- Products

- Commercial divers’ equipment

- Compasses and watches

- Defence divers’ equipment

- Diving instrumentation

- Electrical diving equipment

- Escape and abandonment

- Gas and fluid systems

- Medical and safety equipment

- Recompression chambers

- Submarine intervention

- Submarine rescue

- Tactical Diving Vehicles

- Ansti testing equipment

- Services

- Consultancy and personnel

- Engineering services

- Rescue and support

- Testing services

- Training services

- Ancillary dive gear

- Commercial equipment and tools

- Commercial helmets, masks and SCUBA

- Commercial rebreathers

- Commercial surface supply

- Diver's suits and harnesses

- Contaminated water diving system

- BIBS manifold block

- Divex back pressure regulator

- Divex interlock

- Hy-Fex hyperbaric fire extinguisher

- Hyperbaric flame detector

- Hyperlite hyperbaric stretcher

- Oxygen kits

- Ultralite 2 BIBS mask

- InVicto ventilator system

- DSAR rescue vehicles

- Launch and recovery systems

- Multi-role launch and recovery system

- Submarine rescue bell

- Client representatives

- Dive and ROV system audits

- Diving technical expertise

- Offshore personnel

- Rescue certification

- Remote audit solution

- Altitude testing and trials

- Hyperbaric welding

- Pressure testing and trials

- Test tank

- Breathing laboratory

- Commercial development courses

- Defence training courses

- Medical training courses

- Product specific courses

- Online training courses

- Classroom training FAQ

- Case Study: Roger Chapman Pisces III

- Case Study: HMS Edinburgh

- ANSTI CSTF

- Akademik Tofiq Ismayilov (ATI)

- Archive

- JFD mobilises NSRS during international exercise, Dynamic Monarch

- JFD expands long term partnership with Indian Navy strengthening underwater capabilities

- James Fisher's Tony Tang Kok Yong qualifies as first Singaporean Submarine Rescue Vehicle Pilot 1

- JFD welcomes Peter Laughton MBE as Head of Military Diving

- Archive

- Divulged - Winter 2017

- Divulged - Summer 2017

- Divulged - Winter 2016

- Divulged - Summer 2018

- Divulged - Winter 2018

- Divulged - Winter 2019

- Divulged 2021 Edition 1

- UDT 2019

- Visit JFD at UI 2016

- Visit us at OTC Asia 2018

- Visit JFD on stand 338 at Underwater Intervention 2018

- JFD is exhibiting at ONS 2018

- JFD is exhibiting at OSEA 2018

- Join JFD at IDEX 2019

- See JFD at Subsea Expo 2019

- JFD takes on BALT Military Expo

- JFD presents complete defence offering at UDT 2018 in Glasgow

- Join JFD at ADIPEC 2018

- Visit JFD at Pacific 2017

- Visit JFD at MSPO 2018 in Poland

- JFD presenting at UDT conference

- JFD is exhibiting alongside James Fisher Nigeria at NOG

- JFD exhibiting at UDT 2016

- Visit JFD at Underwater Intervention 2019

- JFD is participating at Underwater Defence & Security

- See JFD at this year’s IMCA Annual Seminar

- JFD is exhibiting at LAAD Defence & Security 2019

- JFD LEXMAR is exhibiting at OSEA 2016

- JFD is exhibiting at Subsea Expo 2017

- Visit JFD at Indo Defence 2018 Expo and Forum

- Visit JFD on stand 403 at Underwater Intervention 2017

- JFD exhibiting at Europoltech

- JFD at IMDEX

- Visit JFD at UDT 2017

- Visit JFD at DSEI 2017

- JFD is exhibiting at OTC 2018

- JFD is exhibiting at Subsea EXPO 2018

- JFD is exhibiting at Sea Air Space 2018

- Visit JFD at DSA 2018

- See JFD at Defexpo 2018

- JFD is exhibiting at ADIPEC 2017

- Come see JFD at DSEI!

- See JFD at IMDEX Asia 2019

- JFD is at Oil & Gas Asia 2019

- Experience DSEI with JFD

- See JFD's full defence capability at MSPO 2019

- JFD is exhibiting at this year's Offshore Europe

- Visit us on stand 2S16 at Pacific

- See JFD at ADIPEC on stand 13572

- Explore our commercial capabilities at Bergen International Diving Seminar

- JFD showcasing commercial and defence capabilities at Underwater Intervention

- JFD exhibiting alongside James Fisher Offshore at Subsea Expo

- Visit our stand at DSEI 2021!

