Preprint

Article

Bearing Capacity and Sustainable Construction of Vacuum Drainage Pipe Pile

Altmetrics

Downloads

184

Views

36

Comments

0

A peer-reviewed article of this preprint also exists.

This version is not peer-reviewed

Submitted:

14 March 2023

Posted:

15 March 2023

You are already at the latest version

Alerts

Abstract

To further explore the bearing capacity and sustainable construction of vacuum drainage pipe (VDP) piles, field tests were carried out to compare and analyze the ultimate single pile bearing capacity, pile side friction and pile end resistance of ordinary piles and vacuum drainage pipe piles. The effect of the VDP pile on energy conservation and emission reduction in practical projects is discussed. The results shows that the VDP pile basically eliminated the soil squeeze and did not cause excessive relative displacement of pile and soil after vacuum consolidation. The VDP pile enhances pile side friction resistance, resulting in a 17.6% increase in ultimate bearing capacity compared to traditional piles. The VDP pile method can reduce carbon emissions by 31.4% compared to traditional methods. This study provides guidance for the production and design of VDP piles in the future and demonstrates their potential for energy conservation and emission reduction benefits compared to traditional methods.

Keywords:

Subject: Engineering - Civil Engineering

1. Introduction

Many large-scale railway, highway, port and airport infrastructure, as well as major industrial bases and logistics centers are distributed in coastal soft soil areas. At present, the common treatment method is: plastic drainage board and pile foundation combined method [1,2]. This method has the following disadvantages: 1) the consolidation process takes a long time, 2) the plastic drainage board is difficult to degrade, which is not conducive to sustainable development, 3) the pile driving after the foundation is hardened, which increases the construction energy consumption. Therefore, the low carbon and sustainable foundation treatment methods for coastal soft clay need to be studied urgently.

In the context of global "carbon neutrality", traditional civil engineering is actively implementing the concept of sustainable development [3,4]. To reduce the construction cost and improve the sustainability of the project, domestic and foreign scholars have explored the feasibility of integration of foundation treatment and pile foundation engineering. For example, permeable concrete pile [5], perforated pile [6], drainage plate combination pile [7,8], geotextile-encased stone columns [9], etc. However, there are the following deficiencies: the pile body material is filled with voids, and the pile body strength is small, so it cannot be directly used as engineering piles [10]. Small holes are opened in the pile body, and the water and soil are not separated, resulting in silting and blocking, which can not effectively drain water for a long time. The combination of pile body and drainage board reduces the friction area and friction coefficient, and the bearing capacity decreases. The energy consumption is similar to that of common construction methods. The strength of the pile depends on the confining pressure, once the geomembrane is broken, the overall strength will decrease significantly [11].

To sum up, there is still a large research space for the integration of foundation treatment and pile foundation engineering. In order to further promote green, low-carbon and sustainable development of foundation treatment, Tang et al. [12,13,14] proposed the vacuum drainage pipe pile (VDP pile). The pile body is uniformly arranged with small holes, and the pile body is covered with degradable geotextile for reverse filtration to prevent the small holes from silting up and ensure the long-term stability of the drainage channel. VDP piles are driven when the soil is soft, and the excess pore water pressure can be dissipated through the drainage channel. After vacuum consolidation they can be directly used as engineering piles. At the same time, plastic drainage boards are not used for drainage, which reduces costs and environmental pollution.

At present, the research on vacuum drainage pipe piles is mainly concentrated on indoor tests. The production and construction process of the VDP pile is not clear and the improvement of the bearing capacity of the vacuum drainage pipe pile has not been verified in the actual project. To further promote the sustainable construction and application of the VDP piles, field tests were carried out to compare and analyze the ultimate single pile bearing capacity, pile side friction and pile end resistance of ordinary piles and vacuum drainage pipe piles. The effect of the VDP pile on energy conservation and emission reduction in practical projects is discussed.

