Preprint

Article

Thermodynamic Optimization and Economic Evaluation of a High-Temperature Triple Organic Rankine Cycle System

Altmetrics

Downloads

102

Views

20

Comments

0

A peer-reviewed article of this preprint also exists.

This version is not peer-reviewed

Submitted:

01 November 2023

Posted:

01 November 2023

You are already at the latest version

Alerts

Abstract

The efficiencies of conventional triple organic Rankine cycle (TORC) configurations are restricted by the low critical temperatures of common working fluids (<320 °C). This paper proposes a high-temperature TORC system. A near-azeotropic mixture biphenyl/diphenyl oxide (BDO), which has stellar track record in the high-temperature ORC applications, is innovatively adopted as the top and middle ORC fluid simultaneously. The top cycle evaporation temperature is up to 400 °C in view of BDO’s high stability. Five conventional organic fluids are chosen for the bottom ORC. Fundamentals of the TORC system are illustrated, and mathematical models are built. Thermo-economic performance is investigated. The results hint that the optimal thermodynamic property is achieved on the use of benzene as the bottom fluid. The maximum thermal and exergy efficiencies are respectively 40.86% and 74.14%. The largest irreversible loss occurs inside the heat exchanger coupling the middle and bottom ORCs, accounting for above 30% of the total entropy generation. The levelized energy cost (LEC) is 0.0284 $/kWh. Given the same heat source condition, the TORC system can boost efficiency by 1.02% and drive down LEC by 0.0024 $/kWh compared with a BDO mixture-based cascade ORC.

Keywords:

Subject: Engineering - Energy and Fuel Technology

1. Introduction

Organic Rankine cycle (ORC) technology is a well-grounded and promising way to convert heat into power. It is one of the leading ways to achieve pumped thermal electricity storage in Carnot battery technology [1]. For high-temperature heat sources, cascade or even triple organic Rankine cycle (TORC) is commonly adopted to extract the exergy more adequately and realize stage-wise utilization of the energy. TORC technology is booming and attracting increasingly widespread attention. Prabhu et al. compared the performance of 10 MWe parabolic trough power stations with different structures. The highest net efficiency of 27.5% was achieved for a TORC arrangement when the top cycle evaporation temperature was 318 °C and the degree of superheat was around 60 °C. Toluene, cyclohexane and butane were the top, middle and bottom cycle fluids, respectively. TORC is inferior to the most efficient cascade cycles due to the additional internal losses, complexity and cost [2]. Mahmoud et al. devised an independent TORC system adopting three hydrocarbons as the working fluids to recover waste heat from comprehensive crude oil refining and aromatics facilities with a maximum temperature of 160 °C [3]. Zhang et al. researched both TORC and four-stage ORC systems. For a single-phase heat source of 300 °C hot air, the highest thermal efficiencies of 26.86% and 26.22%, exergy efficiencies of 79.46% and 77.56%, and levelized energy costs (LECs) of 0.063 $/kWh and 0.072 $/kWh could be achieved by the two systems. For a two-phase heat source of 185 °C saturated steam, the highest thermal efficiencies of 23.64% and 24.43%, exergy efficiencies of 69.94% and 72.26%, and LECs of 0.069 $/kWh and 0.068 $/kWh could be obtained [4]. Yu et al. conducted analysis on an R245fa-based TORC system. When the geothermal fluid temperature was 200 °C, the net power output was 3.8% and 2.4% higher than that of the single-stage and cascade cycles, respectively. The LEC of the TORC was approximately 0.04 $/kWh [5].

Alongside this, TORC configuration is also applied in the field of recovering the cold exergy of liquefied natural gas (LNG). García et al. investigated a TORC system with LNG and industrial waste heat as the cold and heat sources. The working fluid of each stage is argon, methane and R14. The highest exergy efficiency was 85.6% [6]. Zhang et al. found that when the waste heat temperature was above 100 °C, the TORC system has higher net power output and thermal efficiency than those of the single-stage one. The optimal thermal and exergy efficiencies were respectively 32.5% and 39.08% at the heat source temperature of 150 °C [7]. Ma et al. constructed a multi-stage ORC model for LNG cold-energy utilization. The heat source was seawater at 20 °C. The efficiencies of single-stage to five-stage ORC systems were analyzed. The maximum efficiencies of the TORC and five-stage ORC were 55.01% and 67.7%, respectively [8]. Han et al. simulated a TORC system using LNG and 127.17 °C ship power generation waste heat as the cold and heat sources. The highest efficiencies were 31.72%, 19.86% and 27.53% for the top, middle and bottom ORCs using the working fluids of R290, R601a and R236ea, respectively. The cost of each cycle was 0.71, 1.33 and 0.98 million $/year [9].

