Preprint

Article

Combined Porous-Monolith TiNi Materials Surface-Modified with Electron Beam for New-Generation Rib Endoprostheses

Altmetrics

Downloads

113

Views

49

Comments

0

A peer-reviewed article of this preprint also exists.

supplementary.docx (5.41MB )

This version is not peer-reviewed

Submitted:

23 April 2023

Posted:

25 April 2023

You are already at the latest version

Alerts

Abstract

TiNi alloys are very widely used materials for implant fabrication. When applied as rib replacement, they are required to be manufactured as combined porous-monolithic structure, ideally with a thin porous part well-adhered to its monolithic substrate. Additionally, good biocompatibility, high corrosion resistance and mechanical durability are also highly demanded. So far, all these parameters were not achieved in one material, which is why active search in the field is still underway. In the present work, we prepared new porous-monolithic TiNi materials by sintering a TiNi powder (0-100 µm) on monolithic TiNi plates followed by surface modification with high-current pulsed electron beam. The obtained materials were evaluated by a set of surface and phase analysis methods, after which their corrosion resistance and biocompatibility (hemolysis, cytotoxicity, and cell viability) were evaluated. Finally, cell growth tests were conducted. In comparison with flat TiNi monolith, the newly-developed materials were found to have better corrosion resistance, also demonstrating good biocompatibility and potential for cell growth on their surface. Thus, the newly-developed porous-on-monolith TiNi materials with different surface porosity and morphology show promise as potential new-generation implants for rib endoprostheses.

Keywords:

Subject: Chemistry and Materials Science - Metals, Alloys and Metallurgy

1. Introduction

TiNi and alloys on its basis are materials widely used in medicine due to their unique and attractive properties [1,2,3,4,5,6,7,8,9]. Devices based on them have successfully proved themselves in a wide range of areas, such as development of tools [10,11], cardiology [12,13,14,15], orthopedics [16,17], surgery [18,19,20], ophthalmology [21,22] and so on. Both monolithic and porous materials based on TiNi are extensively used to fabricate implantable structures. Owing to the implementation of thermoelastic martensitic transformations, the monolithic materials exhibit very good mechanical characteristics required for implanted constructions, while having quite poor adhesion of tissue cells on their smooth surfaces [23,24,25]. At the same time, porous TiNi materials, while being more compatible with porous bone tissues and demonstrating better cell attachment and growth, do not exhibit satisfactory mechanical performance. Therefore, combining both monolithic and porous TiNi structures into one material for implantation seems to be a very promising approach. In such a material, its monolithic part is necessary to improve the deformation and strength characteristics under alternating loads, whereas the porous part increases the survival rate of the implanted structure due to its better attachment to surrounding biological tissues of various nature (connective, cartilaginous, bone).

Porous-monolithic or composite TiNi materials are already widely used for the creation of endoprostheses targeting different goals, such as replacement of resected fragments of ribs [26], elimination of defects in the lower jaw [27], dental implantation [28], etc. All the above-mentioned implantable devices and structures based on TiNi typically have a similar composite structure that combines a monolithic TiNi plate and a relatively thick porous TiNi part which is obtained by sintering or by self-propagating high-temperature synthesis (SHS). Endoprostheses of the lower jaw and dental implants have relatively massive porous parts as they do not experience bending and should survive one-dimensional mechanical load. At the same time, since rib implants are subjected to bending, their porous TiNi part should be as thin as possible in order to exclude a decrease in the deformation resource of their underlaying monolithic substrate.

In addition, all endoprostheses of the ribs known so far experience the problem of eruption of their porous part, the latter problem manifesting itself over time as such prostheses are exploited for long periods of time [29,30,31]. This problem is known to be exacerbated by two groups of factors: (i) physiological (high deformation loads in the process of respiratory activity and as a result of everyday physical activity of a person), and (ii) technological (difficulties in making a high-quality contact at the boundary of the monolithic and porous parts).

From the technological point of view, the boundary between the porous and monolithic parts in the artificial ribs requires special attention. Initially, such endoprostheses were made by mechanically connecting monolithic TiNi plates and porous SHS-produced plates using titanium rivets or fastening with thin threads. However, this type of connection is not reliable, since the porous plates can potentially crack or break up around the rivets. As a next step, a more complex preparation approach was proposed in which the monolithic plate was loaded in a quartz tube for SHS, surrounded by a Ti–Ni charge, so that the SHS proceeded on its surface and around. After that, the rib endoprosthesis was machined from an as-prepared cylindrical billet. The disadvantage of this preparation method is its high consumption of materials, labor and time (with a high percentage of waste generated during prosthesis formation). Also, the percentage of defective items is known to increase when the SHS temperature regime during their manufacturing was violated. In the latter case, traces of pure nickel could remain at the boundary with the monolithic part, which is inacceptable for implants. To avoid it, the starting temperature of the SHS stage was increased, which however resulted in much larger surface pores and interpore bridges. [26,27,32]. In addition, because of the technological limitations of the SHS method, the porous part on the finished endoprosthesis is often made as thick as up to 3-5 mm, which also limits the deformation resource of the implant [26,27,32]. Thus, up to date, the technology for fabrication of high-performance TiNi materials for artificial ribs is still far from being reliable, cost-efficient and well reproducible.

To address the above-mentioned challenges and prepare TiNi composite materials with a thin porous layer on a monolithic substrate, yet with high adhesion between them, earlier we proposed to sinter properly selected TiNi powders on monolithic plates with a subsequent modification of the formed composite structure [26,27,32]. After surface modification with a low-energy high-current pulsed electron beam (HCPEB), the fabricated materials were shown to have a relatively thin TiNi-based porous layer on monolith TiNi plates, while the porosity and adhesion of the porous layer could be tuned through processing parameters [33,34,35,36]. The as-fabricated materials can meet the requirements for rib endoprostheses.

In the previous work, we demonstrated that sintering of TiNi powder with sizes 100-200 µm followed by HCPEB treatment permitted to produce composite TiNi surfaces with roughness parameters Ra and Rz within the range of 60–80 and 280–360 µm, respectively [33,34,35,36]. For such relatively large powder particles, the sintering mode used was limited to the sintering temperature of 1200°С. As a result, the depth of modified layer was found to be 5–20 μm. So, the thickness of the porous layer, and especially its adhesion strength to the monolithic substrate, still remained issues for further research.

In the course of further development of composite TiNi materials consisting of porous layer on monolith substrate, the present work focused on producing such materials by sintering and surface HCPEB processing of smaller TiNi powders with initially spongy morphology. Owing to a more developed macrostructure of such powder particles, as well as terrace-like features on their surface, the use of such smaller TiNi powders was expected to help increase the specific surface area of materials based on them.

Thus, the present work aimed at the development of new biocompatible porous-monolithic materials based on TiNi that can be used as new-generation rib endoprostheses. With this overall goal in mind, in this study, we: (i) produced such composite TiNi materials by means of surface sintering of small-sized TiNi powders followed by further HCPEB treatment; (ii) studied the effect of manufacturing parameters on product’s surface roughness and morphology; (iii) studied corrosion resistance of prepared composite materials and compared it with similar materials produced using bigger TiNi powder as precursor, as well as with initial TiNi monolith; (iv) evaluated biocompatibility of produced composite TiNi materials by observing cell growth on their surface.

2. Materials and methods

2.1. Material preparation

To prepare samples with combined porous-monolithic structure, monolithic plates and TiNi powder prepared via the calcium hydride approach [37,38,39,40,41] were used.

Plates of Ni (N1, purity of 99.90%) and spongy titanium (TG-90, purity of 99.94%), both from “Ural Metals”, Kamensk-Uralsky, Russia, were remelted in an ISV-0.004-PI M1 (Petra, Ufa, Russia) induction furnace filled with inert argon gas (99.99% “Cryogenmash-Gas”, Tomsk, Russia) to obtain the initial monolithic TiNi plate. The equiatomic ratio of the melt was achieved with the help of a GH-200 balance (A&D, Tokyo, Japan). After solidification, the resulting ingots (cylindrical, 300 mm long and 25 mm in diameter) were processed in a DOU-80 rolling mill (DOU, Moscow, Russia) until they reached the thickness of 2 mm and the width of 15 mm. Annealing temperatures of 800–1000°C were used in a SUOL 0.4.4/12 tube furnace (Tula-Term, Tula, Russia) in order to relieve stresses after rolling. For etching, the material was immersed in acidic solution (3H2O + 2HNO3 + 1HF) for 2-3 s. Both acids, nitric (65%) and hydrofluoric (45%), were chemically pure in grade, and were purchased from SIGMATEK (Khimki, Russia). After etching the material was washed using water and alcohol. The as-prepared TiNi plate was also characterized for comparison and denoted as TiNi-Pl. (see Table 1).

To prepare the porous part of the materials, TiNi powder of grade PV-N55T45 (Polema, Tula, Russia) was used. Powder particles of desired size range (0-100 µm) were obtained by grinding larger fractions and screening with calibration sieves. Then the powder was placed on a monolithic plate for sintering. The powder-on-monolith blanks were placed in a quartz capsule and sintered at a temperature of 1200° for 15 min in an electric vacuum furnace SNVE-1.31/16-I4 (VARP, Moscow, Russia). Thus, sample SP was obtained (Table 1). To evaluate the temperature influence on the monolithic part of the material, sample TiNi-Pl. was heat-treated under the same conditions, giving rise to sample TiNi-Pl./t (see Table 1).

