Welding hose is the necessary tools for welding and cutting work. However, there will be safety risk during the work. because the acetylene is flammable. Then how to keep safe during the welding work?

Focus on the daily maintenance

When storing and using the welding hose, attention must be paid to maintenance to keep the hose clean and undamaged. For example, avoid sunlight, rain and snow. In addition, avoid contact with acids, alkalis, oils and other organic solvents. The storage temperature is -15 to 40℃ and the distance from the heat source should be no less than 1m.

Avoid the external damages

Before use, blow off the talcum powder on the inner wall to prevent the passage of the welding torch from being blocked. During use, avoid external extrusion and mechanical damage. In addition, never fold the hose body.

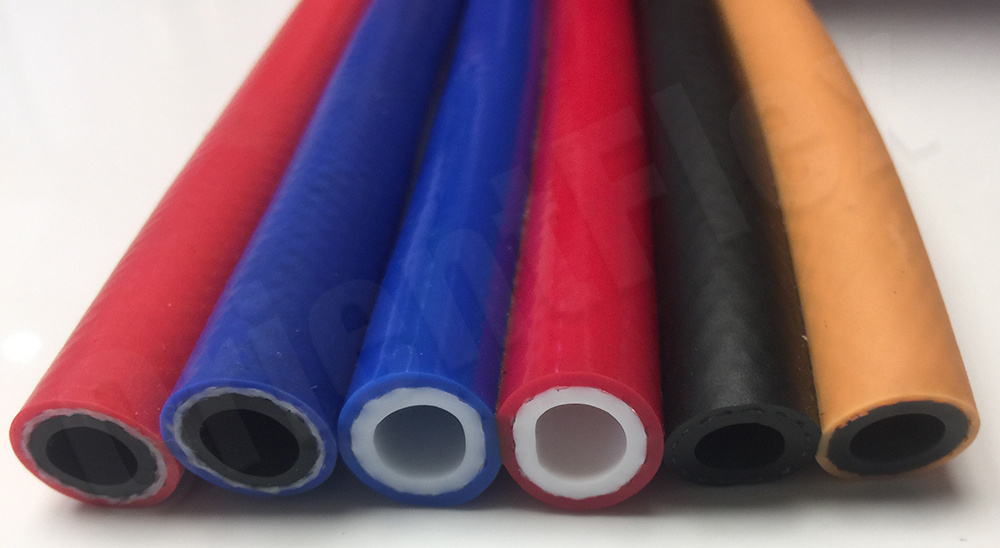

Never mix the oxygen hose and acetylene hose

Oxygen and hoses must not be used to blow away the blockage of acetylene hoses. The defects such as leakage and blockage of the welding torch should be checked and eliminated at any time to prevent the formation of oxygen and acetylene mixed gas in the hose.

If flashback occurs and enters the oxygen hose, the hose can not be used any longer and must be replaced with a new hose. Because tempering often burns the inner rubber layer of the hose. Compressed pure oxygen is a strong oxidant. Therefore, if it continues to be used, it will lose safety.

Gas cutting operation requires a large oxygen output. Therefore, the valve of the gas cylinder connected to the high-pressure end of the oxygen meter should be fully opened to ensure sufficient flow and stable pressure.