Preprint

Article

Analysis of Soiling Loss in Photovoltaic Modules: A Review of the Impact of Atmospheric Parameters, Soil Properties, and Mitigation Approaches

Altmetrics

Downloads

167

Views

67

Comments

0

A peer-reviewed article of this preprint also exists.

This version is not peer-reviewed

Submitted:

18 October 2023

Posted:

19 October 2023

You are already at the latest version

Alerts

Abstract

Soiling accumulated on a photovoltaic (PV) module can significantly reduce the transmittance of the cover glass, resulting in power losses and consequent economic losses. Natural atmospheric parameters influence the accumulation of soiling at the various geographic locations. In this paper, the approaches and outcomes of the research studies on either indoor (simulator-based) or outdoor (field-based) PV soiling have been thoroughly reviewed. Different parameters depicted for the power loss of PV modules are analyzed individually and presented. Moreover, this study delves into a detailed examination of the key factors influencing dust depositions on PV modules in various geographical regions, with a particular focus on their relationship with climatic conditions. This way, probable future research directions to quantify soiling losses are identified. In addition, different loss prevention and mitigation techniques are also reviewed. This makes it possible to highlight effective strategies and pinpoint potential future research lines in these areas.

Keywords:

Subject: Engineering - Other

1. Introduction

Solar photovoltaic (PV) systems are one of the most popular renewable energy conversion technologies due to the availability of solar energy resources on Earth. [1]. The conversion of energy in the PV system depends on the irradiance, and spectral content radiated from the sun, along with environmental and climatic variables, the integral system, and the balance of systems [2]. Soiling on PV modules is the third major concern for the success of PV technology after irradiance and temperature [3,4]. Soiling intrinsically affects PV modules, gradually accumulating after the installation of the PV power plant. As a result, output power and efficiency may completely terminate in the long run [5,6]. Over the years, the impact of soiling has been investigated in several regions worldwide, especially in regions where such soiling is a major showstopper issue or solar energy is the only option to generate electricity [4,7,8,9,10,11].

Soiling particles (1µm to 500µm in size) can comprise dried cells of flora and fauna, microorganisms like fungi and bacteria, human or animal cells, fibers of textiles, and sand, clay, or eroded limestone from geomorphic fallout [12]. In addition, they can include aerosols or atmospheric dust due to soil elements lifted by the wind, volcanic eruptions, vehicle movement on the highway side, and pollution near industrial areas [13,14,15]. The size of dust particles, and their constituents, and their deposition behaviors vary due to a region’s topography, climate, and urbanization. The characteristics of dust can be classified by size or distribution, density or shape, charge, and composition. Different ambient conditions that are related to dust characteristics are humidity and moisture gradients, wind velocity and directions, and season variations [16]. The fundamental characteristics of dust and its effects on power conversion, deposition behaviors, and mitigation techniques are not fully understood yet. Most importantly, the study and observation of post effects on the glass surface after dust deposition and then cleaning have not yet come to the forefront.

The most widely used technique for cleaning PV modules is washing with detergent water [4]. However, this cleaning technique may not be effective in regions with high annual solar insolation but limited water availability. This urges the need for a detailed study of dust deposition behaviors on solar PV modules. Globally, several studies and observations have been conducted for decades in the field of soiling PV modules. Also, many review papers have been published on soiling for different climatic zones, cell types, dust properties, and cleaning techniques. However, in this light, the novelty of this present study relies on the following key points:

- It critically analyzes the degraded outputs of soiled PV modules from most of the reported work for different environmental conditions.

- It also discusses the effect of atmospheric parameters accounted for in soiling as well as on PV module output characteristics in different climatic conditions around the globe.

- It presents a review of soiling loss investigations in outdoor (outdoor exposure) conditions.

- It also presents the importance of soiling loss investigations in artificial environmental (emulator based) conditions.

- It compares mitigation approaches as developed so far with practicality.

A first categorization of global regions is presented in Section 2 based on dust concentration. Different factors accountable for soiling on PV modules under various environmental conditions are analyzed in Section 3. Also, the effect of atmospheric parameters such as wind speed, humidity, rainfall, tilt angle, and the properties of dust particles accountable for dust deposition are discussed critically with reference to earlier research works. In Section 4, soiling loss investigations, both outdoor and emulator-based, are discussed with working models. Different technologies have been developed so far to reduce soiling, and their comparisons are depicted in Section 5. Section 6 forecasts future research paths to improve the conversion of solar energy to electricity using PV technology.

2. Dust belt areas

The amount and rate of dust deposition on the PV module surface depend on the weather conditions of a particular location [17]. The concentration of dust particles and pollutants are not the same for different parts of the world depending on the local conditions. The classification of different countries according to characteristics of dust concentration and climatic zones is mapped in Figure 1A. The dust concentration is represented through PM10, a common metric that expresses the mass of liquid and solid particles of diameter < 10 µm suspended in 1 m3 of air [18]. The darker color in the map represents a higher PM10 concentration; this decreases as the color gets lighter.

Four climatic zones are identified. Zone 1 covers humid and cold regions having the lowest levels of dust density. The humid climatic regions are classified as Zone 2. Many European and North American countries are in this zone, and soiling reduces PV power generation by 25% [19]. In Zone 3, countries around the equator and/or having a humid climate, like India, Mexico, and China, are grouped [18]. These countries are among those that are investigating more photovoltaic capacities and together represent 60% of lower power generation due to soiling [19]. In this zone, annual losses can be as high as 10%. In Zone 4, most of the places fall dry climatic zone and have higher concentrations of PM10. This zone includes countries that have significant PV potential but that experience substantial soiling losses. For example, yearly soiling losses higher than 15% and 10% have been reported for Egypt and Saudi Arabia, respectively, which are both classified as Zone 4 [18,19].

3. Physical factors influencing soiling on PV modules

Dust and local atmospheric conditions determine PV module soiling [21]. The transmittance of a PV module will decrease gradually with time due to the increased soil density of glass surfaces. The soiling characteristics and impacts depend on environmental factors and local weather conditions [22,23]. For example, finer dust particles affect module performance more than coarser particles [21] [24]. Prime factors affecting dust deposition involve wind, relative humidity, rainfall, orientation, the elevation angle, and the surface characteristics of modules, which will be assessed in the following subsections.

3.1. Effect of wind

The velocity of wind and its direction are equally important factors in soiling on PV modules [25]. It is well known that wind enhances PV cell efficiency by reducing the module temperature through dissipative convection [26]. In addition, wind may result in an increase in the module performance by detaching dust particles. On the other hand, dust-laden winds might increase soil accumulation.

A previous study conducted in a wind tunnel reported that high-speed winds might result in more dust deposition on the module surface compared to low-speed winds [27]. However, the impact of wind velocity will also depend on the dust particles present in the local sites [27]. In addition, wind speed and air pressure are not constant over the surface of a PV module. In cases of lower wind speeds, there will be higher pressure over the module’s surface, which may result in higher soil accumulation, and vice versa [23].

3.2. Effect of humidity and dew

Many researchers have examined PV module surface soiling in relation to humidity fluctuations [8,26,28,29]. For example, Mekhilef et al. [26] found that dust, humidity, and air velocity affect each other. Increased humidity leads to dew formation on the module surface, which favors dust coagulation [24]. High humidity can also favor the growth of moss and fungus on the surface of PV modules [21]. Furthermore, at high humidity levels, there is a rise in the vertical adhesion of dust to the glass cover owing to the generated capillary forces between the two. It was observed that due to humidity, capillary adhesion occurred, and dew settled on the surface of modules. For example, Said et al. observed an increase in adhesion to around 80% when the relative humidity level went from 40% to 80% [28]. Also, cementation can occur when the dust particles mix with water and are later heated by the sunlight [28,30].

Vuollekoski et al. [20] mapped the mean number of days for each season in which dew forms on the surface of the earth. In Figure 1B, these are expressed as percentages, ranging from 0% (no days with dew in the season) to 100% (dew present every day of the season). Dew forms in most continental places except hot and deserts, according to the authors. In those locations where more dew is present, there will be more attraction for dust particles. So, vigorous cleaning will be necessary for the coagulated dust from the PV module surface [31].

Eylul et al. [32] observed that dew typically forms on PV module surfaces in semi-arid and tropical environments. The water droplets formed by the dew reduce the transmittance of light through the PV module glass surface. In San Francisco, California, the authors built a south-facing, 30°-tilted solar cell to investigate the impact of dew formation on hour basis. They found that energy production dropped by 53% because of the presence of dew. Increased humidity leads to dew formation, which favors dust coagulation [33].

3.3. Effect of rainfall

Rainfall is often regarded as the most prevalent natural cleaning agent. [34]. However, cleaning effectiveness is known to be affected by rainfall intensity. Many studies have found cleaning thresholds (i.e., the minimum fall of rain needed to realize cleaning effect) ranging from 1 mm/day to 10 mm/day, even if in some cases they can go up to 20 mm/day [23,33].

However, the cleaning mechanisms of rainfall have yet to be fully understood. For example, Pedersen et al. [35] presented a correlation between the amount of precipitation and the observed dust density in Norway. The authors found that a density of deposition 40 mg/m2, even heavy rainfall cannot clean the modules, and the cleaning efficiency saturates.

Mejia et al. [36] analyzed the variation in PV module efficiency due to the events of rainfall in Santa Clara, California, and showed that efficiency drops during the summer drought. The results revealed that events of slight rainfall (< 0.508 mm/day) are not sufficient for cleaning the PV modules but rather maximize dust deposition. The observed efficiency for dust deposition over a 108-day dry spell in the summer was found to drop from 7.2% to 5.6%. As shown in Figure 2A, the first rainfall at the end of that dry period boosted the efficiency to 7.1%. The authors also observed that the first rain after a dry period is more effective at restoring the power output of PV modules than rainfall during a period with significant rain [37]. Rain improves PV performance by 6% in dusty environments. In tropical climates, rain may dramatically impact c-Si PV system performance. Future studies must evaluate the effects of rain on solar PV modules in rapidly changing weather. [38].

