PRACTICAL ELECTRICAL ENGINEERING BASICS Fundamentals Technology Training that

PRACTICAL ELECTRICAL ENGINEERING BASICS Fundamentals Technology Training that works

Alternating Current System • Most common power generators in power stations generate AC voltages • Follow sinusoidal waveforms alternating between positive and negative peaks around zero axis • This waveform of voltage/ current is normally referred to as AC voltage and AC current in Electrical distribution Technology Training that works

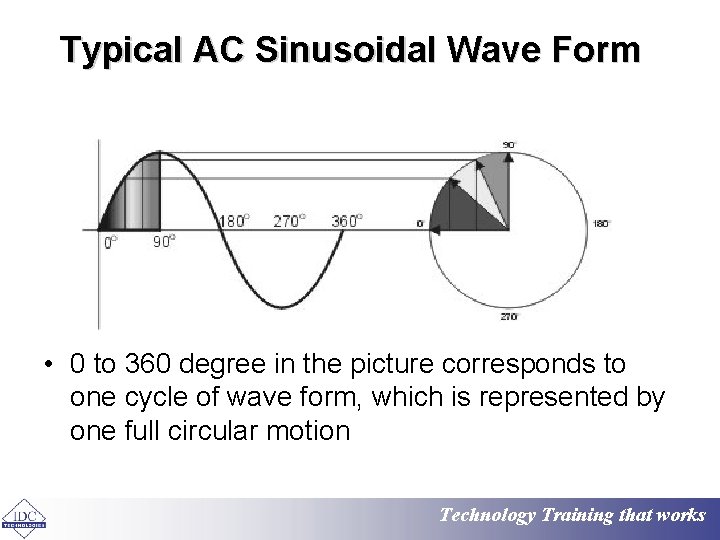

Typical AC Sinusoidal Wave Form • 0 to 360 degree in the picture corresponds to one cycle of wave form, which is represented by one full circular motion Technology Training that works

Why AC? • Almost entire power generation and transmission is by AC (alternating current) • AC lends itself to voltage changes easily • Voltage can be chosen for optimum efficiency and optimum capital cost • Thus better economy of power system operations Technology Training that works

Alternating current system • Power generators generate AC voltages, which follow sinusoidal waveforms • Mathematically expressed as V = Vp Sin(2 × f × t) V – Vp – F – T – Instantaneous magnitude of voltage Peak value of voltage Frequency Time • This voltage/current waveform normally referred to as AC voltage and AC current Typical AC sinusoidal wave form Technology Training that works

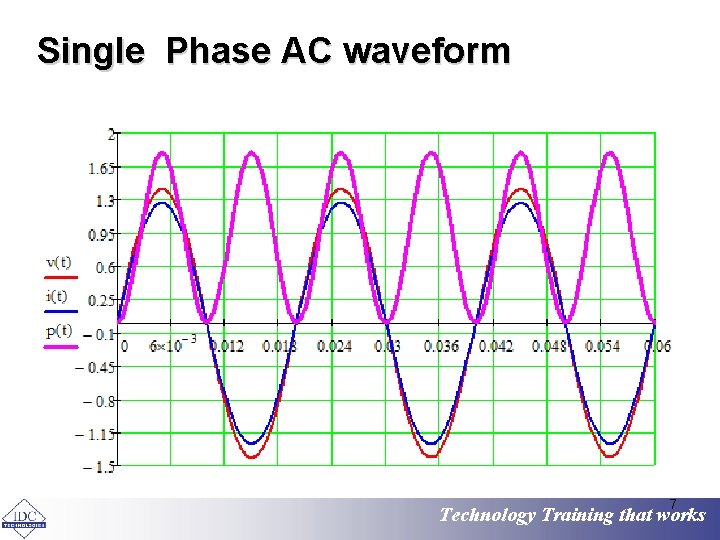

AC Waveform • Voltage or current in AC circuits varies cyclically number of times per second • This number is called frequency (f) • Time for one cycle is 1/f • Variation follows sine relationship and waveform is called sine wave • Electrical system can be of single or 3 phase type Technology Training that works

