Plm design process for startup or maker (1)

- 1. By : SlingX Corp. / David Peng Date : March 19th, 2016 PLM Design Process for Startup or Maker

- 2. Brief of David Peng • David Peng • Title : SlingX Corp. / CEO • Education : Bachelor of Electrical Engineer Dept. of National Central Univ. • Experience : HiTech Energy Inc. / Senior Manager Jabil Circuit Taiwan Branch, STB Div / Senior PM Manager Foxconn – CNSBG , WHN Div. / Senior PM Manger LiteOn – NABU, Product Marketing & Management Dept. / Senior Manager -- IA BU, Wireless Dept. / RD Manager • Major at : RF Circuit & Embedded system Design Product technology analysis, development and integration Product Management Product marketing plan and promotion

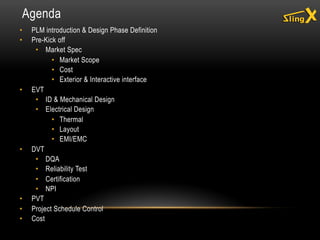

- 3. Agenda • PLM introduction & Design Phase Definition • Pre-Kick off • Market Spec • Market Scope • Cost • Exterior & Interactive interface • EVT • ID & Mechanical Design • Electrical Design • Thermal • Layout • EMI/EMC • DVT • DQA • Reliability Test • Certification • NPI • PVT • Project Schedule Control • Cost

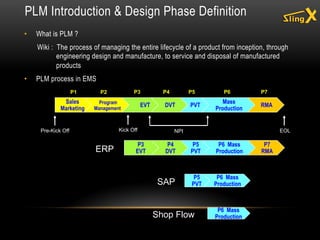

- 4. PLM Introduction & Design Phase Definition • What is PLM ? Wiki : The process of managing the entire lifecycle of a product from inception, through engineering design and manufacture, to service and disposal of manufactured products • PLM process in EMS Sales Marketing Program Management EVT DVT PVT Mass Production RMA Pre-Kick Off EOLNPI P3 EVT P4 DVT P5 PVT P6 Mass Production P7 RMAERP P5 PVT P6 Mass ProductionSAP P6 Mass ProductionShop Flow Kick Off P1 P2 P3 P4 P5 P6 P7

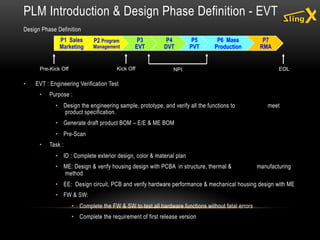

- 5. PLM Introduction & Design Phase Definition - EVT Design Phase Definition • EVT : Engineering Verification Test • Purpose : • Design the engineering sample, prototype, and verify all the functions to meet product specification. • Generate draft product BOM – E/E & ME BOM • Pre-Scan • Task : • ID : Complete exterior design, color & material plan • ME: Design & verify housing design with PCBA in structure, thermal & manufacturing method • EE: Design circuit, PCB and verify hardware performance & mechanical housing design with ME • FW & SW: • Complete the FW & SW to test all hardware functions without fatal errors • Complete the requirement of first release version P1 Sales Marketing P2 Program Management P3 EVT P4 DVT P5 PVT P6 Mass Production P7 RMA Pre-Kick Off EOLNPIKick Off

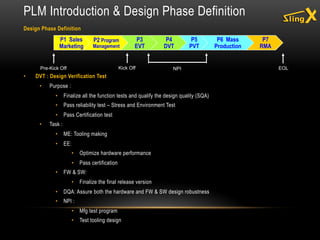

- 6. PLM Introduction & Design Phase Definition Design Phase Definition • DVT : Design Verification Test • Purpose : • Finalize all the function tests and qualify the design quality (SQA) • Pass reliability test – Stress and Environment Test • Pass Certification test • Task : • ME: Tooling making • EE: • Optimize hardware performance • Pass certification • FW & SW: • Finalize the final release version • DQA: Assure both the hardware and FW & SW design robustness • NPI : • Mfg test program • Test tooling design P1 Sales Marketing P2 Program Management P3 EVT P4 DVT P5 PVT P6 Mass Production P7 RMA Pre-Kick Off EOLNPIKick Off