Notably, the maximum evaporation temperatures of the above TORC systems are limited to below 320 °C due to the low critical temperatures of the conventional refrigerants, hydrocarbons and siloxanes [10]. A biphenyl/diphenyl oxide (BDO) mixture has significant potential for high- or medium-temperature ORC applications [11], and has been reported in extensive literature. The mixture is consisting of 73.5% diphenyl oxide and 26.5% biphenyl, and possesses extraordinarily low viscosity and high stability in a large temperature interval from 12 °C to 400 °C [12,13]. Bronicki successfully tested a cascade cycle device employing the BDO mixture and monochlorobenzene as the first- and second- stage cycle fluids. The overall efficiency was 8.5% and the power output was 680 W at the first-stage cycle evaporation temperature of 195 °C [14]. Bombarda et al. employed the BDO mixture as the bottom cycle fluid in a binary liquid metal-ORC distributed system. An efficiency of 46% was claimed [15]. Vescovo briefly introduced the application of BDO mixture in high-temperature ORC. The described system efficiency ranged from 30% to 34% [16,17]. Sampedro et al. presented a toluene ORC topped by a wet-to-dry cycle using the BDO mixture. The maximal power output by the cascade cycle was 96 kW at the heat source temperature of 492 °C [18]. Li et al. innovatively adopted the BDO mixture as the heat transfer, storage and power cycle fluid in a cascade organic-steam Rankine cycle system [19,20]. The thermal efficiency was 42.90% when the BDO was vaporized at 390 °C [20]. Ren et al. put forward a cascade ORC topped by a BDO mixture cycle. The maximum thermal efficiency was 40.26% irrespective of pressure drop in all the heat exchangers [21]. Li et al. analyzed a novel partial cascade organic-steam Rankine cycle utilizing the BDO mixture as the ORC fluid. The maximum efficiency was 45.3% when the ORC and water evaporation temperatures were 400 °C and 290 °C, respectively [22].

In order to ramp up the maximum evaporation temperature and the heat-to-power conversion efficiency of existing TORCs, this paper proposes a BDO mixture-based TORC system for the first time. It uses the BDO mixture as the top and middle ORC working fluid simultaneously, and conventional organic fluids for the bottom ORC. The above experimental and simulation studies on the BDO mixture [11,12,13,14,15,16,17,18,19,20,21,22] set the stage for its application in high temperature TORC. The BDO mixture in the top cycle evaporates at 400 °C and drives the top turbine. Both the top and middle ORCs are equipped with an internal recuperator to recover the exergy in the exhaust vapor at the turbine outlets. The superheated vapor at the recuperators’ outlets serve as the heat source for the next-stage cycle. A mixing heat exchanger (MHX) connects the top and middle ORCs to reduce the irreversible loss in heat transfer.

The operating philosophy and characteristics of the TORC are elaborated, and mathematical models are built. Thermal and exergy efficiencies of the TORC were optimized with respect to the MHX outlet temperature ( or ), middle ORC condensation temperature () and different bottom ORC fluids, followed by the evaluation of the entropy generation in each component and the economic index. Finally, a comprehensive comparison with a BDO mixture-based cascade ORC is carried out.

2. System Description

Figure 1 shows the schematic diagram of the proposed high-temperature TORC system. The heat source can be waste heat in industrial production, exhaust heat from land or marine engines, geothermy, biomass combustion, concentrating solar heat, and etc. The cold source can be ambient temperature air or water. In this study, industrial flue gas and water-cooled device are taken as instances.

The system consists of three loops: top ORC in red, middle ORC in red and bottom ORC in orange. The top and middle cycles are coupled by a MHX. MHXs are open-type direct contact heat exchangers (HXs) where one sort or different fluid streams exchange heat and mix with each other [23]. Indirect heat exchange between the two cycles is thus avoided, leading to enhanced heat transfer performance and reduced cost of equipment [24]. The function of a MHX is similar to that of the absorbers in absorption refrigeration and the jet HXs in jet refrigeration. MHXs are widely applied in fuel cells to ensure adequate mixing of the fuels with oxidant (usually air) and rapid evaporation [25]. MHXs are divided into four types according to the structural characteristics: liquid film, liquid column, packed and jet type. The liquid film type is exemplified in Figure 1. The subcooled liquid of the middle cycle flows into the MHX, and is sprayed to form liquid film after encountering an obstacle. Meanwhile, the superheated vapor of the top cycle flows into the bottom of MHX, and mixed with the liquid film. Due to gravity, the top and bottom outlets of MHX are respectively saturated vapor and saturated liquid after sufficient heat exchange in the middle of MHX. The former drives the turbine 2 (T2) and the latter flows into the pump 1 (P1). Notably, the outlet temperatures and pressures of MHX are correspondingly the same ( and ).