A team from the University of Évora studied organic soiling during rainfall for each season in Alentejo, Portugal, and compared cleaned and uncleaned PV modules [39]. The researchers used the soiling ratio and the soiling rate to describe the measured soiling pattern. The first one describes the fractional part of energy left after soiling (1-loss). The Soiling Ratio (SR) on PV modules can be calculated using the short circuit current (Isc, denominated as SRIsc) or the maximum power output (Pmax, denominated as SRPmax), according to the following mathematical equations: (1), (2) & (3).

The authors of [39] found soiling rates of 4.1%/day, 1.9%/day & 1.6%/day in the spring, summer, and fall seasons in Alentejo. They correlated soiling loss with the rain, recording the soiling ratios and rates for one full year, as reported in Figure 2A. The same figure also shows the soiling rates in periods without rainy days, marked in red dashed lines. In Figure 2A, two long-distance desert dust transport occurrences are highlighted, one in February (F, Event) and the other in March (M, Event). In addition, there are three times when there was no rain, marked as SPR (spring seasons S1 and S2), has led to severe soiling rates and, consequently, a drop in soiling ratio. According to the authors, rain plays a vital role not only as a natural cleaning agent but also for aerosol optical depth (AOD), whose pattern is shown in Figure 2B,C. The soiling ratio is close to 1 during the fall and winter due to frequent rain. The F Event in Figure 2D indicates high soiling due to the transportation of dust from the Sahara to South Europe, which caused losses as high as 8%. The M Event, although its lower intensity, resulted in a decline approximately 3% in SR in March. In spring season (SPR) minimum rainfall occurred, leading to a 4.1% drop in both SRIsc & SRPmax. After the heavy rainfall from May to June, the SR indices were restored to unity. But, in the month of July, dust particles settled on the PV glass and decreased the SR to 1.9% because of the less frequent rainfall. As it rained more in August, PV modules were naturally cleaned, improving the soiling ratio. September saw less rain and more soil accumulation. Heavy October rainfall improved soiling, leading to SR~1.

Souza et al. [40] suggest a statistical prediction for PV power generation based on ambient data and PV system soiling. A log-logistic function was used to fit a nonlinear mixed-effects model. Environmental variables may affect model accuracy. The authors measured the suspended particle content and rainfall precipitation for a 10.45 kWp PV plant in Mato Grosso do Sul, Brazil, for 105 days (Figure 2E). The higher rainfall precipitation level had a direct impact on the airborne particle concentrations at observed site. The authors correlate this effect to soiling on the PV modules during the natural cleaning process. The fitted model’s greatest MSE is 0.0032, and a linear correlation of 0.9997 exists between predicted and observed values. 1.4% of the regular soiling loss was estimated.

3.4. Effect of tilt on dust deposition

It can be anticipated that steeper tilt angles would impede the deposition of soiling and facilitate its natural removal, consequently leading to reduced losses compared to surfaces that are closer to horizontal. Negash et al. [41] conducted observations for tilt angles, namely 0°, 5°, 11.6°, 15°, 21.5°, 25°, 30°, and 35°, to quantify this correlation. It was found that the highest PV energy loss (33.5%) occurred at a 0° tilt angle, and that it decreased progressively up to a 25° tilt (14.5%). Afterwards, the energy loss increased to 17.8% at the 30° tilt angle and then decreased to 14.9% at the 35° tilt angle. The unpredicted variation in power loss due to soiling was not clearly justified in the paper. The reason may be due to the non-uniform dust deposition distribution over the glass surface of the PV modules, a phenomenon studied by Qasem et al. [42]. Indeed, the authors observed higher non-uniformity in the dust distribution at a 30° tilt angle compared to 15° tilt angle [42,43].

Hagazy [44] studied the effect of dust deposition on glass plates exposed for one year by changing tilt angles in the Minia region of Egypt. The experiment was carried out with nine glass slides of 3 mm thickness each, keeping one slide constantly clean for reference. The eight glass slides were kept on wooden casings with inclinations β of 0°, 10°, 20°, 30°, 40°, 50°, 60°, and 90°. It was observed that with the increase in the number of days of exposure, the transmittance decreased due to soiling. In the tested glass samples, soiling decreased with an increase in tilt angles. Xu et al. [45] also observed that tilt angles should be optimized to reduce dust depositions, considering the solar position at each geographical location. In general, higher tilt angles should be preferred to reduce soiling.

3.5. Effect of properties of dust

Fine particles tend to deteriorate PV performance more than coarser particles [24]. This is possibly due to two reasons. First, the fine dust elements scatter on the whole PV module plane, leaving very narrow interparticle gaps. Second, high wind blowing removes more coarse particles than fine particles deposited on the module surface. However, larger dust particles settled faster due to gravity [25].

The deposition of soiling, however, also depends on the characteristics of dust and on its interaction with the modules’ surface. For example, once a first dust layer is deposited, it facilitates the deposition of new layers that overlapped [24]. Therefore, the minimization or elimination of the soiling layer is a very critical challenge. Several studies in the literature focused on the impact of various forms of dust and their deposition on solar modules [21,22,46]. A study in Athens, Greece, used two pairs of Poly-Si PV modules (102 Wp) and three dust samples, i.e., ash, red soil, and limestone [22]. The power generation loss was found to vary depending on the various dust types and deposition patterns. The authors calculated the deposition density (∂M) by measuring the weight of the dust collected (∆m), and by dividing it by the active area of the module surface (Ac), as in equation (4):

The authors observed that, as the deposition density of reddish soil fragments increased from 0.12 to 0.35 g/m2, the power output decreased by 4%. Correspondingly, when the observed deposition density of limestone increased from 0.28 to 1.51 g/m2, the power output dropped by 11%. For ash, when deposition density increased from 0.63 to 3.71 g/m2, the power decreased by 2.3%. According to the findings, 0.35 g/m2 of red soil deposition over PV modules reduces energy by 7.5%, whereas the same density for limestone reduces energy by 4%. Even if ash pollutant mass is practically doubled, produced energy is just 2.3% lower. Red soil’s color, composition, and diameter range may hinder the PV module performance [22].

Adinoyi et al. [47] used scanning electron microscope (SEM) micrographs to show that dust particles have diverse asymmetrical structures, which impact the PV module surface as a shading effect in the Eastern Province of Saudi Arabia. The authors analyzed different dust spectra and showed that oxygen (58% by weight) made the largest content of dust followed by calcium (13%), carbon (10%), and sulfur (6%) respectively. Yilbas et al. [48] also performed characterized environmental dust in Dammam, Saudi Arabia, which is a high-humidity area during spring, summer, and autumn. The average particle size of dust was found to be 1.2 µm (varied from the nanometer range to 30µm). The elemental compositions present were Fe, Si, Ca, Mg, Na, K, O, and S. The elements with the highest concentrations were Na, K, Ca, and O. Among these, Cl was found more frequently in the small particles (≤ 2 µm). This might be because the smaller particles remain suspended in the air for longer periods and interact more with the solar radiation, leading to the attachment of ionic compounds in that area. Also, Mishra et al. [49] in Rajasthan, India, on regional atmospheric dust observed the presence of C, N, O, and Si, including rich in NaCl and CaCO3.

Appels et al. [50] examined the physical properties of dust in Belgium with soil samples collected from glass coupons littered with pollen (approx. 60 µm in size). Power losses as high as 4% were registered due to soiling at the experimental site during the five-week of outdoor exposure period only. After regular intervals of rainfall, a little cleaning effect was found for smaller dust particles having 2-10µm of diameter. The authors compared SEM images taken from coupons that were and were not shielded from rain. The SEM images shielded from rain are shown in Figure 3A. Likewise, unshielded SEM images are shown in Figure 3B. The pollens were completely washed away by rain in the unshielded SEM image, but PM2.5 to PM10 seems to have remained after the rainfall. Mahfaud et al. [51] estimated the distribution of particle sizes of different soil samples using a digital microscope (Dino-lite AM4113). The authors compared the observed particle sizes with those reported in the literature, as shown in Table 1. The variation shown in measured grain sizes may be due to the unalike particles present in the dust types of divergent sites. The authors observed PV power losses of up to 16% when dust deposited on the bottom edges of module surfaces.

Conceição et. al., [53] analyzed the PM present in deposited dust in Évora, southern Portugal, through SEM and Energy Dispersive X-ray Spectroscopy. The experiment was performed during a Saharan dust transportation event in Portugal. Figure 3C,D represents the SEM and EDS images for exposed glass samples. Figure 3A shows agglomerated dust particles, which were mostly mixed with aluminosilicates (AS) and halite (NaCl). The other observed particles present in accumulated dust were aluminum, sulfur and chlorine, marked in the color codes of blue, green, and red, correspondingly as shown in Figure 3B. It has been observed there was a ≈3% decrease in both SRIsc and SRPmax for dry deposition of dust for their experimental setup during the period of March 14th to 16th, 2017.

4. Power loss of PV modules due to soiling

Soiling limits the light transmittance of the PV modules, resulting in a loss in energy conversion. In humid environments, different substances, including alkaline metals (e.g., K, Na) and chemicals that are not soluble (e.g., calcite, silica), can form sticky patches on the module surface that (i) reduce the optical transmittance of a glass surface and (ii) affect surface texture and microhardness [23,48]. In addition, dried leaves, bird droppings, etc. may completely block the sunlight if the modules are left unclean [23]. Soiling can also induce partial shading, which might create hot spots. These make up cells act as a resistance to the flow of current generated by the other cells. Hot spots reduce energy efficiency and shorten the module’s lifespan. Also, some additional adverse effects of hotspot formation on the PV cells are cracking of glass, melting of solders, etc. [23]. A bypass diode can be connected in parallel with the opposite polarity of the cell to solve the problem of hot spot creation due to partial shading in solar modules [22].