- Join JFD at Subsea Expo 2022

- Visit JFD Australia at Indo Pacific 2022

- JFD North America is exhibiting at SOFIC 2022

- Experience CNE 2022 with JFD

- Discover JFD at UDT 2022

- Join JFD at GSOF Symposium Europe this October

Hyperbaric welding

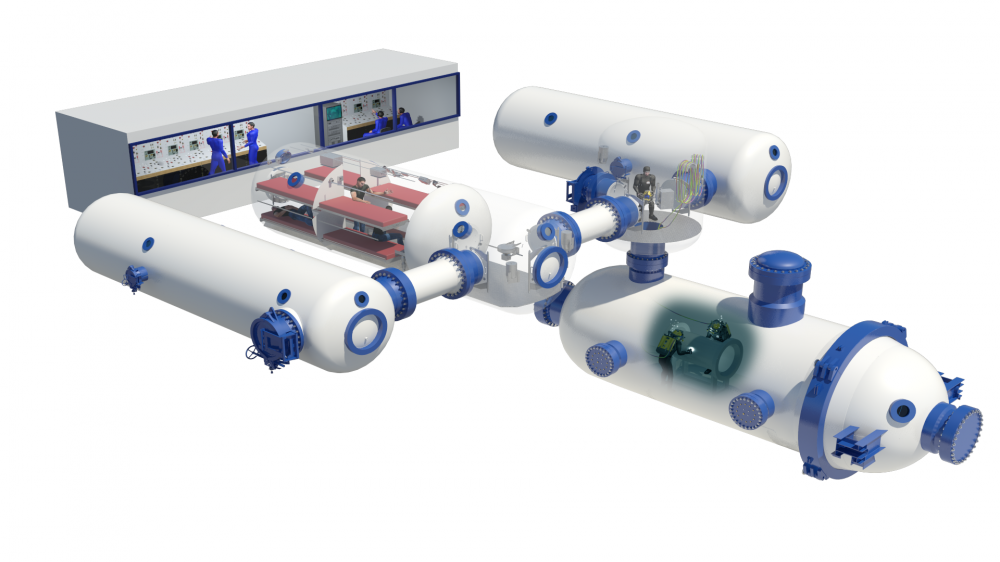

JFD operates the only land-based saturation diving complex in the UK, providing facilities for underwater welding and hyperbaric habitat trials.

Our large work chamber can be adapted for a variety of welding situations and is attached to a full saturation diving system which is comfortably furbished for up to 16 divers to live in under saturation.

The unique facilities at the NHC permit problem free testing of dry welding and wet welding procedures. An established set up combined with interface flexibility allows a variety of habitat welding techniques: manual, mechanised and remotely operated. A tried and tested internal filtration system ensures the maintenance of good visibility during dry and wet welding operations in either a fresh water or mixed gas environment. A full video and communication system means that dives can be monitored and recorded and ensures a controlled and safe environment.

Robotic and mechanised welding

The chamber at the NHC can be used to test robots and mechanical welding systems to a simulated depth of 1000msw in wet or dry hyperbaric conditions. The NHC have completed a number of development projects on subsea welding and robotics developing systems for the repair of underwater pipelines and structures.

Habitat welding

-

Full surface control/monitoring set up for welding and pre-heat

-

Modularised chamber internal welding/control stations

-

Internal regeneration and fume extraction

-

Internal pipe handling system

-

Transfer lock and trolley system to allow removal of test pieces up to 30” diameter

-

Fixed pan and tilt camera system, inspection camera

-

Fume extraction and hood with fume analysis

Wet welding

-

Complete welding equipment hook up, both inside to wet connectors and outside to welding sets, up to surface control panel

-

All diving equipment including hat mounted camera system

-

Dual weld control system with individual communications to divers

-

Pan and tilt camera and fixed cameras

-

Internal handling system to assist test piece preparation

|

Underwater welding |

NHC Saturation System |

Dry welding under pressure |

Weld set up within the work chamber | Wet welding within the work chamber | Dry welding under pressure |

|

|

|

|

|

|

Robotic and mechanised welding

The chamber at the NHC can be used to test robots and mechanical welding systems to a simulated depth of 1000msw in wet or dry hyperbaric conditions. The NHC have completed a number of development projects on subsea welding and robotics developing systems for the repair of underwater pipelines and structures.

Habitat welding

-

Full surface control/monitoring set up for welding and pre-heat

-

Modularised chamber internal welding/control stations

-

Internal regeneration and fume extraction

-

Internal pipe handling system

-

Transfer lock and trolley system to allow removal of test pieces up to 30” diameter

-

Fixed pan and tilt camera system, inspection camera

-

Fume extraction and hood with fume analysis

Wet welding

-

Complete welding equipment hook up, both inside to wet connectors and outside to welding sets, up to surface control panel

-

All diving equipment including hat mounted camera system

-

Dual weld control system with individual communications to divers

-

Pan and tilt camera and fixed cameras

-

Internal handling system to assist test piece preparation

|

Underwater welding |

NHC Saturation System |

Dry welding under pressure |

Weld set up within the work chamber | Wet welding within the work chamber | Dry welding under pressure |

|

|

|

|

|

|