2. Sustainable Construction of the Vacuum Drainage Pipe Pile in Soft Soil

2.1. Production Process of the Vacuum Drainage Pipe Pile

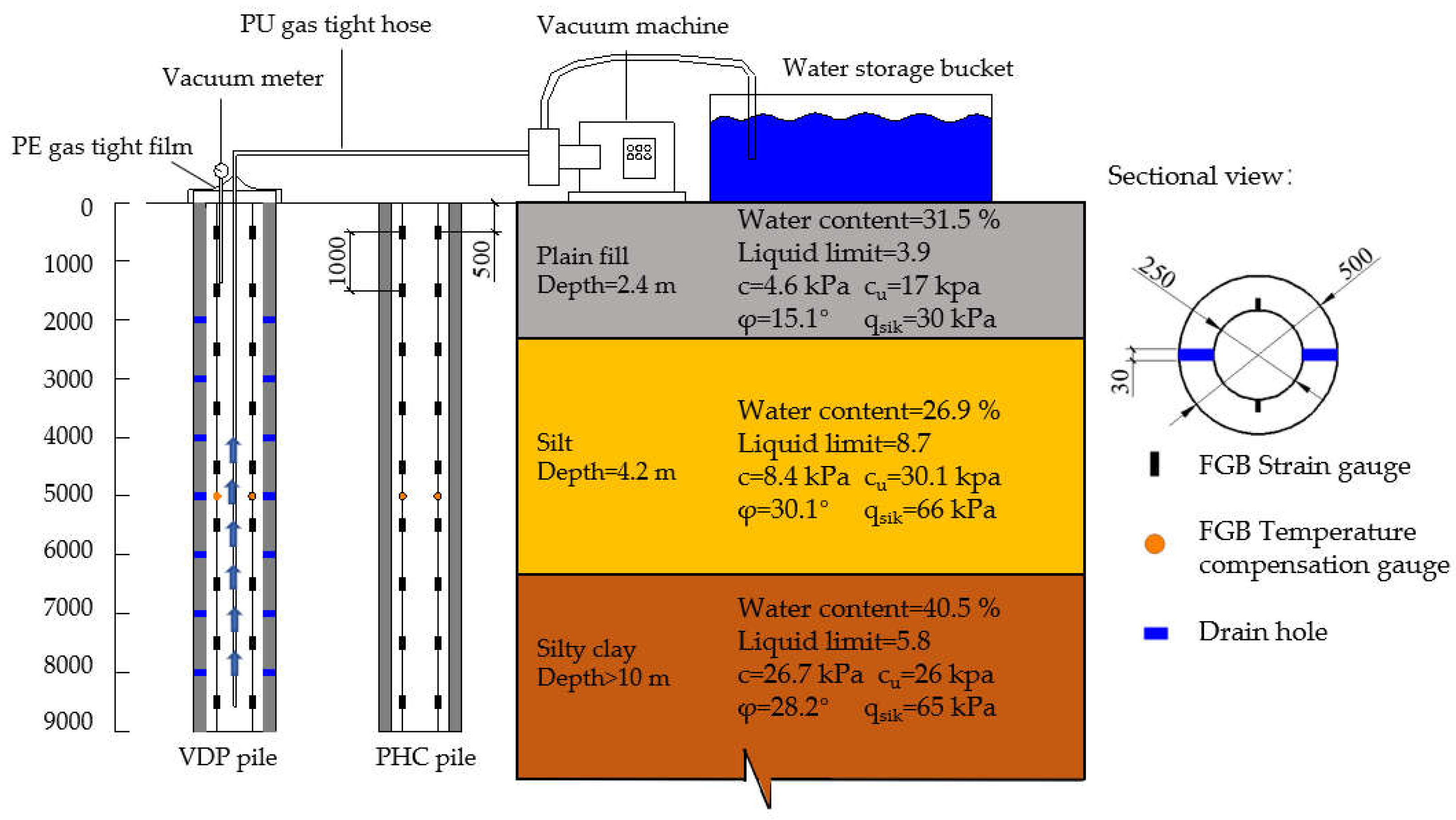

The main material of VDP piles used in the test were concrete, and the concrete strength of the pile is C80 (the compressive strength of the cubic concrete block was 80 MPa). The outer diameter of the pipe pile is 500 mm, the inner diameter is 250 mm, and the pile length is 9 m. The number of holes in a single layer is 2, the spacing between layers of holes is 1 m, and the hole diameter is 30 mm, 14 holes in total. The production process of VDP piles is the same as that of ordinary pipe piles (PHC piles), with the following differences: To ensure the integrity of the holes, after the reinforcement cage is put into the mold, a PVC pipe with a length of 50 cm and an outer diameter of 3 cm is bound to the reinforcement cage through fine steel wires to form a new mold. After concrete curing, PVC pipes are knocked out to form holes. The metal mesh with filter membrane is inserted at holes. The airtight glue is used to fit the metal mesh with the pile body to prevent air leakage in the vacuum process, as shown in Figure 1.

