Today’s Container Terminal business is swiftly evolving and market forces are creating greater challenges for the modern operator. These include:

Port operators need to keep evolving and setting new levels of efficiency. This is paramount to the overall success–unlike their carrier clients that can select which terminals they ply their trade, the terminals have to look at large-scale, long-term capital investments.

Much of these outcomes can be achieved through the adoption of “Next Generation” Technology and this is where Wipro is looking to leverage its global recognized IT services to help terminal operators achieve these goals.

“Collaborative, digitalized big data solutions are the future

The question revolves around seeking more efficient ways to handle and manage all aspects of their business especially as the larger, more diverse groups, have varying levels of management and coverage from:

When carrier groups evaluate their service calls, their objectives will always focus on the following key areas:

Wipro has undertaken considerable research into the type of IT solutions that are commonly found across terminals:

These solutions provide considerable data and we established that a lot of time was spent by operational teams in reviewing and manipulating the information and trying to produce meaningful reports. Lots of consolidation in terms of analyzing the data and in many cases, much of it became obsolete before being used in an actual operational mode. Of course, this data would allow management to review and compare in terms of a historical format, but the goal is to become more proactive and be able to react on essential data in a timely manner.

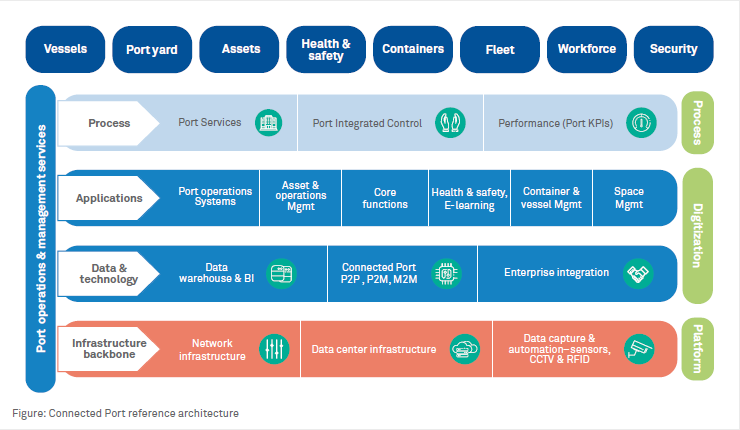

So why do we need Connected Port approach?

We have found that the sheer lack of IT integration is common across the market. The inability to link key solutions and obtain key operational data isn’t being accomplished–yes, data is available from all these various sources but the lack of total integration has created blockages in the overall view of the operations.

Wipro is an expert in the field of solution integration. We believe the first phase in driving greater efficiencies across Terminal groups will be the integration and digitalization of these key solutions. Obtaining collaborative “Big Data” will be the first step towards the future.

Utilizing Wipro’s unique design-led approach, we can interface the key operational solutions, allowing for essential data to be extracted which can then reside within our robust platform. Once the data is collected, the ability of Wipro’s advanced analytical engine like the Data

Discovery Platform (DDP) can be utilized. Wipro can help large Terminal organizations save costs through our cloud-hosting offering which could significantly help reduce local and regional IT infrastructure costs.

So, the question is which areas can be digitalized and the role of big data in achieving the type of improved savings that will entice carriers to maintain their calls at facilities while looking at reducing the Terminals’ overall operational costs.

The emphasis will be to address and manage the processes that will allow for the smooth handling and transition of the vessels and cargo entering these facilities. So, we must look at the following areas:

As mentioned above, the carriers can be quite fickle when planning their revised Terminal calls–and we have already touched on the fact that Terminal operators face major capital investments into infrastructure, asset, and technology. So, the answer will be to build a more cohesive “Mouse Trap” for these carriers. Terminals will need to develop even smarter and more streamlined operations that will induce the carriers to maintain their calls or switch to their facilities with the goal of achieving faster vessel turn times, improved service and looking at reducing their overall costs so that maximum yields can be achieved on every TEU handled. A major factor for Terminals to strive for these goals will be in system integration and the ability to become more proactive in dealing with issues before they occur.

Data integration

The ability to provide seamless integration across all operational solutions–from having the data available within the solutions to be able to deliver:

Equipment asset management

Effective corporate and regional control

Wipro uses the latest integration tools that allow for seamless connectivity and provides a platform where essential data can be stored–having this data at a centralized location can certainly help to streamline local and regional processes and provide a window of “Big Data” to the corporate level management that seeks to become more “hands on” in their approach.

Wipro’s HOLMES advanced artificial intelligence application–the intelligent component of connected Port suite

Data has a shelf life-it’s vital that action is taken or the right information is channelled to the right level of management that can act and respond to it in a timely manner. However, Wipro’s HOLMES takes big data and provides real-time learning solutions. If we stick with the concept of Engineering–HOLMES can be pre-set with business logic–having the ability to pre-empt and predict when routine maintenance or more essential repairs should be undertaken can help to keep machinery operating longer and reduce potential mechanical failures or breakdowns. If you consider that this will help to keep equipment at a more optimal level, and improve overall safety across the Terminal, then these are all points in favour of deploying HOLMES.

Further helping the Terminals engineers at a local level through our HoloLens VR applications

What are the tangibles that can be achieved through connected Port application suite?

After Port Infrastructure build cost, assets and equipment constitutes the next biggest cost element.

On average, a medium-sized facility might indeed invest anywhere between 50 to 100 million dollars on operating equipment and when looking at global operators, they might be spending more than 1.2 to 1.5 billion dollars on equipment along with a sizeable annual budget in terms of maintenance and repairs. So, it’s vital that the equipment can be run efficiently and with minimal operational downtime.

Connected Port utilizes the latest IoT technology which can be easily retro-fitted to all operating equipment. Due to our neutral approach, we are not manufacturer-specific and we look at extracting essential operating data from each piece of machinery at source level data including:

GIS physical location tracking across the facility

Connected Port can interface with the essential back-end operational solutions like the Terminal operations, ERP and data can be extracted on the following areas:

ERP

Terminal operations system

This level of data can help across all levels of the management from a Terminal to corporate level in measuring the overall performance and running efficiencies of every type and make of equipment running.

The benefits:

Data comparing all equipment

Want to know more about how we are helping large real estate firms globally in their business transformation journey? Please drop us note at wipro.enc@wipro.com and we’ll be glad to set up a connect with you!