The field-testing phase of the Residential Cold Climate Heat Pump Technology Challenge is over, and eight manufacturers that took part are in various stages of bringing new, Challenge-certified heat pumps to market.

A couple of those companies, Bosch Home Comfort and Carrier Global Corp., have already started building and selling heat pumps with technology based on what was used during the Challenge.

The Challenge was launched in 2021 by the U.S. Department of Energy (DOE) in order to facilitate the development, testing, and commercialization of heat pumps that could deliver as much heat as needed to homes in Northern climates without the use of backup heating. The heat pumps tested during the challenge were required to be capable of operating at 100% capacity at an outdoor temperature of 5°F or lower and have energy efficiency well beyond what were then best-in-class products.

“Electrification without improved heat-pump technology will put a strain on the grid as the current technology struggles to maintain its efficiency ratings in low temperatures,” Zoe Eckert, sustainable energy program and policy senior manager at the Massachusetts Municipal Wholesale Electric Co., said in a DOE press release. “The (Challenge) is bringing manufacturers and stakeholders together to solve a very real issue, upholding the very definition of innovation and collaboration that the energy industry needs to improve our reliability.”

Initial testing of prototype heat pumps was completed at the Oak Ridge National Laboratory and other facilities. The companies then moved products to about two dozen residential field-testing sites in several U.S. states and two Canadian provinces. In partnership with the Pacific Northwest National Laboratory, at least a full year of heat pump data was gathered from each site.

Now, manufacturers are applying what was learned during the Challenge to their products. Here’s a summary of where those manufacturers are taking their cold-climate heat pumps.

