Paper:

Patterning-Based Self-Assembly of Specific and Functional Structures

Taichi Kokubu, Tatsuya Hikida, and Hiroaki Suzuki

Graduate School of Science and Engineering, Chuo University

1-13-27 Kasuga, Bunkyo-ku, Tokyo 112-8551, Japan

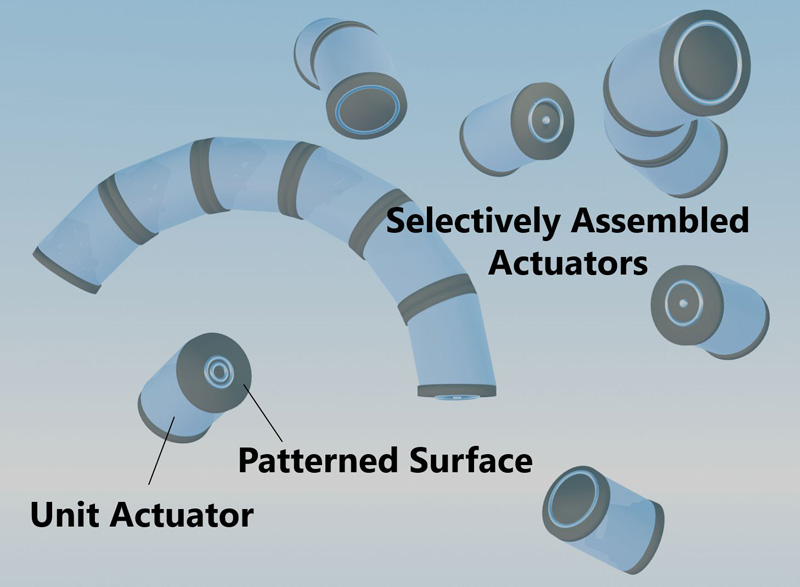

In this study, we developed a system for selective self-assembly of millimeter-scale components differentiated by adhesive patterns. This was achieved by designing concentric circular patterns having different radii but the same total length of peripheries. Small polymer sheets having solder adhesive patterns in these designs were simply attached to the millimeter-scale components to be assembled in a stirring container. This strategy was effective in avoiding an overlap between different patterns and enforcing the selective bonds between identical patterns among three types of components. Finally, the selective assembly of a functional structure (i.e., poly(N-isopropylacrylamide) gel actuator) was demonstrated.

Selective self-assembly of gel actuators

- [1] M. Boncheva and G. M. Whitesides, “Making things by self-assembly,” Mrs. Bull., Vol.30, No.10, pp. 736-742, 2005. https://doi.org/10.1557/mrs2005.208

- [2] M. Mastrangeli, S. Abbasi, C. Varel, C. Van Hoof, J. P. Celis, and K. F. Bohringer, “Self-assembly from milli-to nanoscales: methods and applications,” J. Micromech. Microeng., Vol.19, No.8, Article No.083001, 2009. https://doi.org.10.1088/0960-1317/19/8/083001

- [3] H. O. Jacobs, A. R. Tao, A. Schwartz, D. H. Gracias, and G. M. Whitesides, “Fabrication of a cylindrical display by patterned assembly,” Science, Vol.296, No.5566, pp. 323-325, 2002. https://doi.org.10.1126/science.1069153

- [4] J. Fang and K. F. Bohringer, “Parallel micro component-to-substrate assembly with controlled poses and high surface coverage,” J. Micromech. Microeng., Vol.16, No.4, pp. 721-730, 2006. https://doi.org.10.1088/0960-1317/16/4/008

- [5] N. B. Crane, O. Onen, J. Carballo, Q. Ni, and R. Guldiken, “Fluidic assembly at the microscale: progress and prospects,” Microfluid. Nanofluid., Vol.14, No.3-4, pp. 383-419, 2013. https://doi.org/10.1007/s10404-012-1060-1

- [6] S.-C. Park, J. Fang, S. Biswas, M. Mozafari, T. Stauden, and H. O. Jacobs, “A First Implementation of an Automated Reel-to-Reel Fluidic Self-Assembly Machine,” Adv. Mater., Vol.26, No.34, pp. 5942-5949, 2014. https://doi.org/10.1002/adma.201401573

- [7] S.-C. Park, J. Fang, S. Biswas, M. Mozafari, T. Stauden, and H. O. Jacobs, “Approaching Roll-to-Roll Fluidic Self-Assembly: Relevant Parameters, Machine Design, and Applications,” J. Microelectromech. Syst., Vol.24, No.6, pp. 1928-1937, 2015. https://doi.org.10.1109/JMEMS.2015.2452772

- [8] D. Karnaushenko, T. Kong, V. K. Bandari, F. Zhu, and O. G. Schmidt, “3D Self-Assembled Microelectronic Devices: Concepts, Materials, Applications,” Adv. Mater., Vol.32, No.15, Article No.1902994, 2020. https://doi.org/10.1002/adma.201902994

- [9] A. Terfort, N. Bowden, and G. M. Whitesides, “Three-dimensional self-assembly of millimetre-scale components,” Nature, Vol.386, No.6621, pp. 162-164, 1997. https://doi.org/10.1038/386162a0

