The way I do this kind of thing, is easily, freehand

If you make all your marks, a bit low, then start off with a small bit (maybe 1/8") and predrill to about a quarter inch and punch all the marks with it so they have a starting point for a bigger bit. It doesn't matter how deep really, if you go too deep, it will look bad. Don't go deep.

then take your larger bit, and start it until it goes all the way in until the crown has gotten level with the surface, meaning, the hole is now as wide as its going to get.

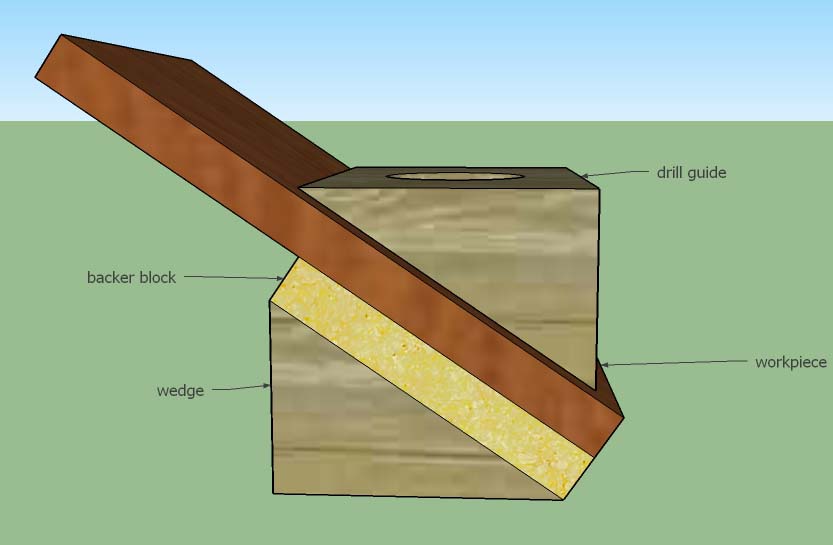

Then while holding the drill still in motion, preferably a higher wood speed, start to tilt it. It's that easy. Have something, like a thin long nail, or something in one of the guide holes to have guide angle template.

SO, each hole, after predrilling,

enlarge your hole fullsize,

keep motor running,

tilt drill to proper angle,

then go to depth.

extraction is your best guess, either motor on, or motor off, but i think on.

This is also probably the way the one in the picture was done, because its not exact..

but i did learn something new from the pros, with their guides they mentioned :-)