Replicas of sample SP were then taken to prepare samples SP-20 and SP-30, as the latter samples were subjected to additional treatment by an electron-beam in different modes performed in a RITMSP station (Microsplav Inc., Tomsk, Russia), as previously described by Markov and co-authors [42]. High current (up to 25 kA) and 30 pulses with a pulse duration of 2–4 s with the beam energy of 20 and 30 keV were used to fabricate samples SP-20 and SP-30, respectively. The beam diameter was up to 80 mm, with energy density being around 3 J/cm2 for SP-20 sample, and 6 J/cm2 for SP-30 sample. In the present work, in addition to the series of small-pored (SP) materials, we also prepared their large-pored (LP) counterparts, the latter materials being obtained under same conditions but with the use of larger TiNi powders, as was previously reported elsewhere [36] (Table 1).

2.2. Sample characterization

The granulometric composition of initial powder was studied using a laser particle size analyzer Analysette 22 NanoTec plus (Fritsch, Idar-Oberstein, Germany). Scanning electron microscopy (SEM) studies were performed on a Quanta 200 3D system (FEI Company, Hillsboro, OR, USA). Surface roughness parameters, such as maximum deviation Rz and average roughness Ra, were found using optical profilometry (MNP-1 tool from Technological Design Institute of Scientific Instrument Engineering, Siberian Branch of RAS, Russia) and the instrument’s original software. X-ray diffraction (XRD) patterns of the samples were recorded on an XRD 6000 diffractometer (Shimadzu, Japan) within the range of 2θ = 20–100° at a sampling rate of 0.02°/s using CuKα radiation. The PDF-4 database and Powder Cell 2.5 software with pseudo-Voigt profile function were used for phase analysis.

2.3. Electrochemical corrosion study

Electrochemical measurements were performed on an R-40X potentiostat-galvanostat (Electrochemical Instruments, Chernogolovka, Russia). An E-7SF three-electrode cell filled with saline (0.9% NaCl), with a graphite auxiliary electrode and an Ag/AgCl reference electrode (4.2 M KCl) was used. The test material was pressed against the current collector and contacted with the electrolyte through a window in the bottom of the cell, 10 mm in diameter. The potential varied from –1 to +1 V with a sweep rate of 3 mV/s. Tafel plots were obtained from the recorded data, while values of corrosion potential Ecorr and corrosion current Icorr were found graphically.

To calculate the corrosion rate, it is necessary to determine the surface area that contacted with the electrolyte during the experiment. The studied samples had different roughness, which determines the specific surface area of the material. Since in this work the main task was to compare materials with each other, it was decided to normalize the surfaces of materials according to their values of roughness parameter. For this, we used a Ti plate as a flat standard, thus taking its roughness parameter as 1. For all the other materials tested, their Ra value was divided by that of the Ti plate (Formula 1). The resulting coefficient (fn) was put into the formula for calculating the corrosion rate instead of the surface area (Formula 2). Thus, the obtained relative corrosion rate for the materials () allowed us to compare the materials with each other.

where the roughness values Ra were measured separately for each material; EW is the equivalent weight of the material, in this case equal to 26.36 (dimensionless); ρ is the density of the material. More detailed description of all formula members along with their dimensions can be found in ASTM G102 (Standard Practice for Calculation of Corrosion Rates and Related Information from Electrochemical Measurements, section 03.02).

2.4. Biocompatibility and cytotoxicity experiments

2.4.1. Hemolysis study

The human blood of a healthy volunteer was used. It was mixed with a sodium citrate solution (3.8 wt.%). Then, it was diluted with saline 9:1. Samples (TiNi-Pl. and LP) were immersed in a standard test tube containing 10 mL of saline preincubated at 37°C for 30 min. After that, 0.2 mL of diluted blood was added to this standard tube and incubated for 60 min at 37°C. Normal saline used as a negative control, and deionized water as a positive control, were treated similarly. Then, all tubes were centrifuged for 5 min at 3,000 rpm in a 2-7 Cyto centrifuge (Sigma Laborzentrifugen, Osterode am Harz, Germany) and the supernatant was carefully transferred to a cuvette for spectroscopic analysis. Hemolysis was calculated using an ultraviolet spectrophotometer (Picon, Uniplan, Russia) using Formula 3:

where OD is the optical density, “test” denotes tested material with blood, while “neg.” and “pos.” are used for negative and positive controls, respectively.

2.4.2. Cytotoxicity study

MTT assay was used to evaluate the cytotoxicity of TiNi-Pl. and LP samples.

MCF-7 cells were cultured in Dulbecco’s Modified Eagle’s Medium (DMEM), 10% fetal bovine serum (FBS), antibiotics (100 U/mL penicillin and 100 mg/mL streptomycin) and 2 mM L-glutamine at 37°C in a humidified room with atmosphere containing 5% of CO2.

Tests for cytotoxicity were performed by direct contact. Control groups included the use of DMEM as a negative control and 0.64% phenolic DMEM as a positive control. Cells were incubated in 12-well cell culture plates with media in each well with samples incubated for 24–72 h. After that, MTT was added to each well. Samples were incubated with MTT for 4 h at 37°C, then the plates were centrifuged for 10 min at 1,500 rpm. The supernatant was carefully removed, and a solution of solubilized formazan (10% SDS in 0.01 M HCl) was added to each well. The spectrophotometric absorbance of the samples was measured at 540 nm on a Picon (Picon, Uniplan, Russia) with a reference wavelength of 630 nm.

2.4.3. Cell viability study

The viability of human peripheral blood mononuclear cells was studied.

At first, 10 mL of blood was diluted 1:1 with PBS, layered on ficoll and centrifuged at 2,000 rpm for 30 min. Thus, a layer containing mononuclear cells was obtained. Then, 5 mL of the buffy coat sample were washed twice with 10 mL of PBS, centrifuged at 1,500 rpm for 5 min, and placed in a 12-well plate containing 2×106 cells/mL of RPMI-1640 (Paneco, Moscow, Russia) with the addition of 10% fetal bovine serum (Paneco, Moscow, Russia), antibiotics (100 units/mL penicillin and 100 mg/mL streptomycin) and 2 mM L-glutamine at 37°C in 5% CO2 atmosphere. The studied samples were placed in a 12-well plate and incubated for 24 and 72 h. Viability was then determined using the trypan blue dye exclusion method.

2.4.4. Cell growth study

All research procedures complied with the ethical rules for working with laboratory animals, including the European Directive FELASA-2010. Research plans were reviewed and approved by the Bioethics Commission of the National Research Tomsk State University. Bone marrow stem cells of F1 CBA/j hybrid mice were used as cellular material. The femur was removed under sterile conditions, after which the bone marrow was washed out with a syringe into vials.

The cell concentration was adjusted to 107 cells/ml of complete medium, after which they were seeded on TiNi samples and placed in 50 mL plastic bottles (Corning, USA). Cultivation took place in a medium that consisted of DMEM-F12 medium (Paneco, Moscow, Russia), 10% fetal calf serum (HyClone, USA), gentamicin 40 μg/ml (Paneco, Moscow, Russia), glutamine 250 mg/mL (Paneco, Moscow, Russia).

Differentiation additives were used in the system with osteogenic differentiation: beta-glycerophosphate 3 mg/ml (Sigma-Aldrich, St. Louis, MO, USA) in combination with 0.15 mg/ml ascorbic acid (Sigma-Aldrich, St. Louis, MO, USA). Incubators with cells were kept at T = 37°C and 100% humidity with 5% CO2 concentration. Experimental samples were examined on days 1, 7, 10, and 17. Incubators were fixed for 1 h in 2.5% glutaraldehyde (Sigma-Aldrich, St. Louis, MO, USA), then washed three times in PBS medium (15 min each), then fixed for 1 h in 1% osmium tetroxide (Sigma-Aldrich, St. Louis, MO, USA), washed 3 times in PBS and then dehydrated by passing through a series of ethanol solutions (30%, 50%, 70%, 90%, 100%) for 15 min each.

SEM and confocal laser scanning microscopy (CLSM on LSM 780 NLO, Zeiss, Germany) were used to observe the cells growing on the samples. The second method was performed for non-dried samples using suitable vital stains (acridine orange and ethidium bromide).

3.1. Structure and composition of combined monolithic-porous material

3.1.1. Monolithic part of the material

To obtain a TiNi monolithic plate after melting the ingot, a two-roll rolling mill was used. This allowed us to produce 2-mm-thick plates from a cylindrical ingot. After multiple rolling and intermediate annealing procedures, the as-prepared TiNi monolithic material was covered with a massive TiO2 layer up to 300 µm in thickness. The latter layer has a granular structure and it was constantly renewed during processing, since in the process of compression its outer part cracked and fragmented. Bilateral deformation is known to lead to the formation of a longitudinally textured oxide layer which, in addition to titanium oxide, may also contain secondary elements (C, Si, Fe, etc.) that enter into it during thermo-mechanical treatments. And because surface oxides are known often to prevent the surface of a monolithic plate from being wetted by a melt during sintering [43] such materials should be cleaned from their massive oxide layer before covering their monolithic part with a porous powder layer.

