Cement Plant

- 1. ALUMINIUM INDUSTRIES LIMITED Corporate Office #1-55/4/RP/L6/W2 Raja Praasadamu, Maseed Banda Botanical Garden Road, Kondapur Hyderabad - 500 084, Telangana Factory Serilingampally, Hyderabad - 500 019 Telangana, India Phone: 040 - 2301 0817/18/19 Email: [email protected] CRUSHING MINING SPONGE IRON PLANT EQUIPMENTS, SPARES & SERVCES CEMENT PLANT EQUIPMENT, SPARES & SERVICES BULK MATERIAL HANDLING SYSTEM POWER PLANTS. CONTACT US R.V.RAJESH AGM MARKETING & SERVICES 9109226602/9418508505 Visit us:- www.alind.org Visit us:- www.alind.org

- 2. About us Our unit, which is a part of ALIND group, is located at, Serilingampally Hyderabad is well connected by Road, Railway & with the Airport. Originally the unit at Hyderabad was established in 1963 to manufacture Material Handling systems, Power conductors and cables as a part expansion of ALIND Company with its head office located at Kundra in Kollam district of Kerala. Kundra unit of ALIND started its operations in 1946 at Kundra to manufacture power transmission and distribution cables. ALUMINIUM INDUSTRIES LIMITED ALUMINIUM INDUSTRIES LIMITED Later in 1969, as a part of backward integration of the Conductors and cables plant established at Hyderabad, Machinery Division was established to manufacture Material Handling systems, Wire Drawing and Wire stranding machines required for manufacturing conductors and cables. Fabrication shop, Foundry and machine shop were established at the machinery division. The machinery division supplied conductor and cables processing machinery to domestic as well as well as overseas customers. Existing facilities at the Machinery Division were also used to manufacture Material Handling equipment for Mining, Coal and Cement Industry. Industries We serve Cement Industries. Steel Plant (Sponge iron and Mineral processing Industry). ACC Block’s. Sugar & Paper plants. Crushing Units. Power Plants. Railways. Machines & Facility Available with Us Welding facilities for Arc, MIG and TIG and SAW welding, Stress relieving furnace, 1000-ton Hydraulic Press, Oil Bath heater for Shrink fitting, EOT cranes for material handling. Adequate working space under the shed below the crane and plenty of open space for Yard Fabrication, if required Machine shop for various machining operations, with host of machine, at one place. Floor Horizontal Boring machine (WMW make). Vertical Turret Lathe (VT-1) (COOPWER-SHEISS, POONA) Vertical Boring Turning Mill (Titan Romania make) Double Column Planning machine with Milling head (Make Cooper Loudon) Gear Hobbing machines (Make Shibura Japan) All geared slotting Machines. (Make Cooper Engg Co Poona) Gear shaping Machine (Make MAAG). Centre Lathes 6 nos. Facing Lathe (Make Fuji Japan) Milling Machines (HMT M2PO & HMT-FN 2 V) 2 no's Radial Drilling Machines.3 no's Hydraulic press 1000 Tones. Plate bending machine 40x3000 Width. Visit us:- www.alind.org Visit us:- www.alind.org