Single Phase AC waveform 7 Technology Training that works

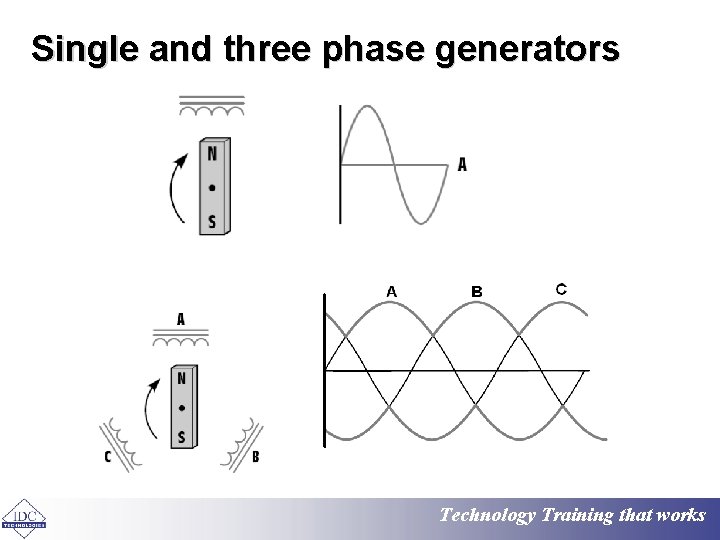

Single and three phase generators Technology Training that works

Three phase AC • Universally adopted because of lower equipment cost per unit power handled • Helpful while interconnecting several generating sources (sources tend remain in phase or stay synchromised) • Three phase AC motors (which account for most of the energy used) have simple design and are self starting Technology Training that works

Benefits of 3 -phase ac power system • • Higher power output for a given size of motor Better conductor economy per unit power Self starting induction motors Better synchronising torque makes parallel operation of alternators possible Technology Training that works

Electrical Power and Energy • In DC circuits Power = Voltage x Current (Watts) Energy = Power x Time (Watt Hours) • In AC circuits instantaneous voltage and current keep changing as they follow a sine curve – Power is computed using Root Mean Square (RMS) voltage and RMS current Technology Training that works

AC Power • Fundamental Definition of Power: • In an AC circuit both are sinusoidal against time • Sinusoidal Voltage and Current are defined in RMS magnitudes where: 12 Technology Training that works