Bosch

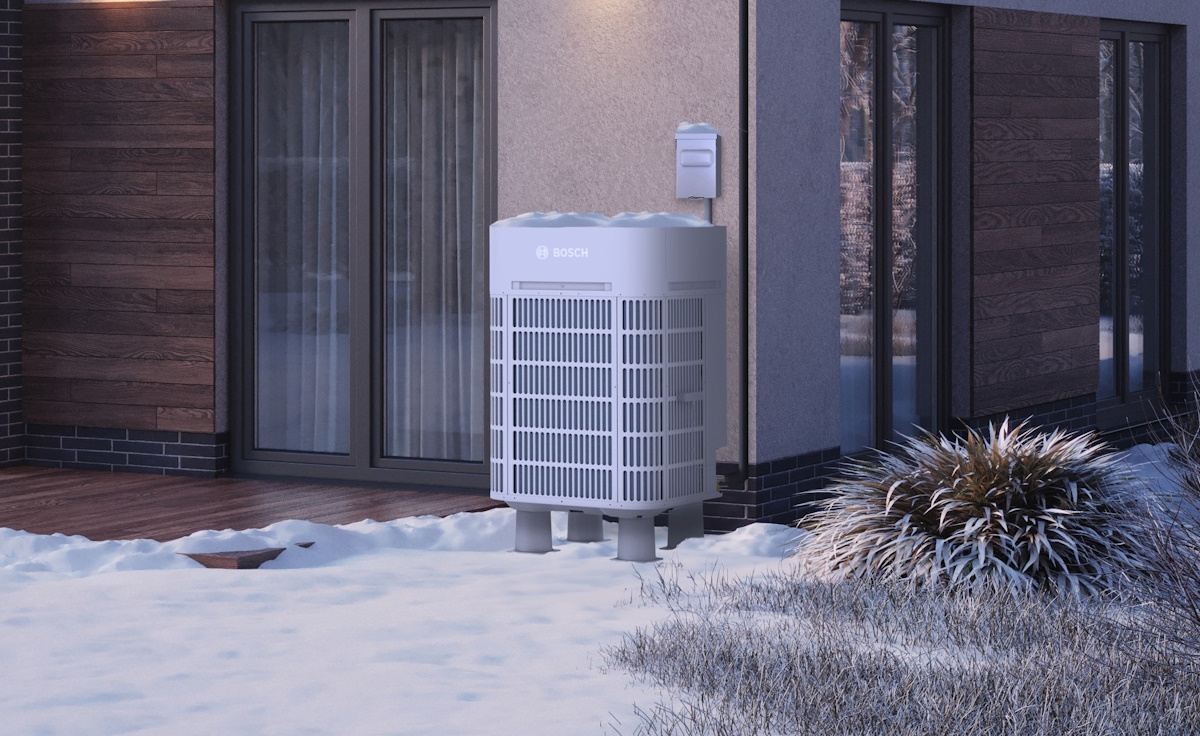

Bosch Home Comfort announced in October that it was bringing its IDS Ultra Cold-Climate Heat Pump, which was certified by the DOE following Challenge field-testing, to market.

The IDS Ultra can provide heat in temperatures as low as -13°F, and has a 100% heating capacity down to 5°F. Its efficiency ratings are up to 19 SEER2 and up to 10 HSPF2, and it uses the low-GWP A2L refrigerant R-454B, the company said.

ON THE MARKET: Bosch is building and selling the IDS Ultra Cold-Climate Heat Pump, which leverages insights gained during the Challenge. (Courtesy of Bosch Home Comfort)

The IDS Ultra builds on Bosch’s inverter ducted split platform and includes enhanced vapor injection (EVI), which allows the refrigerant to absorb more heat at low temperatures, and an elevated fan shroud, which allows for greater coil surface area, the company said.

“The IDS Ultra has been carefully designed and rigorously tested to withstand low temperatures while maintaining strong performance,” said Mohamad Nasab, senior product manager at Bosch. “With this latest innovation, Bosch is proud to be the first to market with an extreme heat system, as well as play a role in making energy-efficient home heating and cooling more accessible across almost all climate zones in the United States.”

Carrier

Carrier Global Corp. began building the Infinity Variable-Speed Ultimate Cold-Climate Heat Pump, its Challenge-designated heat pump, in September at its Collierville, Tennessee, factory. More than 30 units had been completed as of mid-December, said Michael Carter, associate director for residential outdoor product management. The company was preparing dealers for best installation practices, Carter said.

The new heat pump is an updated version of the Infinity with a variable-speed compressor, Carrier’s Greenspeed Intelligence technology, and new algorithms designed for cold-climate equipment, Carter said. The new Infinity includes Bluetooth connectivity for system monitoring and servicing, uses the refrigerant R-454B (Carrier’s Puron Advance), works with Carrier’s Infinity control system, and has an advanced coil-defrost feature, Carter said.

OUTSIDE THE BOX: A worker shines up the outdoor unit of a Carrier Infinity Variable-Speed Ultimate Cold-Climate Heat Pump at the company’s Technical Training Center in Indianapolis, Indiana. Carrier’s Collierville, Tennessee, factory builds the Challenge-certified heat pump. (Courtesy of Carrier Global Corp.)

“All the enhanced technological updates and new features improve the unit’s reliability in harsh climates,” Carter said.

The new Infinity operates at 100% capacity at outdoor temperatures down to 0°F, reliably provides some heat down to -13°F, and has a SEER2 rating of up to 21 and an HSPF2 rating of up to 12, Carter said.

“We looked at this challenge as more than an opportunity to help electrify colder climates; we saw unlimited potential in what our heat pumps could do in even the harshest regions,” said Nick Arch, vice president and general manager of residential HVAC solutions at Carrier. “We’re proud of our engineering team, which didn’t just meet the challenge criteria but also incorporated new, innovative technologies.”

Daikin

The results of the “Challenge” field trials of Daikin equipment have supported the company’s internal efforts in developing heat-pump technology, and Daikin is planning to expand its lineup of inverter heat pumps, said King Tong, director of product management at Daikin Comfort Technologies North America Inc.

ADDED KNOWLEDGE: A Daikin cold-climate heat pump in winter conditions. The company is leveraging what it learned during the Challenge and plans to expand its lineup of residential inverter cold-climate heat pumps. (Courtesy of Daikin Comfort Technologies North America Inc.)

