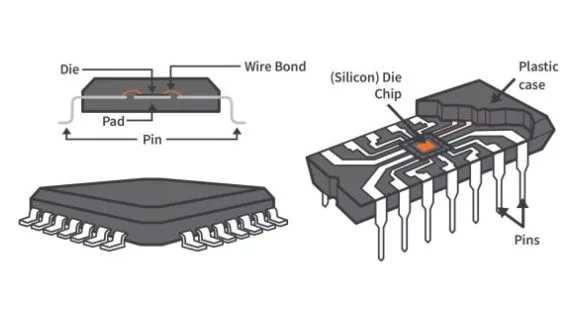

A Solid State Relay, also referred to as SSR, is an electronic switching device. Similar to an electromechanical relay, it can switch a load on or off when an external control signal is applied across its control terminals. However, SSRs do not have any moving parts like contacts, armature, springs, etc. They make use of the electrical and optical properties of semiconductors to perform the switching and provide complete isolation between the control circuit and load circuit.

But how exactly do SSRs make use of the optical properties of semiconductor materials? Before diving into that, let us understand what a phototransistor is and how it works.

Inside a Phototransistor

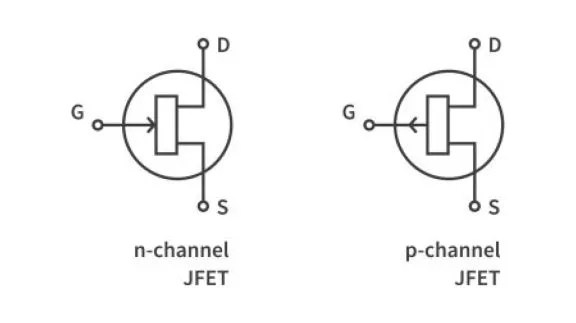

A phototransistor is basically a light-controlled transistor. In a regular NPN transistor, the emitter and collector are made up of N-type semiconductor material and the base is made up of P-type semiconductor material. The emitter is heavily doped, the base is moderately doped, and the collector is a lightly doped region. An external voltage is applied to the base of the transistor to develop the base current and switch it on. To get more in-depth information about the working of a transistor, check out our tutorial on Bipolar Junction Transistor (BJT).

When it comes to phototransistors, they are slightly different from regular transistors. They have a light-sensitive base region that develops the base current only when light falls on it.

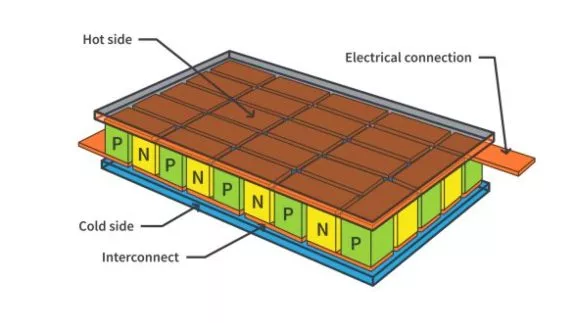

When the N-type and P-type materials are joined together while manufacturing the phototransistor, they form two PN junctions, known as the base-emitter junction and the other one as the base-collector junction. Extra electrons on the N side and the holes (space for an electron) on the P side of the PN junctions combine instantaneously, forming a depletion region that creates a potential difference near the PN junction, restricting the flow of current. This potential difference is called the barrier potential, as it creates a barrier that must be overcome for electrons to pass. VBE is the barrier potential at the base-emitter junction and VBC is the barrier potential at the base-collector junction.

When the light from an LED is focused onto the phototransistor, the emitted photons hit the base of the phototransistor, which narrows down the width of the depletion region and also provides sufficient energy for the electrons to move across the base-collector depletion region and into the collector.

The shifted electrons leave holes in the base region and the extra electrons in the emitter region can now move into these holes. This process continues and electrons start flowing, developing a current in the circuit. Turning off the LED stops the flow of electrons as the depletion region is formed again due to the absence of photons adding their energy to the circuit.

Now that we understand how a phototransistor works, we can move forward to understand how an SSR uses the properties of phototransistors and other semiconductor devices having similar working principles like photodiodes, MOSFETs, thyristors, or TRIACs to perform switching in AC and DC loads.