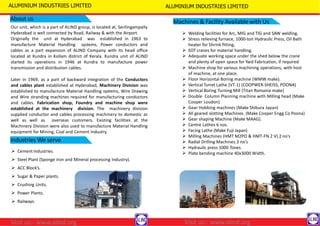

- 3. Benefits and Features Modular construction and higher feedcapacity Welded steel body reinforced with heavy joists for impact loads Easily adjustable to suit application requirements Heavy coil spring supportsystem Modular heavily built twin-vibrator mechanism Maintenance free oil bathlubrication Minimum maintenance, due to no gear on vibrators, larger bearing sizes and long oil-change intervals Unique feature of stroke angle adjustment to suit application needs Operation ALIND’s Grizzly are heavy-duty machines and Large lumps are scaled into the crusher or to a rip rap stock pile, the maximum lump sizes can range up to 6' cubes fines pass through the grizzlies, relieving the crusher and reducing wear. Vibration is generated by precision-machined, twin eccentric shafts. The vibrating drive assembly is connected directly to the pan to assure positiveaction underthe mostadverseloadingconditions Specification Thecapacitiesbasedonbulkdensityof1.6t/Cumofhardstone. Forothersizesandspecial applicationcontactfordetails Model Feeder Size - mm DriveMotor kW Capacity Range -TPH Max.Feed Size -mm Width Length 830 800 3000 9.3 - 15 up to 150 450 1039 1000 3900 15 - 22 90 - 300 650 1245 1200 4500 22 - 30 200 - 450 850 1350 1300 5000 30 - 37 350 - 650 1000 8 Gear shaping Machine a. Make Model Spindle dia: & Taper Axial Tr, boring spindle Vertical Tr. Spindle–head Width Tr. Of Column Long column Traverse Max. dia facing Max: dia of Boring Rotatingtablesize Floor Plates Digital Read Outaccuracy b. Make Dia on Spindle Taper ofSpindle Tables size c. Make Dia on SpindleXMovement Taper inspindle Table size : WMW : BFD/165/2 : 165 mm &ISO-50 : 1250mm : 2400mm : 3150mm : 500 mm : 1800 mm : 650 mm with spindle : 1800 X 2000mm. with ORO : 3500 X 1750X 350mm : For X,Y,Z 0.1 mm : TOS W 100 : 100 mm. with vertical milling : MT6 : 1250 X 1250mm : WMW- BERLING : 63 mm x 500mm : MT 4 : 700 mm W x 875 mmL Make Model Max. dia of gear to be cut Max. module of gear to be cut : MAAG : SH/100 :1200mm : 12 9 CentreLathes a. Make Swing overbed Distance between centers b. Make Centralheight wing overbed Distance between centres c. Make Swing overbed Distance between centres d. Make Swing overbed Distance between centres : OKUMA-LEB Japan : 630 mm : 6000mm : OKUMA L.D.A. Japan : 600 mm : 1200mm : 3000mm : HUNGARIAN : 700 mm : 2500mm : HUNGARIAN : 700 mm : 3000mm d Make Dia of spindle &Movement Taper inspindle Table size Vertical Traverse Horizontal Traverse Facing Headmovement : HITACHI- JAPAN : Dia 100 mm & 900 mm : MT6 : 1260 X1400 mm. : 1400mm : 1700mm : 150 mm e. Make Swing overbed Distance between centres f. Make Swing overbed Distance between centres : H.M.TH-26 : 530MM : 1000mm : H.M.TH-26 : 530MM : 1500mm 10 FacingLathe : COOPER-SHEISS,POONA : 13 BK 125 : 1400mm : 4 tons : 1250 mm Make Model Max. turning dia. Max weight ofwork Max. distancebetween Table & turrethead Make wing overbed wing ingap Distance between centres :FUJI, Japan : 2500mm : 3500mm : 2500mm 11 Milling Machines: Universal Milling M/c with Vertical swiveling type head : H.M.T. – M2 PO : 1110X1275 mm : 950 mm : 200 mm : 300 mm : ISO-40 a. Make & Model Table Size TraversesLongitudinal Cross Vertical Spindle Taper Vertical Milling Machine b. Make &Model Table size Traverselongitudinal Cross Vertical SpindleTaper Make Model Max. M/c Dia. with rail head Max. M/c Dia. with side head Max.Height.of Machined Part plate of plate dia. weight of workpiece : TITAN,ROMANIA : SC 43F : 4300dia mm : 4300dia mm. : 2060 mm Face : 4000 mm Max. : 18000Kg : H.M.T. – FN 2V : 1110x1275 mm :1250mm : 250 mm : 400 mm : ISO-50 Make Model Max. width of work piece Max. Height of workpiece Max. Length ofstroke H.P.of geared millinghead : CooperLoudon : DH-5 : 1600mm : 1200mm : 2600mm : 30 HP 12 Radial Drilling Machines Max. dia of gear to be cut Max. module of gear to be cut : SHIBURA,Japan : 1600 mm : 16Module b. Make Max.dia of gear to becut Max. moduleof gear to be cut : KASHIFUJI-Japan : 600 mm : 5Module a Make Drilling capacity insteel Drilling capacity in C.I. b. Make Model Drilling capacity in steel Drilling capacity in C.I. 6 All GearedSlotting Machine Make Model Max.Stroke Dia. of cirdular table Max. slotting table Max. heightof thejob Max. dia of thejob : COOPER ENGG. CO, POONA : HOV Type CH-40 : 400 mm : 800 mm : 440 mm : 580 mm :2000mm c. Make Model Drilling capacity in steel Drilling capacity in C.I. Distance from Column to Spindle : : HUNGARIAN : 75 mm : 90mm Distance from Column to Spindle : 1750 mm : H.M.T : RM-62 : 50mm : 90mm Distance from Column to Spindle : 1250 mm : H.M.T : RM-63 : 50mm : 90mm 1250mm 13 HydraulicPress : 1000Tons 7 EOTCranes : 10T, 5T,3T 4 Double column planning machine with milling head 1 Horizontal Boring & Milling Machines 2 Vertical Turret Lathe(VTL-1) 3 Vertical Boring TurningMill 5 Gear Hobbing Machines a. Make 14 Plate BendingMachine : 40 Thk x 3000 Width LIST OF MAIN EQUIPMENT -MACHINE SHOP Visit us:- www.alind.org Visit us:- www.alind.org