Tong said the Challenge helped Daikin better understand how heat pumps can work in cold temperatures.

“We have understood the capabilities of heat pump technology more deeply, especially heat pumps with inverter technology, which provide outstanding efficiency and homeowner comfort and offer sustained and powerful heating in extreme climates. It is because of these abilities that we hope that inverter technology will have more widespread adoption,” Tong said. “We will continue to find ways after the DOE Challenge to advance heat pump inverter technology so that it can reach more customers.

Johnson Controls

Piero Caballero, senior product manager at Johnson Controls, said the company is pleased with the performance of the heat pump it designed for the Challenge and plans to commercialize it with a new model that the company will start manufacturing in late 2026.

The new heat pump, the York YHV Ultra-Premium Cold-Climate Heat Pump, will replace the York YZV Variable-Capacity Heat Pump, and its introduction will align with the launch of a new controls platform that will offer improved commissioning and serviceability, Caballero said.

The York YHV will be able to provide heat at 100% capacity at an ambient temperature as low as 5°F and at reduced capacity down to -20°F, Caballero said. It will feature an inverter variable-speed compressor and use R-454B refrigerant. The York YHV is tentatively rated at up to 20-plus SEER2 and up to 8.5-plus HSPF2, Caballero said.

“Our company is very proud to have successfully met the DOE’s Residential Cold Climate Heat Pump Technology Challenge requirements, showcasing our longstanding ability to innovate and deliver high-efficiency heating solutions for cold climates,” Caballero said. “This level of air-source heat pump performance is a remarkable accomplishment, and it strengthens our product roadmap and positions us as a leader in energy-efficient, cold-climate solutions.”

Lennox

Lennox International Inc. plans a launch this year of the Dave Lennox Signature Collection SL22KLV Cold-Climate Heat Pump, a new model that is evolving from the prototype tested during the Challenge. The SL22KLV “leverages the latest technology to push the boundaries of efficiency” and includes a variable-speed compressor, Lennox proprietary algorithms, and a new cabinet designed for inverter-driven heat pumps, said Nicolas Orth, a Lennox product management director.

LATEST MODEL: Lennox plans a 2025 launch of the Dave Lennox Signature Collection SL22KLV Cold-Climate Heat Pump, a model that is evolving from the prototype tested during the Challenge. (Courtesy of Lennox International Inc.)

During the Challenge, the SL22KLV prototype operated at a 5°F ambient temperature while maintaining efficiency, Orth said.

“Our prototype performance showcases that Lennox not only meets industry expectations but consistently exceeds them, allowing us to produce products that truly meet homeowners’ needs,” Orth said. “Looking ahead, we are confident that we will continue to stand as a leader in innovation and sustainability for next-generation heating and cooling systems.”

Orth also said that data compiled during the Challenge was shared with state and utility partners in order to encourage collaboration and help improve the electrical grid.