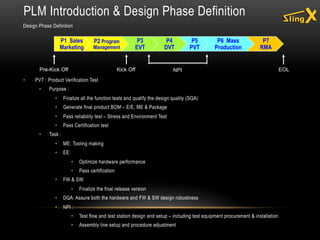

- 7. PLM Introduction & Design Phase Definition Design Phase Definition • PVT : Product Verification Test • Purpose : • Finalize all the function tests and qualify the design quality (SQA) • Generate final product BOM – E/E, ME & Package • Pass reliability test – Stress and Environment Test • Pass Certification test • Task : • ME: Tooling making • EE: • Optimize hardware performance • Pass certification • FW & SW: • Finalize the final release version • DQA: Assure both the hardware and FW & SW design robustness • NPI : • Test flow and test station design and setup – including test equipment procurement & installation • Assembly line setup and procedure adjustment P1 Sales Marketing P2 Program Management P3 EVT P4 DVT P5 PVT P6 Mass Production P7 RMA Pre-Kick Off EOLNPIKick Off

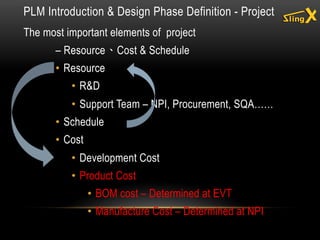

- 8. PLM Introduction & Design Phase Definition - Project The most important elements of project – Resource、Cost & Schedule • Resource • R&D • Support Team – NPI, Procurement, SQA…… • Schedule • Cost • Development Cost • Product Cost • BOM cost – Determined at EVT • Manufacture Cost – Determined at NPI

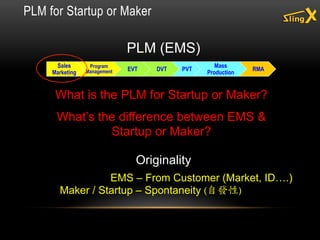

- 9. PLM for Startup or Maker Sales Marketing Program Management EVT DVT PVT Mass Production RMA PLM (EMS) What is the PLM for Startup or Maker? What’s the difference between EMS & Startup or Maker? Originality EMS – From Customer (Market, ID….) Maker / Startup – Spontaneity (自發性)

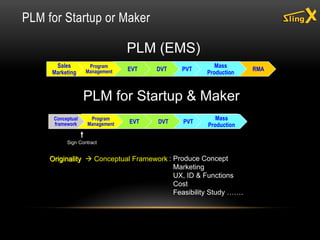

- 10. PLM for Startup or Maker PLM (EMS) EVT DVT PVT Mass Production Program Management EVT DVT PVT Mass Production PLM for Startup & Maker Sales Marketing Program Management EVT DVT PVT Mass Production RMA Originality Sign Contract Conceptual framework Program Management EVT DVT PVT Mass Production Originality Conceptual Framework : Produce Concept Marketing UX, ID & Functions Cost Feasibility Study …….

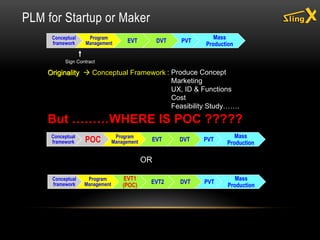

- 11. Conceptual framework Program Management EVT DVT PVT Mass Production PLM for Startup or Maker Originality Sign Contract Originality Conceptual Framework : Produce Concept Marketing UX, ID & Functions Cost Feasibility Study……. But ………WHERE IS POC ????? Conceptual framework POC Program Management EVT DVT PVT Mass Production Conceptual framework Program Management EVT1 (POC) EVT2 DVT PVT Mass Production OR