- 4. Benefits and Features Designed for effective crushing of bigger feed sizes with large crushing ratio to give optimum productshape Longer life for jaw plates and other components, due to built-in features like no jerks or rubbing action and Hydraulic adjustment of CSS Relatively simpler and smaller machine, to save on foundations, components and service costs. Grease lubricated self-aligning double row roller bearing Lubrication free toggle and toggle seat with minimum friction Large crushing chamber, longer stroke and high crushing speed Thecapacityfiguresindicatedintheabovechartareapproximateandarebasedoncontinousregularfeedofstoneof bulkdensity1.6t/cu.mwithstandardjawliners Operation ALIND’s Jaw crushers are designed to operate in most rugged environment and need less maintenance for all types of rocks, mineral ores. These single toggle jaw crushers are designed with an upward facing toggle system, which guarantees a high efficient production rate at every setting. These crushers are designed for exceptionally heavy duty and continuous operations and are wellsuitedfor stationaryandmobileapplications. Specification Model Feeder Size-mm Capacity at Closed Side Setting in TPH Drive Motor kW RPM 75 100 125 150 175 200 225 250 36 x 24 500 75-85 85-125 125-150 150-180 75 275 44 x 32 650 105-170 155-230 180-275 210-315 245-360 285-460 132 250 48 x 38 800 190-285 235-345 265-405 295-445 340-540 370-560 400-585 160 225 The backbone of ALIND is the integrated manufacturing facility at Hyderabad, manned by a highly skilled workforce. A well-laid-out Machine Shop, with a battery of imported precision machine tools, including gear-shaping & hobbing, caters to the wholerange ofmanufacturingprocess. A Fabrication Shop, with a high frequency induction- hardening furnace and a 1000-tonne hydraulic press, is equipped for heavy machine-building. An extensive Assembly Shop facilitates the final assembling and testing of custom-built equipment. And as for quality control, all equipments are built to the inspection standards ofLloydsand other reputedagencies. Visit us:- www.alind.org Visit us:- www.alind.org

- 5. The capacityfigures indicatedin the above chartare approximateand are based on continuousregularfeed of stone of bulkdensity1.6t/cu.m.They varywith feed material characteristics,feedgradationandpercentageoffractionbelowCSSinthefeed Benefits and Features High speed and Roller Bearing construction - less frictional resistance, less power consumption and longer life Precision machined alloy steel main shaft Perfect dust seal - combined air pressure and mechanical seal protection to all bearings Cartridge type eccentric & main shaft assembly and countershaft assembly for easy removal and maintenance Automatic lubrication of all bearings with built-in machine protection controls! Variable stroke that can be set for different throughput and capacities Hydraulic main shaft positioning system - tramp iron release, quick CSS by push button operation and over load protection Profiled crushing chamber geometry for uniform flow of material, cubical product and well balanced grain distribution Compact and well balanced machine for fixed & mobile plant installations Operation ALIND’s Cone crusher - chamber profiles are designed for uniform flow and optimum material interactions to produce a cubical shaped product. A positive lock-tight fitting of mantle and concave with a backing compound provides an effective cushion to the manganese against the crushing loads. The machine is built to meet varied crushing needs - fine, medium and coarse - of hard rocks and mineral ores. The compact, well balanced, sturdy design and simple to operate. An ideal secondary and tertiary crusher suitable for stationary, skid mounted, portableor mobile crushing in toughest quarries and mines. Specification Typeof Cone Feed Size Feed Opening mm Stroke mm Capacity at Closed Side Setting in TPH Drive Motor kW 10 19 22 25 28 32 Aggregate (-) 150 mm 190 19 135-145 145-155 155-160 160-170 132 22 130-140 145-155 155-165 160-170 170-185 132 25 155-165 165-175 170-185 185-200 132 32 165-175 175-185 185-200 200-220 160 Sand 5 - 40mm 190 25 50-60 160 CONE CRUSHERS CEMENT PLANT EQUIPMENT Range of Plant & Equipment Design BELTCONVEYORS Capacity-50TPH to 10000TPH. AndBelt width-400to 2400mm Belt Width. SCREW CONVEYORS Capacity- 10 TPH to 500 TPH. And Screw Dia- 150 to 1400 mm. BUCKET ELEVATORS Capacity- 10 TPH to 600 TPH. And Height- 15 Mtrs to 110 mtrs. ROD GATES SLIDE GATES AIRSLIDES & JUNCTION BOXES, FANS BALL MILL SHELLS, KILN SHELL, SUPPORT ROLLERS FABRICATED HOPPER & SILO’s ALL KINDS OF MACHINING COMPONENTS BATCHING PLAT CEMENT SILO’s ANY EQUIPMENT & SPARES OF CEMENT & SPONGE IRON PLANTS Conveyor Drum Pulleys Cement Mill Bare Shell Bucket Elevator Casing Double Column Planner Boring & Milling Machine AirSlide BlowerFans Shell Welding Eqpt Flap Valvel Bare Shell Transportation Visit us:- www.alind.org Visit us:- www.alind.org