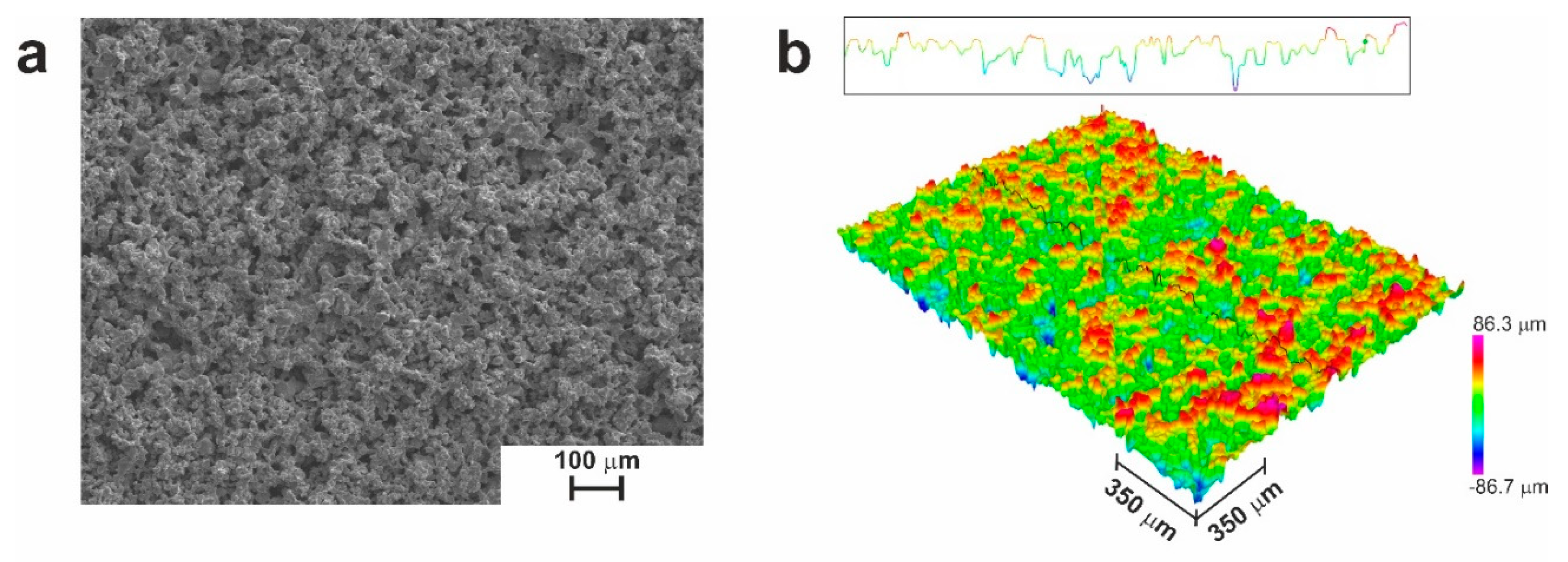

For surface cleaning, chemical etching with an aqueous solution of nitric and hydrofluoric acids was used in the present work. Such a treatment removed the oxide layer, along with the TiNi and Ti2Ni compounds. Since TiNi is the main phase of the prepared monolithic material, and particles of the secondary Ti2Ni phase have sizes in the range of 0.1-3 µm, after chemical pretreatment, the TiNi plate had surface craters up to 3 µm in size. Further etching led to gradual disappearance of such craters, eventually resulting in the TiNi plate with surface morphology presented in Figure 1. The average roughness parameter of the material after chemical etching was Ra = 0.5 µm, with the maximum profile deviation Rz = 5.5 µm. This surface topography was considered appropriate for further deposition of a porous layer through sintering of TiNi powder followed by HCPEB processing.

3.1.2. TiNi powder used in the study

As mentioned in the Experimental section, the powder particles in the desired size range were obtained by grinding larger fractions of the same powder. TiNi powders obtained by the calcium hydride reduction are known to have a spongy structure [37]. Their grinding therefore leads to destruction of individual large spongy particles and formation of spongy and compact ones with drop-like and dumbbell-like shapes, as well seen in Figure 2. The average particle size of the resulting powder was found to be approximately 25.5 µm and had a normal Gaussian distribution (Figure 2, Inset). The use of smaller particles (with sizes up to 100 μm) resulted in the increase of the specific surface area of resultant powder to 470 cm2/g (or 3050 cm2/cm3), while the use of a larger fraction with sizes 100–200 μm showed a lower value of 65 cm2/g (or 410 cm2/cm3).

Thus, potentially, fabrication of a thin porous TiNi alloy based on a powder with sizes below 100 µm should permit to obtain a thin and more structurally developed surface layer on a monolithic TiNi substrate.

3.1.3. Resultant structure of TiNi powder and monolithic parts and their subsequent treatment

Sintering the above described TiNi powder on the surface of preprepared monolithic TiNi plate at a temperature of 1200 °C led to a well-developed porous surface structure with Ra of 22 µm and Rz of 140 µm (Figure 3).

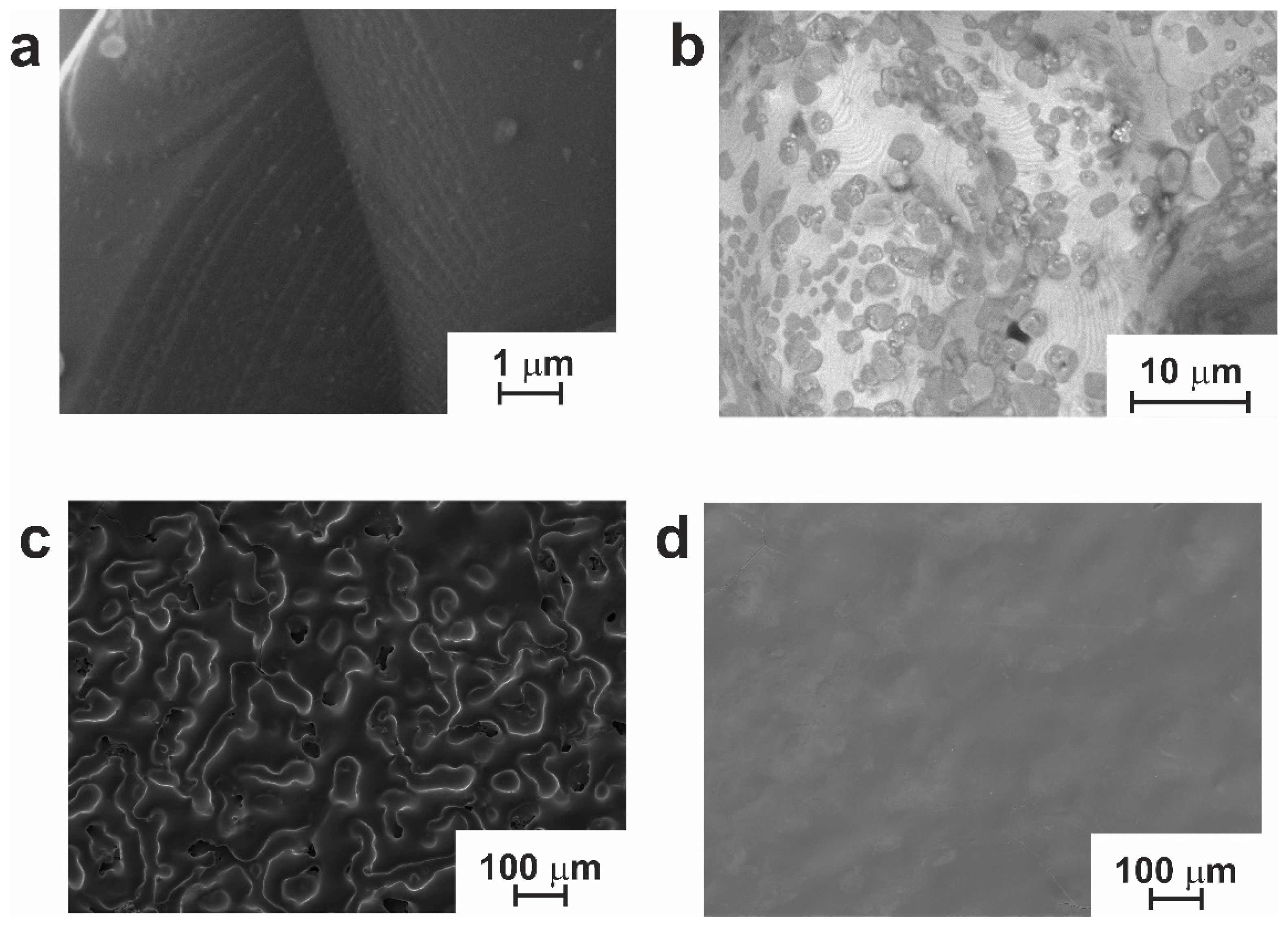

It is seen that the surface of the manufactured material inherited the spongy-like structure of sintered powder particles. Also, a specific terrace-like structures could be found on the surface of the TiNi phase of the material (Figure 4a). Additionally, during high-temperature processing, inevitable interaction with carbon atoms from oil vapor (from the diffusion pump) occurred, with Ti2Ni secondary phase particles dissolving it to form Ti4Ni2(C,O) oxycarbide phases seen in Figure 4b.