2.2. Construction Process of the Vacuum Drainage Pipe Pile

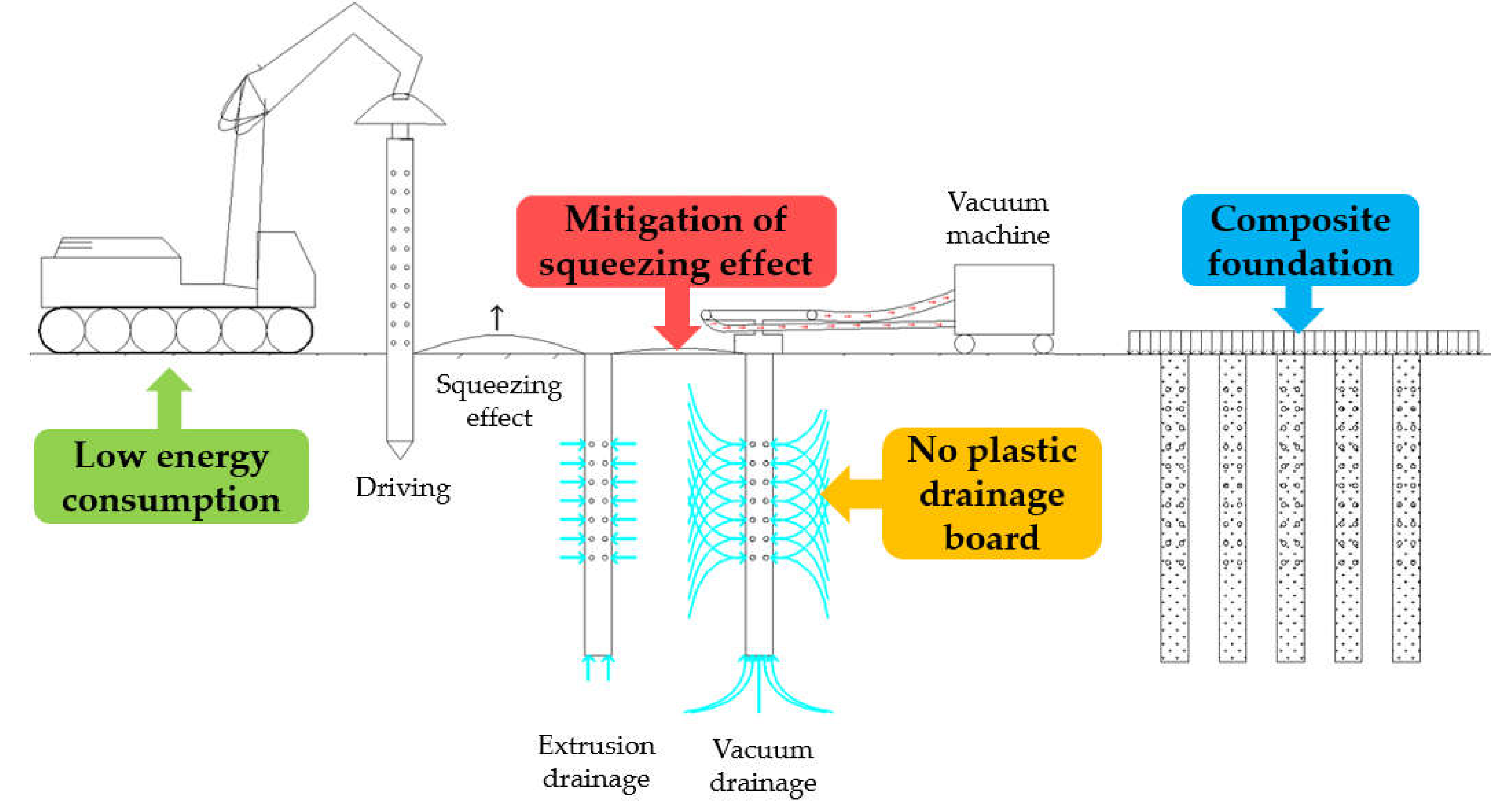

Unlike plastic drainage board and pile foundation combined method, the construction process of the VDP piles are as follows:

1) When the soil is soft, the universal prefabricated pipe pile driver is used to drive the vacuum drainage pipe pile. At this time, the required energy consumption for driving the pile is low.

2) Use pile driving disturbance and its own drainage channel to reduce soil squeezing effect, and connect external vacuum machine to accelerate drainage and consolidation.

3) After the soil hardens, the pile composite foundation is formed to undertake the upper load jointly and directly serve as the engineering pile.

4) The plastic drain board is not used in the whole process, which is environmentally friendly.

The construction and service of vacuum drainage pipe piles are integrated, which improves the overall bearing capacity and greatly reduces the construction period, with good economic benefits, as shown in Figure 2.