The BDO mixture from P1 outlet is heated in HX2 by the exhaust vapor from T1, and further heated to saturated vapor in HX1 to drive T1 and generate electricity. The exhaust vapor in superheated state is precooled in HX2 and enters MHX. The operating principles of the middle ORC is the same as those of the top ORC. In the bottom ORC, conventional fluids such as benzene, toluene, R141b, cyclohexane and pentane can be adopted. The middle ORC is coupled with the bottom ORC through HX4. The exhaust vapor from the bottom ORC turbine enters HX5, and is cooled to saturated liquid by ambient temperature water.

3. Mathematical Models

3.1. Thermodynamic Models

Subcritical cycles are considered for the TORC. Figure 2 illustrates the T-s diagram.

3.1.1. Turbines

The work produced by T1, T2 and T3 can be derived as follows

where , and are the mass flow rates of the top, middle and bottom ORCs (kg/s). is the turbine efficiency.

3.1.2. Heat Exchangers

The heat balance in HX2, HX3 and HX4 are described by

The efficiencies of HX2 and HX3 are determined as

3.1.3. Pumps

The work consumed by P1, P2 and P3 are given by

where is the pump efficiency.

3.1.4. Saturated Entropies of the BDO

The saturation state parameters of the BDO mixture (such as , , , , , , etc.) at intervals of 10 °C can be obtained from a supplier Eastman Corp [27]. The saturated parameters at other temperatures can be calculated by linear interpolation.

The specific entropy in a saturated state can be deduced by

3.1.5. Superheated Enthalpies of the BDO

The BDO mixture at both T1 and T2 outlets are in superheated state, and the enthalpies and cannot be derived directly. To tackle this problem, an equivalent hot side temperature ()-based ORC efficiency model was developed [28], in which only the saturated parameters were required. For the middle ORC

The efficiency of ORC in a basic structure () without an internal heat exchanger can be established with the assistance of [26].

where is the generator efficiency. can be obtained according to the composite trapezoidal rule.

Meanwhile, can also be expressed as

can then be deduced, and the same is true for .

Most ORC fluids in liquid state are incompressible, and most of the heat is taken away during the condensation process [28]. can thus be calculated by

3.1.6. Thermal Efficiency

The thermal efficiencies of the top, middle and bottom ORCs are

where is the net power output.

The thermal efficiency of the TORC can be appraised by

3.1.7. Entropy Generation

The entropy generation represents the thermodynamic irreversibility in the components. The equations are listed in Table 2.

3.1.8. Exergy Efficiency

The exergy absorbed by the top, middle and bottom ORCs are estimated as

where is the ambient temperature (°C).

The exergy efficiencies of the top, middle, bottom ORCs and TORC can be appraised by

3.2. Economic Models

3.2.1. Cost of Equipment

The purchased cost of a HX is [21,29]

where is the HX area (m2). , , and are the material factor, pressure factor and temperature factor.

The purchased cost of a pump is [34,35]

where is the basic cost of the equipment assuming ambient operating pressure and carbon steel construction in the year of 2001.

3.2.2. Cost of Fluids

The cost of BDO mixture () and the cost of bottom ORC fluid () can be respectively appraised by

where and are the prices of BDO mixture and bottom fluid. and represent their filling mass.

However, it is difficult to accurately calculate the weight of working fluid charged for an ORC system because the report on this aspect is rare. The filling mass is 5.57 kg and 5.4 kg for a 1-kWe power output generated by the turbine according to the Ref [36,37]. Pursuant to this data, and are proportional to and , respectively.