- 6. ALIND’s Vibrating Screens being used very efficiently in a wide range of applications - both dry and wet systems of crushed stone separation, fine sand screening and for a variety of mineral classifications. A simple vibrating mechanism located at the screen’s centre of gravity, provides a circular stroke of high vibration strength best suited to meet each application. The screenis ofa bolted-construction, light, robustand freefromstress. Forothersizesandspecialapplications,contactfordetails Benefits and Features Modular design with high degree of component inter-changeability Lesser cost of installation, due to low feedheight High operational efficiency, due to quick stroke adjustment facility by changing counter weights and rapid mesh-changing features. 1-2-3 deck configurations set for 15ºinclination Bolted frame construction reinforced with heavy steelpipes Simple adjustment of vibration amplitude by counter-weights on flywheels Standard feed box reduces direct impact on mesh andevenly spreads material for greater efficiency Operation Specification Model Screen Size (mm) ScreeningArea m2 Drive Motor (kW) Width Length 2-Deck 3-Deck 4-Deck 1548 1500 4800 7.2 15 18.5 1848 1800 4800 8.6 18.5 22 22 / 30 2148 2100 4800 10.1 22 30 CEMENT PLANT EQUIPMENT Cement Plant & Sponge Iron Plant Machinery Our engineering skills for material handling cover designing, manufacture and installation of bulk materials handling systems - conveying, storage, reclamation and process feeding - for Cement, Steel, Thermal power plants, Mining and process plants. We possess the know-how and many years of experience that we use to meet the requirements specific to the customerandindustrythrough ourturnkeysystems. Our products are made using fine quality raw material and state-of-the-art technology. At all levels of production the quality is maintained and vouched for by our team of professionals. These cement plants are madeas perthe needsandrequirementsof the clients. BeltFeeder Silo on Transportation CementSilo JunctionBoxes BeltConveyor Air BlowerFans RodGaes Screw Conveyor Visit us:- www.alind.org Visit us:- www.alind.org

