Lifting Operation Safety ppt.pptx

- 2. • Understanding difference between Routine versus Non- routine lifts • Hazards in Lifting activities • AZDP Requirements • Planning the lifting operations • Roles & Responsibilities • Method of slinging the load • Examination testing & control 2

- 3. • Routine Lift A lift can be categorized as routine if it is repetitive in nature and involves loads that are similar in terms of shape & size. • Non-Routine Lift A lift refers to lifting operations that are complex, carried out for the first time or lifting close to the lifting capacity of the crane. 3

- 4. • Lifting involved with more than one crane/Equipment. • Lift of load without designated hooking points. • Operator cant see the load. • Lifting of people • Lifting near existing buildings • Operations of lifting equipment more than 75% of weight capacity of lifting equipment etc. 4

- 5. - failure of lifting equipment; - falling loads; - workers being crushed by a moving load or lifting equipment. - Soil Collapse - Boom touching the power line - Fall from height while assisting lifting operations by standing at height above floor level 5

- 6. Equipment failure Falling Objects Collision Boom touching power lines 6

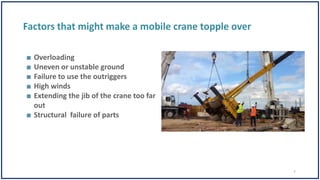

- 7. ■ Overloading ■ Uneven or unstable ground ■ Failure to use the outriggers ■ High winds ■ Extending the jib of the crane too far out ■ Structural failure of parts 7

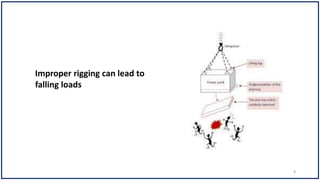

- 8. Improper rigging can lead to falling loads 8

- 9. A lifting plan must be prepared, checked and issued by competent authorised persons prior to any lifting operation No person shall be positioned under any suspended load or between any suspended load and fixed objects All equipment and accessories used for lifting operations must be uniquely identified, marked with the safe working load, listed in a register, and subject to formal regular inspections: every 6 months minimum for accessories every 12 months minimum for equipment All lifting equipment and accessories must have a valid manufacturer’s certificate or thorough examination records. 9

- 10. A formal documented risk assessment must be undertaken and communicated to the persons performing any lifting operations Alstom must ensure that a designated leader is formally appointed to supervise each work activity where there are lifting operations All persons preparing and issuing lifting plans must be subject to recorded competence checks to ensure necessary training experience and qualification All persons involved in lifting operations must be subject to recorded competence checks to ensure necessary training experience and qualification prior to commencing work A Permit to Work must be established prior to any non-routine lifting operation 10

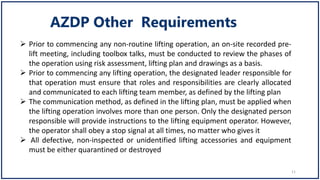

- 11. Prior to commencing any non-routine lifting operation, an on-site recorded pre- lift meeting, including toolbox talks, must be conducted to review the phases of the operation using risk assessment, lifting plan and drawings as a basis. Prior to commencing any lifting operation, the designated leader responsible for that operation must ensure that roles and responsibilities are clearly allocated and communicated to each lifting team member, as defined by the lifting plan The communication method, as defined in the lifting plan, must be applied when the lifting operation involves more than one person. Only the designated person responsible will provide instructions to the lifting equipment operator. However, the operator shall obey a stop signal at all times, no matter who gives it All defective, non-inspected or unidentified lifting accessories and equipment must be either quarantined or destroyed 11

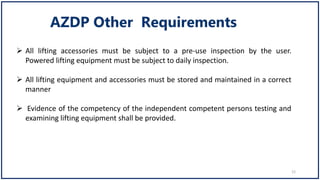

- 12. All lifting accessories must be subject to a pre-use inspection by the user. Powered lifting equipment must be subject to daily inspection. All lifting equipment and accessories must be stored and maintained in a correct manner Evidence of the competency of the independent competent persons testing and examining lifting equipment shall be provided. 12

- 13. Lifting Plan should be prepared, reviewed and issued only by authorised competent persons and consider below 1.The Weight Of The Load (Including Rigging) 2.The Size Of The Load 3.Available Head Room 4.Method Of Lifting 5.Selection Of The Appropriate Rigging 13

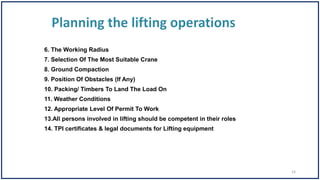

- 14. 6. The Working Radius 7. Selection Of The Most Suitable Crane 8. Ground Compaction 9. Position Of Obstacles (If Any) 10. Packing/ Timbers To Land The Load On 11. Weather Conditions 12. Appropriate Level Of Permit To Work 13.All persons involved in lifting should be competent in their roles 14. TPI certificates & legal documents for Lifting equipment 14

- 15. All Discipline Engineers/Technicians are responsible for: Those personnel who directly supervise any lifting operation are responsible for ensuring that all materials are handled in a safe and correct manner and in accordance with this Procedure. Site Engineer/Supervisor Role: Safety Officer /Engineer Role: The HSE Officer /Engineers are responsible for monitoring safe working practices on site 15