3. Field Test

3.1. Test Site and Pile Description

The soil parameters, vacuum method and strain gauges distribution are shown in Figure 3. The field tests were carried out on the site of a highway project to be built in Hangzhou, Zhejiang Province. To ensure the progress of the pile foundation project, the vacuum consolidation time was set as 10 days in this test. And the vacuuming time was 18 hours per day, for a total of 180 hours. During the vacuum interval, the water inside the pile was pumped to the water storage bucket. During the vacuum period, the vacuum degree was about 0.5~0.7 atmospheres. FBG (Fiber Bragg Grating) has the advantages of high precision and real-time performance. The fiber grating strain gauge and fiber grating thermometer from Zhixing Technology Nantong Co., Ltd. were used in this test. The strain gauges are arranged from 500 mm below the pile top with a spacing of 1000 mm. The thermometer is buried 5000 mm below the pile top.

3.2. Test Process

Single pile static load compression test was carried out for one PHC pile and one VDP pile. For the PHC pile, the first level load is 300 kN, and then each level load is 150 kN. For the VDP pile, the first level load is 400 kN, and then each level load is 200 kN. The slow maintenance load method is adopted in the test [15]. The loading can be terminated when the total settlement of the pile top exceeds 40 mm. To verify that the VDP pile will not produce a large relative displacement of pile and soil in vacuum consolidation, it is necessary to monitor the surface displacement and pile top displacement of the soil around the test pile. Use precision total station to observe the ground settlement around the pile. The layout of measuring points is shown in Figure 4. Six measuring points shall be uniformly arranged at a distance of 0 mm~1000 mm from the pile side, and the same measuring points shall be arranged in four vertical directions. Finally, the average displacement shall be taken as the surface displacement of the soil around the test pile.

3.3. Test Results

3.1.1. Surface Displacement of Soil Around Piles

Figure 5 and 6 are the surface displacement curves of the soil around the PHC pile and the VDP pile respectively. The soil surface uplift was the highest at 20 cm from the side of the PHC pile. And there was still an uplift after 10 days. This shows that the soil-squeezing effect caused by pile driving had not completely disappeared. On the 4th day, the VDP pile basically eliminated the soil squeeze and even caused a settlement of about 1.5 mm at the 60 cm side of the pile. From the 5th day to the 7th day, the settlement velocity of the pile side soil of the two types of piles decreased, and even the reverse arch phenomenon appeared. This is mainly due to the heavy rain on these two days, which increased pore water among the soil particles. Over time, the soil around the piles of the two types of piles continued to consolidate, and the surface uplift gradually disappeared.