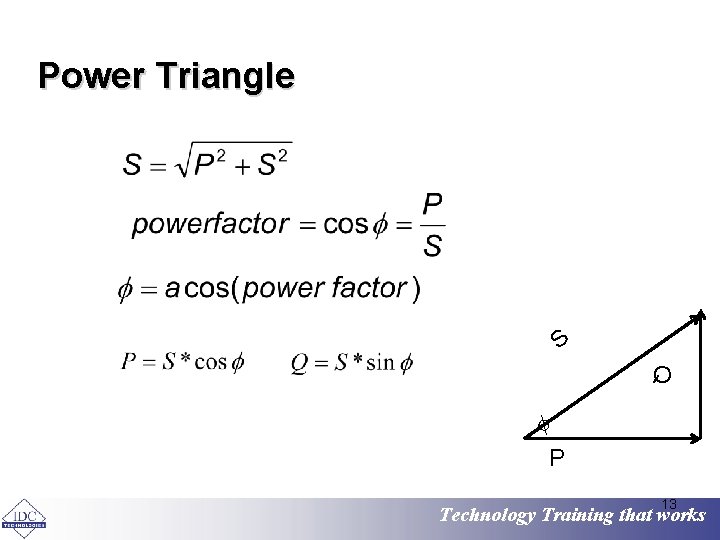

Power Triangle S Q f P 13 Technology Training that works

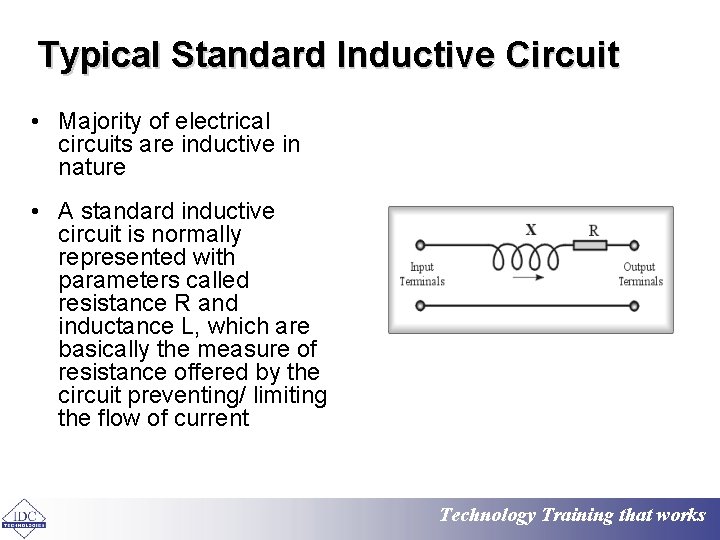

Typical Standard Inductive Circuit • Majority of electrical circuits are inductive in nature • A standard inductive circuit is normally represented with parameters called resistance R and inductance L, which are basically the measure of resistance offered by the circuit preventing/ limiting the flow of current Technology Training that works

Formulae for Power • • Apparent power S = V*I Active Power P = V*I*Cos f Reactive Power Q = V*I* Sin f Cos f is known as the Power Factor and f is power factor angle • The angle depends on ratio of resistance to the reactance in a circuit Technology Training that works

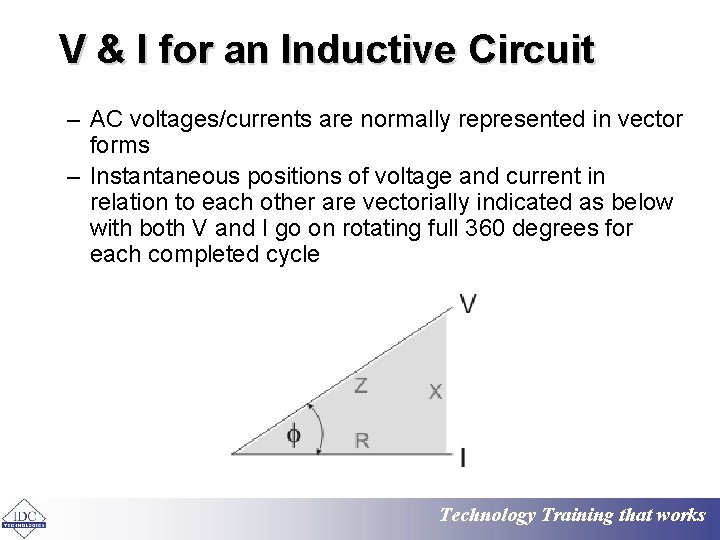

V & I for an Inductive Circuit – AC voltages/currents are normally represented in vector forms – Instantaneous positions of voltage and current in relation to each other are vectorially indicated as below with both V and I go on rotating full 360 degrees for each completed cycle Technology Training that works

