the restoring force that brings the rubber back to its original shape when you release it.

In an LCE the polymer chains are stretched out into the extended subset of conformations even without any external force applied. The extension is along  ; the long-range orientational order of the LC state, with the resulting macroscopic anisotropic physical properties, restricts the conformational freedom of the polymer chains to fluctuate perpendicular to

; the long-range orientational order of the LC state, with the resulting macroscopic anisotropic physical properties, restricts the conformational freedom of the polymer chains to fluctuate perpendicular to  , and promotes alignment along

, and promotes alignment along  . But just like when you release a stretched piece of ordinary rubber, the polymer chains will rearrange into their preferred set of isotropic conformations if the stretching force disappears. With an LCE this corresponds to heating above the clearing point of the LC phase, or otherwise inducing the transition into an isotropic state. The interesting thing is that, because the system is lightly crosslinked, this change of conformation brings with it a change in macroscopic sample shape, as schematically illustrated in figure 8. The process is fully reversible, so when the sample is brought back into the LC state, the shape reverts as well. There are a number of excellent reviews of LCEs and their actuation behavior [17–23]. As we here can only give a very brief introduction to the basic concept we refer the interested reader to these texts for more details.

. But just like when you release a stretched piece of ordinary rubber, the polymer chains will rearrange into their preferred set of isotropic conformations if the stretching force disappears. With an LCE this corresponds to heating above the clearing point of the LC phase, or otherwise inducing the transition into an isotropic state. The interesting thing is that, because the system is lightly crosslinked, this change of conformation brings with it a change in macroscopic sample shape, as schematically illustrated in figure 8. The process is fully reversible, so when the sample is brought back into the LC state, the shape reverts as well. There are a number of excellent reviews of LCEs and their actuation behavior [17–23]. As we here can only give a very brief introduction to the basic concept we refer the interested reader to these texts for more details.

Figure 8. The working principle of actuation of a nematic liquid crystal elastomer (LCE). In the nematic ground state (left) the polymer chains are stretched out along  in an entropically unfavored reduced set of conformations. Upon inducing the phase transition into the isotropic phase (right), the anisotropic environment disappears and the polymer chains adapt the preferred isotropic random coil average conformation. The crosslinks couple this conformational change to a macroscopic sample shape change, with compression along the original

in an entropically unfavored reduced set of conformations. Upon inducing the phase transition into the isotropic phase (right), the anisotropic environment disappears and the polymer chains adapt the preferred isotropic random coil average conformation. The crosslinks couple this conformational change to a macroscopic sample shape change, with compression along the original  and expansion in both orthogonal dimensions. Reproduced from [21] John Wiley & Sons. Copyright © 2010 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim.

and expansion in both orthogonal dimensions. Reproduced from [21] John Wiley & Sons. Copyright © 2010 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim.

Download figure:

Standard image High-resolution imageLCEs may be subdivided into three main classes [17, 21, 24], differing in the generic chemical structure, see figure 9. In main chain LCEs, the mesogens are part of the polymer chain, whereas they are attached as pendants to the polymer chain in side chain LCEs. The latter are further subdivided into side-on and end-on versions, referring to the attachment point within the mesogen to the polymer chain.

Figure 9. Schematic drawings of the three main types of LCEs, together with example mesogenic monomers for each case; main chain LCE (the example structure is studied in Ahir et al [25]), side-on side chain LCE (example structure studied in Naciri et al [26]) and end-on side chain LCE (example structure studied in Finkelmann et al [27]).

Download figure:

Standard image High-resolution imageA prerequisite for the operation of LCEs is that  is uniform in the ground state. Often this is achieved by starting with a liquid crystalline but non-polymeric mixture of low molar mass precursors. This mixture can be aligned by placing it in contact with substrates coated with an aligning layer [28–30], applying a magnetic[31–33] or electric field [34], or subjecting it to shear flow [35–37]. The precursor mixture typically consists of reactive mesogens, such as the acrylate mesogens exemplified in Figure 9, a small amount of diacrylate crosslinkers, and often a suitable photoinitiator. Then polymerization and crosslinking can be initiated by UV illumination after the desired uniform alignment has been ensured (in case of alignment by shear flow, photopolymerization must be initiated during shearing). Using photosensitive mesogenic components in the mixture, also the alignment can be achieved by UV illumination, in that case using linearly polarized UV light [23, 38, 39].

is uniform in the ground state. Often this is achieved by starting with a liquid crystalline but non-polymeric mixture of low molar mass precursors. This mixture can be aligned by placing it in contact with substrates coated with an aligning layer [28–30], applying a magnetic[31–33] or electric field [34], or subjecting it to shear flow [35–37]. The precursor mixture typically consists of reactive mesogens, such as the acrylate mesogens exemplified in Figure 9, a small amount of diacrylate crosslinkers, and often a suitable photoinitiator. Then polymerization and crosslinking can be initiated by UV illumination after the desired uniform alignment has been ensured (in case of alignment by shear flow, photopolymerization must be initiated during shearing). Using photosensitive mesogenic components in the mixture, also the alignment can be achieved by UV illumination, in that case using linearly polarized UV light [23, 38, 39].