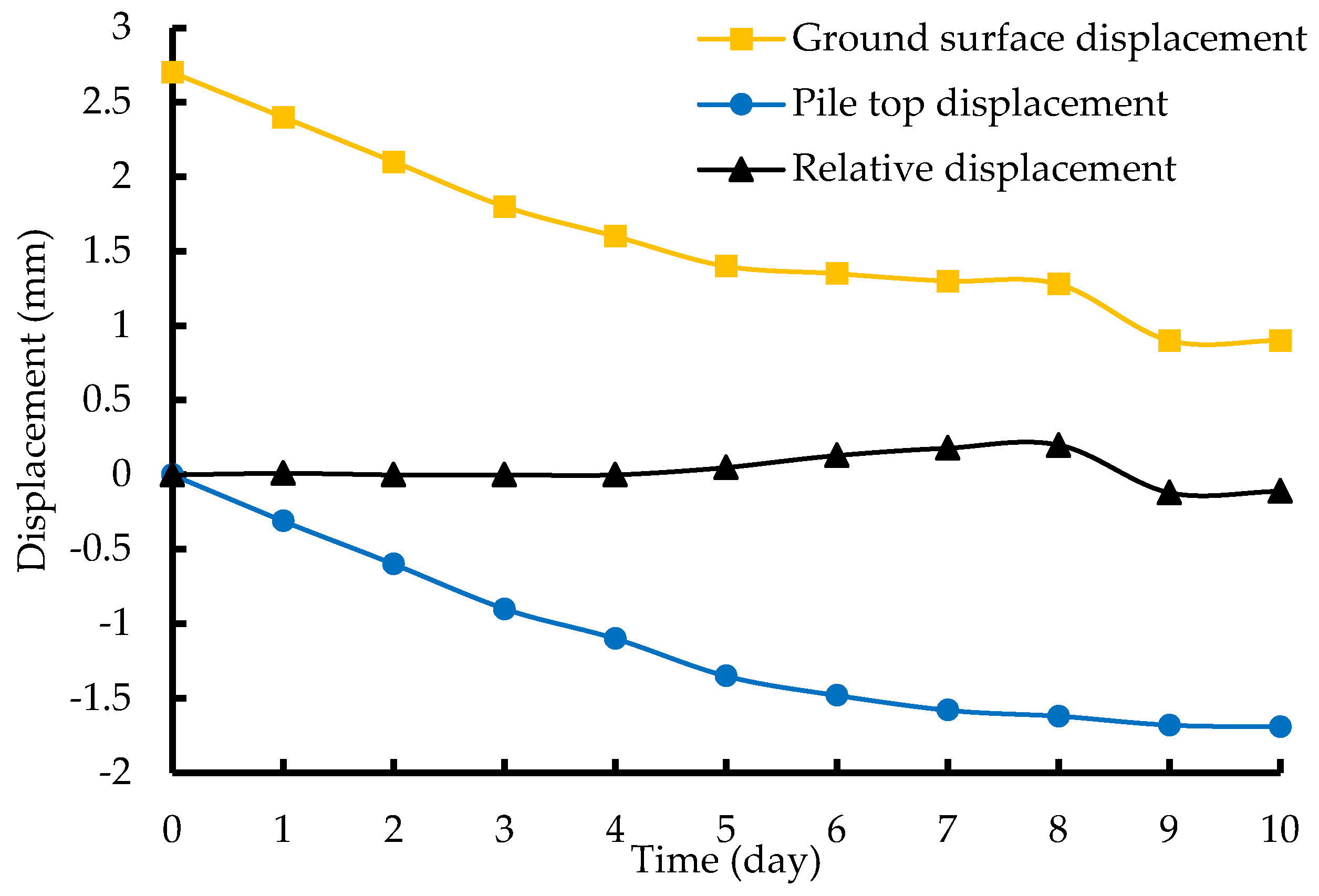

If the settlement of the soil around the pile is greater than the settlement of the pile itself, it will cause negative frictional resistance. The displacement of the top of the VDP pile and the ground displacement at the 0 cm side of the pile were drawn in the same diagram, and the relative displacement curve was added (as shown in Figure 7). It can be seen from the relative displacement curve that the maximum difference between the two was 0.18 mm~-0.12 mm. The relative displacement of the pile and soil caused by the vacuum effect can be almost ignored. Therefore, vacuum consolidation will not lead to excessive pile-soil displacement and negative frictional resistance.

3.1.2. Relationship between Pile Head Displacement and Load

The load-settlement curves of the PHC pile and the VDP pile are slowly changing type., as shown in Figure 8. The slope of the VDP pile curve was comparatively smaller. Throughout different stages, the VDP pile demonstrated a larger bearing capacity and anti-deformation capacity than the PHC pile. To determine the vertical ultimate bearing capacity of a single pile, the method outlined in the technical code [15] was employed. The load value that corresponded to a 40 mm settlement of the pile top was considered the ultimate compressive bearing capacity. Using linear interpolation, the ultimate compressive bearing capacity of the PHC pile and the VDP pile were calculated to be 1482 kN and 1743 kN, respectively. The single pile ultimate bearing capacity of the VDP pile is about 17.6% larger than that of the PHC pile.

3.1.3. Analysis of the Pile Side Frictional Resistance

The pile side friction resistance can be calculated by dividing the difference between the axial forces of two sections by the pile side area of the section. The average pile side friction resistance of PHC pile and VDP pile under different pile top loads is shown in Figure 9. As the pile top load increases from 600 kN to 1200 kN: The friction resistance of the PHC pile and the VDP pile at a depth of 1 m~2 m increased from 30 kPa ~ 35 kPa to 55 kPa ~ 60 kPa, but the gap between the two did not further expand. At a depth of 3 m ~ 6 m, the friction resistance of the two piles increased from 35 kPa ~ 40 kPa to 65 kPa ~ 75 kPa, and the difference between them increased slightly. At a depth of 7 m~8 m, the friction resistance of the PHC pile increases from 20 kPa ~ 25 kPa to 30 kPa ~ 35 kPa, while the friction resistance of the VDP pile increases from 30 kPa ~ 35 kPa to 60 kPa ~ 65 kPa, and the difference between the two increases from 40.40% ~ 55.32% to 81.79% ~ 98.29%. When the pile top load reaches the limit load, the friction resistance of the VDP pile mainly acts on the middle and lower part of the pile, and the distribution is more uniform than that of PHC pile.

To further analyze the influence of soil layers on the side friction resistance, the average side friction resistance of different soil layers is calculated by the difference method. The depth of plain fill is 0 m~2.4 m, the depth of silt is 2.4 m~6.6 m, and the depth of silty clay is more than 6.6 m. The distribution of pile side friction resistance of two piles with soil layer is shown in Figure 10. It can be found that compared with the PHC pile, the pile side friction resistance of the VDP pile to silty clay layer is greatly increased, with an increase of 170.69%. For the other two soil layers, there is also an increase of nearly 40%. Therefore, the vacuum consolidation effect of the VDP pile can improve the pile side friction resistance of the pile, and the lifting effect is more obvious for the soil layer with a worse structure.

