ONE CALL. ONE SOURCE.

POWERFUL SOLUTIONS.

S E R V I C E S

BOWED ROTOR STRAIGHTENING

TURBINE CONSULTANTS

®

MD&A /

TURBINE CONSULTANTS

®

For more information on this product or service please contact Turbine Consultants

®

at 314-880-3000.

© Mechanical Dynamics & Analysis, Ltd. 2011

Cause and Effect of Rotor Bowing

A large steam turbine rotor must run with low vibration levels during operation and when going through critical speeds. Rotors must be straight and true within a tight tolerance, typically, 0.0005” (half a mil) per foot length of span. For most HP and HP/IP rotors, the Total Indicated Runout (TIR) should not exceed 0.007” (7 mils).

Overheating of localized rotor areas during

•

a rubbing incident while at operating speed, during start up or shut down.Uneven heating, cooling or quenching

•

of a hot rotor during operation or after shutdown.

Excessive runout can be caused by:

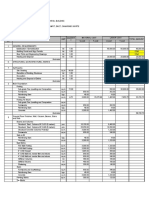

Rotor Bow Plot

-20-1001020304050

A B C D E F G H I J K L M N O

M a g n i t u d e ( m i l s / . 0 0 1 " )

Location of Bend / KinkMax. Runout = 0.041”

-20-10010203040-15-5515253545

11 10 9 8 7 6 5 4 3 2 116

C E T E

THRST T-1 N-1N-2N-3 T-2 CPL12 13 14 15 16 17 18

A B C D E F G IH J K L M N O

Rotor as found shaft runout measurements, taken on rollers at the journal bearings.Runout measurement after rotor was straightened using only heat treating methods. No machining required.

Some bows may partially relax out after the temperature equalizes and the rotor fully cools, while others may remain excessive and then show signs of eccentricity while operating on turning gear. When bows do occur, measuring the shaft runout in a lathe is the best way to quantify the magnitude and the location of these bowed regions.

These operating issues can then result in:

Local rubbing resulting in permanent

•

metallurgical changesLocal expansion and yielding that results

•

in permanent bowing and crackingResidual stresses and material hardness

•

above OEM limitsBowing that can not be balanced out

•

For more information on this product or service please contact Turbine Consultants

®

at 314-880-3000.

© Mechanical Dynamics & Analysis, Ltd. 2011

MD&A /

TURBINE CONSULTANTS

®

3804 Weber Road

•

St. Louis MO 63125

•

Ph: 314-880-3000

•

Fax: 314-842-3527

•

www.MDAturbines.com

TURBINE CONSULTANTS

®

CORRECTING BOWING & HARDNESS

The horizontal method involves setting the rotor in a lathe or similar turning device. The rotor is turned when needed to measure shaft straightening progress with dial indicators. This method is typically used when shafts have high values of bowing and can also reduce excess hardness during heating cycles. Electric heating methods are applied. Differential heating methods can be utilized to correct local bending.A third and less attractive alternative is known as the “Offset” or “Throwing of the Journals” method. This involves shifting the centerline of the journals to reduce rotor runout and then offset machining rotor surfaces to further reduce residual runout.While this third method can reduce excess runout, it can also require excessive machining. Excessive machining typically results in the need to acquire non-standard shaft and diaphragm packings, oil deflectors, coupling bolts, bearings and governor parts, etc. Off setting of a shaft coupling can then require extensive further machining to make coupling bolt holes concentric. All coupling bolts may then require replacement due to the resulting oversized holes. The horizontal and vertical methods typically utilize heat treat cycles to reduce shaft bowing and any excess hardness.

TURBINE CONSULTANTS

®

prefers to perform sufficient straightening with the horizontal or vertical methods to avoid extensive dimensional compromises, mating parts replacement and follow up site work.Rotor straightening repair projects are typically performed at MD&A’s St Louis Turbine-Generator Repair Facility and performed by

TURBINE CONSULTANTS

®

engineers, employees of MD&A’s Repair Division. There, we maintain all the necessary equipment and personnel required to perform a properly engineered repair and also perform any necessary steampath work.We also provide services to machine out any cracking defects such as local surface cracking on the rotor body or shrouds and restore journal and couplings to operable condition. Our low speed balancing also reduces the need to balance rotors after they are re-installed at the plant.

TURBINE CONSULTANTS

®

prefers to utilize one of two methods to correct these damaged areas and restore shaft straightness.

Vertical Method:Horizontal Method:

The vertical method involves upending the shaft so it hangs or stands vertically. This method allows uniform heating with a minimum use of floor space. A lathe is not needed. It does not allow interim measuring of rotor bowing correction.

TURBINE CONSULTANTS

®

applies this method typically on rotors that have lesser amounts of bowing which need hardened areas softened by heat soaking at temperatures above the operating temperature. Blading is protected from excessive heating and therefore, it can typically be reused. Electric heating methods are applied.