- [10] J. Tien, T. L. Breen, and G. M. Whitesides, “Crystallization of millimeter-scale objects with use of capillary forces,” J. Am. Chem. Soc., Vol.120, No.48, pp. 12670-12671, 1998. https://doi.org/10.1021/ja982246y

- [11] S. R. J. Oliver, N. Bowden, and G. M. Whitesides, “Self-assembly of hexagonal rod arrays based on capillary forces,” J. Colloid. Interf. Sci., Vol.224, No.2, pp. 425-428, 2000. https://doi.org.10.1006/jcis.1999.6695

- [12] T. D. Clark, J. Tien, D. C. Duffy, K. E. Paul, and G. M. Whitesides, “Self-assembly of 10-µm-sized objects into ordered three-dimensional arrays,” J. Am. Chem. Soc., Vol.123, No.31, pp. 7677-7682, 2001. https://doi.org/10.1021/ja010634l

- [13] H. Onoe, K. Matsumoto, and I. Shimoyama, “Three-dimensional sequential self-assembly of microscale objects,” Small, Vol.3, No.8, pp. 1383-1389, 2007. https://doi.org/10.1002/smll.200600721

- [14] J. H. Chung, W. Zheng, T. J. Hatch, and H. O. Jacobs, “Programmable reconfigurable self-assembly: Parallel heterogeneous integration of chip-scale components on planar and nonplanar surfaces,” J. Microelectromech. Syst., Vol.15, No.3, pp. 457-464, 2006. https://doi.org.10.1109/JMEMS.2006.872226

- [15] W. Zheng and H. O. Jacobs, “Fabrication of multicomponent microsystems by directed three-dimensional self-assembly,” Adv. Funct. Mater., Vol.15, No.5, pp. 732-738, 2005. https://doi.org/10.1002/adfm.200400595

- [16] L. Abelmann, T. A. G. Hageman, P. A. Lothman, M. Mastrangeli, and M. C. Elwenspoek, “Three-dimensional self-assembly using dipolar interaction,” Sci. Adv., Vol.6, No.19, Article No.eaba2007, 2020. https://doi.org.10.1126/sciadv.aba2007

- [17] J. G. Fernandez and A. Khademhosseini, “Micro-Masonry: Construction of 3D Structures by Microscale Self-Assembly,” Adv. Mater., Vol.22, No.23, pp. 2538-2541, 2010. https://doi.org/10.1002/adma.200903893

- [18] C. Murphy, Y. Q. Cao, N. Sepulveda, and W. Li, “Quick self-assembly of bio-inspired multi-dimensional well-ordered structures induced by ultrasonic wave energy,” PLoS One, Vol.16, No.2, Article No.e0246453, 2021. https://doi.org/10.1371/journal.pone.0246453

- [19] I. Routa, B. Chang, A. Shah, and Q. Zhou, “Surface Tension-Driven Self-Alignment of Microchips on Low-Precision Receptors,” J. Microelectromech. Syst., Vol.23, No.4, pp. 819-828, 2014. https://doi.org.10.1109/JMEMS.2013.2293602

- [20] M. Mastrangeli, Q. Zhou, V. Sariola, and P. Lambert, “Surface tension-driven self-alignment,” Soft Matter, Vol.13, No.2, pp. 304-327, 2017. https://doi.org/10.1039/C6SM02078J

- [21] T. Okuyama, T. Hikida, T. Okano, and H. Suzuki, “Selective self-assembly of three-component system based on hydrophilic/hydrophobic patterning,” Sens. Act. A: Physical, Vol.312, Article No.112143, 2020. https://doi.org/10.1016/j.sna.2020.112143

- [22] M. R. de Moura, F. A. Aouada, M. R. Guilherme, E. Radovanovic, A. F. Rubira, and E. C. Muniz, “Thermo-sensitive IPN hydrogels composed of PNIPAAm gels supported on alginate-Ca2+ with LCST tailored close to human body temperature,” Polym. Test., Vol.25, No.7, pp. 961-969, 2006. https://doi.org/10.1016/j.polymertesting.2006.06.002

- [23] K. Matsubara, D. Tachibana, R. Matsuda, H. Onoe, O. Fuchiwaki, and H. Ota, “Hydrogel Actuator with a Built-In Stimulator Using Liquid Metal for Local Control,” Adv. Intell. Syst.-Ger., Vol.2, No.5, Article No.2000008, 2020. https://doi.org/10.1002/aisy.202000008

- [24] K. Nakayama, T. Hikida, and H. Suzuki, “In-plane orientational control of electric components using pattern complementarity in a self-assembling system,” J. Microelectromech. Syst., 2023. https://ieeexplore.ieee.org/document/10198510

- [25] U. Srinivasan, D. Liepmann, and R. T. Howe, “Microstructure to substrate self-assembly using capillary forces,” J. MEMS, Vol.10, No.1, pp. 17-24, 2001. https://doi.org.10.1109/84.911087

- [26] M. Mastrangeli, Q. Zhou, V. Sariola, and P. Lambert, “Surface tension-driven self-alignment,” Soft Matter, Vol.13, pp. 304-327, 2017. https://doi.org/10.1039/C6SM02078J

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.