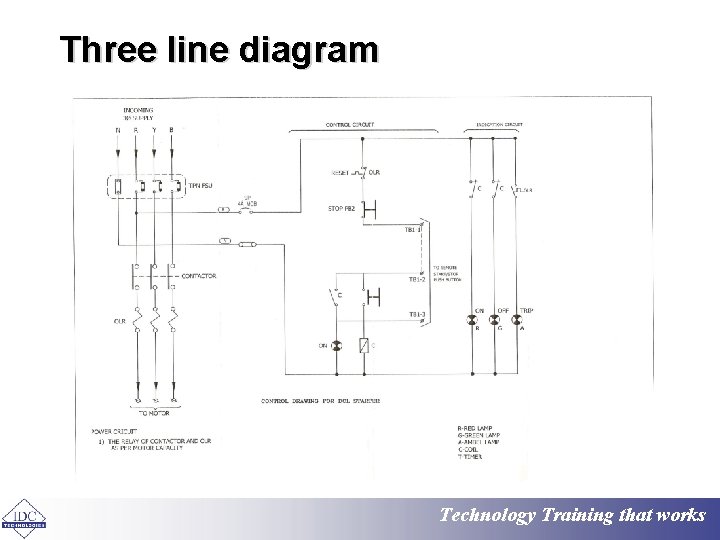

Three line diagram Technology Training that works

Single line diagram Technology Training that works

Advantages of a single line diagram • It requires much lesser space and hence leaves room for designer for providing other useful information in the drawing • It is very versatile and comprehensive because it can depict very simple DC circuits, or very complicated three-phase system • Simple, hence requires much lesser time for reader to understand the basic system design Technology Training that works

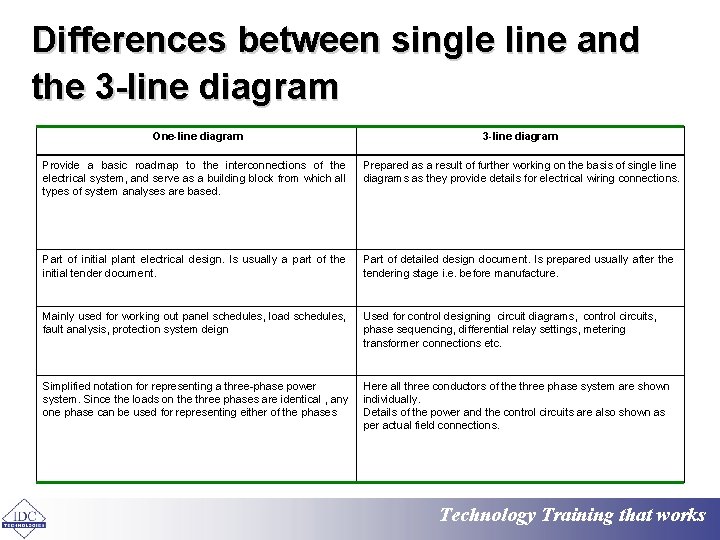

Differences between single line and the 3 -line diagram One-line diagram 3 -line diagram Provide a basic roadmap to the interconnections of the electrical system, and serve as a building block from which all types of system analyses are based. Prepared as a result of further working on the basis of single line diagrams as they provide details for electrical wiring connections. Part of initial plant electrical design. Is usually a part of the initial tender document. Part of detailed design document. Is prepared usually after the tendering stage i. e. before manufacture. Mainly used for working out panel schedules, load schedules, fault analysis, protection system deign Used for control designing circuit diagrams, control circuits, phase sequencing, differential relay settings, metering transformer connections etc. Simplified notation for representing a three-phase power system. Since the loads on the three phases are identical , any one phase can be used for representing either of the phases Here all three conductors of the three phase system are shown individually. Details of the power and the control circuits are also shown as per actual field connections. Technology Training that works

Power network • • Generation Transmission/sub-transmission Distribution Utilisation Technology Training that works

Three phase power network • All AC generation, Transmission and Distribution is through 3 phase systems – Exception: Single phase/SWER distribution systems • Utilisation can be 3 phase (motors and rectifiers for drives, furnaces) or single phase (commercial and lighting) • Ability to transmit larger amount of power for a given voltage/conductor volume • Availability of rugged 3 phase cage motors with self starting capability Technology Training that works

Power system • Power generation plants are located based on fuel availability • Other considerations like water, pollution issues etc. • Often they are in remote locations • Loads are situated in population centers • Transporting generated power to population centers for use requires a power system Technology Training that works

A 400 k. V Transmission line and Structure Technology Training that works

Substations • A facility incorporating – Transformers – Switching/isolation equipment – Control/protection/measuring – Auxiliary power equipment • Indoor or Outdoor type • Air-insulated or gas-insulated • Different configurations Technology Training that works