Figure 4 also shows an SEM surface image of sample SP which was prepared after treatment with the electron beam in modes 20 and 30. It is seen in Figure 4c that sample SP-20 (prepared in mode 20) preserved the developed surface structure of the initial powder material. On the contrary, sample SP-30 exhibits an excessive degree of electron beam processing, which led to a surface structure consisting of concave and convex sections (Figure 4d).

Energy-beam treatment is known to homogenize the surface of processed materials. Repeated exposure to a high-energy electron beam leads to the melting of surface layers as thick as several micrometers. With an increase in pulse number, the volume of forming liquid phase increases due to thermal heating. Over time, the latter liquid phase intermixes and partially evaporates, while rapid crystallization occurs during intervals between irradiation pulses. Non-equilibrium phase transformations proceed in the surface layer, giving rise to ultrafine-grained or nanosized structures [44]. However, the presence in the surface layer of secondary-phase particles (e.g., Ti2Ni), oxycarbonitrides, or titanium carbide TiC was reported to lead to the formation of craters [45,46]. Repeated irradiation of the formed material induces the formation of new craters, and thus overlapping and melting of such craters eventually leads to surface smoothening. That is why the surface morphology, as well as surface roughness parameters, of sample SP-30 was found to approach that of the original monolithic plate, as well seen in Figure 4d and Table 2.

So, sintering followed by modification with electron beam permits to effectively control the macrostructure of the porous top layer formed on the surface of monolithic TiNi material.

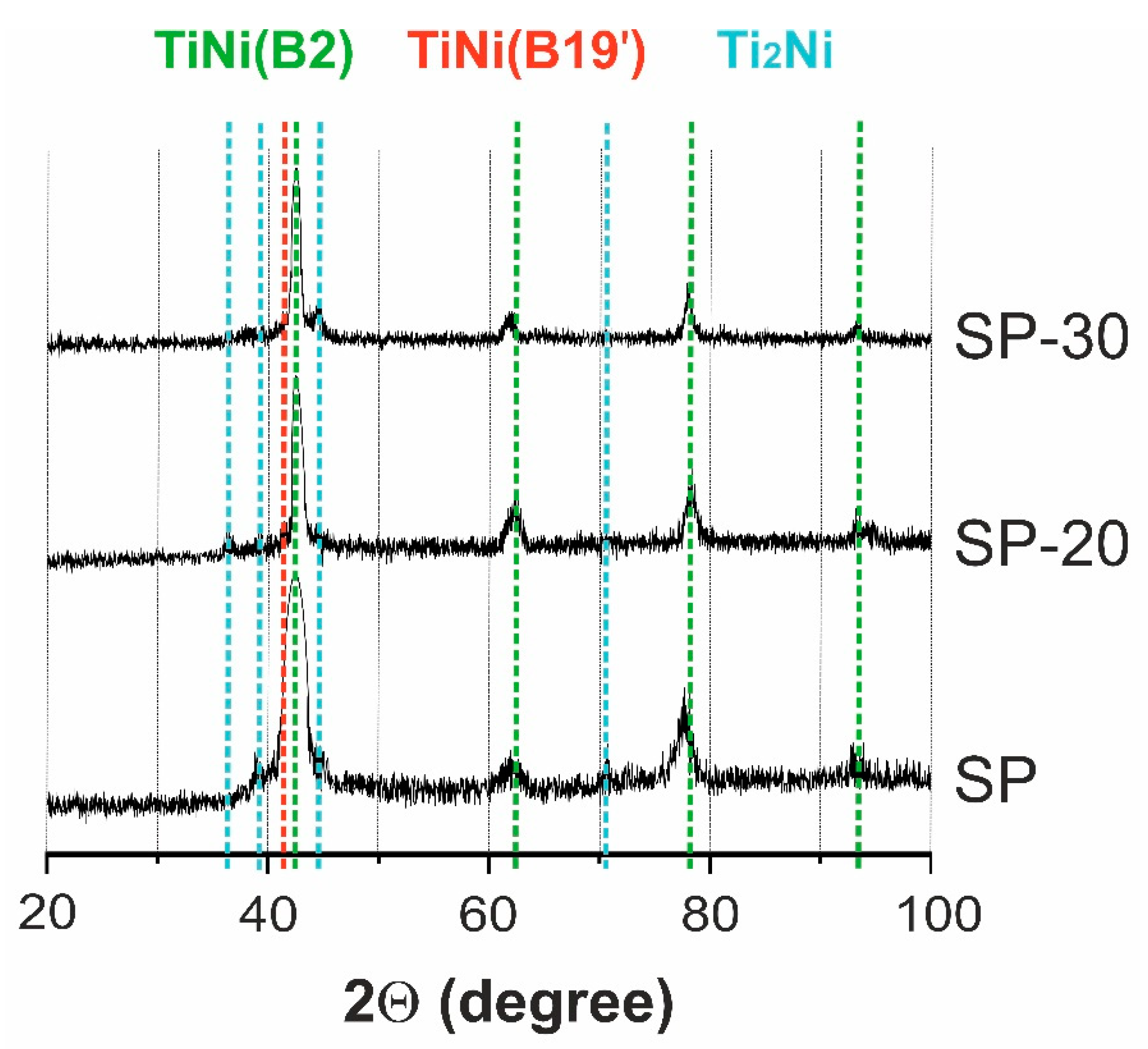

3.1.4. Composition of obtained materials

The results of XRD analysis of the SP group samples are presented in Figure 5, where the XRD patterns of all samples demonstrate their matrix compound TiNi being in the austenitic (B2) and martensitic (B19’) states. The presence of second-phase particles Ti2Ni/Ti4Ni2(O,С) is also confirmed, with the calculated content of all detected phases presented in Table 3. It is seen that with an increase in the energy of the electron beam impact, the volume fraction of the main TiNi phase increases while the volume fraction of secondary phases decreases. This finding is consistent with the work of several other teams [47,48,49]. During electron-beam treatment, desorption of light elements (O, C) from the surface and secondary recrystallization to a depth of up to 20 µm occur. This leads to dissolution of second-phase particles in the irradiated part of the powder layer. Thereby, as a result of electron-beam treatment, the phase composition of the material’s top layer is homogenized.

3.2. Corrosion study of the materials

In the present work, in addition to corrosion performance of newly-developed materials (materials of the SP series), for comparison we also tested corrosion performance of their counterparts prepared with larger TiNi particles (materials of the LP series) whose preparation was reported elsewhere [36]. This allowed us to reveal the effect of particle size of TiNi powders on corrosion resistance of potential rib implants manufactured on their basis (materials of series LP and SP).

Figure 6 and Figure 7, and Figures S1–S7 show microscopic images of samples from the LP and SP series taken before and after electrochemical corrosion tests. It is seen that after polarization cycles, all materials underwent changes in the structure and composition of their surface. Based on the images obtained after corrosion (low rows in Figure 6 and Figure 7), one can assume uneven corrosion, local corrosion, including pitting and corrosion by spots.

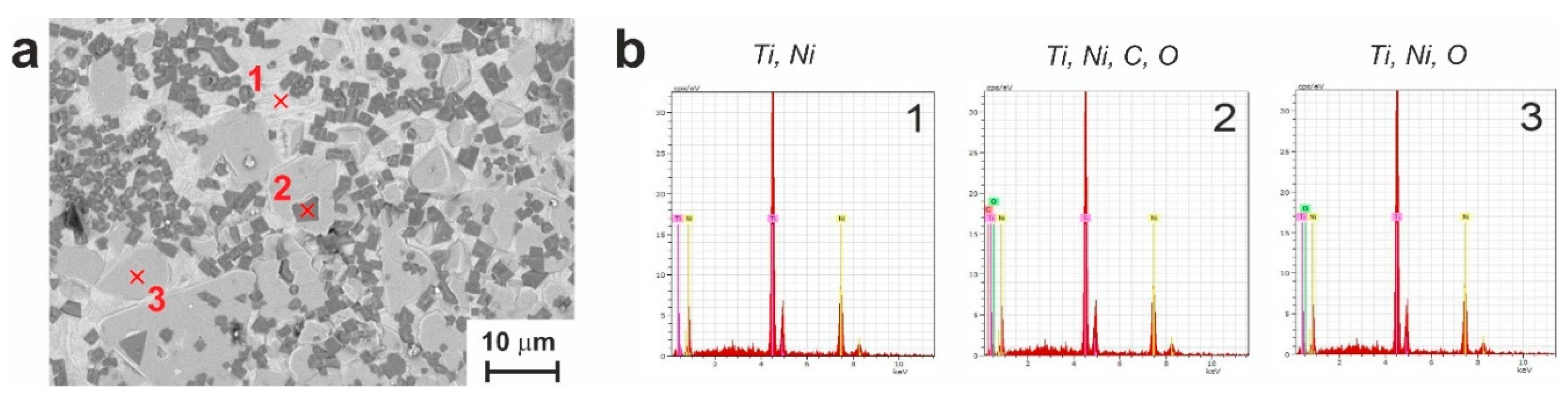

Two corrosion processes are possible for combined porous-monolith materials: (1) structural corrosion, which is associated with the initial structural inhomogeneity of the surface of the samples; (2) selective corrosion, which destroys only one component of the material or one of its structural components (for example, only protrusions or only the bottom of pores). Both these processes were observed for the LP and SP series samples, with corrosion products quite clearly seen on the surface in Figure 6 and Figure 7 (lower rows). Bulk particles located on the surface undergone corrosion are of a particular interest, which is why we applied EDX to various particles and found two distinct types exhibited in Figure 8. It is clearly seen that while one contains C and O atoms, the other one shows only O as impurity (compare spectra for points 1 and 2). Both types formed from the Ti2Ni phase and are generally defined as the Ti4Ni2(O,N,C) class.

