Technical Features & Applications of Flexible Packaging Printing

Summary: Packaging printing has garnered particular attention in the printing industry. With the continuous development of digital printing technology, the traditional packaging printing technology is undergoing a revolution. This article will deeply explore the combination of packaging printing technology and digital printing technology, and analyze the development trends, challenges and opportunities in this emerging field.By comparing the features of traditional packaging printing and digital printing technology, this article discusses the application of digital printing in the packaging industry, and its advantages in improving the quality, efficiency and customization of packaging printing. Besides, it will also study the application of digital printing in sustainable packaging and explore its contribution to environmental protection. Finally, through case analysis and market survey, it will also summarized the current situation and prospect of digital printing in packaging printing, and provide suggestions and prospects for the future development of packaging industry.

Keyword:Packaging Printing Technology, Digital Printing, Printing Technology, Sustainable Packaging, Customization

1. Introduction

Packaging plays a vital role in modern commercial society, which is not only the protection of products, but also the brand image display. Because of the increasingly diverse and personalized demands of consumer, packaging design and printing technologies are constantly innovating. The rise of digital printing technology has brought new possibilities to packaging printing, making it more personalized, refined, and more eco-friendly. This article will discuss the combination of packaging printing and digital printing technology, and analyze its application and influence in the packaging industry.

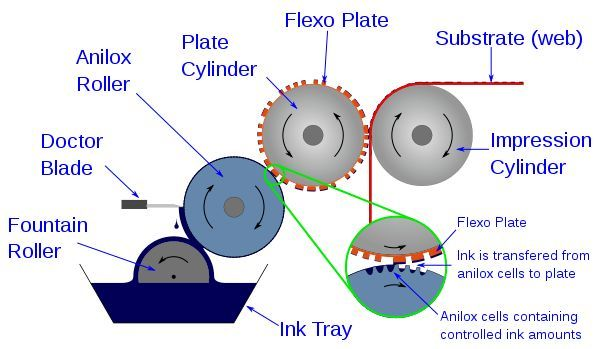

2.Features Comparison of Intaglio Printing,Digital Printing, Flexographic Printin

| Element | Intaglio Printing | Digital Printing | Flexographic Printing |

| Printing Quality | High, full color & clear detail | High, high resolution & color reproduction | Medium, suitable for some low-demand applications |

| Printing Speed | High, usually 8000-12000 printing pieces/hour | Medium, usually 2000-3000 printing pieces/hour | Medium, usually 4000-6000 printing pieces/hour |

| Customization | Limited, mainly for large-scale market | High, suitable for customization | Medium, Less customizable |

| Plate - making process | Requires preparation time for plate-making | No need for plate-making | Requires preparation time for plate-making |

| Environmental Protection | Use of organic solvents may cause environmental pollution | Use of eco-friendly ink can reduce environmental pollution | Use of eco-friendly ink can reduce environmental pollution |

| Applicable Materials | Paper, plastic film,aluminum foil etc. | Paper, plastic film,aluminum foil etc. | Paper, plastic film,aluminum foil etc. |

| Cost | Low cost | Expensive equipment but saving material cost | Medium, more economical than intaglio printing |

| Disadvantages | Long period and high cost of plate-making, not suitable for short-run printing | High equipment investment and consumables cost, suitable for small batch printing | High consumables cost and low accuracy, not suitable for large-scale printing |

| Available Pouch Type | Food, cosmetics, daily necessities, etc. | Special customized products, seasonal products, small batch packaging products, etc. | Food packaging, beverage packaging, drug labels, cosmetics labels, etc. |

3.Digital Printing technology in packaging printing

Individualized packaging design: Digital printing technology makes packaging design more personalized, customizing unique packaging appearance to customer needs and enhancing brand image.

Short-run printing: digital printing can flexibly respond to small batch orders, meet the market demand and reduce inventory pressure.

Printing effect improvement: Digital printing technology can achieve higher resolution and printing accuracy, providing clearer and fuller printing effect and increasing the attractiveness of products.

Fast delivery: Digital printing does not require plate-making and printing preparation time, which can quickly start production, shorten the delivery times and improve customer satisfaction.

In the field of flexible packaging, common ink types for digital printing include water-based ink and solvent inks, which have different features and range of application:

Water-based ink is a kind of eco-friendly ink, which is composed of water, pigments, additives and colloids. Its main features include:

• Eco-friendly: Water-based ink does not contain harmful solvents, it’s eco-friendly and in line with environmental laws and regulations

• Less smell: Water-based ink has a lighter smell than solvent ink, which is suitable for packaging with higher requirements of smell.

• Applicable materials:It is suitable for materials such as paper and cardboard with good absorption.

Solvent inks usually use organic solvents as media and have the following features:

• Water resistance: Solvent ink has good water resistance after printed and is suitable for packaging materials required waterproof treatment.

• Applicable materials: it’s suitable for all kinds of materials, including plastic film, metal foil, composite materials, etc., and widely used in flexible packaging.