The studies available in the literature have investigated the effects of soiling on PV modules from two different perspectives. In one case, natural soiling has been collected on PV modules or glass coupons. In the other case, the soiling deposition has been realized indoors, in a controlled environment. These two different categories of studies have been reviewed individually in the two following subsections:

4.1. Study of soiling in outdoors

In general, dust deposition is more observed in tropical regions due to PV modules installed with a lower tilt [54]. In various regions of Spain, soiling loss ranging from 1 to 7% was observed, whereas for dry climatic regions like Kuwait, Cyprus, and Egypt, it was found to be more than 10% [30,35]. It is necessary to formulate the relationship between power drops due to soiling and accumulated dust over a PV module at installation sites. Since dust accumulation per unit area depends on local environment [55], the dust deposition rate can be formulated from the data obtained from PV performance parameters such as Voc, Isc, and FF compared with environmental parameters. Furthermore, analysis can be performed by advanced electronic monitoring tools and sensors present in the market for emerging PV technology [56].

Said [13] observed the performance of a PV module long time outdoor exposure oriented to the south with a tilt angle of 26° in the Dhahran desert, Saudi Arabia. The efficiency of clean and soiled photovoltaic modules were compared. The authors found that the average degradation rate of efficiency was 7% per month due to dust deposition. Numerous pieces of research untill 2021 reported that soiling loss per unit area of PV modules occurred in the vicinity of 2 to 3.7% gm-2 [57]. As previously stated, dust impact degradation is site- and system-dependent; natural cleaning does not eradicate all degradation, and irreversible decrease in maximum power may attain a constant value after a long period of time. [58,59]. Oh et al. [60] have reported a 14.3% reduction in the average power of modules after two months of outdoor exposure in Middle Eastern deserts in Asia. Massi Pavan et al. [61] studied two 1-MW PV systems in the southern Italian countryside and found that the system on sandy soil lost 6.9% of its power in seven weeks while the system on compacted soil lost 1.1%.

Previous research suggests that dust deposition is linked to solar collector tilt angle, period of installation, site geography, wind movement, and dust characteristics. Few studies have examined how PV module features, like cell types and surface materials, affect dust deposition and efficiency deterioration [62]. Likewise, in 2014, Rao et al. [54] conducted a simulated experiment to study the impact of dust on PV modules in Bangalore, India. They found a power loss of 5-6% of the Pmax with a deposition density of 1.4 g/m2 at a cell temperature of 30°C with 800w/m2 radiation.

Lopez et al. [63] carried out a study on the long-term soiling loss of silicon PV modules in Ispra, Northern Italy. They analyzed 28 modules installed from 1981 to 1985, kept unclean, and dismantled in 2014. After cleaning, the value of Pmax improved in the range of 3.5% to 19.4%, averaging 9.8%, indicating a reduction of 0.20% and 0.31% in Isc and Pmax, respectively.

The correlations between deposition density and glass transmittance losses have also been investigated to foster an understanding of the detrimental effects of soiling [49,50]. Pederson et al. [35] used clean glass pieces to study the reduction in transmittance due to soiling for two months of exposure in Kalkbult, South Africa. They used uncoated and anti-soiling coated glass coupons placed on the rooftop at an elevation angle of 45°. There was a finding that the transmittance decreased by 0.09% and 0.11%, respectively, with 10 mg/m2 of dust density. Shehri et al. [64] plotted seven days of observation results by exposing glass samples in the outdoor environment of Thuwal, Saudi Arabia. It was found that the maximum drop in transmittance occurred on the first day (i.e., a 2% reduction in transmittance with respect to clean glass slides). Likewise, Tanesab et al. [65] observed the seasonal effect of dust on the degradation of PV module performance at all inclinations in NTT, Indonesia and Perth, Australia. They found the lowest drop in transmittance at the end of the wet season and the maximum in the summer season.

As can be seen, the soiling losses strongly depend on the local conditions, which vary both geographically and seasonally. In addition, the geometry of the system does impact the soiling accumulation as well. To provide a comprehensive overview of the current knowledge, a list of studies where the impact of natural soiling was assessed in various locations worldwide is reported in Table 2.

4.2. Study of soiling in an artificial environment

In this emerging time of need and optimistic demand for energy, solar PV indoor-based studies are a prerequisite to understanding the soiling phenomenon to optimize power generation as well as economy [66]. Indeed, indoor investigations make it possible to assess PV performance in a controlled environment. In 1993, El–Shobokshy et al. [55] designed a solar simulator with three 1000 W tungsten halogen lamps maintaining constant radiation and surface temperature on PV modules. Experimental dusts (i.e., ground, dried, and sieved), containing materials like calcite and silica, were uniformly spread in the simulator on pre-cleaned modules. The investigation showed that when dust deposition density rose, there was a nonlinear drop in normalized short circuit current and normalized power. At a deposition density of 250 g/m2, the particles with a mean diameter of 80 µm were found to reduce the Isc by 82%, leading to power degradation of about 84%. The fill factor was also affected by dust deposition density. In 1999, Goossens et al. [27] designed a simulator with a wind tunnel and observed that the drop in short circuit current due to soiling in high wind speed conditions was higher compared to low wind speed. It was observed that the voltage and power dropped as the speed of the dust-laden artificial wind increased, whereas no systematic variation was observed for the fill factor of the module. Jiang et al. [62] constructed a test chamber with ESD acrylic plates to simulate the natural dust deposition process virtually, as shown in Figure 4A. A dust generator and a particle counter were utilized to generate dust and measure its concentration within the simulator. Industries, laboratories, and studies of the environment all make use of dust generators to simulate or evaluate dust-related conditions. A small fan was used to spread the dust particles inside the test space. A solar simulator created artificial solar radiation in the range of 0 to 1000W/m2, and a pyranometer was used to measure radiation at various points inside the chamber. The temperature and relative humidity inside the chamber were monitored. The η of the tested module rose linearly from 0 to 26% with a soiling density of 0 to 22 g/m2. The authors also found that surface material can considerably affect dust deposition and accumulation.

Naveed et al. [66] assembled an indoor soiling chamber to investigate dust deposition patterns and losses on PV modules. The overall working system concept with electrical connections and components used is shown in Figure 4B. A PV module was subjected to a daily cycle of outdoor circumstances, and it was observed that after seven days, the module lost 33.54% of its Isc. The suggested soiling station was to investigate optimum soiling loss on PV modules by altering elevation angle and atmospheric conditions.

Rao et al. [54] used a solar simulator made of halogen lamps to study soiling losses on PV modules in a dark room. Power loss from 45% to 55% was observed for a soil density of 7.155 g/m2. Sulaiman et al. [21] investigated the effect of different types of dust particles on cleaned and soiled solar PV modules under different solar insolations. The authors used spotlights to simulate natural radiation conditions by applying varieties of dust, which included moss, talcum, sand, etc. on modules exposed to radiations of 310 W/ m2 and 250 W/m2. Maximum power was found to be lowered by 86% due to moss accumulation on PV modules. Because of their small size, dust particles impede transmission.

Many writers have focused on indoor optical soiling detection approaches that have been validated in real-world soiling situations. [67]. Rahman et al. [68] studied the PV cell performance parameters, including dust on power and efficiency. The authors compared the efficiency degradation caused by increasing the solar cell temperature with and without dust conditions. It was found that efficiency dropped by 1.47% for a soiling rate of 0.012 g/cm2 and a cell temperature at 72.57°C under 800 W/m2 irradiation.

As previously shown in Table 2, the dust deposition patterns and losses vary with different geographic locations, climatic conditions, and types of dust presence. In simulator-type observations, it is not possible to reproduce all the variables that interact with and influence soiling. Despite that, they are equally important as outdoor studies, as they make it possible to analyze and evaluate the impact of specific factors on losses while keeping other variables controlled.

5. Prevention and restoration from soiling of PV modules

5.1. Manual cleaning

PV modules output degrades in high-soiling areas [64,120]. However, low soiling conditions or recurrent precipitation that naturally cleans the surfaces pose a risk for long-term exposure to dust. Differently from other performance issues, soiling can be artificially removed from PV modules, either manually or using cleaning robots. Cleanings, however, have a cost that must be lower than the profits made from the recovered energy to make them viable. So, understanding the magnitude of the losses is an essential step to correctly planning an effective cleaning schedule.

The study by Mani et al. [24] may be consulted for a first estimate of the most favorable cleaning cycle at a given location. The authors categorized three different climatic zones based on the study of dust deposition on field-based samples. The authors identified low-, medium-, and high-latitude regions and different dust deposition behaviors, and for each category, they reported recommended mitigation tools and cleaning cycles.

Yu Jiang et al. [121] estimated the cleaning rate of PV modules in a desert area (located at low latitudes; the chosen elevation angle was equal to 0°) based on dust deposition rate and the relationship between deposited dust concentration. The authors found that a 20-day cleaning frequency at the investigated site restored a power output reduction of 5% for a 100 µg/m3 particle concentration of dust. The authors of [121] also proposed a method to assess the most effective cleaning interval for different particle sizes and tilt angles. Indeed, gravity impacts glass dust deposition. Due to Brownian and turbulent diffusion, frequent cleaning is required for areas with high-diameter dust particles. Brownian and turbulent diffusion both contribute to the overall soiling process, but their relative impact is determined by particle size and atmospheric conditions. The authors estimated cleaning interval time (Ti) using equation (4). Md represents the particle accumulation density for certain energy losses, Cd represents the particle mass concentration in the ambient air at a particular location, and Vd, represents the particle deposition velocity.

Ti = Md / (Cd × Vd.)