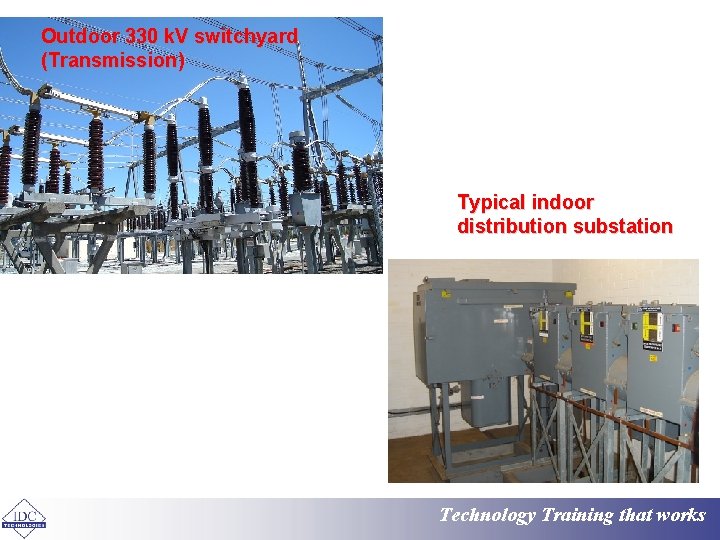

Outdoor 330 k. V switchyard (Transmission) Typical indoor distribution substation Technology Training that works

Voltage classification BS and IEC • Circuits supplied at nominal voltage up to and including 1000 V a. c. or 1500 V d. c. are said to be in the low voltage range, and equipment rated for voltages above these values are classified as high voltage (HV) equipment. Technology Training that works

Voltage classification as per IEEE 141: 1993 • Low voltage (LV) – Systems of nominal voltage up to 1000 V • Common usage: 380 V, 415 V, 480 V • Medium voltage (MV) – Systems of nominal voltage 1000 V and above but less than 100000 V • Common usage: 4160 V, 6900 V, 12000 V, 13800 V, 34500 V, 69000 V • High voltage (HV) – Systems of nominal voltage 100000 V and above and up to 230000 V • Common usage: 115 k. V, 138 k. V, 230 k. V Technology Training that works

Basis of voltage selection • System segment – Generation: MV – Transmission: HV and Extra High Voltage (230 k. V+) – Sub-transmission: HV/MV – Distribution: MV/LV – Utilization: MV/LV Technology Training that works

Distribution and utilisation voltages • Domestic, commercial and small industry loads at LV • Utilities distribute power at MV and also at LV • Large industries have a mix of MV drives, Transformers and LV loads • Distribution and utilisation can involve more than one voltage Technology Training that works

Distribution voltage options for industries • Receiving and distribution at the same voltage – Avoids need for transformer – Difficult to regulate voltage – Independent earthing of plant system is not possible • Receiving at a higher voltage – – Involves a transformer Internal voltage independently variable through OLTC Can choose system earthing independent of the utility Transformer acts as a buffer (harmonics, voltage dips) Technology Training that works

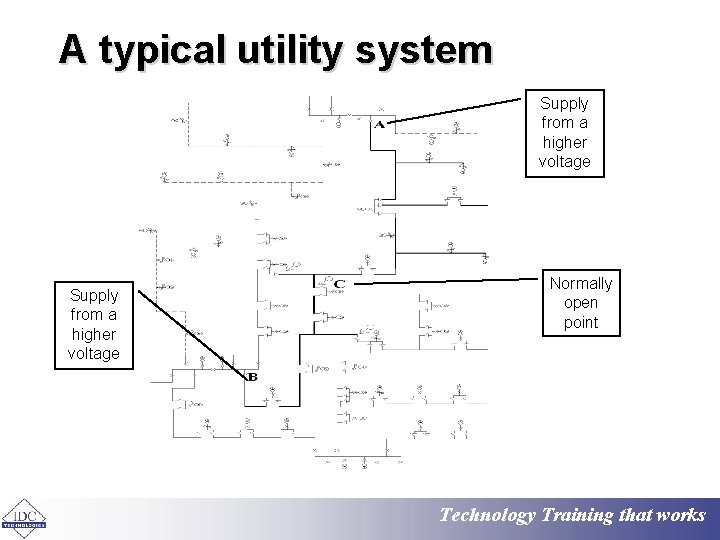

A typical utility system Supply from a higher voltage Normally open point Technology Training that works