Inside a Solid State Relay

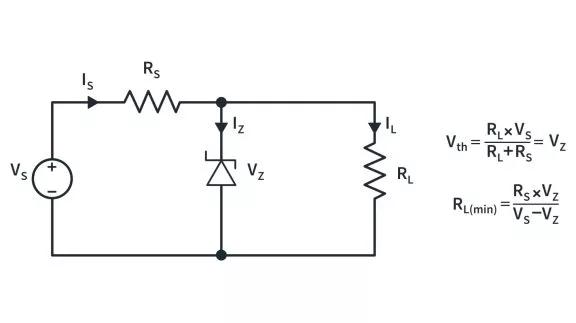

An SSR is a 4 terminal device having a pair of terminals for the input side and the other pair for the load/output side. There is an LED light source and a photosensitive device, like a phototransistor, inside a single case, separated by an air gap. The photosensitive switching element on the output side can also be a photodiode, thyristor, MOSFET, or a TRIAC depending on the nature of the load - AC or DC. SSRs with higher current capacity also have some additional circuitry along with the photo-sensitive device on the load side to increase the current output.

The LED on the input side is controlled by a small DC input signal called the control signal. When the LED is turned on, the emitted light is focused on the photo-sensitive device on the load side. This emitted light falls on the photosensitive device and it gets switched ON, allowing current to flow in the load circuit and switching ON our load. This is known as opto-coupling.

Opto-coupling is a popular way to provide electrical isolation between two circuits. Isolation is necessary if the two circuits are operating at different reference voltages. Because the only connection between the input and output side of an SSR is the emitted light from the LED, it provides complete physical and electrical isolation between the two sides, as we don’t want the high current flowing in the load side to flow into the low capacity input side. It also prevents noise generated in one circuit due to voltage spikes from passing into the other, increasing the overall noise immunity of the circuit.

Turning off the input LED stops the flow of current in the load as the photo-sensitive device isn't in the ON state anymore.

Solid State Relay vs Electromechanical Relay

Traditional electromechanical relays have been used as electronic switching devices for a long time. They come in various capacities to meet our current and voltage requirements. However, they have their own limitations which cause hindrance in several applications.

- Contacts get eroded over time and with increased usage

- Arcing between the contacts generates a lot of heat

- A limited number of switching operations, etc.

The introduction of SSRs solved a lot of these drawbacks. Some of the major advantages of using SSRs over electromechanical relays are:

- They do not have any moving parts so there is no wear and tear

- Completely eliminate arcing as there are no contacts for switching

- Smaller in size

- Much longer electrical life and not limited by the number of switching operations

- High-speed and high-frequency switching

- No noise while switching

- Lesser power consumption

- Have much better input/output isolation

- Not affected by vibration and shocks

- Available in high current and voltage capacities

However, just like any other electronic device, solid state relays also have some drawbacks. Some of them are mentioned below:

- SSRs are comparatively expensive than an electromechanical relay

- Difficult to have multiple switch configurations like Single-Pole-Double-Throw (SPDT)

- They have a higher output resistance

- They have some leakage current even when the control signal is OFF

Classification Based on Switching Property

Zero crossing relay: The zero switching SSR turns on the load circuit when the load voltage crosses zero volts after applying the control signal. Because the switching happens close to zero volts, the current required to operate the relay is very low.

Instant-on relay: This type of relay is activated immediately after the control signal is applied. In this case, we have a faster switch-on time than zero crossing relays.

Peak switching relay: This type of relay turns on the load circuit when the load voltage reaches the next peak after applying the control signal.

Conclusion

SSRs are extremely powerful switching devices for both AC and DC loads. But one should always look for the important factors before choosing a relay like its current capacity, temperature thresholds, switching time, etc. Keeping the operating conditions under the maximum limits is crucial to ensure safe usage. In most cases, the advantages of SSRs make them a better candidate for switching purposes as they eliminate a lot of problems someone would face while using an electromechanical relay. With the advancement in technology, we can expect SSRs to become more efficient and cheaper than the currently available versions.