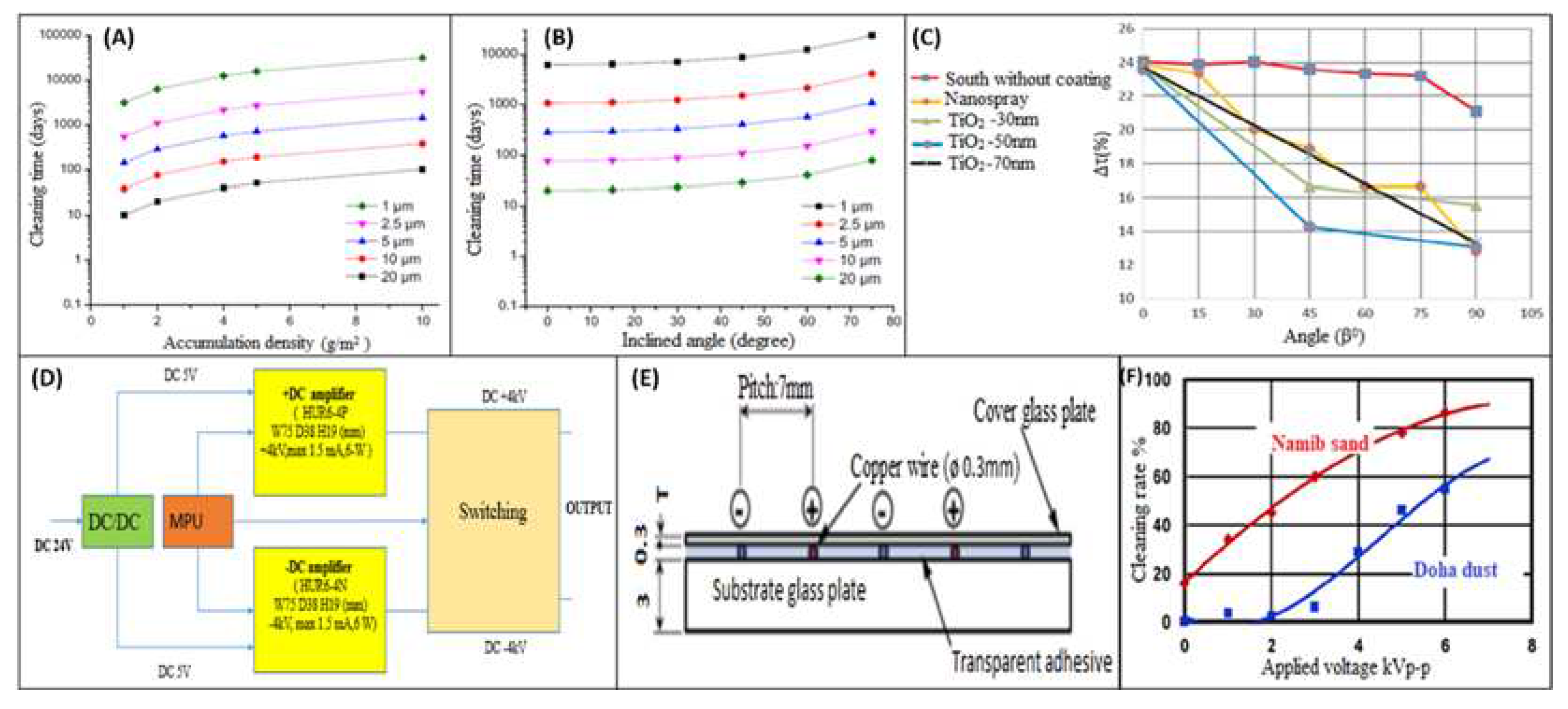

Figure 5A shows that cleaning times increased with particle accumulation density. In Figure 5B, the authors tested tilt angle effects on cleaning time. The inclined angle increases cleaning time, which also relies on particle concentration and diameter. The authors used a novel method to compute cleaning time that excludes rainfall to present site-based results. Therefore, the approach works in dry environments. The cleaning time for 5 µm, 10 µm, and 20 µm dust particulates with wind speeds ranging from 1 to 10 m/s was determined to be 287, 76, and 20 days, respectively. The authors determined the cleaning time to be 287, 76, and 20 days for 5 µm, 10 µm, and 20 µm dust particulates at wind speeds ranging from 1 to 10 m/s.

5.2. Natural cleaning

Soiling on PV modules can also be cleaned at no cost by natural processes like rainfall, wind, gravitational forces, and melting snow. As aforementioned, among these cleaning mechanisms, rainfall is the most effective and common one. Snowmelt and enough rain may restore a PV module’s power output. Furthermore, smart tracking solutions can be incorporated to enhance the cleaning process through rain [121]. However, it has been observed that slick mud puddles can form on the surface of solar modules just after light rainfall [120]. Also, in arid and semi-arid zones, rainfall effects are irregular and low. Likewise, occasional rainfall events in desert lands, including semi-arid zones, cannot clean PV modules [121]. High wind speed is another natural cleaning process that can remove larger dust particles from solar PV modules, but it is restricted to seasonal durations and high tilt angles [120]. Moreover, the cleaning effectiveness depends on the dust particle diameter and microstructure of the dust layer. Indeed, the force to remove dirt from module surfaces is restricted by the air velocity in the boundary-layer and ineffective for particles under 50 mm diameter at free stream velocities less than 50 m/s [109,121].

5.3. Passive cleaning

As an alternative to manual cleanings, operators can try to prevent soil deposition, facilitate its removal, or adopt automated cleaning technologies. Various solutions have been proposed over the years, reaching different stages of development. Their status, limitations, and potential are assessed in the following subsections:

5.3.1. Anti-soiling coatings

Anti-soiling coatings may be used as passive measures to reduce dust adherence on PV module surfaces[123,124,125]. To protect the PV system from dust deposition, hydrophobic and hydrophilic self-cleaning coatings may be used [1]. Magnum et al. [126] performed a study on the feasibility of anti-soiling coatings for solar cell glass covers in Brazil, Italy, and Spain. They developed and tested super hydrophilic sol-gel films composed of TiO2/SiO2, super hydrophilic e-beam evaporation films composed of TiO2, and hydrophobic sol-gel films composed of functionalized SiO2. The TiO2/SiO2 layers had a superhydrophilic character with water contact angles about 0°, whereas the functionalized SiO2 presented hydrophobic properties. The comparative soiling testing emphasized the importance of developing anti-soiling techniques in a drier climate region. The authors observed that in the driest periods, the transmittance losses were halved when the TiO2/SiO2 coating was employed. Gholami et al. [127] observed transmittance losses of up to 22% affected by the accumulation of dust on a PV module surface over a 70 day test period. They also proposed a nanospray coating with titanium dioxide to reduce dust deposition and tested it at the facilities of the Isfahan University of Technology (Isfahan, Iran). The hydrophobic film was created by nano spray on the sample surface, and TiO2 was coated in three different thicknesses to create a hydrophilic film. The transmittance of each sample was measured after 70 days for different tilt angles, as illustrated in Figure 5C. The samples installed at 0° to 90° tilt angles show the best performance when surface modifications are done in no-rain conditions. The authors found that the amount of dust that settled on the sample surface decreased by 41%, with a 24% loss in transmission efficiency. A TiO2 layer with a thickness of 50 nm worked the best after 70 days. It was also found that, in addition to having a better self-cleaning property, the TiO2 nanofilms are more permanent, while nano-spray coatings should be reinstated after two years. The findings have not optimized the thickness of the coatings, the durability of anti-soiling behaviors in the long run, or cost-effectiveness.

Anti-soiling coatings are an effective approach to make the module’s surface either highly hydrophobic or very hydrophilic [16,123,125]. However, this method has proven to have a short lifespan and to be site-dependent in terms of both effectiveness and durability [128,129]. Another disadvantage of these approaches is that re-application of coatings may reduce the transmittance of PV glass, and dust adhesion is heavily reliant on the electrostatic characteristics of the coating. Also, the market segment has yet to produce acceptable coatings with multifunctional properties such as anti-reflection and anti-soiling [130,131].

5.3.2. Electrodynamics screens (EDS)

Cleaning dust off solar PV modules is a difficult process since it requires labor, the use of natural resources such as water, the expense of the technology utilized, and its dependability [132,133]. The use of integrated EDS is a recent breakthrough for self-cleaning solar modules. The EDS technique does not require mechanical movement, water, or labor for cleaning [134]. In EDS, an electrodynamic field is generated to repel the particles from the PV surface with minimum power consumption. The EDS is a thin layer of electrodes, either straight or complicated, produced on a substrate. Electrodes are isolated from the air by a transparent, dielectric thin sheet. Standing or traveling waves can be used on EDS. Dust is moved horizontally by traveling waves, whereas standing waves move it upward and downward. The traveling-waves system needs a voltage booster circuit to produce alternating high voltages [1]. Jennifer et al. [135] proposed a computational model to simulate micro-scale particle interactions to optimize an electrodynamic dust shield for desert area applications. The authors computationally simulated the transit, collision, and adhesion of the charged particles, which were a representation of the soiling in Doha, Qatar, using the discrete element approach. Two-phase waves were modeled on an inclined EDS. The simulation showed the optimal distance between electrodes, voltage, and dust transport distance per cycle, as well as different ways dust particles were repelled and attracted by electrodes under different conditions that produced different transport patterns to minimize dust deposition on solar modules. The present limitations of the use of EDS consist of their early development stage and the limited conditions in which they can operate (i.e., RH < 50%). Furthermore, the durability of this technique has not yet been demonstrated and requires further investigation [136]. Extensive research aims to identify and characterize key parameters that influence EDS cleansing efficiency, increase electrode optical transmission and conductivity, and develop scalable electrode coatings. Fine dust particle removal efficiency must be enhanced while optimizing power consumption; theoretical models constructed to compute cleaning efficiency for simulated EDS must be experimentally validated further; and new materials must be explored for electrode production on a large scale [137].

5.3.3. Electrostatic cleaning

Hiroyuki et al. [122] suggested an electrostatic cleaning method that delivered a two-phase high voltage to parallel wire electrodes implanted in the glass plate of a PV module to remove dust from the surfaces of solar modules. The process of high voltage source applied in the experimental set is shown in Figure 5D,E shows a cross-sectional drawing of the cleaning equipment with cover glass plate thickness. They conducted the experiment in an air-conditioned laboratory, maintaining a temperature of 20–27°C and a relative humidity of 40–60%, using dust samples from Namib and Doha. The sample diameter of the Namib dust was 200–300 μm and the Doha dust was about 6 to 10 μm. The system enhances performance by applying high voltage, reducing the adhesion force, and operating it frequently. The authors assessed the high-voltage source’s frequency response and actual power consumption in order to provide data for system design and efficiency evaluation. As shown in Figure 5F, 15% of Namib dust particles slipped down from the slanted glass plate without voltage, but applying a high voltage increased performance to 90%. Doha dust samples did not fall until high voltages were applied. Even at high voltage, the adhesive force hindered small cleanings of Doha dust particles. This supports the previous finding that tiny particles have a larger adhesion force than the Coulomb driving force. Thus, minute particles stick to the glass plate, reducing the cleaning system’s efficiency. The electrostatic force applied to the particle was outweighed by the adhesion force between the particle and the glass plate; hence, the plate could not be cleaned with a low applied voltage (2 kVp-p). A large-scale solar PV plant’s technology must be tested in desert, dry, and semi-arid regions.