Midea

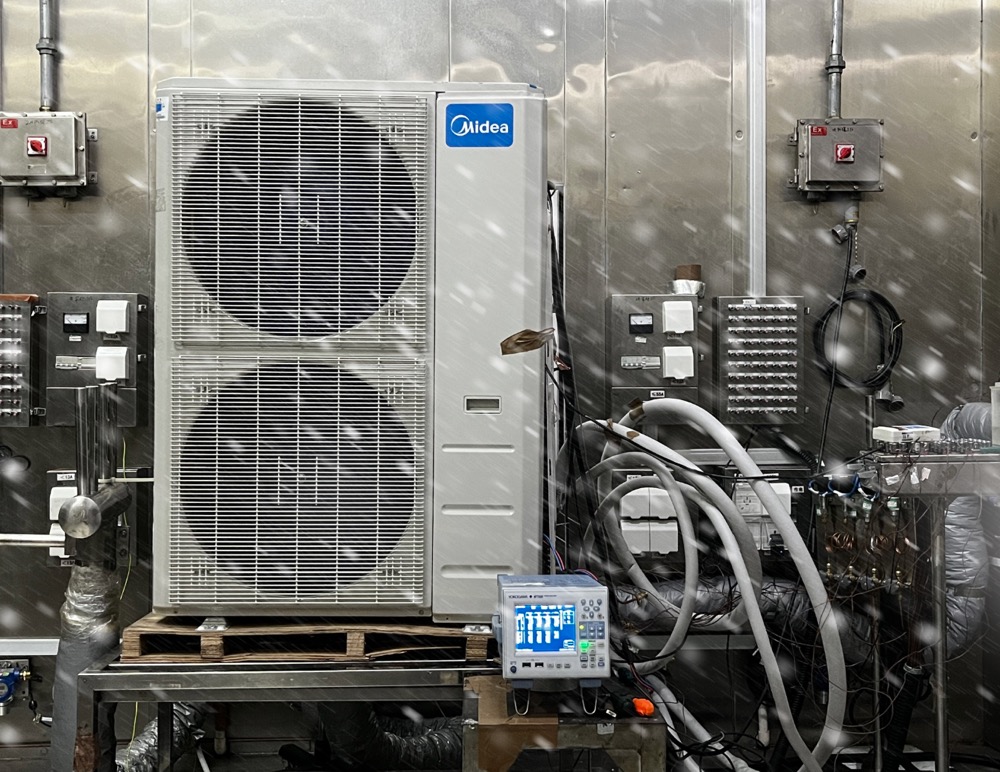

The next steps for Midea America Corp. are leveraging the insights gained during the Challenge in order to commercialize the company’s existing heat-pump models, and continuing research and development toward new models, said David Rames, a senior product manager.

SNOW-TESTED: A Midea heat-pump system in snowy conditions. The company is developing a new heat pump based on the advancements brought about by its participation in the Challenge. (Courtesy of Midea America Corp.)

Rames said Midea’s EVOX G3 heat pump system performed exceptionally well during the Challenge. A new heat pump, based on the advancements brought about through its participation in the Challenge, is in development and could expand the EVOX G3 series, he said.

“The challenge reinforced Midea’s leadership in energy-efficient HVAC technology, providing valuable insights for future innovation, Rames said. “Benefits included enhanced credibility in the North American market, strengthened partnerships with energy agencies, and a clearer path toward achieving decarbonization goals in residential heating.”

The EVOX G3, Rames said, can run at full capacity at ambient temperatures as low as -13°F, is operational down to -22°F, has a SEER2 rating of up to 19 and an HSPF2 rating of up to 10.8, and uses R-454B. Its features include EVI, a variable-speed compressor, side discharge, and a modular design.