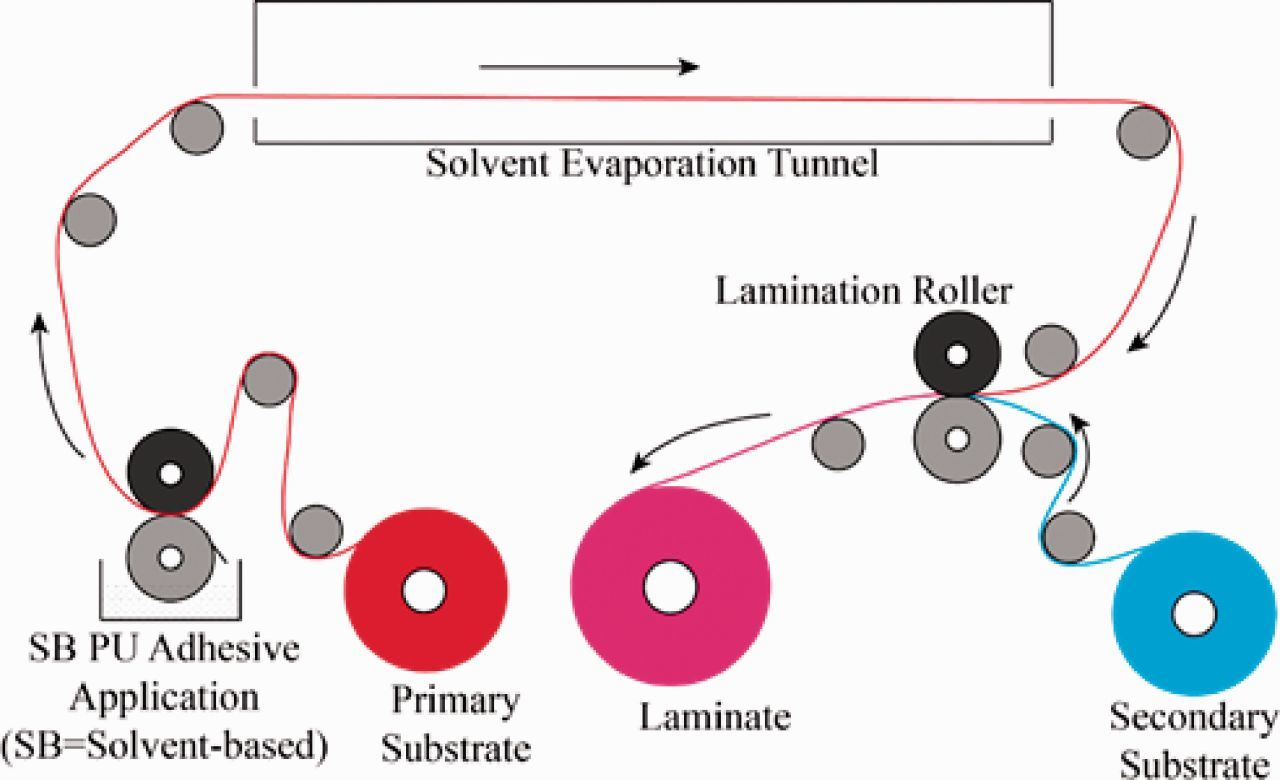

Digital printing materials for flexible packaging mainly include:

Plastic film: Digital printing can be applied to a variety of plastic films, including polyethylene (PE), polypropylene (PP), polyester (PET), etc. These materials are often used in food packaging, medicine packaging and other flexible packaging.

Aluminum foil: Aluminum foil is often used in coffee packaging, medicine packaging and so on. It has good moisture, light insulation performance, suitable for those sensitive products required resistant of light, oxygen and moisture.

Composite materials: Various composite materials are often used in flexible packaging, including paper-plastic, aluminum-plastic composite film etc, which combine the features of different materials to make packaging more functional.

4. Digital printing technology in sustainable packaging

Reduce garbage and waste: Digital printing can flexibly produce according to actual demand, so as to reduce the unnecessary inventory and realize customized production.

Application of eco-friendly materials: Digital printing can use a variety of eco-friendly materials, such as degradable ink, recycled paper, etc., to reduce environmental pollution and facilitate the sustainable development of the packaging industry.

Energy saving and emission reduction: Compared with traditional printing technology, digital printing saves a lot of energy and reduces carbon emissions, reducing the impact on the environment.

5. Challenges and Opportunities

Technical challenges: Digital printing technology still needs to be constantly innovated and improved, so as to meet higher printing requirements, such as larger printing specifications and faster printing speed, etc.

Cost control: The costs of digital printing equipment and consumables are relatively high, how to reduce production costs and improve competitiveness is a problem to be solved.

Market competition: With the popularity of digital printing technology, market competition will be more intense. Enterprises have to improve the technology, quality and service constantly to maintain their competitiveness.

6. Conclusion and Prospect

The continuous development of digital printing technology has brought new opportunities and challenges to packaging printing. With in-depth research on the features and applications of digital printing technology and the concept of sustainable development, the packaging industry can be better to meet the market demand and improve its competitiveness. In the future, with the continuous maturity and popularization of digital printing technology, it is believed that packaging printing will usher in a broader development space to provide higher quality and more personalized packaging products for all walks of life.