5.3.4. Robotics-based cleaning

Robotics-based cleaning technology can automate both cleaning and scrubbing [138,139]. Robots are currently commercially available and are already in use in large solar power plant facilities in the Middle East [34,140]. A dry-cleaning robotic device was designed for use in the UAE. This robot had its own battery, charged by solar panels. This device had soft microfiber brushes as a cleaning tool. The robot was equipped with four wheels, a rain detection sensor, a controller, and three stepper motors [1]. Parrott et al. [141] developed a robotic dry cleaner and conducted a study of its effectiveness using a silicone rubber brush to clean solar PV modules in Thuwal, Saudi Arabia. The authors claimed the effectiveness of cleaning module surfaces using a silicone rubber foam brush in the automated cleaning technology compared to monthly or weekly cleaning, but might not consider the power consumption for the said design.

Ahmed et al. [142] created a dry-cleaning robot for Egypt to remove soiling from PV modules. A machine vision camera actuated a microcontroller, which ran the robot. A cleaning hold head was linked to a microfiber bush for cleaning operations. Color differences for various densities of dust deposition were used to create the control mechanism. The cleaning robot was put through three levels of dust density testing: basic (43.69 g/m2), moderate (61.19 g/m2), and intensive (75.23 g/m2). The authors discovered efficiency enhancements of 1.09%, 7.31%, and 37.89% for simple, moderate, and strong dust concentrations, respectively.

Al Shehri et al. [64] mentioned that choosing an optimal brush type is important to meet the required level of cleaning while preventing abrasion, which can lead to the degradation of the transmittance. To address the issues of severe climatic conditions, tough roadways, and incomplete dust particle cleaning on solar module surfaces, an improved robotic cleaning system might be a solution [143].Furthermore, robotic devices consume power, resulting in high operation and maintenance costs, which may not be cost-effective in some applications [144].

5.3.5. High-pressure water jet

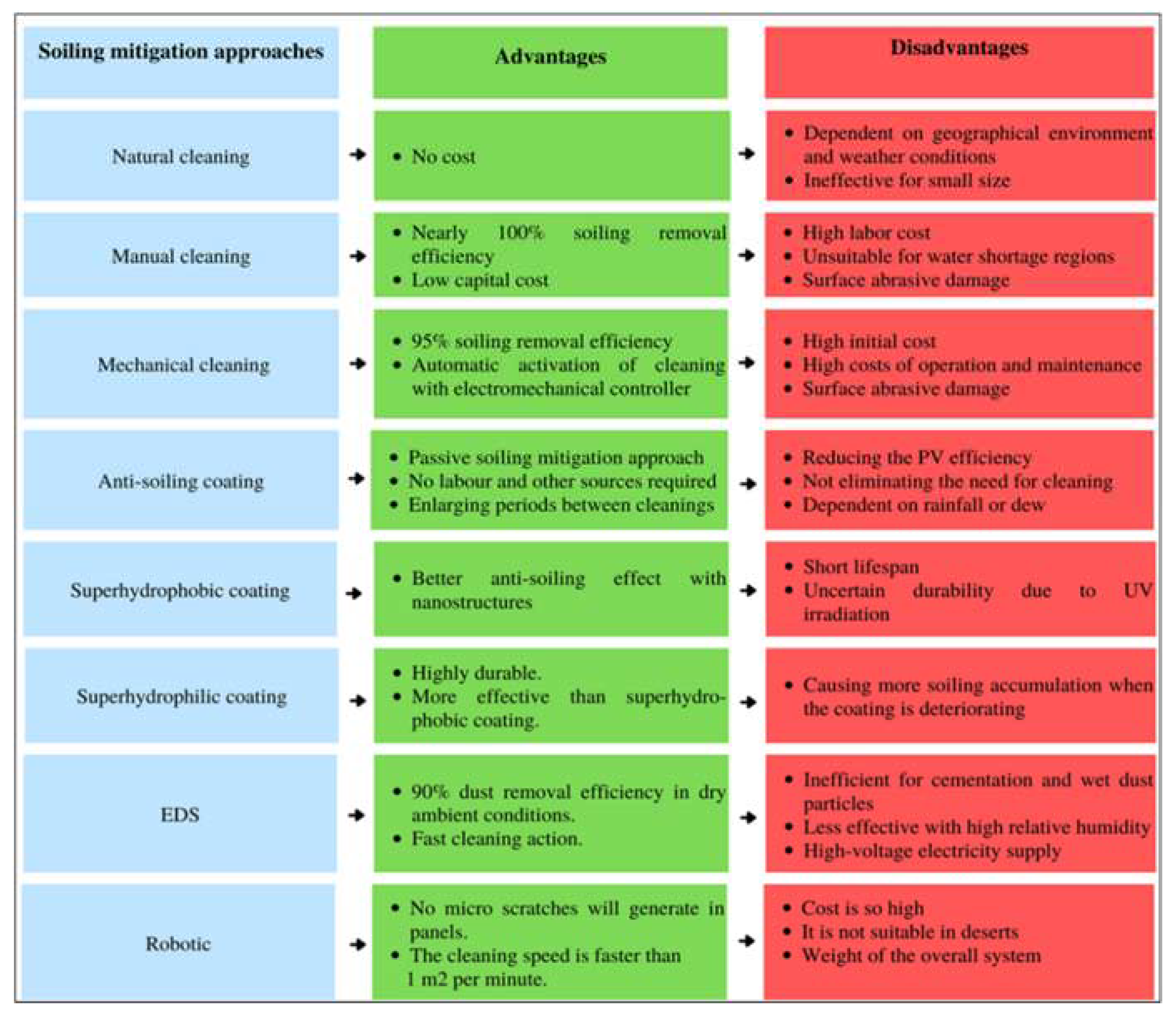

A commonly used method for cleaning solar PV modules nowadays is high-pressure water jets and controlled water sprays [145]. In these processes, cleaning is performed by automatically or manually activating a well-designed pump. Water washing improves module performance in two ways: it lowers cell operating temperature and gets rid of soiling. Moharram et al. [104] observed the influence of cleaning using liquid (water containing surfactants) on dust-deposited solar PV modules. The cell efficiency was preserved at a constant level after the application of water spray and surfactants made of a mixture of anionic and cationic surfactants. The main drawbacks of these processes are the need for water resources and surfactants and the not yet cost-effective scalability of the process. Desert regions have a very limited supply of water, and the surfactants used for cleaning are bad for the environment and might eventually degrade the transmittance of the solar module’s glass cover. Organic salts may form sticky-like coatings on the surface of PV modules if they are not removed. So, the water spraying process does not necessarily provide uniform cleaning and requires trained labor to avoid scratches when scrubbing with a brush. Also, the power required to drive the high-pressure pumps is also a determinant factor for the PV power plant applied by these processes [104]. In Figure 6 the different cleaning techniques and systems for PV systems are showcased with their advantages and disadvantages [146].

6. Recommendation for the future direction of research

To create efficient soiling mitigation and prevention strategies, it is difficult to understand the connections between dust particle physical characteristics, deposition patterns, and PV module performance. So, research and development are still fundamental to addressing needs and challenges related to dust issues in solar PV systems. Additionally, there are several issues that need more research, including the use of natural resources for cleaning, the deterioration of PV glass surfaces caused by dust, the site-specificity of dust particle composition and size distribution, and the effects of cleaning on PV module glass surfaces.

From numerous studies, we can observe that the current cleaning tools and technologies are not properly utilized in PV power plants because of technological, technical, or economic constraints [138,139,141,145,146]. It has been observed that the electrostatic cleaning system and the water-free automated solar cleaning system are the most effective in cleaning [146]. If a new method is developed that combines both (an electrostatic cleaning system and water-free automated solar cleaning system), it will be more efficient [139,141]. More research should be conducted on it to build the most economically acceptable and efficient one. Novel anti-soiling and cleaning technologies can still be developed and need further research to improve their techno-economic viability and reliability.

7. Conclusion

Soiling (i.e., dust deposition) is a major concern for PV power systems, as it affects their efficiency and their economics. Soiling does not only reduce the transmittance of the glass but may also cause permanent degradation as it can lead to the formation of hot spots and abrasion. In this work, the factors that govern soiling on PV modules are discussed based on earlier studies’ findings, and the losses reported in the literature for various locations are assessed. Some indoor studies have been carried out to understand the effect of environmental circumstances on soiling, but these are not sufficient yet to identify long-term dust deposition patterns for a given location. The advantages and disadvantages of different mitigation techniques and tools have been discussed in earlier observations and designs. Overall, it is found that the effects of soiling and mitigation activities on the glass surface of PV modules still require some more in-depth analyses.

Data Availability Statement

Data sharing is not applicable to this article as no new data was created or analyzed in this study.

Acknowledgments

Leonardo Micheli was supported by Sole4PV, a project funded by the Italian Ministry of University and Research under the 2019 «Rita Levi Montalcini » Program for Young Researchers.

