Seam And its Classification with seam problem

- 1. Seam And its Classification By:Md.Mohit-Ul Alam Daffodil International University 12/06/15

- 2. Seam What is Seam? A seam is a joint of two pieces of fabric in producing a three -dimensional shape of a garment. Properties of good seam are, = Smooth fabric joints = No Missed or Uneven stitches = No damage to the material being sewn = Achievement of strength, elasticity, Durability, security and comfort = Comfortable while garment is in use

- 3. 12/06/15

- 4. Seam and Classification SEAMS DESIGNATION Each stitched seam is designed numerically by five digits: 0.00.00 refers to the CLASS, 1-8; 0.00.00 refers to the material configuration, 01 to 99; 0.00.00 refers to needle penetrations, material configurations, 01-99.

- 5. Seam Classification: According to British Standard 3870: 1991, seam is classified as- Class 1- superimposed Class 2- lapped Class 3- bound Class 4- flat Class 5- decorative/channel Class 6- edge neatening Class 7- applied Class 8- others

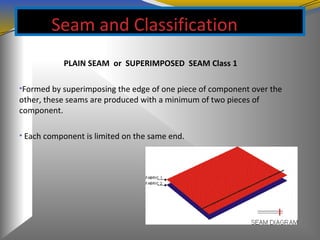

- 6. Seam and Classification PLAIN SEAM or SUPERIMPOSED SEAM Class 1 •Formed by superimposing the edge of one piece of component over the other, these seams are produced with a minimum of two pieces of component. • Each component is limited on the same end.

- 7. Seam and Classification PLAIN SEAM or SUPERIMPOSED SEAM Class 1

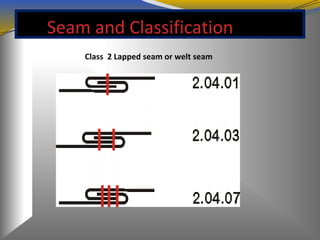

- 8. Seam and Classification Class 2 Lapped seam or welt seam * Formed by lapping two pieces of component, they are produced with minimum of two pieces of component. * One component is limited on one end and the other is limited on the other end. The limited edges of these two components are put in opposite directions. * Used for: main seaming of denim jackets, jeans, and overalls. Fabrics that will not ravel, unlined garments, side seams of shirts, joining lace to another fabric, attaching patch pockets, decorative finish

- 9. Seam and Classification Class 2 Lapped seam or welt seam

- 10. Seam and Classification Class 3 Bound seam Constructed by binding the component edge with another narrow component. The seam produced with minimum of two pieces of component. One component is limited on one end and the other is limited on both ends. Used for : finishing necklines, sleeves hems, inside waistbands of trousers and pants, finishing seams on unlined jackets and coats, adding interest as a design or decorative detail, finishing raw edges, continuing the motif design of lace.

- 11. Seam and Classification Class 3 Bound seam

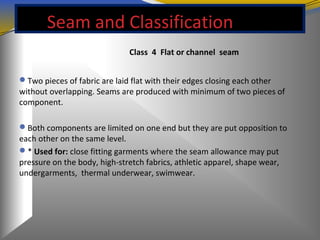

- 12. Seam and Classification Class 4 Flat or channel seam Two pieces of fabric are laid flat with their edges closing each other without overlapping. Seams are produced with minimum of two pieces of component. Both components are limited on one end but they are put opposition to each other on the same level. * Used for: close fitting garments where the seam allowance may put pressure on the body, high-stretch fabrics, athletic apparel, shape wear, undergarments, thermal underwear, swimwear.

- 13. Seam and Classification Class 4 Flat or channel seam

- 14. Seam and Classification Class 5 Ornamental Seam A seam class for decorative sewing on garments. Seams are produced with minimum of one piece of component, with unlimited edges on both ends. * Used for: adding a design detail, cording, piping, tucking, welting, decorative stitching

- 15. Seam and Classification Class 5 Ornamental Seam

- 16. Seam and Classification Class 6 Turned hem or Edge neatening Stitching work made on the fabric edges for neatening. Seams are produced with one piece of component. This seam has one limited edge on one end.

- 17. Seam and Classification Class 6 Turned hem or Edge neatening

- 18. Seam and Classification Class 7 Edge Stitched Seam A narrow piece is sewn to the edge of a garment part. Seams are produced with minimum of two pieces of component. One component is limited on one end, and the other narrow one is limited on both ends.

- 19. Seam and Classification Class 7 Edge Stitched Seam

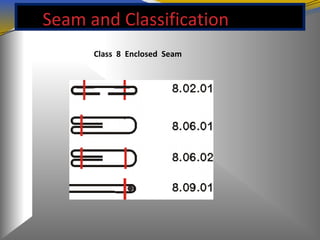

- 20. Seam and Classification Class 8 Enclosed Seam Only one piece of component involved in construction the seam, stitches are applied on its edge/s. Seams are produced with minimum of one piece of component with a limited edge on two ends.

- 21. Seam and Classification Class 8 Enclosed Seam

- 22. Seam Problems SEAM PROBLEMS • Seam Pucker • Grinning • Skipped Stitches • Broken Needle Threads • Broken Bobbin Threads • Needle Damage on Fabric • Seam Slippage

- 23. Seam problems SEAM PROBLEMS SEAM PUCKER • Bad tension • Bad feed • Fabric-Thread instability • Uneven shrinkage during finishing • Thread-bloat from washing • Structural jamming/Inherent pucker • Tight weaving does not have enough room between yarns for thread • Sewing caused yarns to be pushed out of place

- 24. Seam problems Grinning • Loose tension • Incorrect stitch choice • Lockstitch is the tightest stitch and will grin less than other stitches

- 25. Seam problems SKIPPED STITCHES • Bad tension • Machine timing is off • Bobbin hook or looper is not entering needle thread loop at • correct time • Incorrect needle choice • The wrong needle can cause problems in creating the needle • thread loop • Damaged needle • If the needle is bent, or is striking the throat plate, it may not create the loop in the right place for the hook to catch

- 26. Seam problems NEEDLE THREAD BREAKAGE • Tight tension • Trapping at package base • Snarling before tension disc • Poor needle choice • If eye is too small, there will be increased friction • Excessive heat • Poor quality thread

- 27. Seam problems BOBBIN/LOOPER THREAD BREAKAGE •Tight tension •Badly wound bobbin •Incorrect fit of bobbin case •Trapping at package base (for loopers) NEEDLE DAMAGE •Incorrect needle/thread choice •Damaged needle

- 28. Seam problems SEAM SLIPPAGE • Problem is with the fabric – not the stitch • Low yarn count, and continuous filament yarns that don’t grip each other well are to blame • Very minimal improvement can be achieved through increasing seam allowance, adding top stitching, or changing to a lapped felled seam • When possible, seams can be fused • Best option – Change fabric

- 29. Thank You