3.1.4. Analysis of the Pile End Resistance

The pile end resistance ratio can be defined as the ratio of the pile bottom resistance to the top pile load, which is used to analyze the bearing characteristics of the pile foundation and determine the pile type classification. In this filed test, no pressure sensor is installed at the pile end, and the pile end resistance is approximately calculated by subtracting the total side friction from the pile top load. The relationship between the pile end resistance ratio of PHC and VDP is shown in Figure 10.

At the initial stage of pile top load loading, the rising slope of the two pile types is basically the same. When the load on the top of the pile exceeds 750 kN, the increase of the pile end resistance of the VDP pile slows down. At this time, pile side frictional resistance is further developed to bear the load. The slope of the PHC pile is basically unchanged, and the load is more borne by the pile bottom. When approaching the ultimate load, the slope of both increases, the pile end resistance of PHC changes abruptly, and the pile end resistance ratio exceeds 50% at the last level of load, which can be determined as the frictional end bearing pile, dominated by end bearing. On the contrary, the slope of the VDP pile has increased, but it is basically consistent with the initial stage of load loading. There is no sudden change and the final pile end resistance ratio is less than 40%. It can be determined as an end-bearing friction pile, dominated by pile side frictional resistance.

Figure 10.

The pile end resistance of piles

4. Carbon Emission Estimation in the Whole Process of the VDP Pile

The carbon emission of pile foundation projects refers to the total amount of greenhouse gas emitted into the external environment when the building materials and energy are consumed during the whole life cycle from production, and transportation to the construction of piles. The calculation method is the total consumption of materials or energy multiplied by the carbon emission factor, which can be estimated according to Equation (1). The carbon emission factors used in this paper refer to the IPCC Guidelines for National Greenhouse Gas Emission Inventory and the Chinese Academy of Engineering.

where:

is total carbon emissions (kg);

is total consumption of the i-th material in engineering (kg);

is the carbon emission factor of the i-th material (kg/kg);

is Total consumption of the j-th energy in engineering (kg, kW·h);

is the Carbon emission factor of the j-th energy (kg/unit).

The material of the pile body is mainly composed of concrete and steel, the material of the plastic drainage board is mostly PVC, and the metal mesh for VDP piles is steel. The energy data required for transportation is taken from China Transportation Yearbook 2021 [16]. The materials and energy consumption required for construction shall be calculated according to the Budget Quota of Electric Power Construction Project [17] and the Quota of Construction Machinery Shift Cost of Electric Power Construction Project [18].

Taking the working condition of this field test as an example, for the treatment of 10000m2 soft soil foundation, if the combined method of common piles and drainage boards is used, the pile spacing is 2.5 m, 1600 piles with diameter of 0.5 m and length of 9 m are required, and 1600 plastic drainage boards with a length of 15 m are added. If VDP piles are used, the pile spacing is 3m, and 1111 piles with diameter of 0.5 m and length of 9 m are required (The bearing capacity of VDP piles is higher than that of PHC piles, so the pile spacing can be appropriately increased. For soft soil, when the pile spacing exceeds 5 diameter, the pile group effect coefficient is about 1.3 [19]).

The results of carbon emissions in the whole process of the combined method of common piles and drainage boards are shown in Table 1, and the results of carbon emissions in the whole process of the VDP piles are shown in Table 2. From the perspective of total carbon emissions, The VDP piles method can reduce 31.4%, and the main factor for reducing carbon emissions is the reduced use of piles. In addition, the energy consumption of the whole process has also decreased, with 6.8 tons of diesel oil, 13.9 tons of coal and 8678 kw·h of electricity. Therefore, compared with traditional methods, VDP pile treatment of soft soil foundation reduces the use of pile foundation, which conforms to the development principles and models of circular economy and low-carbon economy. It reduces carbon emissions and helps protect the ecological environment. And It reduces energy consumption and promotes the sustainable development of the project.

5. Conclusions

To further explore the bearing capacity and sustainable construction of vacuum drainage pipe (VDP) piles, the VDP pile and PHC pile with a pile length of 9 meters and a pile diameter of 500 mm were fabricated. The field test was carried out on the site composed of fill, silt and silty clay. The ultimate single pile bearing capacity, pile side friction and pile end resistance of PHC piles and VDP piles were compared and analyzed. The effect of the VDP pile on energy conservation and emission reduction in practical projects is discussed. It provides some guidance for the production and design of the VDP pile in the future. And the following conclusions were drawn:

1. The VDP pile will not cause excessive relative displacement of pile and soil during the vacuum consolidation stage. After 4 days of vacuum consolidation, the VDP pile basically eliminated the soil squeeze. But there is still surface uplift on the 10th day after pile sinking for PHC.