Another solution is the two-step polymerization introduced by the Finkelmann group, [40, 41] producing the very first LCEs after they had been predicted by de Gennes [42]. An intermediate main-chain polymer is produced in a first step of incomplete polymerization. Because the sample is now polymeric, uniaxial stretching can align  throughout the sample. Then, under the influence of the aligning mechanical field, the second polymerization and crosslinking step is triggered, which fixes the ground state orientation and produces the LCE film. This approach has the limitation that the resulting elastomer still remains somewhat mechanically constrained due to the presence of sharp domain boundaries, and it is difficult to remove excessive random crosslinks which persist [43].

throughout the sample. Then, under the influence of the aligning mechanical field, the second polymerization and crosslinking step is triggered, which fixes the ground state orientation and produces the LCE film. This approach has the limitation that the resulting elastomer still remains somewhat mechanically constrained due to the presence of sharp domain boundaries, and it is difficult to remove excessive random crosslinks which persist [43].

Following the Finkelmann group principle, Yakacki and co-workers recently introduced a convenient approach to prepare LCE actuators that uses solely commercially available components [44]. The LCE formation here follows a two-stage thiol-acrylate Michael addition and photopolymerization reaction. The approach is attractive as it opens for low-cost and large-scale LCE synthesis without requiring in-house synthetic chemistry facilities.

When producing LCEs in shape of droplets, shells or fibers, the requirement on uniform alignment may be fulfilled in alternative ways, since the production method and/or the sample geometry impose a specific director field. External alignment fields or substrates may not be necessary (in fact, it may even be impossible to apply them) and some rather interesting curved LCE actuators can be realized with relative ease. This will be further discussed in section 3.4.

Heating is not the only means of inducing the phase transition that triggers actuation. A powerful method is to incorporate dyes that change shape between rod- and kink-shaped upon illumination with light of adequate wavelength. [19, 45] The most common choice is azo dyes, which switch from a rod-shaped trans-isomer in the dark state to a kinked cis-isomer upon illumination by UV-light. Visible light illumination speeds up the reverse isomerization, back to the trans state, allowing switching in both directions using light with different wavelengths [46]. Because the cis-isomer disturbs the liquid crystalline ordering, all LC-related phase transitions, including the clearing point, are brought down to lower temperatures by the presence of cis-isomer azo dye, compared to when the dye is in its rod-shaped trans-isomer. The latter isomer is fully compatible with the long-range order. With the right amount of azo dye one can thus modulate the clearing point between above room temperature without UV illumination and below room temperature during UV illumination. This means that light can trigger the LCE actuation, not by heating, but by dynamically changing the phase diagram.

3. Liquid crystal shells and droplets

We now have the required basic knowledge about LCs and LCEs to discuss the effects of varying types of confinement. This section is devoted to spherical confinement, in droplets and shells, whereas section 4 covers cylindrical confinement. In section 3.1 we introduce the microfluidic production technique, which has revolutionized our capability of producing droplets and shells with high precision and reproducibility. This is followed by a survey of options for making LC spheres, including but not limited to microfluidics, how to stabilize them and at the same time control the alignment (section 3.2.1), and how to tune the size and thickness of shells via osmosis (section 3.2.2).

Section 3.3 deals with topological defects in LC spheres. After defining the key concepts for describing and quantifying topological defects we continue with surveying the experimental and simulation data on nematic, cholesteric and SmA/SmC droplets and shells. We discuss actuators made by polymerizing LC droplets and shells into LCEs, followed by an overview of application opportunities of short-pitch N* spheres in security, ending the section with a quick look at the role of droplets and shells in the emerging field of active LCs.