Nomenclature

| ∂M | Deposition density (g/m2) |

| ∆m | Weight of dust collected (gm) |

| Ac | Area of module surface (m2) |

| AOD | Aerosol optical depth |

| Cd | Particle mass concentration |

| E | Energy (J) |

| FF | Fill factor |

| G | Irradiance over PV module surface |

| G0 | Irradiance at Standard Test Conditions (STC) |

| Isc | Short circuit current (A) |

| Isc at STC of the dusty module (A) | |

| Isc at STC of the clean module (A) | |

| Isc of the clean PV module (A) | |

|

Md MSE |

Dust accumulation density (g/m2) Maximum mean squared error |

| PM | Particulate Matter (PMx) |

| Pmax | Maximum power (W) |

| Maximum power at clean condition (W) | |

| Maximum power of the soiled PV module (W) | |

| Pout | Output power (W) |

| RM | Relative humidity |

| SEM | Scanning Electron Microscope |

| SR | Soiling Ratio |

| SRIsc | Short circuit current on soiling (A) |

| SRPmax | Maximum power output on soiling (W) |

| T | Transmission of light |

| cleaned module temperature (°C) | |

| soiled module temperature (°C) | |

| T0 | Temperature at 25°C |

| Ti | Cleaning interval time (Day) |

| Vd | Dust deposition velocity (m/s) |

| Voc | Open circuit voltage |

| α | Short-circuit temperature correction coefficient |

| γ | Maximum power temperature correction coefficient |

| η | Efficiency PV module (%) |

References

- Ghosh, A. Soiling losses: A barrier for India’s energy security dependency from photovoltaic power. Challenges 2020, 11, 9. [Google Scholar] [CrossRef]

- Cabanillas, R.; Munguía, H. Dust accumulation effect on efficiency of Si photovoltaic modules. Journal of Renewable and Sustainable Energy 2011, 3, 043114. [Google Scholar] [CrossRef]

- Comello, S.; Reichelstein, S.; Sahoo, A. The road ahead for solar PV power. Renewable and Sustainable Energy Reviews 2018, 92, 744–756. [Google Scholar] [CrossRef]

- Sarver, T.; Al-Qaraghuli, A.; Kazmerski, L.L. A comprehensive review of the impact of dust on the use of solar energy: History, investigations, results, literature, and mitigation approaches. Renewable and sustainable energy Reviews 2013, 22, 698–733. [Google Scholar] [CrossRef]

- Toth, S.; Muller, M.; Miller, D.C.; Moutinho, H.; To, B.; Micheli, L.; Linger, J.; Engtrakul, C.; Einhorn, A.; Simpson, L. Soiling and cleaning: Initial observations from 5-year photovoltaic glass coating durability study. Solar Energy Materials and Solar Cells 2018, 185, 375–384. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, C.; Tang, Y.; Zheng, F.; Meng, M.; Miao, C. Criteria for particles to be levitated and to move continuously on traveling-wave electric curtain for dust mitigation on solar panels. Renewable energy 2018, 119, 410–420. [Google Scholar] [CrossRef]

- Laarabi, B.; Sankarkumar, S.; Rajasekar, N.; El Baqqal, Y.; Barhdadi, A. Modeling investigation of soiling effect on solar photovoltaic systems: New findings. Sustainable Energy Technologies and Assessments 2022, 52, 102126. [Google Scholar] [CrossRef]

- Dahlioui, D.; Laarabi, B.; Barhdadi, A. Review on dew water effect on soiling of solar panels: Towards its enhancement or mitigation. Sustainable Energy Technologies and Assessments 2022, 49, 101774. [Google Scholar] [CrossRef]

- Raillani, B.; Chaatouf, D.; Salhi, M.; Amraqui, S.; Mezrhab, A. Effect of wind barrier height on the dust deposition rate of a ground-mounted photovoltaic panel. Sustainable Energy Technologies and Assessments 2022, 52, 102035. [Google Scholar] [CrossRef]

- Khodakaram-Tafti, A.; Yaghoubi, M. Experimental study on the effect of dust deposition on photovoltaic performance at various tilts in semi-arid environment. Sustainable Energy Technologies and Assessments 2020, 42, 100822. [Google Scholar] [CrossRef]

- Derakhshandeh, J.F.; AlLuqman, R.; Mohammad, S.; AlHussain, H.; AlHendi, G.; AlEid, D.; Ahmad, Z. A comprehensive review of automatic cleaning systems of solar panels. Sustainable Energy Technologies and Assessments 2021, 47, 101518. [Google Scholar] [CrossRef]

- Tsoar, H. Bagnold, RA 1941: The physics of blown sand and desert dunes. London: Methuen. Progress in physical geography 1994, 18, 91–96. [Google Scholar] [CrossRef]

- Said, S. Effects of dust accumulation on performances of thermal and photovoltaic flat-plate collectors. Applied Energy 1990, 37, 73–84. [Google Scholar] [CrossRef]

- Al-Alawy, I.T. Wind and other factor requirements to solar energy applications in Iraq. Solar & Wind Technology 1990, 7, 597–600. [Google Scholar] [CrossRef]

- Biryukov, S. An experimental study of the dry deposition mechanism for airborne dust. Journal of Aerosol Science 1998, 29, 129–139. [Google Scholar] [CrossRef]

- Arabatzis, I.; Todorova, N.; Fasaki, I.; Tsesmeli, C.; Peppas, A.; Li, W.X.; Zhao, Z. Photocatalytic, self-cleaning, antireflective coating for photovoltaic panels: Characterization and monitoring in real conditions. Solar Energy 2018, 159, 251–259. [Google Scholar] [CrossRef]

- Asl-Soleimani, E.; Farhangi, S.; Zabihi, M. The effect of tilt angle, air pollution on performance of photovoltaic systems in Tehran. Renewable Energy 2001, 24, 459–468. [Google Scholar] [CrossRef]

- Ghazi, S.; Sayigh, A.; Ip, K. Dust effect on flat surfaces–A review paper. Renewable and Sustainable Energy Reviews 2014, 33, 742–751. [Google Scholar] [CrossRef]

- Li, X.; Mauzerall, D.L.; Bergin, M.H. Global reduction of solar power generation efficiency due to aerosols and panel soiling. Nature Sustainability 2020, 3, 720–727. [Google Scholar] [CrossRef]

- Vuollekoski, H.; Vogt, M.; Sinclair, V.; Duplissy, J.; Järvinen, H.; Kyrö, E.; Makkonen, R.; Petäjä, T.; Prisle, N.; Räisänen, P. Estimates of global dew collection potential. Hydrol. Earth Syst. Sci. Discuss 2014, 11, 9519–9549. [Google Scholar] [CrossRef]

- Sulaiman, S.A.; Singh, A.K.; Mokhtar, M.M.M.; Bou-Rabee, M.A. Influence of dirt accumulation on performance of PV panels. Energy Procedia 2014, 50, 50–56. [Google Scholar] [CrossRef]

- Kaldellis, J.; Fragos, P.; Kapsali, M. Systematic experimental study of the pollution deposition impact on the energy yield of photovoltaic installations. Renewable energy 2011, 36, 2717–2724. [Google Scholar] [CrossRef]

- Maghami, M.R.; Hizam, H.; Gomes, C.; Radzi, M.A.; Rezadad, M.I.; Hajighorbani, S. Power loss due to soiling on solar panel: A review. Renewable and Sustainable Energy Reviews 2016, 59, 1307–1316. [Google Scholar] [CrossRef]

- Mani, M.; Pillai, R. Impact of dust on solar photovoltaic (PV) performance: Research status, challenges and recommendations. Renewable and sustainable energy reviews 2010, 14, 3124–3131. [Google Scholar] [CrossRef]

- Said, S.A.; Hassan, G.; Walwil, H.M.; Al-Aqeeli, N. The effect of environmental factors and dust accumulation on photovoltaic modules and dust-accumulation mitigation strategies. Renewable and Sustainable Energy Reviews 2018, 82, 743–760. [Google Scholar] [CrossRef]

- Mekhilef, S.; Saidur, R.; Kamalisarvestani, M. Effect of dust, humidity and air velocity on efficiency of photovoltaic cells. Renewable and sustainable energy reviews 2012, 16, 2920–2925. [Google Scholar] [CrossRef]

- Goossens, D.; Offer, Z.Y.; Zangvil, A. Wind tunnel experiments and field investigations of eolian dust deposition on photovoltaic solar collectors. Solar energy 1993, 50, 75–84. [Google Scholar] [CrossRef]

- Said, S.A.; Walwil, H.M. Fundamental studies on dust fouling effects on PV module performance. Solar Energy 2014, 107, 328–337. [Google Scholar] [CrossRef]

- Ramli, M.A.; Prasetyono, E.; Wicaksana, R.W.; Windarko, N.A.; Sedraoui, K.; Al-Turki, Y.A. On the investigation of photovoltaic output power reduction due to dust accumulation and weather conditions. Renewable Energy 2016, 99, 836–844. [Google Scholar] [CrossRef]

- Corn, M. The adhesion of solid particles to solid surfaces, I. A review. Journal of the Air Pollution Control Association 1961, 11, 523–528. [Google Scholar] [CrossRef]

- Isaifan, R.J.; Johnson, D.; Ackermann, L.; Figgis, B.; Ayoub, M. Evaluation of the adhesion forces between dust particles and photovoltaic module surfaces. Solar Energy Materials and Solar Cells 2019, 191, 413–421. [Google Scholar] [CrossRef]

- Simsek, E.; Williams, M.J.; Pilon, L. Effect of dew and rain on photovoltaic solar cell performances. Solar Energy Materials and Solar Cells 2021, 222, 110908. [Google Scholar] [CrossRef]

- Beysens, D. Estimating dew yield worldwide from a few meteo data. Atmospheric research 2016, 167, 146–155. [Google Scholar] [CrossRef]

- Ilse, K.; Micheli, L.; Figgis, B.W.; Lange, K.; Daßler, D.; Hanifi, H.; Wolfertstetter, F.; Naumann, V.; Hagendorf, C.; Gottschalg, R. Techno-economic assessment of soiling losses and mitigation strategies for solar power generation. Joule 2019, 3, 2303–2321. [Google Scholar] [CrossRef]

- Pedersen, H.; Strauss, J.; Selj, J. Effect of soiling on photovoltaic modules in Norway. Energy Procedia 2016, 92, 585–589. [Google Scholar] [CrossRef]

- Mejia, F.; Kleissl, J.; Bosch, J. The effect of dust on solar photovoltaic systems. Energy Procedia 2014, 49, 2370–2376. [Google Scholar] [CrossRef]

- Valerino, M.; Ratnaparkhi, A.; Ghoroi, C.; Bergin, M. Seasonal photovoltaic soiling: Analysis of size and composition of deposited particulate matter. Solar Energy 2021, 227, 44–55. [Google Scholar] [CrossRef]

- Del Pero, C.; Aste, N.; Leonforte, F. The effect of rain on photovoltaic systems. Renewable Energy 2021, 179, 1803–1814. [Google Scholar] [CrossRef]