The Tafel curves recorded during electrochemical corrosion tests for all studies materials (as well as for Ti and TiNi plates used as reference) are shown in Figure 9. The obtained data allowed us to determine graphically the values of corrosion current and corrosion potential which are all presented in Table 4. Since in the present work the real (electrochemical) surface area of the samples could not be determined, corrosion rates of the materials could not be evaluated. Thus, for the sake of comparison, Table 4 which were calculated taking into account samples’ surface roughness (See Section 2 for details).

It is seen in Table 4 that the most positive value of the corrosion potential was demonstrated by the Ti plate. So, according to the values of corrosion potential, one can conclude that this material is the most resistant to corrosion when compared to the other samples. However, the most reliable way to assess the corrosion resistance of a material is to analyze its corrosion rate. Therefore, in Figure 10, a general histogram of calculated corrosion rates is presented.

Figure 10 shows that the highest corrosion rate was observed for the original TiNi plate. This was expected since the plate has a lot of surface defects which are potential sites for corrosion. After heat-treatment, the corrosion rate of the same plate (TiNi-Pl./t) expectedly decreased as annealing is well-known to lead to surface passivation through the growth of thicker surface oxide layers. Thus, thermal treatment increases the resistance of TiNi to corrosion in a biological environment.

In general, all the other tested materials demonstrated corrosion rates lower than that of reference Ti plate. That is, their corrosion resistance in biological media should be better than that of titanium (which is a standard material for numerous implants). Among the two-dimensional porous materials based on TiNi, the lowest corrosion rate was found for samples LP, LP-20, and SP-30 (see Figure 10).

An interesting point worth discussing is the anomalously increased corrosion rate seen in Figure 10 for sample SP-20, especially in comparison with samples SP and SP-30. Unlike the other samples, the powder-based layer on sample SP-20 was found to crack during polarization (see Figure S5c), and this could have a crucial effect on the sample’s behavior. It can be assumed that cracks, and freshly exposed surfaces associated with them, could be the reason and sites for higher-rate corrosion.

Thus, with a comprehensive consideration of corrosion parameters extracted from electrochemical measurements, it was demonstrated that the newly-developed materials consisting of porous and monolithic TiNi parts, both with and without additional modification with electron beam, exhibit increased corrosion resistance compared to monolithic TiNi alloy (see Figure 10). The obtained results pave the road for further research in this direction aiming at finding the best optimal conditions for powder-based coating with highest possible corrosion resistance.

3.3. Biomedical characterization

3.3.1. Hemolysis and cytotoxicity study

Hemolysis and cytotoxicity were studied for the TiNi plate and one of newly-developed materials based on a combination of monolithic and porous TiNi, namely sample LP. Standard test for biocompatible materials showed that the hemolysis of erythrocytes was (1.98 ± 0.34) % and (1.65 ± 0.31) % for samples TiNi-Pl and LP, respectively. Thus, having the degree of hemolysis below 2%, the newly-developed TiNi materials meet the standard requirements for biocompatible materials that contact with the circulatory system.

The index of cytotoxicity studied using the MTT test during daily cultivation with MCF-7 line cells showed a decrease from (24±2.2)% for TiNi-Pl, with no porous layer, to (13 ± 1.3 )% for sample LP. Thus, the newly-developed TiNi materials with a porous surface are shown to reduce the cytotoxicity index by 11% when compared with a conventional flat TiNi plate.

The viability of human peripheral blood mononuclear cells was assessed during their long-term cultivation in presence of sample LP. The experiment carried out for up to 72 h demonstrated an increase in the viability of human blood mononuclear cells showing (80 ± 5)% on day two and (62 ± 4)% on day three. For comparison, sample TiNi-Pl showed similar values of (71 ± 5)% and (46±4)% for day two and day three, respectively. Since the composition of both materials is similar, it can be concluded that it is the surface morphology that affects the cellular biocompatibility observed. This implies that the modification of TiNi with a porous layer has a long-term potential for cytocompatibility.

3.3.2. Cell growth experiments

The test was carried out for different periods of cultivation (namely, 3, 7, 10, and 17 days) with cell cultures and using SEM and CLSM for visualization.

Figures S8 and S9 show the surface of materials after 3 days of cell growth. Separate cells, rather than agglomerates, can be seen on the surface of both series LP and SP samples. Cells grown after one week are shown in Figures S10 and S11, where the number of cells is clearly larger than it was after 3 days. In general, at the initial stage (days 3-7), the best results in terms of cytocompatibility were demonstrated by the SP series samples, especially SP-20 (Figures S8–S11, Supplementary Materials). In general, both electron and confocal microscopy showed an increase in the number of cells on the surface of all small-pored samples when compared with their large-pored counterparts. This may be explained by the increased surface area of the SP samples, as well as surface terrace-like structures, both of them apparently leading to better cell adhesion on such samples.

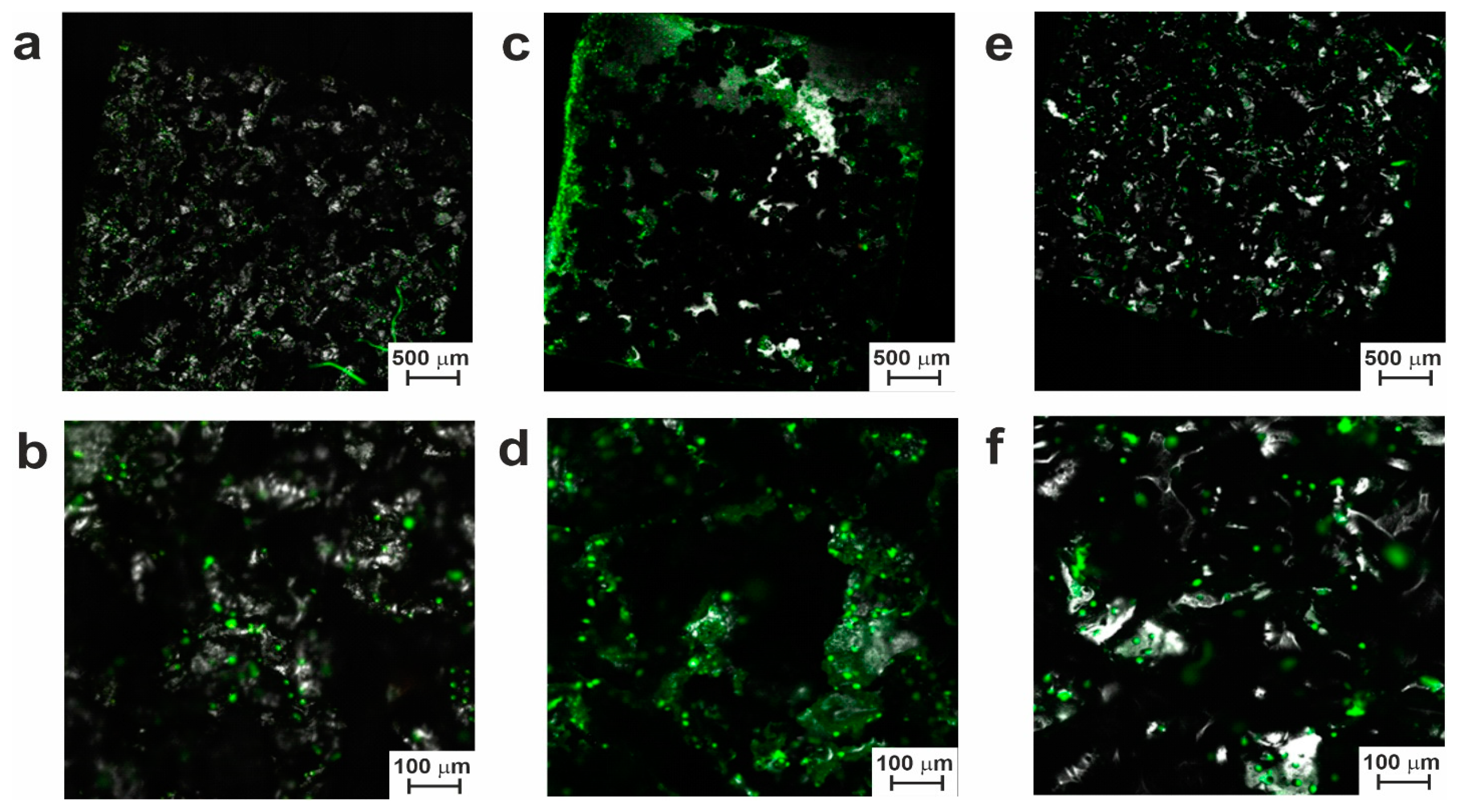

As clearly seen in Figures S8–S11, during the initial periods of growth, cells were mainly located in local surface trenches and valleys that had formed along with surface hillocks as a result of TiNi fusion on a smooth TiNi substrate and subsequent electron-beam treatment of samples 20 and 30. This could be explained by the spontaneous sedimentation of cells in suspension and the ingress of more cells before attaching into surface valleys. As the cell colonies grew further, later they gradually populated the tops and hillocks of the surface (Figure 11 and Figure 12, and Figures S12 and S13, Supplementary Materials). This indicates that cell culture can successfully colonize and grow on porous TiNi surfaces developed in this work as potential materials for implants.