Rheem

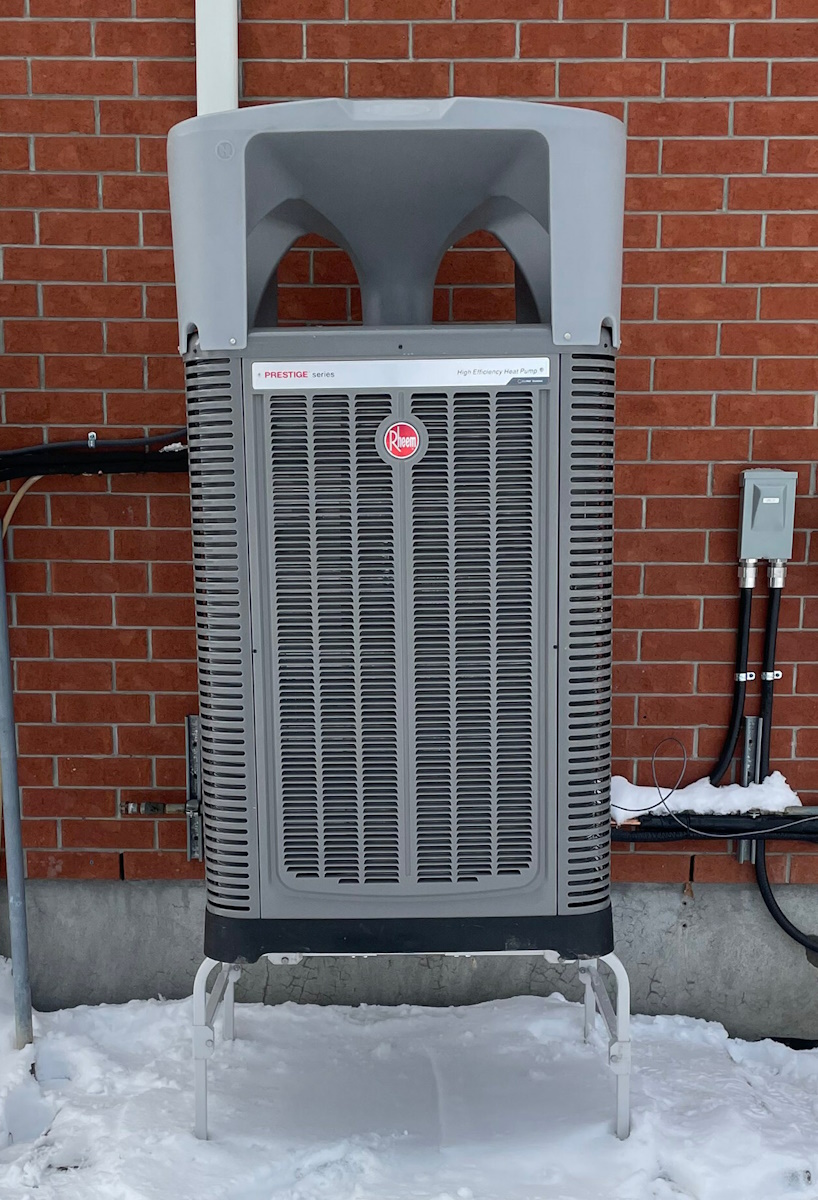

Rheem Manufacturing Co. is incorporating features it added to heat pumps to meet Challenge requirements, such as vapor injection, which helps achieve heating at low temperatures, and a snow guard for extreme weather conditions, into its heat pumps, said Tony Young Sr., a product manager for residential air conditioning at Rheem.

IN THE FIELD: A Rheem cold-climate heat pump prototype at a field-testing site during the Challenge. The company is working to bring a new residential cold-climate heat pump to market. (Courtesy of Rheem Manufacturing Co.)

“Rheem’s larger focus in this process is to ensure we deliver an innovative, affordable heat pump for consumers that can work in a wide array of temperatures while delivering all the energy-efficient benefits heat pumps offer,” Young said.

The company is working to develop a new product based on Challenge results but does not have a projected release date. Young said the new heat pump will meet required heating capacities at outdoor temperatures down to -13°F.

“Rheem performed very well in the heat pump challenge and learned the importance of integrating the new technologies of vapor injection, low ambient heating, and weather protection into our products to support the ongoing transition to heat pumps in the North American market,” Young said. “It’s rewarding to take part in challenges like these that test the boundaries of the technologies and require OEMs, like Rheem, to find new ways to enhance our products and provide the basis for us to bring these products to market.”

Trane

Trane’s prototype cold-climate heat pump was field-tested at a residence in Boise, Idaho, for two winters and two summers, delivering energy bill savings and relying on its backup heating strip just 10% of the time during the two winters, said Mark Woodruff, senior product manager for residential HVAC in the Americas at Trane Technologies.

The company plans to complete its design for a new residential cold-climate heat pump this year, Woodruff said. The new model will be compatible with Trane Link, which will enable integration with Trane’s smart home technologies, he said. Full specifications will be available upon the model’s release.

“Trane’s cutting-edge, highly efficient solution delivered outstanding energy savings and strong homeowner reviews throughout our successful completion of the U.S. Department of Energy’s Residential Cold Climate Heat Pump Challenge,” Woodruff said. “We are ready to advance electrification of heating in homes while maintaining both comfort and efficiency for occupants.”