2. In this field test, the ultimate bearing capacity of a single pile of the VDP pile is 1743kN, and that of the PHC pile is 1482 kN, which is increased by 17.6%. This is mainly because the VDP pile enhances the side friction of the pile.

3. Compared with PHC pile, the pile side friction resistance of VDP pile to silty clay layer increased by 170.69%, and the vacuum consolidation effect is more obvious for the soil layer with poor structure. When the load on the pile top reaches the limit, the pile end resistance ratio of the VDP pile is less than that of the PHC pile, and the bearing capacity is mainly provided by friction.

4. From the perspective of total carbon emissions, the VDP pile method can reduce 31.4% compared with the traditional method, and the main factor is the reduced use of piles. the energy consumption is also less than the traditional method, which conforms to the principle of low-carbon sustainable development.

Author Contributions

Conceptualization, W.L. and X.T.; methodology, W.L.; software, W.L. and K.L.; validation, W.L., X.T. and Y.Z.; formal analysis, J.L.; investigation, W.L.; resources, W.L.; data curation, Y.Z.; writing—original draft preparation, W.L.; writing—review and editing, X.T.; visualization, Y.Z.; supervision, X.T.; project administration, X.T.; funding acquisition, X.T. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Zhejiang Province Public Welfare Technology Application Research Project (LGG22E080002), the Key Water Science and 477 Technology Project of Zhejiang Province (RB2027) and the Cultural Heritage Bureau of Zhejiang Province (2023006).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

Gratitude is expressed to the construction department, Hongyang Construction Co., Ltd. for its contributions to constructing the test piles and assisting with the static load tests. Gratitude is expressed to the vacuum equipment production department, Jiangsu Xintai Rock Technology Co., Ltd. for its contributions to the vacuum equipment supply and installation. Gratitude is expressed to the pile production department, Zhejiang Xinye Pipe Pile Co., Ltd for its contributions to the production, production and transportation of pipe piles. Gratitude is expressed to the sensor production department, Zhixing Technology Nantong Co., Ltd. for its contribution to sensor installation and technical guidance.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mesri, G. Discussion of “Field study of pile – prefabricated vertical drain (PVD) interaction in soft clay”. Canadian Geotechnical Journal 2021,58(5): 747-747. [CrossRef]

- Wu, Y.; Fang, L.; Li, X.; Hu, S. Technical discussion on tube pile combined with prefabricated strip drain to soft soil treatment. Chinese Journal of Rock Mechanics and Engineering 2006, (z2):3572-3576. (in Chinese).

- Cakiroglu, C.; Islam, K.; Bekdaş, G.; Kim, S.; Geem, Z.W. CO2 Emission Optimization of Concrete-Filled Steel Tubular Rectangular Stub Columns Using Metaheuristic Algorithms. Sustainability 2021, 13, 10981. [CrossRef]

- Zavadskas, E.K.; Antucheviciene, J.; Vilutiene, T.; Adeli, H. Sustainable Decision-Making in Civil Engineering, Construction and Building Technology. Sustainability 2018, 10, 14.

- Umaiyan, U.; Muthukkumaran, M. Improved radial consolidation in soft clay using pervious concrete piles. Civil Eng-Geotec (published online) 2022. [CrossRef]

- Ni, P.; Mangalathu, S.; Mei, G. Compressive and flexural behaviour of reinforced concrete permeable piles. Engineering Sructures 2017, 147: 316-327. [CrossRef]

- Chen, Z.; Wang, B.; Wang, C.; Wang, Y.; Xiao, P.; Li, K. Performance of a Subgrade-Embankment-Seawall System Reinforced by Drainage PCC Piles and Ordinary Piles Subjected to Lateral Spreading. Geofluids (published online) 2023. [CrossRef]

- Deng, Y.; Zhang, R.; Sun, J. Novel technology of statical-drill and rooted drainage pile and its large-scale model test. Journal Building Struct 2022, 43(8): 293-302 (in Chinese). [CrossRef]

- Miranda, M.; Da, C.; Castro, J. Influence of geotextile encasement on the behaviour of stone columns: Laboratory study. Geotextiles And Geomembranes 2017, 45(1):14-22. [CrossRef]

- Poornachandra, V.; Venkataraman, P.; Krishna, P.B. Discrete element method to investigate flexural strength of pervious concrete. Construction and Building Materials 2022, 323, 126477. [CrossRef]

- Tan, X.; Cai, M.; Feng, L. Numerical Study on Mechanical Behaviors of Geotextile-wrrapped Stone Column. China Journal of Highway and Transport 2020, 33(9): 136-145 (in Chinese).