- Conceição, R.; Silva, H.G.; Mirão, J.; Collares-Pereira, M. Organic soiling: the role of pollen in PV module performance degradation. Energies 2018, 11, 294. [Google Scholar] [CrossRef]

- Souza, G.; Santos, R.; Saraiva, E. A Log-Logistic Predictor for Power Generation in Photovoltaic Systems. Energies 2022, 15, 5973. [Google Scholar] [CrossRef]

- Negash, T.; Tadiwose, T. Experimental investigation of the effect of tilt angle on the dust photovoltaic module. Int. J. Energy Power Eng 2015, 4, 227–231. [Google Scholar] [CrossRef]

- Qasem, H.; Betts, T.R.; Müllejans, H.; AlBusairi, H.; Gottschalg, R. Dust-induced shading on photovoltaic modules. Progress in Photovoltaics: Research and Applications 2014, 22, 218–226. [Google Scholar] [CrossRef]

- Costa, S.C.S.; Kazmerski, L.L.; Diniz, A.S.A. Impact of soiling on Si and CdTe PV modules: Case study in different Brazil climate zones. Energy Conversion and Management: X 2021, 10, 100084. [Google Scholar] [CrossRef]

- Hegazy, A.A. Effect of dust accumulation on solar transmittance through glass covers of plate-type collectors. Renewable energy 2001, 22, 525–540. [Google Scholar] [CrossRef]

- Xu, R.; Ni, K.; Hu, Y.; Si, J.; Wen, H.; Yu, D. Analysis of the optimum tilt angle for a soiled PV panel. Energy Conversion and Management 2017, 148, 100–109. [Google Scholar] [CrossRef]

- El-Shobokshy, M.S.; Hussein, F.M. Degradation of photovoltaic cell performance due to dust deposition on to its surface. Renewable energy 1993, 3, 585–590. [Google Scholar] [CrossRef]

- Adinoyi, M.J.; Said, S.A. Effect of dust accumulation on the power outputs of solar photovoltaic modules. Renewable energy 2013, 60, 633–636. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Ali, H.; Al-Aqeeli, N.; Khaled, M.M.; Said, S.; Abu-Dheir, N.; Merah, N.; Youcef-Toumi, K.; Varanasi, K.K. Characterization of environmental dust in the Dammam area and mud after-effects on bisphenol-A polycarbonate sheets. Scientific reports 2016, 6, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.K.; Agnihotri, R.; Yadav, P.K.; Singh, S.; Prasad, M.; Praveen, P.S.; Tawale, J.S.; Mishra, N.D.; Arya, B.C.; Sharma, C. Morphology of atmospheric particles over Semi-Arid region (Jaipur, Rajasthan) of India: Implications for optical properties. Aerosol and air quality research 2015, 15, 974–984. [Google Scholar] [CrossRef]

- Appels, R.; Lefevre, B.; Herteleer, B.; Goverde, H.; Beerten, A.; Paesen, R.; De Medts, K.; Driesen, J.; Poortmans, J. Effect of soiling on photovoltaic modules. Solar energy 2013, 96, 283–291. [Google Scholar] [CrossRef]

- Abderrezek, M.; Fathi, M. Experimental study of the dust effect on photovoltaic panels’ energy yield. Solar Energy 2017, 142, 308–320. [Google Scholar] [CrossRef]

- Kaldellis, J.K.; Kapsali, M. Simulating the dust effect on the energy performance of photovoltaic generators based on experimental measurements. Energy 2011, 36, 5154–5161. [Google Scholar] [CrossRef]

- Conceicao, R.; Silva, H.G.; Mirao, J.; Gostein, M.; Fialho, L.; Narvarte, L.; Collares-Pereira, M. Saharan dust transport to Europe and its impact on photovoltaic performance: A case study of soiling in Portugal. Solar Energy 2018, 160, 94–102. [Google Scholar] [CrossRef]

- Rao, A.; Pillai, R.; Mani, M.; Ramamurthy, P. Influence of dust deposition on photovoltaic panel performance. Energy Procedia 2014, 54, 690–700. [Google Scholar] [CrossRef]

- Fernández-Solas, Á.; Montes-Romero, J.; Micheli, L.; Almonacid, F.; Fernández, E.F. Estimation of soiling losses in photovoltaic modules of different technologies through analytical methods. Energy 2022, 244, 123173. [Google Scholar] [CrossRef]

- Bessa, J.G.; Micheli, L.; Almonacid, F.; Fernández, E.F. Monitoring photovoltaic soiling: assessment, challenges, and perspectives of current and potential strategies. Iscience 2021, 24, 102165. [Google Scholar] [CrossRef]

- Javed, W.; Guo, B.; Figgis, B.; Aïssa, B. Dust potency in the context of solar photovoltaic (PV) soiling loss. Solar Energy 2021, 220, 1040–1052. [Google Scholar] [CrossRef]

- Micheli, L.; Theristis, M.; Livera, A.; Stein, J.S.; Georghiou, G.E.; Muller, M.; Almonacid, F.; Fernández, E.F. Improved PV soiling extraction through the detection of cleanings and change points. IEEE Journal of Photovoltaics 2021, 11, 519–526. [Google Scholar] [CrossRef]

- Nimmo, B.; Said, S.A. Effects of dust on the performance of thermal and photovoltaic flat plate collectors in Saudi Arabia: preliminary results. Altern. Energy Sources;(United States) 1981, 1. [Google Scholar]

- Oh, W.; Kang, B.; Choi, S.; Bae, S.; Jeong, S.; Kim, S.M.; Lee, H.-S.; Kim, D.; Hwang, H.; Chan, S.-I. Evaluation of anti-soiling and anti-reflection coating for photovoltaic modules. Journal of Nanoscience and Nanotechnology 2016, 16, 10689–10692. [Google Scholar] [CrossRef]

- Pavan, A.M.; Mellit, A.; De Pieri, D. The effect of soiling on energy production for large-scale photovoltaic plants. Solar energy 2011, 85, 1128–1136. [Google Scholar] [CrossRef]

- Jiang, H.; Lu, L.; Sun, K. Experimental investigation of the impact of airborne dust deposition on the performance of solar photovoltaic (PV) modules. Atmospheric environment 2011, 45, 4299–4304. [Google Scholar] [CrossRef]

- Lopez-Garcia, J.; Pozza, A.; Sample, T. Long-term soiling of silicon PV modules in a moderate subtropical climate. Solar Energy 2016, 130, 174–183. [Google Scholar] [CrossRef]

- Al Shehri, A.; Parrott, B.; Carrasco, P.; Al Saiari, H.; Taie, I. Impact of dust deposition and brush-based dry cleaning on glass transmittance for PV modules applications. Solar Energy 2016, 135, 317–324. [Google Scholar] [CrossRef]

- Tanesab, J.; Parlevliet, D.; Whale, J.; Urmee, T. Seasonal effect of dust on the degradation of PV modules performance deployed in different climate areas. Renewable Energy 2017, 111, 105–115. [Google Scholar] [CrossRef]

- Hussain, N.; Shahzad, N.; Yousaf, T.; Waqas, A.; Javed, A.H.; Khan, S.; Ali, M.; Liaquat, R. Designing of homemade soiling station to explore soiling loss effects on PV modules. Solar Energy 2021, 225, 624–633. [Google Scholar] [CrossRef]

- Fernández-Solas, Á.; Micheli, L.; Almonacid, F.; Fernández, E.F. Indoor validation of a multiwavelength measurement approach to estimate soiling losses in photovoltaic modules. Solar Energy 2022, 241, 584–591. [Google Scholar] [CrossRef]

- Rahman, M.; Hasanuzzaman, M.; Rahim, N.A. Effects of various parameters on PV-module power and efficiency. Energy Conversion and Management 2015, 103, 348–358. [Google Scholar] [CrossRef]

- Al-Kouz, W.; Al-Dahidi, S.; Hammad, B.; Al-Abed, M. Modeling and analysis framework for investigating the impact of dust and temperature on PV systems’ performance and optimum cleaning frequency. Applied Sciences 2019, 9, 1397. [Google Scholar] [CrossRef]

- Simal Pérez, N.; Alonso-Montesinos, J.; Batlles, F.J. Estimation of soiling losses from an experimental photovoltaic plant using artificial intelligence techniques. Applied Sciences 2021, 11, 1516. [Google Scholar] [CrossRef]

- KHOSHAIM, B.H. Performance characteristics of 350 kW photovoltaic power system for Saudi Arabian villages. International Journal of Solar Energy 1982, 1, 91–103. [Google Scholar] [CrossRef]

- Riaz, M.H.; Mahmood, T. Experimental Analysis of Soiling Loss on PV Module in Cement Plant Environment. Engineering Proceedings 2022, 20, 13. [Google Scholar] [CrossRef]

- Sayyah, A.; Horenstein, M.N.; Mazumder, M.K. Energy yield loss caused by dust deposition on photovoltaic panels. Solar Energy 2014, 107, 576–604. [Google Scholar] [CrossRef]

- Romero-Fiances, I.; Muñoz-Cerón, E.; Espinoza-Paredes, R.; Nofuentes, G.; De la Casa, J. Analysis of the performance of various pv module technologies in Peru. Energies 2019, 12, 186. [Google Scholar] [CrossRef]

- Bajpai, S.; Gupta, R. Performance of Silicon solar-cells under Hot and dusty environmental-conditions. Indian Journal of Pure & Applied Physics 1988, 26, 364–369. [Google Scholar]

- Alghamdi, A.S.; Bahaj, A.S.; Blunden, L.S.; Wu, Y. Dust removal from solar PV modules by automated cleaning systems. Energies 2019, 12, 2923. [Google Scholar] [CrossRef]

- Yahya, H.; Sambo, A. The effect of dust on the performance of photovoltaic modules in Sokoto. Nigerian Journal of Renewable Energy 1991, 2, 36–42. [Google Scholar]

- Ketjoy, N.; Konyu, M. Study of dust effect on photovoltaic module for photovoltaic power plant. Energy Procedia 2014, 52, 431–437. [Google Scholar] [CrossRef]