- 16. Lifting Supervisor Role: • Competent & trained • Confirm the weight of the load before rigging commences. • Ensure the load is properly rigged and supervise the rigging crew. • Ensure rigging material or equipment is correctly assembled. • Ensure the safety of lifting crew and any others who may be affected. • Ensure everyone is in a safe area before lifting. • Carry out regular checks on any rigging/lifting equipment. • Ensure hazardous areas properly barricaded. • Issue a Permit to Work for non-routine lifts. • Conduct pre-lift briefings. • Ensure hands signals and communication are properly managed 16

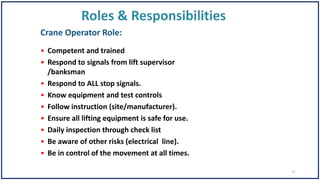

- 17. • Competent and trained • Respond to signals from lift supervisor /banksman • Respond to ALL stop signals. • Know equipment and test controls • Follow instruction (site/manufacturer). • Ensure all lifting equipment is safe for use. • Daily inspection through check list • Be aware of other risks (electrical line). • Be in control of the movement at all times. Crane Operator Role: 17

- 18. Crane Operator Must NOT: • Bypass any safety system. • Leave a load suspended when unattended. • Undertake a lifting operation if it is unsafe. • Lift loads above people. • Do anything that will distract their attention. 18

- 19. • Attach & remove the lifting gears (slings, shackles, tag lines, etc.), • Attend the tag lines of loads being lifted, • Shall be medically fit, with particular regard to strength, agility, eyesight, hearing & reflexes, • Shall have received minimum training or shall have experience of lifting, • Shall be able to select lifting gears suitable for the loads to be lifted, • Shall be able to understand the language of the signalman. Riggers Role 19

- 20. Signal Man: • Supervises the lifting operations, • Is responsible for the safety of the whole lifting operation, • Shall have been trained in the job or shall be able to demonstrate his ability & experience, • Shall ensure the riggers operate safely and follow the basic rules for safe lifting (use of tag lines, means of escape, safe location, etc.), • Shall ensure that personnel not involved with the lifting operation is kept well away, • Shall keep visual or radio communication with the crane driver, • Shall ensure that he is identified & fully understood by the crane driver and by the riggers. 20

- 21. 21

- 22. 22

- 23. 23

- 24. 24

- 25. 25

- 26. 26

- 27. 27

- 28. 28

- 29. 29

- 30. 30

- 31. 31

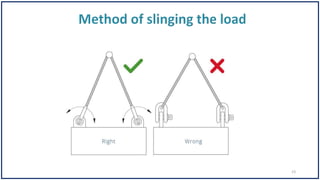

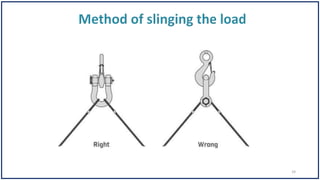

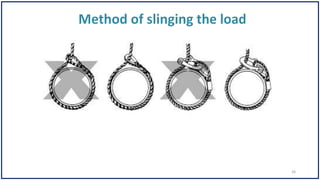

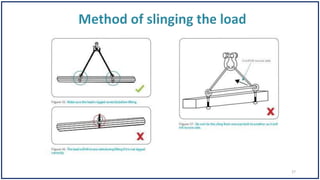

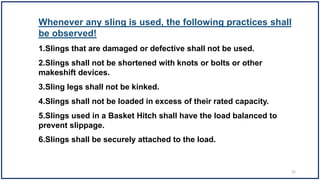

- 32. Whenever any sling is used, the following practices shall be observed! 1.Slings that are damaged or defective shall not be used. 2.Slings shall not be shortened with knots or bolts or other makeshift devices. 3.Sling legs shall not be kinked. 4.Slings shall not be loaded in excess of their rated capacity. 5.Slings used in a Basket Hitch shall have the load balanced to prevent slippage. 6.Slings shall be securely attached to the load. 32

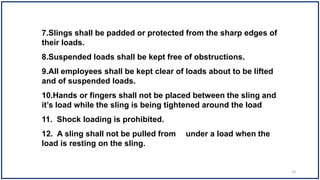

- 33. 7.Slings shall be padded or protected from the sharp edges of their loads. 8.Suspended loads shall be kept free of obstructions. 9.All employees shall be kept clear of loads about to be lifted and of suspended loads. 10.Hands or fingers shall not be placed between the sling and it’s load while the sling is being tightened around the load 11. Shock loading is prohibited. 12. A sling shall not be pulled from under a load when the load is resting on the sling. 33

- 34. Examples of wire ropes sling to be removed from service 34

- 35. 35

- 36. Examples of shackles to be removed from service 36

- 37. 37

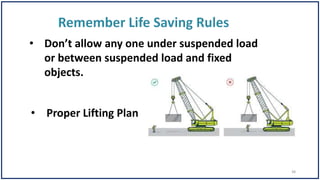

- 38. • Don’t allow any one under suspended load or between suspended load and fixed objects. • Proper Lifting Plan 38

- 39. 39