For all its transformative potential, the high costs of 3-D printing continue keeping it from achieving mass consumer adoption. Now a new open source device may change that with its ability to create plastic filament at a fraction of current prices.

The design, created by 83-year-old engineer and inventor Hugh Lyman, is the winner of the Desktop Factory Competition, an X-Prize-style challenge that kicked off last May. Created by Inventables CEO Zach Kaplan and Pocket Factory founder Bilal Ghalib, and backed by the Kauffman Foundation, the challenge set a goal to turn cheap, common plastic pellets into the filament utilized by most desktop 3-D printers in order to make it easier to access the 3-D printing world.

The competition's stakes were high: Winners would receive $40,000 provided by the Kauffman Foundation and a 3-D printer, CNC mill, and laser cutter from Inventables. The specifications seemed simple enough; the new machine had to be open source, cost less than $250 in parts, accept PLA or ABS resin pellets, be able to mix in colorant, and extrude 1.75mm filament.

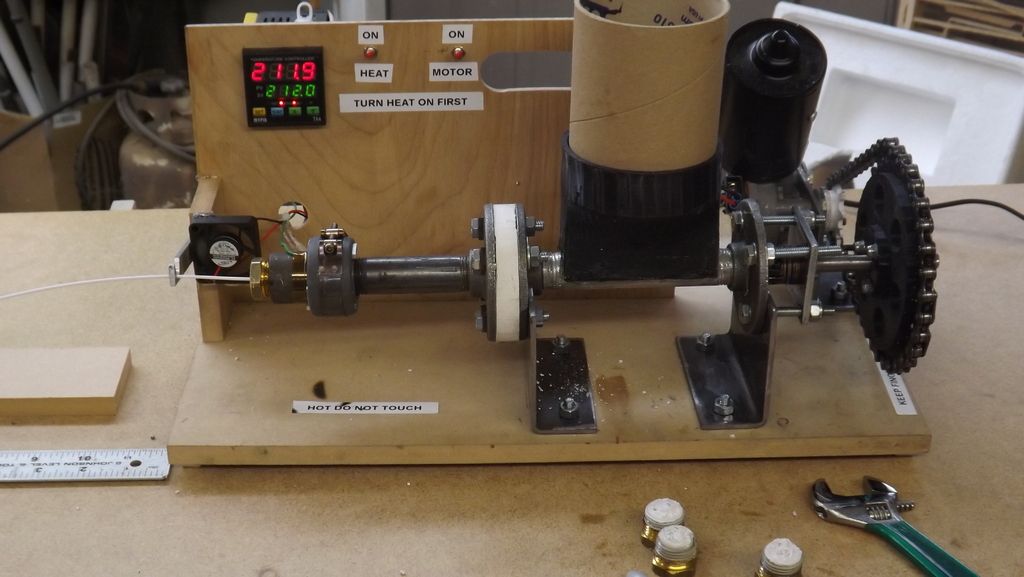

While the project seems straightforward, it still took 10 months before a device that met all the specifications was submitted, despite 38 teams clamoring to solve the challenge. Lyman's design stores raw plastic pellets in a hopper, melts them into a liquid state, and extrudes print-ready filament for a fraction of the cost of store-bought equivalent.

"I was running out of money paying $40 to $50 for a couple pounds of plastic," Lyman says, discussing his interest in the competition. "By the time I got my extruder running I was filling garbage cans with filament."

And even after winning the Desktop Factory Competition, Lyman was hard at work on the Lyman Extruder III, which he says will be smaller, less expensive, feature fewer parts and work in a horizontal or vertical orientation. Like his first two extruders, Lyman says this one will also be open source "I'm not happy with patents," he says. "Only 1 percent of them are any good."Lyman has run three engineering and manufacturing businesses in his 83 years, but warns that there is a world of difference between inventing and marketing. "To make a product and produce it is easy," he says. "but unless you want to deal with accountants, attorneys, and lawsuits, don't start a business."

Despite having witnessed decades of technological advances in his lifetime, Lyman is still impressed with 3-D printing. "It's the most exciting thing I've done, he says. "I love it. When I designed my center point finder back in 2005, I had it 3-D printed by a service bureau in Tacoma, Washington, and they looked great. Then I just forgot about it, until browsing one day I found the RepRap website. I bought a kit, made it, and it worked. Then I saw another 3-D printer that was uploaded on Thingiverse, thought it was better, and made that from scratch. Then I found another model on Thingiverse and I'm printing that out now."

As for the $40,000 prize, Lyman says after the IRS takes its share, half of the prize will go to his wife while the rest will fund his hobby. "I'm just gonna use it for another exciting option to make parts and things," he says. "It's gonna be some nice fun money and I'm going to use it for tinkering."

The competition was not won easily. One competitor, the Filabot, had raised over $30,000 on Kickstarter to fund its development, and Lyman's first entry, submitted in September 2012, was rejected by the judges because he had forgotten to account for the cost of 3-D printed parts used to assemble the machine, pushing it over the $250 limit. His winning design is now available on Thingiverse, where it has already been downloaded over 10,000 times, and has even been modified and improved by others in the community.

The cost-slashing device will potentially remove one of the major barriers of entry to 3-D printing. Today a 2.2-pound spool of filament costs approximately $50, but if makers generate their own with resin pellets, an equivalent amount will cost just over $5, according to Lyman.

For all the new 3-D printers that have launched over the last year, aside from the B9 Creator and the Formlabs Form 1, there haven't been a lot of new concepts brought to market. "There are a lot of incremental improvements, but it seems like optimizing for a local maximum," says Kaplan, who wants to spur on new ideas. "For instance, if you could have a filament extruder that dramatically reduces the cost, maybe we can just build a 3-D printer that takes pellets instead of filament?"

The machine has the potential for further driving down the costs, both financial and environmental, by recycling and turning empty soda bottles and failed prints into new products, although it'll require additional attention. "I think that it's possible," say Kaplan. "From a little experience in recycling projects with soda manufacturers there are complexities with combining different plastics. You need to have the same plastics; it's possible but there are challenges in the purity."

Kaplan, whose company manufactures a $900 3-D printer and $600 CNC mill believes that inventors are beginning to enjoy the freedom that the web enjoyed with the advent of open source programming tools. "We're trying to taking away all the financial barriers to invention," he says. "Now the question is, do you have the ideas and ambition to see them through? This competition demonstrated that it's totally possible for anyone to get inventing — an 83-year-old retiree from a suburb of Seattle won this competition. You no longer need to get a job, you can make a job."

Kaplan says he's in the planning stages of a new competition, but isn't ready to release details yet. He did hint at inventions that make the machines more reliable, improvements to the print heads that would make them less likely to clog and offer higher resolution, and better software as things on his wishlist.

"The idea was to get the 3-D printing market to think about different approaches moving forward," says Inventables CEO Zach Kaplan. "If we were comparing 3-D printing to desktop publishing we're in the late '70s or early '80s. The Visicalc of 3-D printing hasn't come out, I don't think the Apple II has even come out yet."

Photos: Hugh Lyman except where otherwise noted.