tolerance stack up analysis

- 1. TOLERANCE STACK UP ANALYSIS

- 2. Introduction Tolerance analysis : Study of individual tolerances Process of determining the cumulative variation possible between two or more features. Tolerance stack up analysis is one part of tolerance analysis. Analyzes and predicts the variation between the parts. Determines the maximum possible variation between two components in an assembly.

- 3. Merits of Tolerance Stack Up Analysis Optimize the tolerances of parts and assemblies in a new design Balance accuracy , precision and cost with manufacturing process Determine the part tolerance required to satisfy a final assembly condition Determine allowable part tolerance if assembly tolerance is known Determine the effect changing a tolerance will have on assembly component

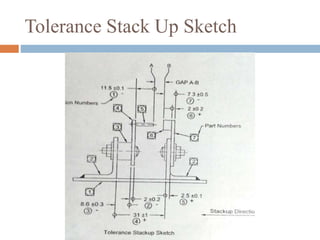

- 4. Steps in Tolerance Stack Up Analysis The Distance to be studied is identified and labeled The positive and negative directions are identified A tolerance stack up sketch is created The dimensions in positive direction and negative directions are added individually The nominal distance is found out by subtracting negative direction total from the positive direction total The total possible variation is obtained by adding all tolerances The maximum and minimum variations are obtained from the nominal distance and total variation values.

- 5. Problem For an inseparable assembly using tolerance stack up analysis find the maximum and minimum distance between the part 5 and 6 in assembly.

- 6. Tolerance Stack Up Sketch

- 7. Tolerance Stack Up Report

- 8. Dimensional Chain Analysis Dimensional Chain is a consecutive series of interrelated dimensions that contribute to the tolerance of a dimension and form a closed loop. Two Basic tasks in tolerance design process : Dimensional Chain analysis Dimensional Chain synthesis In Dimensional analysis component tolerance are specified and resulting assembly variation is calculated. Dimensional Synthesis involves allocation of specified assembly tolerance between component dimension of the assembly.

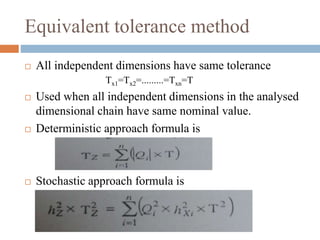

- 9. Equivalent tolerance method All independent dimensions have same tolerance Tx1=Tx2=.........=Txn=T Used when all independent dimensions in the analysed dimensional chain have same nominal value. Deterministic approach formula is Stochastic approach formula is

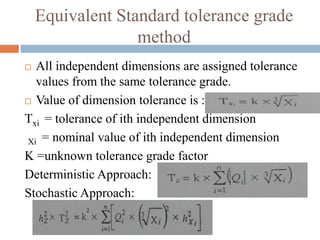

- 10. Equivalent Standard tolerance grade method All independent dimensions are assigned tolerance values from the same tolerance grade. Value of dimension tolerance is : Txi = tolerance of ith independent dimension Xi = nominal value of ith independent dimension K =unknown tolerance grade factor Deterministic Approach: Stochastic Approach:

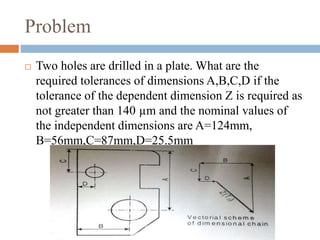

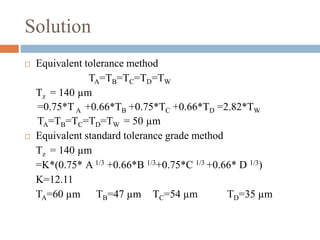

- 11. Problem Two holes are drilled in a plate. What are the required tolerances of dimensions A,B,C,D if the tolerance of the dependent dimension Z is required as not greater than 140 µm and the nominal values of the independent dimensions are A=124mm, B=56mm,C=87mm,D=25.5mm

- 12. Solution

- 13. Solution Equivalent tolerance method TA=TB=TC=TD=TW Tz = 140 µm =0.75*T A +0.66*TB +0.75*TC +0.66*TD =2.82*TW TA=TB=TC=TD=TW = 50 µm Equivalent standard tolerance grade method Tz = 140 µm =K*(0.75* A 1/3 +0.66*B 1/3+0.75*C 1/3 +0.66* D 1/3) K=12.11 TA=60 µm TB=47 µm TC=54 µm TD=35 µm

- 14. THANK YOU