3.1. Microfluidics in a nutshell

The emergence of microfluidics started around the 1980's from the miniaturisation of flow geometries through micro- and nano-fabrication technologies [47–49]. Microfluidics is a rapidly growing multidisciplinary field, where physical, biological, chemical and engineering sciences converge into a single platform. It deals with the process and manipulation of fluids in channels with dimensions of tens of microns [48, 50–52]. Consequently, the surface to volume ratio increases in microfluidic systems, thus inertial forces are often negligible in comparison to viscous, electrostatic/electrodynamic, or surface tension forces. Especially, the surface forces are crucial for regulating the fluid flow in microfluidic devices [53]. Typical values of the Reynolds number, Re, which is a dimensionless number that relates the inertial to the viscous forces, are less than 10 for microfluidic flows [54, 55].

The revolutionary growth of the microfluidics field was triggered by the advancement of a lithography technique originated from the Whitesides group, known as soft lithography. The term soft refers to the design of channels using a soft elastomer, typically polydimethylsiloxane, or PDMS. The PDMS based soft lithography system has several advantages. It is easy to design and fabricate various flow patterns, from simple to complex and multiphase. PDMS is inexpensive, optically transparent for microscopy and permeable to gases, the latter aspect crucial for microbiological culture [52]. Thus, soft lithography is rapidly spreading in various research fields like diagnostics and biological research [56], fluid physics [57–60], chemical synthesis [61], the study of infectious diseases and preventive medicine [62, 63] and many other interdisciplinary research fields [52].

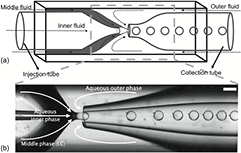

When chemical and thermal stability is required, alternative materials to PDMS are needed, such as glass, steel or silica [52]. A completely different design for microfluidics, based on nested glass capillaries with circular and square cross sections, respectively, was developed in the Weitz group. The basic principle for this method, which allows easy production of multiple emulsions with excellent control, is shown in figure 10. Since the outer diameter of the tapered cylindrical capillaries matches the inner side length of the square one, all capillaries are easily aligned in a concentric fashion. An inner (often aqueous) phase, which is immiscible with the middle phase, is injected through the left cylindrical capillary. The middle phase is flown in the same direction, through the corner spaces between cylindrical and square capillaries. While the two phases are co-flowing, they meet a counter-flowing outer phase, also immiscible with the middle phase (also the outer phase is often aqueous), introduced from the opposite side, again via the corner spaces between cylindrical and square capillaries. The pressure of the outer fluid flow-focuses the co-flowing liquids as a narrow jet [64, 65]. The interfacial tension between the middle and outer fluids causes breaking of the stream into shells via the Rayleigh–Plateau instability. Several modifications of the basic device are possible, the one depicted in figure 10 yielding a double emulsion. If a simple emulsion of droplets is preferred, the same device can be used with the flow rate of the inner fluid reduced to zero.

Figure 10. (a) Schematic illustration of the nested glass capillary microfluidic device for generating double emulsions from coaxial jets. Two tapered cylindrical glass capillaries are inserted into a square capillary, its inner side length identical to the outer diameter (∼1 mm) of the cylindrical capillaries. Injection and collection tubes are tapered using a micropipette puller, in order to ensure the desired constriction size, and a micro forge is then used to cut off the tips and establish the orifices. The middle fluid must be immiscible with the inner as well as the outer fluid, and interface stabilisers are added to prevent coalescence of the dispersed phase. (b) Liquid crystal shell production. The shells in this example are about 130 μm in diameter and below 3 μm in thickness and there are small satellite droplets next to each individual shell. The scale bar is 200 μm.

Download figure:

Standard image High-resolution imageCompared to the PDMS-based microfludic set-up, a glass micro capillary device has the advantage of reusability, thanks to its chemical resistance, and it does not suffer from swelling problems when working with organic solvents. A disadvantage is the difficulty in designing curved flow patterns. So far, the nested glass capillary technique dominates over PDMS-based microfluidics when the target is to prepare LC droplets and shells. Irrespective of the type of microfluidic device, the fluids are generally injected into the different channels by syringe pumps or pneumatic control units specially designed for microfluidics. The manipulation of multiphase flows in both systems enables generation of mono disperse bubbles [66], droplets [67], shells [68, 69], micro reactors for biology and medicine and various chemical reactions [56, 61–63, 70, 71].