Power distribution • • • Distribution is done at lower voltage levels Distances are much shorter than transmission Voltage levels are typically 33 k. V and less Bulk of consumers draw power at lower voltages This requires distribution at two different levels Distribution substations convert power from transmission to distribution voltages Technology Training that works

Governing principles of Power Distribution • Safety of operating personnel and plant assets • Reliable power supply (continuity of power) • Adequate quality of power • Prevention of load generated problems Technology Training that works

Electrical safety and power security • • Electricity-a good servant but a bad master Safety is a predominant issue Legislative requirements Standards for ensuring quality and reliability • Good O&M practices to ensure power security Technology Training that works

Industrial distribution components • An incoming section • In-plant emergency/standby generation and associated distribution system • A primary distribution system, usually medium/high voltage • A step down transformer section • A secondary low voltage distribution system • Controlgear for individual loads • Supervisory control system Technology Training that works

Main equipment types • • Circuit isolation devices Circuit switching devices (circuit breakers) Transformers HV and LV distribution equipment Motor control panels DC supply system Power system protection Cable (or overhead line based) distribution systems • Earthing system • Power quality improvement equipment Technology Training that works

Types of distribution • Radial with redundancy – Selective • Looped or Ring type – Ring type with spur lines • Mesh connections Technology Training that works

Radial distribution • • A single incoming feeder Failure causes total disruption Restoration only after the problem is rectified Not desirable where critical production processes are involved • If at all used, internal standby source to be planned also Technology Training that works

Redundancy • Ensuring alternative supply such that – Any one of the sources/incoming feeders may take up full load (100% redundancy) – Only partial load can be taken up (partial redundancy) • Reduces period of interruption • Two types of redundancy (selective and looped) Technology Training that works

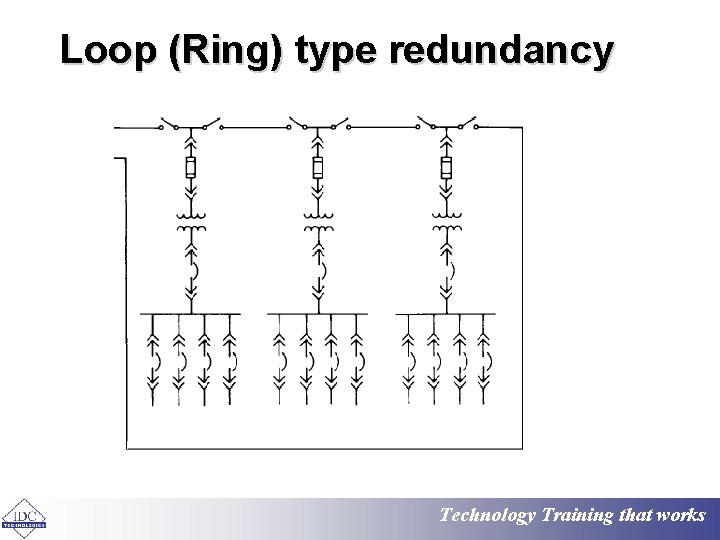

Redundancy Selective Redundancy: Two feeders to each load One feeder used at a time and can be selected Automatic restoration schemes to switch feeders Reduces time of interruption Results in under-utilisation (because of 100% redundancy) Loop (Ring) type redundancy Technology Training that works

Loop (Ring) type redundancy Technology Training that works

Ring type distribution • Favoured by power distribution utilities • Fault in a ring section of a closed loop cleared from both ends • Selective closing of isolators to detect fault • Easy to extend the ring for inclusion of additional loads • Supply can be restored to all consumers without waiting for repair of faulty section • Automation possibilities for restoration Technology Training that works

Mesh type system • Similar to ring type • Additional connections between some of the nodes • Usual in transmission systems • Distribution systems provide such connections for additional security • Complexity of protection Technology Training that works

