Revised ppt High rise OHE (1).pptx

- 2. Need for Dedicated Freight Corridor The increase in transport volume of domestic freight shows a growth rate of 15 to 18% per annum. As a part of this strategy, Indian Railways have planned to build a 10,000 Kms. Network of dedicated heavy - haul freight Corridor for 25 tonne axle load (or possibly more) movement called Dedicated Freight Corridor (DFC). All this has led to the concept of the Dedicated Freight Corridors along the Eastern and Western Routes.

- 3. Need for Dedicated Freight Corridor The idea is to segregate Passenger and Freight traffic, and thereby maximising the line capacities. The new lines would allow movement of heavier trains as compared to present freight trains. The new lines would run parallel to the so-called Golden Quadrilateral linking Kolkata, Delhi, Mumbai and Chennai as well as other high-density corridors. The first two lines will be designated as the Eastern Corridor and Western corridor.

- 4. High Rise OHE High rise OHE commissioned first time in IR in RE- RGS-FL section of Jaipur Division (213 RKM/264 TKM)

- 5. Design of High Rise OHE Development of high rise OHE have the following salient challenges: • Design of Foundation • Design of Portals/Masts • Design of ATD • Ensuring adequate Stagger & Span for OHE Ensuring proper gradient of transition phase OHE, so that Pantograph may negotiate it smoothly in both directions. Modification of Tower wagon to make it suitable for running on high rise OHE lines.

- 6. High Rise OHE Movement of double stack container with maximum height 6809 mm on electric traction Single stack container Double stack container 7.100 m

- 7. Advantage of Double Stack Container The major advantages of Double Stack Container operation are: Increase in transport volume Increased throughput Reduction in unit cost.

- 8. Parameters High Rise OHE Description Conventional OHE High Rise OHE Height of contact wire at support 5.80 m 7.57 m Height of contact wire at mid span 5.70 (Pre sag 100mm) 7.52 m (Pre sag 50mm) Height of catenary wire 7.20 m 8.97 m Maximum OHE span 72.00 m 54.00 m Maximum speed 160 kmph 140 kmph

- 9. Parameters High Rise OHE Description Conventional OHE High Rise OHE SS wire rope of ATD 08.00 m 10.00 m Guy rod length 09.00 m 12.30 m Length of OHE mast 9.50 m 11.40 m Maximum stagger on tangent track 200 mm +_ 150 mm Maximum stagger on curve 300 mm +_ 250 mm

- 10. Clearances under over line structure (High rise OHE) SN Type of over line structure Minimum headroom clearance 1 Light overhead structure, such as FOB 8.43 m 2 Heavy overhead structure such as ROB, Flyovers 8.05 m 3 Heavy overhead structure such as ROB, Flyovers, if any turnout or crossover is located underside or nearby 40 m 8.43 m

- 11. Clearances under over line structure (Under restriction) For these minimum restricted heights, catenary wire shall be terminated outside overhead structure. SN Type of over line structure Minimum restricted heights 1 Light overhead structure, such as FOB 7.568 m 2 Heavy overhead structure such as ROB, Flyovers 7.468 m 3 Heavy overhead structure such as ROB, Flyovers, if any turnout or crossover is located underside or nearby 40 m 7.568 m

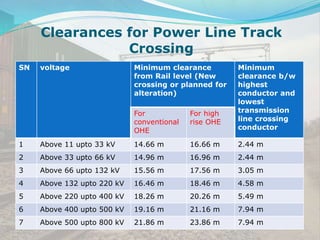

- 12. Clearances for Power Line Track Crossing SN voltage Minimum clearance from Rail level (New crossing or planned for alteration) Minimum clearance b/w highest conductor and lowest transmission line crossing conductor For conventional OHE For high rise OHE 1 Above 11 upto 33 kV 14.66 m 16.66 m 2.44 m 2 Above 33 upto 66 kV 14.96 m 16.96 m 2.44 m 3 Above 66 upto 132 kV 15.56 m 17.56 m 3.05 m 4 Above 132 upto 220 kV 16.46 m 18.46 m 4.58 m 5 Above 220 upto 400 kV 18.26 m 20.26 m 5.49 m 6 Above 400 upto 500 kV 19.16 m 21.16 m 7.94 m 7 Above 500 upto 800 kV 21.86 m 23.86 m 7.94 m

- 13. Maintenance of High rise OHE Schedules of maintenance are as under:- Foot Patrolling Trolley Inspection / Foot Plate Current Collection Tests Annual Maintenance & TOWER WAGON Checking Periodical Overhauling (POH) Live line checking / HOT Line Checking Special Checks

- 14. Foot patrolling Due to more height of OHE visibility during foot patrolling is difficult Constraints in Maintenance in High Rise OHE

- 15. Tower Wagon Design Due to almost 2mtr higher height of OHE during live line checking visibility is not proper. Pantograph needs modification with high reach OHE. Deck needs modification for working on high rise OHE Constraints in Maintenance in High Rise OHE

- 16. As height of OHE is 7.57 m (Contact) and 8.97 m (Catenary), working of staff at this height is difficult. Constraints in Maintenance in High Rise OHE

- 17. Emergency Mast Height of Emergency mast in conventional OHE is 8.90 m (as per RDSO spec. ETI/C/0072) For High rise OHE no drawing of emergency mast has been provided by RDSO the matter was discussed in 30th MSG and matter is under consideration of RDSO Constraints in Maintenance in High Rise OHE

- 18. Tools & Plants for High Rise OHE Discharge rod Length of cable is 10.50 m + 2.50 mtr in compare to conventional discharge rod of length 7.50 m + 1.50 mtr cable Folding fibre sticks (1.66m each) for holding cable – 04 nos. Erection of discharge rod demands extra manpower.

- 19. Tools & plants for High Rise OHE Discharge Rod It needs to be bound at bottom fitting instead of number plate as in conventional hence unsafe. Due to too much length of discharge rod while erecting it in mid lines of yard it enters in to another elementary sections. It is very difficult to handle when lifting it for erection.

- 20. Tools & Plants for High Rise OHE Extensible ladder Length of extensible straight ladder has been proposed as 13.00 m compared to conventional ladder of 11.00 m

- 21. Tools & plants for High Rise OHE Extensible ladder • More manpower needs to be employed for working on it. • It swings due to increased length but no modification in thickness.

- 22. Merging with Conventional OHE with High Rise OHE Height of Conventional Contact wire = 5.80 m Height of High Rise Contact wire = 7.57 m Difference between contact wire = 1.77m Gradient @ 10 mm/m