- Tang, X.; Yu, Y.; Zhou, L. A Prefabricated Pipe Pile with Drainage and Enlarged Friction Resistance and its Construction Method. 2015 CN Patent 104846809A (in Chinese).

- Tang, X.; Zou, Y.; Lin, W. Model experiment on improving bearing capacity of perforated pipe piles by vacuum consolidation. Journal of Zhejiang University ( Engineering Science) 2022; 56(7): 1320-1327 (in Chinese).

- Tang, X.; Lin, W.; Zou, Y. Experimental study of the bearing capacity of a drainage pipe pile under vacuum consolidation. Journal of Zhejiang University-Science A (Applied Physics & Engineering) 2022; 23(8), 639-651.

- Technical Code for Testing of Building Foundation Piles (JGJ106-2014). Ministry of Housing and Urban-Rural Construction of the People's Republic of China. (in Chinese).

- Ministry of Transport of People’s Republic of China. China Transportation Yearbook 2021.China Communications Press: Beijing, China, 2021.

- National Energy Administration. Budget Quota of Electric Power Construction Project. China Electric Power Press: Beijing, China, 2018.

- China Electricity Council. Quota of Construction Machinery Shift Cost of Electric Power Construction Project. China Electric Power Press: Beijing, China, 2020.

- Liu, J. Group Effects and Some Problems on the Concept Design of Pile Group Foundation Under Vertical Load. China Civil Engineering Journal 2004, 37(1):78-83.

Figure 1.

Production process of the vacuum drainage pipe pile.

Figure 2.

Production process of vacuum drainage pipe pile.

Figure 3.

Soil parameters and pile parameters.

Figure 4.

The layout of measuring points (unit: mm).

Figure 5.

Surface displacement of soil around the PHC pile.

Figure 6.

Surface displacement of soil around the PHC pile.

Figure 7.

Relative displacement curve.

Figure 8.

Load-settlement curve of pile.

Figure 9.

Distribution of pile side frictional resistance with depth.

Figure 10.

Distribution of pile side frictional resistance with soil layer.

Table 1.

Carbon emission of PHC piles+Plastic drainage boards.

| Project | unit | Material or energy consumption | Emission factor (kg/unit) | Carbon emission (kg) |

|||

| Fabrication | Transport | Construction | Total | ||||

| Concrete | m3 | 2128 | \ | \ | 2128 | 470 | 1000160 |

| Steel | kg | 252160 | \ | 1942 | 254102 | 2 | 508204 |

| PVC | kg | 3000 | \ | \ | 3000 | 6.79 | 20370 |

| Diesel oil | kg | \ | 5704 | 12862 | 18566 | 0.59 | 10953 |

| Electricity | kw·h | 19420 | \ | 8580 | 28000 | 0.28 | 7840 |

| Coal | kg | 45431 | \ | \ | 45431 | 0.73 | 33164 |

| Total carbon emissions in the whole process | 1580693 | ||||||

Table 2.

Carbon emission of VDP piles.

| Project | unit | Material or energy consumption | Emission factor (kg/unit) | Carbon emission (kg) |

|||

| Fabrication | Transport | Construction | Total | ||||

| Concrete | m3 | 1478 | \ | \ | 1478 | 470 | 694660 |

| Steel | kg | 175405 | \ | 1942 | 177347 | 2 | 354694 |

| Diesel oil | kg | \ | 3960 | 7761 | 11721 | 0.59 | 6915 |

| Electricity | kw·h | 13480 | \ | 5842 | 19322 | 0.28 | 5410 |

| Coal | kg | 31537 | \ | \ | 31537 | 0.73 | 23022 |

| Total carbon emissions in the whole process | 1084701 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Copyright: This open access article is published under a Creative Commons CC BY 4.0 license, which permit the free download, distribution, and reuse, provided that the author and preprint are cited in any reuse.

Bearing Capacity and Sustainable Construction of Vacuum Drainage Pipe Pile

Wei-Kang Lin

et al.

,

2023

The Influence of Backfill on the Driving Energy Intensity and Axial Load Resistance of Piles with Shaft Widening: Modeling Research

Isabai Bekbasarov

et al.

,

2023

Development and Mechanical Testing of Porous-Lightweight Geopolymer Mortar

Ghulam Qadir

et al.

,

2020

MDPI Initiatives

Important Links

© 2024 MDPI (Basel, Switzerland) unless otherwise stated