- Som, A.; Al-Alawi, S. Evaluation of efficiency and degradation of mono-and polycrystalline PV modules under outdoor conditions. Renewable energy 1992, 2, 85–91. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E.; Rudnicka, M. The analysis of working parameters decrease in photovoltaic modules as a result of dust deposition. Energies 2020, 13, 4138. [Google Scholar] [CrossRef]

- Vásquez, P.; Devoto, I.; Ferrada, P.; Taquichiri, A.; Portillo, C.; Palma-Behnke, R. Inspection data collection tool for field testing of photovoltaic modules in the atacama desert. Energies 2021, 14, 2409. [Google Scholar] [CrossRef]

- López, G.; Ramírez, D.; Alonso-Montesinos, J.; Sarmiento, J.; Polo, J.; Martín-Chivelet, N.; Marzo, A.; Batlles, F.J.; Ferrada, P. Design of a low-cost multiplexer for the study of the impact of soiling on PV panel performance. Energies 2021, 14, 4186. [Google Scholar] [CrossRef]

- Sengupta, S.; Ghosh, A.; Mallick, T.K.; Chanda, C.K.; Saha, H.; Bose, I.; Jana, J.; Sengupta, S. Model based generation prediction of SPV power plant due to weather stressed soiling. Energies 2021, 14, 5305. [Google Scholar] [CrossRef]

- Elminir, H.K.; Ghitas, A.E.; Hamid, R.; El-Hussainy, F.; Beheary, M.; Abdel-Moneim, K.M. Effect of dust on the transparent cover of solar collectors. Energy conversion and management 2006, 47, 3192–3203. [Google Scholar] [CrossRef]

- Abdallah, R.; Juaidi, A.; Abdel-Fattah, S.; Qadi, M.; Shadid, M.; Albatayneh, A.; Çamur, H.; García-Cruz, A.; Manzano-Agugliaro, F. The effects of soiling and frequency of optimal cleaning of PV panels in Palestine. Energies 2022, 15, 4232. [Google Scholar] [CrossRef]

- Alquthami, T.; Menoufi, K. Soiling of photovoltaic modules: Comparing between two distinct locations within the framework of developing the photovoltaic soiling index (PVSI). Sustainability 2019, 11, 4697. [Google Scholar] [CrossRef]

- Shah, A.H.; Hassan, A.; Laghari, M.S.; Alraeesi, A. The influence of cleaning frequency of photovoltaic modules on power losses in the desert climate. Sustainability 2020, 12, 9750. [Google Scholar] [CrossRef]

- Kaldellis, J.; Kokala, A. Quantifying the decrease of the photovoltaic panels’ energy yield due to phenomena of natural air pollution disposal. Energy 2010, 35, 4862–4869. [Google Scholar] [CrossRef]

- Aldihani, A. Performance and cost assessment of three different crystalline silicon PV modules in Kuwait environments. International Journal of Renewable Energy Research (IJRER) 2017, 7, 128–136. [Google Scholar] [CrossRef]

- Urrejola, E.; Antonanzas, J.; Ayala, P.; Salgado, M.; Ramírez-Sagner, G.; Cortés, C.; Pino, A.; Escobar, R. Effect of soiling and sunlight exposure on the performance ratio of photovoltaic technologies in Santiago, Chile. Energy Conversion and Management 2016, 114, 338–347. [Google Scholar] [CrossRef]

- Ibrahim, A. Effect of shadow and dust on the performance of silicon solar cell. Journal of Basic and applied scientific research 2011, 1, 222–230. [Google Scholar]

- Al Hanai, T.; Hashim, R.B.; El Chaar, L.; Lamont, L.A. Environmental effects on a grid connected 900 W photovoltaic thin-film amorphous silicon system. Renewable energy 2011, 36, 2615–2622. [Google Scholar] [CrossRef]

- Zeedan, A.; Barakeh, A.; Al-Fakhroo, K.; Touati, F.; Gonzales Jr, A.S. Quantification of PV power and economic losses due to soiling in Qatar. Sustainability 2021, 13, 3364. [Google Scholar] [CrossRef]

- Chanchangi, Y.N.; Ghosh, A.; Baig, H.; Sundaram, S.; Mallick, T.K. Soiling on PV performance influenced by weather parameters in Northern Nigeria. Renewable Energy 2021, 180, 874–892. [Google Scholar] [CrossRef]

- Mohamed, A.O.; Hasan, A. Effect of dust accumulation on performance of photovoltaic solar modules in Sahara environment. Journal of Basic and applied scientific Research 2012, 2, 11030–11036. [Google Scholar]

- Rahman, M.M.; Islam, M.A.; Karim, A.; Ronee, A.H. Effects of natural dust on the performance of PV panels in Bangladesh. International Journal of Modern Education and Computer Science 2012, 4, 26. [Google Scholar] [CrossRef]

- Rehman, S.; El-Amin, I. Performance evaluation of an off-grid photovoltaic system in Saudi Arabia. Energy 2012, 46, 451–458. [Google Scholar] [CrossRef]

- Sanusi, Y. The performance of amorphous silicon PV system under Harmattan dust conditions in a tropical area. Pacific Journal of Science and Technology 2012, 13, 168–175. [Google Scholar]

- Zorrilla-Casanova, J.; Piliougine, M.; Carretero, J.; Bernaola-Galván, P.; Carpena, P.; Mora-López, L.; Sidrach-de-Cardona, M. Losses produced by soiling in the incoming radiation to photovoltaic modules. Progress in photovoltaics: Research and applications 2013, 21, 790–796. [Google Scholar] [CrossRef]

- Liqun, L.; Zhiqi, L.; Chunxia, S.Z.L. Degraded output characteristic at atmospheric air pollution and economy analysis of PV power system: a case study. Przeglad Elektrotechniczny 2012, 88, 281–284. [Google Scholar]

- Kalogirou, S.A.; Agathokleous, R.; Panayiotou, G. On-site PV characterization and the effect of soiling on their performance. Energy 2013, 51, 439–446. [Google Scholar] [CrossRef]

- Caron, J.R.; Littmann, B. Direct monitoring of energy lost due to soiling on first solar modules in California. IEEE Journal of Photovoltaics 2012, 3, 336–340. [Google Scholar] [CrossRef]

- Piliougine, M.; Canete, C.; Moreno, R.; Carretero, J.; Hirose, J.; Ogawa, S.; Sidrach-de-Cardona, M. Comparative analysis of energy produced by photovoltaic modules with anti-soiling coated surface in arid climates. Applied energy 2013, 112, 626–634. [Google Scholar] [CrossRef]

- Moharram, K.; Abd-Elhady, M.; Kandil, H.; El-Sherif, H. Influence of cleaning using water and surfactants on the performance of photovoltaic panels. Energy Conversion and Management 2013, 68, 266–272. [Google Scholar] [CrossRef]

- Weber, B.; Quiñones, A.; Almanza, R.; Duran, M.D. Performance reduction of PV systems by dust deposition. Energy Procedia 2014, 57, 99–108. [Google Scholar] [CrossRef]

- Ndiaye, A.; Kébé, C.M.; Charki, A.; Ndiaye, P.A.; Sambou, V.; Kobi, A. Degradation evaluation of crystalline-silicon photovoltaic modules after a few operation years in a tropical environment. Solar energy 2014, 103, 70–77. [Google Scholar] [CrossRef]

- Semaoui, S.; Arab, A.H.; Boudjelthia, E.K.; Bacha, S.; Zeraia, H. Dust effect on optical transmittance of photovoltaic module glazing in a desert region. Energy Procedia 2015, 74, 1347–1357. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E. Degradation of electrical performance of a crystalline photovoltaic module due to dust deposition in northern Poland. Renewable Energy 2015, 78, 418–426. [Google Scholar] [CrossRef]

- Rajput, P.; Tiwari, G.; Sastry, O.; Bora, B.; Sharma, V. Degradation of mono-crystalline photovoltaic modules after 22 years of outdoor exposure in the composite climate of India. Solar Energy 2016, 135, 786–795. [Google Scholar] [CrossRef]

- Paudyal, B.R.; Shakya, S.R. Dust accumulation effects on efficiency of solar PV modules for off grid purpose: A case study of Kathmandu. Solar Energy 2016, 135, 103–110. [Google Scholar] [CrossRef]

- Tanesab, J.; Parlevliet, D.; Whale, J.; Urmee, T. Dust effect and its economic analysis on PV modules deployed in a temperate climate zone. Energy Procedia 2016, 100, 65–68. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T. Experimental analysis of the effect of dust’s physical properties on photovoltaic modules in Northern Oman. Solar Energy 2016, 139, 68–80. [Google Scholar] [CrossRef]

- Touati, F.; Al-Hitmi, M.; Chowdhury, N.A.; Hamad, J.A.; Gonzales, A.J.S.P. Investigation of solar PV performance under Doha weather using a customized measurement and monitoring system. Renewable Energy 2016, 89, 564–577. [Google Scholar] [CrossRef]

- Saidan, M.; Albaali, A.G.; Alasis, E.; Kaldellis, J.K. Experimental study on the effect of dust deposition on solar photovoltaic panels in desert environment. Renewable Energy 2016, 92, 499–505. [Google Scholar] [CrossRef]

- Olivares, D.; Ferrada, P.; de Matos, C.; Marzo, A.; Cabrera, E.; Portillo, C.; Llanos, J. Characterization of soiling on PV modules in the Atacama Desert. Energy Procedia 2017, 124, 547–553. [Google Scholar] [CrossRef]

- Guan, Y.; Zhang, H.; Xiao, B.; Zhou, Z.; Yan, X. In-situ investigation of the effect of dust deposition on the performance of polycrystalline silicon photovoltaic modules. Renewable energy 2017, 101, 1273–1284. [Google Scholar] [CrossRef]

- Fraga, M.M.; de Oliveira Campos, B.L.; de Almeida, T.B.; da Fonseca, J.M.F.; Lins, V.d.F.C. Analysis of the soiling effect on the performance of photovoltaic modules on a soccer stadium in Minas Gerais, Brazil. Solar Energy 2018, 163, 387–397. [Google Scholar] [CrossRef]