It should be noted that while at initial stages, the SP samples demonstrated more colonies on their surface, after days 10-17, more cells and cell agglomerations were found on electron-beam-treated samples from the LP group (see Figure 11 and Figure 12, and Figures S12 and S13, Supplementary Materials). This implies that surface morphology indeed plays a crucial role in cell growth dynamics on the samples prepared in this study.

In addition to cells, adult tissue is known to contain an intercellular matrix with colloidal and fibrous components. After 10 days of cultivation, the population of bone marrow stromal cells was found to continue developing on the tested samples. By day 10, most of the cells were found to protrude the plasma membrane and form intercellular connections. Thus, Figure 11 and Figure 12, and Figures S12 and S13 exhibit the areas where growing cells accumulated on the tested surfaces. On day 17 of cell growth, an increase in the formation of the intercellular matrix was well seen, which is known to happen when the required critical level mass in achieved by growing cells. At this point, the concentration gradient of growth and nutritional factors inside local surface valleys increases, and the cells gradually fill their initial locations, moving further and covering the nearby hillocks on the sample’s surface (Figure 11 and Figure 12).

Obviously, the small-pored samples with more developed surface structures (of the SP series) are more favorable for initial cell fixation on the material surface. However, further growth of cell populations proceeds better on smoother surfaces (of the LP series). This can be explained by easier cell motion over short distances on a smoother surface in comparison with more energy-demanding expansion and growth on a rougher surface. Hence, optimization of surface morphology is necessary to provide a TiNi material with a good balance between the initial adhesion of cells and their further spreading over the entire surface.

Thus, based on the obtained results, it can be concluded that the materials developed in the present study, with their fused surface structures based on TiNi powders, are biocompatible with mesenchymal cells of the bone marrow of CBA mice and, consequently, with their derivatives: bone, cartilage, and adipose tissues. At the same time, the use of different powder fractions and different parameters for electron-beam processing during sample preparation permits to tune surface morphology and the way the produced material interacts with surrounding living tissues.

4. Conclusion

Aiming at developing new-generation materials for rib endoprostheses, this work reports on a newly-prepared TiNi material combining thin porous layer and monolithic plate as substrate. The material was obtained using a TiNi powder with relatively small (below 100 µm) particles which were sintered on monolithic TiNi plate, followed by a subsequent treatment with high-current pulsed electron beam (HCPEB). By tuning beam parameters, a series of porous-monolithic TiNi materials with small-pored surface layer were prepared. For comparison, a similar series of large-pored materials was prepared applying a similar TiNi powder with lager particles (100-200 µm).

Before HCPEB treatment, sintered small-pored materials demonstrated terrace-like features on their porous surface, while after irradiation with high-energy beam they exhibited homogenized surface structure and composition due to dissolution of secondary phases. Expectedly, the surface of such materials was more porous and rougher than that of initial TiNi monolith used as substrate.

Comparison with large-pored samples demonstrates that use of TiNi powders with different sizes for surface modification of monolithic substrate permits to tune surface morphology and roughness, which is important for manufacturing implants with tuned cell adhesion.

Electrochemical corrosion experiments carried out on both small-pored and large-pored porous-on-monolith TiNi materials demonstrated improved corrosive resistance of such materials in comparison with flat TiNi monolith used as their substrate. Thus, the corrosion resistance of powder-modified monolith TiNi materials tested in biological media was found to be good enough for their application as implants.

Hemolysis degree was found to be below 2%, implying that the newly-developed TiNi materials meet the standard requirements for biocompatible materials contacting with the circulatory system. The cytotoxicity index was revealed to be lower by 11% in comparison with the initial flat TiNi monolith plate, and the viability test of human peripheral blood mononuclear cells showed that the modification of TiNi with a porous layer has a long-term potential for cytocompatibility.

Cell growth experiments carried out for both large-pored and small-pored porous-monolithic materials showed their biocompatibility with mesenchymal cells of the bone marrow of CBA mice and, consequently, with their derivatives: bone, cartilage, and adipose tissues. During the test, cell spreading was observed to be dependent on surface morphology. This implies that the ability of the approach used to tune surface roughness and morphology is very useful for optimizing the surface of potential implant for its best compatibility with surrounding tissues.

Overall, the newly-developed porous-on-monolith TiNi materials with different surface porosity and morphology show promise as potential new-generation implants for rib endoprostheses.

Supplementary Materials

The following supporting information can be downloaded at the website of this paper posted on Preprints.org.

Author Contributions

Conceptualization, V.A.V., M.I.K., N.V.A. and V.N.H.; methodology, S.G.A., A.V.M. and S.A.K.; software, N.V.A., V.A.V. and M.I.K.; validation, A.V.S., M.I.K., N.V.A., S.A.K. and V.N.H.; formal analysis, A.V.S., E.V.Y. and E.A.P.; investigation, M.I.K., A.V.L. and M.N.V.; resources, V.N.H.; writing— original draft preparation, M.I.K., V.N.H., A.V.S. and S.A.K.; writing—review and editing, V.N.H., S.A.K., A.V.M. and V.E.G.; visualization, A.V.S., S.P., O.M. and V.V.S.; supervision, V.N.H. and V.V.S.; project administration, V.A.V. and S.G.A.; funding acquisition, V.A.V. and S.G.A. All authors have read and agreed to the published version of the manuscript.

Funding

The study was supported by the Russian Science Foundation (grant no. 19-79-10045). https://rscf.ru/project/19-79-10045/.

Data Availability Statement

Not applicable.

Acknowledgments

The analyses (SEM studies) were carried out with the equipment of Tomsk Regional Core Shared Research Facilities Center, National Research Tomsk State University. The Center was supported by the Ministry of Science and Higher Education of the Russian Federation (grant no. 075-15-2021-693 (no. 13.RFC.21.0012)).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Buehler, W.J.; Gilfrich, J.W.; Wiley, R.C. Effect of low-temperature phase changes on the mechanical properties of alloys near composition TiNi. J. Appl. Phys. 1963, 34, 1475–1477. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti-Ni based shape memory alloys. Prog. Mater Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Saburi, T. Ti-Ni shape memory alloys. In Shape Memory Materials; Otsuka, K., Waymann, C.M., Eds.; Cambridge University Press: Cambridge, UK, 1999; pp. 49–96. [Google Scholar]

- Parvizi, S.; Hashemi, S.M.; Asgarinia, F.; Nematollahi, M.; Elahinia, M. Effective parameters on the final properties of NiTi-based alloys manufactured by powder metallurgy methods: A review. Prog. Mater. Sci. 2021, 117, 100739. [Google Scholar] [CrossRef]

- Saber, O.; Ansari, S.A.; Alshoaibi, A. Development of Ti/Ni nanolayered structures to be a new candidate for energy storage applications. Appl. Sci. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Carpegna, G.; Alovisi, M.; Paolino, D.S.; Marchetti, A.; Gibello, U.; Scotti, N.; Pasqualini, D.; Scattina, A.; Chiandussi, G.; Berutti, E. Evaluation of pressure distribution against root canal walls of NiTi rotary instruments by finite element analysis. Appl. Sci. 2020, 10. [Google Scholar] [CrossRef]

- Sachdeva, R.C.L.; Miyazaki, S. Nitinol as a biomedical material. Encycl. Mater. Sci. Technol. 2001, 6155–6160. [Google Scholar] [CrossRef]

- Wadood, A. Brief overview on nitinol as biomaterial. Adv. in Mater. Sci. and Eng. 2016, 4173138. [Google Scholar] [CrossRef]

- Dagna, A.; Gastaldo, G.; Beltrami, R.; Poggio, C. Debris evaluation after root canal shaping with rotating and reciprocating single-file systems. J. Funct. Biomater. 2016, 7, 28. [Google Scholar] [CrossRef]

- Poggio, C.; Dagna, A.; Chiesa, M.; Beltrami, R.; Bianchi, S. Cleaning effectiveness of three NiTi rotary instruments: a focus on biomaterial properties. J. Funct. Biomater. 2015, 6, 66–76. [Google Scholar] [CrossRef]

- Stoeckel, D.; Pelton, A.; Duerig, T. Self-expanding nitinol stents for the treatment of vascular disease. Shape Mem. Alloy. Biomed. Appl. 2009, 237–256. [Google Scholar] [CrossRef]