To make LC droplets or shells, the LC is the disperse phase while the continuous phase is isotropic. It is worth mentioning that fascinating effects can also be seen when flowing LC as a continuous phase in microchannels. This brings novel flow profiles generated from the combination of surface anchoring and topological flow constraints within the channel, which are not observed with an isotropic continuous phase. As with conventional flat glass substrates, the alignment of an LC in a PDMS flow channel can be controlled by treating the channel walls chemically for either homeotropic or planar alignment, and even combinations of opposing alignment on different walls can be obtained by combining chemical alignment agents and plasma treatment and/or leave one side open to air [72, 73].

The different possibilities for surface anchoring combinations and the freedom to vary the channel aspect ratio (width/depth) open a playground for the creation of various topological constraints. In this way one can trigger the formation of topological point or line defects in nematics, which in turn are useful for guided transportation of micro-scale objects and tunable flow shaping [73–75]. Further interesting possibilities arise with SmA liquid crystals in rectangular channels, as reported by several research groups [76–78]. Here, the main focus is on inducing arrays of focal conic defects with controlled size and locations, again using different anchoring conditions and channel geometries to tune the final defect arrangements. Besides the channel-confined focal conic defect structures, Shojaei et al reported the formation of a two-dimensional network of the same defect structures in a thin film of the SmA-forming LC 8CB using cracked PDMS films [77]. Here, the crack pattern is controlled by stretching the plasma treated PDMS film.

3.2. How to make liquid crystal shells and droplets using microfluidics

A typical way of producing LC droplets is preparing emulsions by dispersing liquid crystals in an immiscible liquid. Among numerous methods for the emulsion preparation, stirring or vortexing constitute quick and low-cost approaches. The drawback of these methods, crudely breaking the bulk liquid crystal into small droplets by mechanical agitation, is the difficulty in controlling the size and obtaining uniformity. A common alternative is ultrasonication, in which a strong oscillating shear flow is induced by pressure waves at ultrasonic frequencies. This technique can provide a somewhat narrower size distribution with smaller droplets, even below the micron scale, in form of a miniemulsion [79]. Yet, also with ultrasonication one is far from achieving monodispersity, and the non-uniform size further leads to Ostwald ripening, which reduces emulsion stability. The high interface curvature of a small droplet raises the solubility of the disperse phase, triggering molecular diffusion from small to large droplets.

With the coaxial microfluidic technology developed in the Weitz group, a new alternative appeared that enables the production of highly controlled monodisperse simple as well as multiple emulsions [68], the liquid crystal taking the role of the middle phase. Now, not only LC droplets of selectable size could be produced, but even thin shells of LC, where a few microns thick spherical layer of the desired liquid crystal material is surrounded by isotropic immiscible phases (typically aqueous) on both sides. The shell/droplet dimensions, i.e. diameter and thickness (in case of shells), can be adjusted by tuning the production parameters: capillary/orifice size, flow rates, interfacial tension and viscosities of the fluids involved. The orifice sizes of the tapered cylindrical capillaries have a direct impact on the shell/droplet sizes. At low flow rate the resulting droplet/shell diameter can be estimated to be close to the orifice diameter [80].

However, the relative flow rates also play a critical role in controlling the shell/droplet sizes, even determining whether or not emulsion formation is at all possible. Utada et al distinguished between two different droplet-forming mechanisms in co-flowing Newtonian fluids, namely dripping and jetting modes [81]. Which of the two modes is active depends on the interplay between interfacial tension and viscous drag force, acting on the interface between middle and outer fluids. If the flow rates of the inner and middle phases are fixed, a high flow rate of the outer fluid increases viscous stress at the interface, eventually dominating over the interfacial tension such that a long stream of inner+middle phase is stabilized (jetting mode). In contrast, at lower flow rate of the outer fluid the inner complex stream is rapidly broken up into shells (dripping mode), because now the interfacial tension dominates. Even if liquid crystals are (weakly) non-Newtonian fluids, the basic drop-forming process is expected to be similar to that of Newtonian fluids [81]. On the other hand, the LC is most often brought to the isotropic state, for instance by heating, during production, turning it into a Newtonian fluid at this stage. Further tuning of shell/droplet size is possible via variations of interfacial tension (e.g. using surfactants) and viscosity [80, 82].

3.2.1. The connected problems of interface stabilization and liquid crystal alignment control.

The stabilization of liquid crystal shells/droplets can be ensured by adding interface stabilizers, also called emulsifiers, most often to the aqueous phases. Compared to water a thermotropic LC can be considered an oil phase, immiscible with water, thus the stabilizers are needed to reduce the interfacial tension between the phases. Without stabilizers, droplets would coalesce and shells would collapse into droplets. Importantly, the stabilizers may also play another key role, namely to determine the liquid crystal alignment.