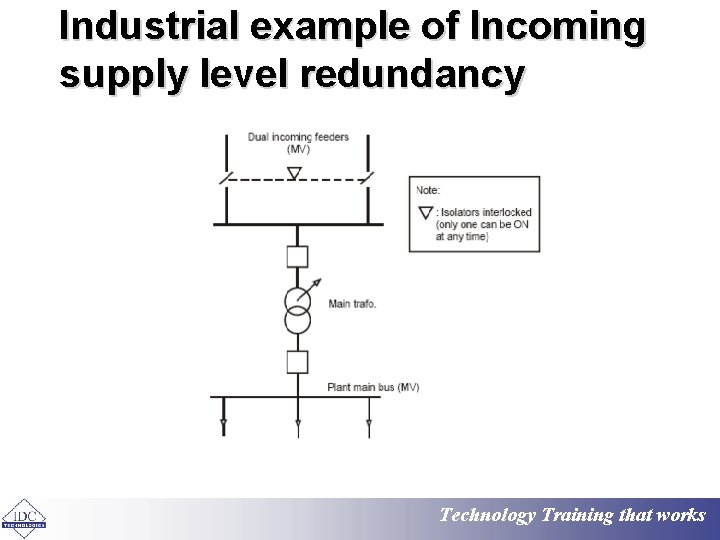

Industrial example of Incoming supply level redundancy Technology Training that works

Industrial example of Main Transformer level redundancy Technology Training that works

Industrial distribution-Typical Technology Training that works

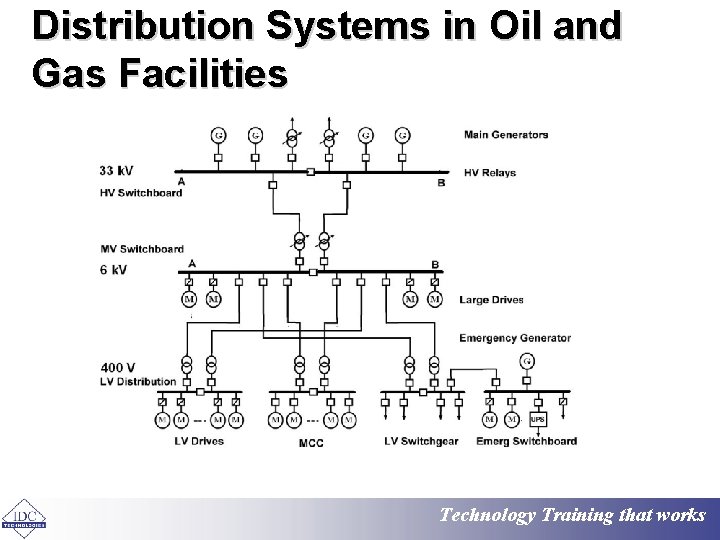

Distribution Systems in Oil and Gas Facilities • Large facilities have power demands ranging from 30 MW and upwards to several hundred MW. • Voltage levels for high, medium and low voltage distribution boards are in the range of 13 - 130 k. V, 2 -8 k. V and 300 -600 V respectively. • Generated power is exchanged with mains or other facilities on the HV distribution board and relays are used to provide protection. Technology Training that works

Distribution Systems in Oil and Gas Facilities Technology Training that works

Distribution Systems in Oil and Gas Facilities • Electrical power needed for gathering station induction engines, injection steam generators & wells with units of mechanical & centrifuge pumping is supplied by 15 -150 k. VA substations and 13. 8/0. 48 k. V transformers. • Building facilities, external lighting, communication and automation are powered by 575/480/380 -220 V, 5 k. VA to 15 k. VA transformers. • 13. 8 k. V, 150 -1200 k. VA capacitor banks are connected to the electrical distribution feeders to regulate voltage & correct power factor. Technology Training that works

Distribution equipment • Switching and isolation equipment – Circuit breakers – Disconnectors – Control gear • Conductors for carrying power – Overhead bare – Overhead insulated – UG cables Technology Training that works

Any questions ? Technology Training that works

- Slides: 52