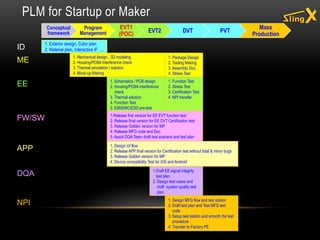

- 12. PLM for Startup or Maker Conceptual framework Program Management EVT1 (POC) EVT2 DVT PVT Mass Production ID 1. Exterior design, Color plan 2. Material plan, Interactive IF….. 1. Mechanical design, 3D modeling 2. Housing/PCBA interference check 3. Thermal simulation / solution 4. Mock-up Making ME 1. Package Design 2. Tooling Making 3. Assembly Doc. 4. Stress Test 1. Schematics / PCB design 2. Housing/PCBA interference check 3. Thermal solution 4. Function Test 5. EMI/EMC/ESD pre-test EE 1. Function Test 2. Stress Test 3. Certification Test 4. NPI transfer 1.Release first version for EE EVT function test 2. Release final version for EE DVT Certification test 3. Release Golden version for MP 4. Release MFG code and Doc. 5. Assist DQA Team draft test scenario and test plan FW/SW 1. Design UI flow 2. Release APP final version for Certification test without fatal & minor bugs 3. Release Golden version for MP 4. Device compatibility Test for iOS and Android APP 1. Design MFG flow and test station 2. Draft test plan and Test MFG test code 3. Setup test station and smooth the test procedure 4. Transfer to Factory PE NPI DQA 1.Draft EE signal integrity test plan 2. Design test cases and draft system quality test plan

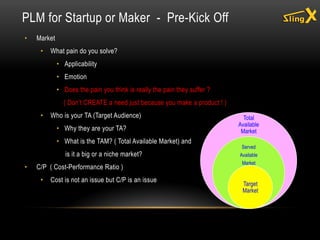

- 13. • Market • What pain do you solve? • Applicability • Emotion • Does the pain you think is really the pain they suffer ? ( Don’t CREATE a need just because you make a product ! ) • Who is your TA (Target Audience) • Why they are your TA? • What is the TAM? ( Total Available Market) and is it a big or a niche market? • C/P ( Cost-Performance Ratio ) • Cost is not an issue but C/P is an issue PLM for Startup or Maker - Pre-Kick Off Total Available Market Served Available Market Target Market

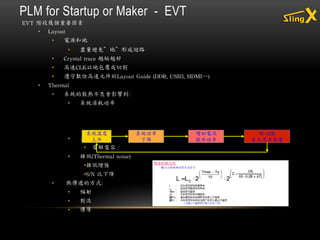

- 14. EVT 階段幾個重要因素 • Layout Layout 是EVT階段最重要的因素. • 電源和地 • 溝渠理論: 電源就如同乾淨的水源流入系統,此水源經過系統後將一些 髒的訊號借由地來排除。 • 盡量減少接地迴路 • 各區塊地對大地的阻抗值越低, 抗雜訊力越好 • 雜訊越大的地離大地的路徑越短越好 • 地越完整越好, 不要零零散散的 PLM for Startup or Maker - EVT 電源 大地 RF Digital Analog

- 15. EVT 階段幾個重要因素 • Layout • 電源和地 • 盡量避免”地”形成迴路 • Crystal trace 越短越好 • 高速CLK以地包覆或切割 • 遵守數位高速元件的Layout Guide (DDR, USB3, HDMI…) • Thermal • 系統的散熱不良會影響到: • 系統消耗功率 • 元件壽命 • 電解電容 : • 雜訊(Thermal noise) •雜訊增強 •S/N 比下降 • 熱傳遞的方式: • 幅射 • 對流 • 傳導 PLM for Startup or Maker - EVT 系統溫度 上升 系統功率 下降 增加電流 提升功率 W=I2R 產生更多熱量

- 16. EVT 階段幾個重要因素 • Thermal • 解決散熱方式: • 風扇:對流(空氣) • 散熱片,石墨片:傳導 • 鰭片: 對流 + 傳導 + 幅射 • 水冷式散熱: 傳導 + 對流(水) • Thermal simulation • Pro-E & Solidworks • Thermal report PLM for Startup or Maker - EVT

- 17. To Be Continue