- Pelton, A.R.; Schroeder, V.; Mitchell, M.R.; Gong, X.Y.; Barney, M.; Robertson, S.W. Fatigue and durability of nitinol stents. J. Mech. Behav. Biomed. Mater. 2008, 1, 153–164. [Google Scholar] [CrossRef] [PubMed]

- Early, M.; Kelly, D.J. The consequences of the mechanical environment of peripheral arteries for NiTi stenting. Med. Biol. Eng. Comput. 2011, 49, 1279–1288. [Google Scholar] [CrossRef] [PubMed]

- Dordoni, E.; Meoli, A.; Wu, W.; Dubini, G.; Migliavacca, F.; Pennati, G.; Petrini, L. Fatigue behaviour of nitinol peripheral stents: the role of plaque shape studied with computational structural analyses. Med. Eng. Phys. 2014, 36, 842–849. [Google Scholar] [CrossRef] [PubMed]

- Wawrzynski, J.; Gil, J.A.; Goodman, A.D.; Waryasz, G.R. Hypersensitivity to orthopedic implants: A review of the literature. Rheumatol. Ther. 2017, 4, 45–56. [Google Scholar] [CrossRef] [PubMed]

- Majumdar, T.; Eisenstein, N.; Frith, J.E.; Cox, S.C.; Birbilis, N. Additive manufacturing of titanium alloys for orthopedic applications: A materials science viewpoint. Adv. Eng. Mater. 2018, 20, 1800172. [Google Scholar] [CrossRef]

- Anikeev, S.G.; Kaftaranova, M.I.; Hodorenko, V.N.; Ivanov, S.D.; Artyukhova, N.V.; Shabalina, A.V.; Kulinich, S.A.; Slizovsky, G.V.; Mokshin, A.V.; Gunther, V.E. TiNi-based material with shape-memory effect for surgical treatment of diseases of small intestine in newborn and young children. J. Funct. Biomater. 2023, 14, 155. [Google Scholar] [CrossRef]

- Iliushenov, V.N.; Iliushenov, A.V.; Iliushenov, S.V.; Anikeev, S.G.; Marchenko, E.S.; Baigonakova, G.A.; Gunther, V.E. Surgical treatment of fractures of long tubular bones of elderly and old-aged people with the usage of shape memory implants. KnE Mater. Sci. 2017, 2, 227–235. [Google Scholar] [CrossRef]

- Shtin, V.I.; Novikov, V.A.; Gunther, V.E.; Choinzonov, E.I.; Ryabova, A.I.; Sirkashev, V.A.; Surkova, P.V.; Yasenchuk, Y.F.; Anikeev, S.G.; Vasilev, R.V. Current aspects in reconstructive surgery for nasal cavity and paranasal sinus cancer. KnE Mater. Sci. 2017, 2, 327–333. [Google Scholar] [CrossRef]

- Steblyuk, A.N.; Gunther, V.E.; Bodnia, V.N.; Avakimyan, R.A.; Tserkovnaya, A.A. A new method for non-invasive surgery in ophthalmology. KnE Mater. Sci. 2017, 2, 261–266. [Google Scholar] [CrossRef]

- Gunther, S.V.; Anikeev, S.G.; Ji-soon, K.; Monogenov, A.N.; Gunther, V.E. The technology of the manufacturing thin wire of TiNi-based alloys by using infrared radiation. KnE Mater. Sci. 2017, 2, 88–97. [Google Scholar] [CrossRef]

- Nikoomanzari, E.; Karbasi, M.; C.M.A. Melo, W.; Moris, H.; Babaei, K.; Giannakis, S.; Fattah-alhosseini, a. impressive strides in antibacterial performance amelioration of Ti-based implants via plasma electrolytic oxidation (PEO): A Review of the Recent Advancements. Chem. Eng. J. 2022, 441, 136003. [CrossRef]

- Jang, S.R.; Suh, I.W.; Heng, L. Nanoscale polishing technique of biomedical grade NiTi wire by advanced maf process: relationship between surface roughness and bacterial adhesion. J. Funct. Biomater. 2023, 14, 177. [Google Scholar] [CrossRef] [PubMed]

- Bencina, M.; Mavriˇc, T.; Junkar, I.; Bajt, A.; Krajnovi’c, A.; Lakota, K.; Igliˇc, A. The importance of antibacterial surfaces in biomedical applications. Adv. Biomembr. Lipid Self-Assem. 2018, 28, 115–165. [Google Scholar] [CrossRef]

- Sysolyatin, P.G.; Gunther, V.E.; Sysolyatin, S.P. et. al. Medical Materials with Shape Memory. In Shape memory implants in maxillofacial surgery, 4th ed.; NPP «MIC»: Tomsk, Russia, 2012; p. 384. (In Russian) [Google Scholar]

- Dambaev, G.Ts.; Topolnitsky, E.B.; Gunter, V.E. et. al. Shape memory implants in thoracic surgery; NPP «MIC»: Tomsk, Russia, 2016; p. 232. (In Russian) [Google Scholar]

- Mirgazizov, M.Z.; Gunter, V.E.; Galonsky, V.G. et al. Materials and implants with shape memory in dentistry, 5th ed.; NPP «MIC»: Tomsk, Russia, 2011; p. 220. (In Russian) [Google Scholar]

- Topolnitskiy, E.; Chekalkin, T.; Marchenko, E.; Yasenchuk, Y.; Kang, S.B.; Kang, J.H.; Obrosov, A. evaluation of clinical performance of TiNi-based implants used in chest wall repair after resection for malignant tumors. J. Funct. Biomater. 2021, 12. [Google Scholar] [CrossRef] [PubMed]

- Topolnitskiy, E.; Chekalkin, T.; Marchenko, E.; Yasenchuk, Y. Repair of huge thoracic defect combined with hernia after multimodality treatment of breast cancer. Respir. Med. case reports 2021, 34. [Google Scholar] [CrossRef] [PubMed]

- Zheravin, A.A. et.al. Reconstruction of the chest wall using titanium nickelid for cancer patients. Siberian journal of oncology. 2015, 1, 31–37. (In Russian) [Google Scholar]

- Choinzonov, E.L.; Gunter, V.E.; Mukhamedov, M.R. Medical Materials with Shape Memory. In Shape memory implants in oncology, 13st ed.; NPP «MIC»: Tomsk, Russia, 2012; p. 336. (In Russian) [Google Scholar]

- Scientific electronic library Elibrary.ru (in Russian). Available online: https://www.elibrary.ru/item.asp?id=49994737 (accessed on 21 April 2023).

- Anikeev, S.; Yakovlev, E.; Artyukhova, N.; Mamazakirov, O.; Kaftaranova, M. and Promakhov, V., Production of two-dimensional porous TiNi-based powder material by diffusion sintering and electron-beam processing, In 7th International Congress on Energy Fluxes and Radiation Effects (EFRE), Tomsk, Russia, 2020, pp. 1240-1243. [CrossRef]

- Anikeev, S.G.; Artyukhova, N. V.; Kaftaranova, M.I.; Khodorenko, V.N.; Yakovlev, E. V.; Markov, A.B.; Promakhov, V. V.; Mamazakirov, O.R. The influence of electron-beam treatment on the structure of a TiNi powder alloy obtained by calcium-hydride reduction. J. Surf. Investig. 2021, 15, 1067–1071. [Google Scholar] [CrossRef]

- Anikeev, S.G.; Shabalina, A. V.; Kulinich, S.A.; Artyukhova, N. V.; Korsakova, D.R.; Yakovlev, E. V.; Vlasov, V.A.; Kokorev, O. V.; Hodorenko, V.N. Preparation and electron-beam surface modification of novel TiNi material for medical applications. Appl. Sci. 2021, 11, 4372. [Google Scholar] [CrossRef]

- Anikeev, S.G.; Garin, A.S.; Artyukhova, N. V.; Khodorenko, V.N.; Gunther, V.E. Structural and morphological features of TiNi-based powder manufactured by the method of hybrid-calcium reduction. Russ. Phys. J. 2018, 61, 749–756. [Google Scholar] [CrossRef]

- Kasimtsev, A. V.; Markova, G. V.; Shuitsev, A. V.; Levinskii, Y. V.; Sviridova, T.A.; Alpatov, A. V. Change in structure during consolidation of calcium hydride powders of TiNi intermetallic. Metallurgist. 2015, 58, 1038–1045. [Google Scholar] [CrossRef]

- Kasimtsev, A. V.; Markova, G. V.; Volodko, S.S.; Yudin, S.N.; Karpov, B. V.; Alimov, I.A. Powder titanium nickelide: technology and properties. Russ. Metall. 2020, 11, 1267–1273. [Google Scholar] [CrossRef]

- Abdul’menova, E. V.; Kul’kov, S.N. Ti-Ni powder structure after mechanical activation and interaction with hydrogen. Russ. Phys. J. 2019, 62, 1455–1460. [Google Scholar] [CrossRef]

- Abdulmenova, E. V.; Buyakova, S.P.; Kulkov, S.N. Electrochemical hydrogenation of Ti–Ni powder mechanochemically alloyed with titanium. Intermetallics 2022, 151, 107739. [Google Scholar] [CrossRef]

- Markov, A.B.; Mikov, A.V.; Ozur, G.E.; Padei, A.G. A PÈTM-CP facility for the surface alloying. Instrum. Exp. Tech. 2011, 54, 862–866. [Google Scholar] [CrossRef]

- Frolov, Yu. G. Course of colloidal chemistry. Surface phenomena and disperse systems: Chemistry, Metallyrgy; Moscow, Russia, 1988; р. 464. (In Russian).