- 7. Motoroutputindicatedinabovetableis basedonfeedingof materialwith true specificgravityof2.7underdoublespiralribbonandtankinclinationof16deg.Max.rake-upcapacityis basedonthe capacityTPH/1rpmofspiralribbonundersingleshaft,doubleribbontypeandtreatingmaterialwithtruespecificgravityof2.7 Benefits and Features Segmented wear-shoes assureeasy replacement Infinitely variable speeds to meet capacity requirements Specially sealed submergedbearing Adjustable pool volume and weir Low operation and maintenance costs Fabricated and reinforced tank construction with heavy gauge steel Adjustable weirs for classification control Heavy duty and large diameter seamless tubular shaft designed for minimum deflection Operation ALIND’s Spiral Classifiers are applicable for various ore classification of different mesh sizes. The rake-up capacity of ALIND’s classifiers is suitably designed for eliminating surging of the feed. These classifiers are applicable for seperation of ores, silicate gangue, sulphide minerals and slurry sands and also in closed circuit grinding applications. The slope of the classifier can be adaptedtosuitthe characteristicsof the material. Specification Spiraldia (mm) Tanklength (mm) Rotation (rpm) Motor output for main shaft drive (kW) Max. Take-up capacity (tph / rpm) 600 5000 10 ~ 17 2.2 ~ 3.7 1.41 900 6500 8 ~ 12 3.7 ~ 5.5 4.77 1200 8000 6 ~ 8.5 5.5 ~ 7.5 11.3 Model Dimensions (mm) Max.FeedSize (mm) Area of Outlet (m2 ) Conveying Capacity (TPH) Motor Output (kW) Variable M/c Length (mm) Apron Speed (m/min) Apron Speed (m/min) 2 4 6 2 4 6 SAF-621 600 x2125 100 x 140 x200 0.25 30 60 90 0.75 1.5 1.5 250 SAF-726 750 x2625 150 x 210 x300 0.4 50 100 150 0.75 1.5 2.2 250 SAF-928 900 x2875 200 x 260 x400 0.6 85 170 255 1.5 2.2 3.7 250 SAF-1031 1000 x3150 200 x 260 x400 0.8 110 220 330 2.2 3.7 5.5 300 Benefits and Features Superior load bearing performance against high impact load and hopper pressure Simple construction and centralized lubrication system Rugged Apron Pans of Hi-MN Steel / High tensile steel with deep ribbed construction Side-mounted apron chains subject only to tensile loads; hence longer life Special alloy steel Chains to counter heavy wear& tear conditions Specially designed feed rollers to take high impactloads Built-in overload safetyfeatures Operation ALIND’s Apron Feeders are rationally and strongly designed and manufactured to operate under severe conditions prevailing at quarry pits, storage bins and under vertical shaft holes receiving huge impact loads, material pressure due to falling and jamming of large ore lumps. ALIND’s ApronFeeders comein threeversions. The performanceshown above is relatedtothe case where raw materialsof bulkdensity1.6 t/cu.m are continuouslysupplied.The conveyingcapacityand the outputof motoror decreaseaccordingtothelengthofmachineandtheapronspeed. Specification Visit us:- www.alind.org Visit us:- www.alind.org

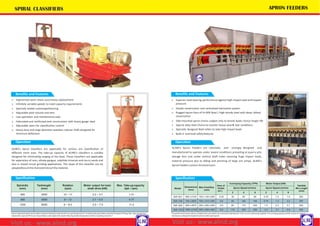

- 8. BUCKET ELEVATORS ROTARY KILN & COOLERS Services We Provide Kiln shell replacement & Alignment services. Kiln Girth gear replacement/reversal & alignment services. Services for all type of retrofitjobs. Equipment health check up and submissionof reports for Kiln, Ball Mills, VRM’s all other equipment's of Cement, Sponge iron plants. Providing supervision services for all types projects, trouble shooting, shutdown related jobs in Cement, Sponge ironplants. Providing services for All type of alignment and balancing related jobs. Services of ALIND We are having our expertise team in kiln alignment, Kiln erection and as well as Kiln shell replacement. We also undertaking complete package of Kiln shell replacement from Kiln shell supply to replacement. Supply of all types of spares of Cement & Sponge Iron Industry. Supplying of Major Equipment components like support roller, Kiln shell, Ball mill, Rotary airlocks, Slide gates, Rod gates, Metallic non metallic expansion joints, Pinions, Spring plates of girth gear all type of shafts, Bearings, Expansion joints, Shell air tubes, Coal Injectors for sponge iron plants, Rotary coolers for Sponge iron plants, Grate coolers spares of Cement plants, Bucket elevators, Air slides, Blowers, Fans, Screw conveyors, Belt conveyors etc. . Fabrication & Supply of Cyclones, Structures of all types, Tanks, Ducts, Chutes and all type of fabrication facility available at our factory workshop. Equipment's Ball Mills Fans Thrust Roller We are Offering a Wide range of Equipment's and spares as well as services to our customers after understanding their requirements. Our dedication towards commitment is always giving us a separate path from others & Our customers repeatedly comes to us because of our commitment & Timely delivery. Heavy Erections Jobs All typical Fabrication Manufacturing Visit us:- www.alind.org Visit us:- www.alind.org

- 9. Some Valuable customers of ALIND Our Credential WHY OUR CUSTOMERS COMES TO US. More than 52 years of Engineering Excellence in the field of Manufacturing. Around 38720 Square yards Closed & 445280 Open Work Area in Central Hyderabad. World class Calibrated Machineries. Uninterrupted after sales services to our customers. Proven Engineering team & Service expertise staff. Inspections of Girth gear ISO Certificate Visit us:- www.alind.org Visit us:- www.alind.org