- Rotshtein, V.P.; Shulov, V.A. Surface modification and alloying of aluminum and titanium alloys with low-energy, high-current electron beams. J. Metall. 2011, 2011, 1–15. [Google Scholar] [CrossRef]

- Meisner, L.L.; Markov, A.B.; Proskurovsky, D.I.; Rotshtein, V.P.; Ozur, G.E.; Meisner, S.N.; Yakovlev, E. V.; Poletika, T.M.; Girsova, S.L.; Semin, V.O. Effect of inclusions on cratering behavior in TiNi shape memory alloys irradiated with a low-energy, high-current electron beam. Surf. Coatings Technol. 2016, 302, 495–506. [Google Scholar] [CrossRef]

- Meisner, L.L.; Markov, A.B.; Rotshtein, V.P.; Ozur, G.E.; Meisner, S.N.; Yakovlev, E. V.; Gudimova, E.Y. Formation of microcraters and hierarchically-organized surface structures in TiNi shape memory alloy irradiated with a low-energy, high-current electron beam. AIP Conf. Proc. 2015, 1683. [Google Scholar] [CrossRef]

- Zhang, K.M.; Zou, J.X.; Grosdidier, T.; Gey, N.; Weber, S.; Yang, D.Z.; Dong, C. Mechanisms of structural evolutions associated with the high current pulsed electron beam treatment of a NiTi shape memory alloy. J. Vac. Sci. Technol. A Vacuum, Surfaces, Film. 2007, 25, 28–36. [Google Scholar] [CrossRef]

- Meisner, L.L.; Semin, V.O.; Mironov, Y.P.; Meisner, S.N.; D’yachenko, F.A. Cross-sectional analysis of the graded microstructure and residual stress distribution in a TiNi alloy treated with low energy high-current pulsed electron beam. Mater. Today Commun. 2018, 17, 169–179. [Google Scholar] [CrossRef]

- Meisner, L.L.; Lotkov, A.I.; Mironov, Y.P.; Neyman, A.A. Evolution of structural-phase states in TiNi surface layers synthesized by electron beam treatment. J. Nanotechnol. 2010, 2010, 605362. [Google Scholar] [CrossRef]

Figure 1.

Surface morphology of chemically etched monolithic TiNi plate used for further preparation of monolithic-porous material: (a) SEM image; (b) optical profilometry image.

Figure 1.

Surface morphology of chemically etched monolithic TiNi plate used for further preparation of monolithic-porous material: (a) SEM image; (b) optical profilometry image.

Figure 2.

SEM image of smaller fraction of TiNi powder used to prepare porous TiNi layer. Inset: particle size distribution.

Figure 2.

SEM image of smaller fraction of TiNi powder used to prepare porous TiNi layer. Inset: particle size distribution.

Figure 3.

Surface morphology of sample SP: (a) SEM image; (b) optical profilometry image.

Figure 4.

SEM images of the obtained materials: (a) terraces and (b) secondary phase particles on the surface of sample SP; (c) sample SP-20; (d) sample SP-30.

Figure 4.

SEM images of the obtained materials: (a) terraces and (b) secondary phase particles on the surface of sample SP; (c) sample SP-20; (d) sample SP-30.

Figure 5.

XRD patterns of the SP group materials.

Figure 6.

SEM images of the LP group samples before (upper row) and after (lower row) corrosion: (a) sample LP; (b) sample LP-20; (c) sample LP-30.

Figure 6.

SEM images of the LP group samples before (upper row) and after (lower row) corrosion: (a) sample LP; (b) sample LP-20; (c) sample LP-30.

Figure 7.

SEM images of the SP group samples before (upper row) and after (lower row) corrosion: (a) sample SP; (b) sample SP-20; (c) sample SP-30.

Figure 7.

SEM images of the SP group samples before (upper row) and after (lower row) corrosion: (a) sample SP; (b) sample SP-20; (c) sample SP-30.

Figure 8.

(a) SEM surface image of sample LP subjected to corrosion, with marked areas analyzed by EDX; (b) EDX spectra taken at points marked in panel (a).

Figure 8.

(a) SEM surface image of sample LP subjected to corrosion, with marked areas analyzed by EDX; (b) EDX spectra taken at points marked in panel (a).

Figure 9.

Tafel curves for materials of (a) LP group; (b) SP group; (c) Ti plate and TiNi plates.

Figure 10.

Corrosion rate values evaluated for all studied samples and their comparison with Ti plate, TiNi plate, and thermally-treated TiNi plate. Surface roughness of all samples was taken into account.

Figure 10.

Corrosion rate values evaluated for all studied samples and their comparison with Ti plate, TiNi plate, and thermally-treated TiNi plate. Surface roughness of all samples was taken into account.

Figure 11.

CLSM images of materials from the LP group after 17 days of cell growth: (a,b) sample LP; (c,d) sample LP-20; (e,f) sample LP-30.

Figure 11.

CLSM images of materials from the LP group after 17 days of cell growth: (a,b) sample LP; (c,d) sample LP-20; (e,f) sample LP-30.

Figure 12.

CLSM images of materials from the SP group after 17 days of cell growth: (a,b) sample SP; (c,d) sample SP-20; (e,f) sample SP-30.

Figure 12.

CLSM images of materials from the SP group after 17 days of cell growth: (a,b) sample SP; (c,d) sample SP-20; (e,f) sample SP-30.

Table 1.

Samples’ nomenclature and details of their preparation.

| Scheme 1200. | Plate | Powder | Sintering | Energy mode of HCPEB |

|---|---|---|---|---|

| TiNi-Pl. | TiNi | – | – | – |

| TiNi-Pl./t | TiNi | – | 1200° for 15 min | – |

| SP | TiNi | 0-100 µm | 1200° for 15 min | – |

| SP-20 | TiNi | 0-100 µm | 1200° for 15 min | 20 keV |

| SP-30 | TiNi | 0-100 µm | 1200° for 15 min | 30 keV |

| LP | TiNi | 100-200 µm | 1200° for 15 min | – |

| LP-20 | TiNi | 100-200 µm | 1200° for 15 min | 20 keV |

| LP-30 | TiNi | 100-200 µm | 1200° for 15 min | 30 keV |

Table 2.

Roughness parameters of the initial monolithic TiNi plate and materials of the SP group.

| Sample | Ra (µm) | Rz (µm) |

|---|---|---|

| TiNi-Pl. | 0.5 | 5.5 |

| SP | 22 | 140 |

| SP-20 | 18 | 90 |

| SP-30 | 3 | 15 |

Table 3.

Phase composition of the SP group samples according to XRD data.

| Phase | Content in samples (vol.%) | ||

|---|---|---|---|

| SP | SP-20 | SP-30 | |

| TiNi (B2) | 73 | 85 | 91 |

| TiNi (B19′) | 15 | 9 | 5 |

| Ti2Ni | 12 | 6 | 4 |

Table 4.

Corrosion parameters obtained for all studied samples and Ti plate, TiNi plate, and thermally-treated TiNi plate.

Table 4.

Corrosion parameters obtained for all studied samples and Ti plate, TiNi plate, and thermally-treated TiNi plate.

| Sample | Icorr, µA | Ecorr, mV | Ra, µm | C*corr, mm/year |

|---|---|---|---|---|

| LP | 0.936 | –345.6 | 80 | 7.3·10-5 |

| LP-20 | 0.533 | –391.4 | 70 | 4.8·10-5 |

| LP-30 | 1.44 | –350.2 | 60 | 1.5·10-4 |

| SP | 0.452 | –278.7 | 22 | 1.3·10-4 |

| SP-20 | 1.86 | –332.9 | 18 | 6.5·10-4 |

| SP-30 | 0.014 | –343.2 | 3 | 2.9·10-5 |

| Ti plate | 0.058 | –194.9 | 0.48 | 7.6·10-4 |

| TiNi-Pl. | 0.742 | –358.5 | 1.41 | 3.3·10-3 |

| TiNi-Pl./t | 0.036 | –313.6 | 0.55 | 4.3·10-4 |

* Calculated taking into account surface roughness. For the titanium plate having the lowest roughness, the roughness coefficient was taken as 1.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Copyright: This open access article is published under a Creative Commons CC BY 4.0 license, which permit the free download, distribution, and reuse, provided that the author and preprint are cited in any reuse.

Combined Porous-Monolith TiNi Materials Surface-Modified with Electron Beam for New-Generation Rib Endoprostheses

Anastasiia V. Shabalina

et al.

,

2023

Preparation and Electron-Beam Surface Modification of Novel TiNi Material for Medical Applications

Sergey G. Anikeev

et al.

,

2021

MDPI Initiatives

Important Links

© 2024 MDPI (Basel, Switzerland) unless otherwise stated