3.2.3. Levelized Energy Cost

The total capital cost () is determined by the cost of working fluid and main equipment, including HXs, turbines, pumps and generators. The investment in MHX can be ignored as it has significant lower cost than other components [21,38]. Determining is reasonable by

The actual cost needs to be converted from the cost of 2001 by calculating the Chemical Engineering Plant Cost Index (CEPCI) [34,39]. The cost of 2020 should be corrected as

4. Results and Discussion

Table 4 displays the design parameters. Given the top ORC evaporation temperature () and bottom ORC condensation temperature (), the middle ORC evaporation and condensation temperatures ( and ) emerge as crucial parameters because they not only affect each subcycle efficiency, but also influences the TORC efficiency. As equals to the top ORC condensation temperature, i.e., MHX outlet temperature (), and are taken as variables in this simulation. The parameters for the rest state points can be determined by the conditions such as conservation of energy, pump and turbine efficiencies, and heat transfer temperature difference.

The ranges of and are determined in the following considerations. First, maintaining a vacuum below 5 kPa in the HXs is a technical limit [47,48]. As 5 kPa corresponds to the saturation temperature of 153 °C for the BDO mixture, the lower limit of is chosen as 153 °C. Second, limited by the minimum heat transfer temperature difference (), . The lower limit of is selected as 163 °C. Third, the upper limit of is taken as the critical temperature of each bottom ORC fluid plus in HX4. Forth, as in the top ORC, the upper limit of is set as 390 °C.

4.1. Thermodynamic Performance Analysis

4.1.1. Thermal Efficiency

Figure 3 exhibits the variation of with and in the circumstance of considering pressure drop. The actual pressure drop is taken as the minimum allowable pressure drop in Table 1. The size of each curved surface varies because the different critical temperatures of bottom ORC fluids limit the maximum . Each surface becomes narrower as increases. The reason is that as , the lower limit of rises as ascends, while the upper limit of is maintained at 390 °C. For example, ranges from 170 °C to 390 °C when is 160 °C, while varies from 310 °C to 390 °C when is 300 °C for benzene, toluene or pentane. The curves representing benzene and toluene almost coincide because of their close efficiencies. Given , decreases monotonously with the increment in . The optimum is achieved at the lowest of 153 °C for the five bottom fluids.

Figure 3 displays the cross section corresponding to of 153 °C. first increases and then decreases with . The peak value of each curve is obtained when is 257 °C. The maximum is 40.86% when benzene is employed, and it is noticeably higher than that of the results obtained by all the previous TORC studies [2,4,7,8,21,22]. Table 5 summarizes the thermodynamic parameters of each state point for benzene at the optimum condition. The pressure drop of the cold side in HX1, HX2 and HX4 is postulated to be 35 kPa, and it is 5 kPa for HX3. Whereas it is 5 kPa, 0.633 kPa, 0.57 kPa and 1.76 kPa on the hot side of HX2, HX3, HX4 and HX5, respectively.

Figure 4.

Variations of TORC thermal efficiency with when 153 °C.

Figure 5 and Figure 6 present the variations of subcycle net power outputs and efficiencies on the use of benzene at of 153 °C. The net power output for the top ORC drops linearly as rises, while it increases linearly for the middle ORC and keeps almost stable for the bottom ORC. Similarly, the top ORC efficiency () decreases linearly, the middle ORC efficiency () increases approximately linearly, and the bottom ORC efficiency () remains constant with . The reason is that given , and , the temperature difference between the top ORC declines, while it increases for the middle ORC and remains unchanged for the bottom ORC. As the optimal and are fixed for different bottom ORC fluids, of 16.22% and of 14.71% can be calculated at the optimal condition. But varies depending on the bottom fluids, leading to a difference in . The minimum is 15.45% for pentane and the maximum is 17.76% for benzene. Table 6 posts some key thermodynamic indicators by using benzene.

4.1.2. Mass Flow Rate

Figure 7 portrays the variations of subcycle mass flow rates on the use of benzene when is 153 °C. The mass flow rate of top ORC () first increases appreciably, and then soars with . The reason is as follows. Given and , increases with and () reduces. As the net power output of TORC system () is fixed at 10 MW, is inversely proportional to the total heat absorbed () according to Eq. (25). As rises when 257 °C and falls down when 257 °C as displayed in Figure 4, first diminishes, and then increases. However, the magnitude of reduction is smaller than that of () when ranges from 163 °C to 257 °C. For instance, is 24.78, 24.62 and 24.53 MW when is 180, 200 and 220 °C. The corresponding () is 545.82, 512.82 and 480.44 kJ/kg. increases moderately when 163 °C 257 °C according to . As rises and () descends when 257 °C, therefore grows considerably. The mass flow rate of middle ORC () decreases and mass flow rate of bottom ORC () remains almost constant with . The reasons can be deduced similarly.

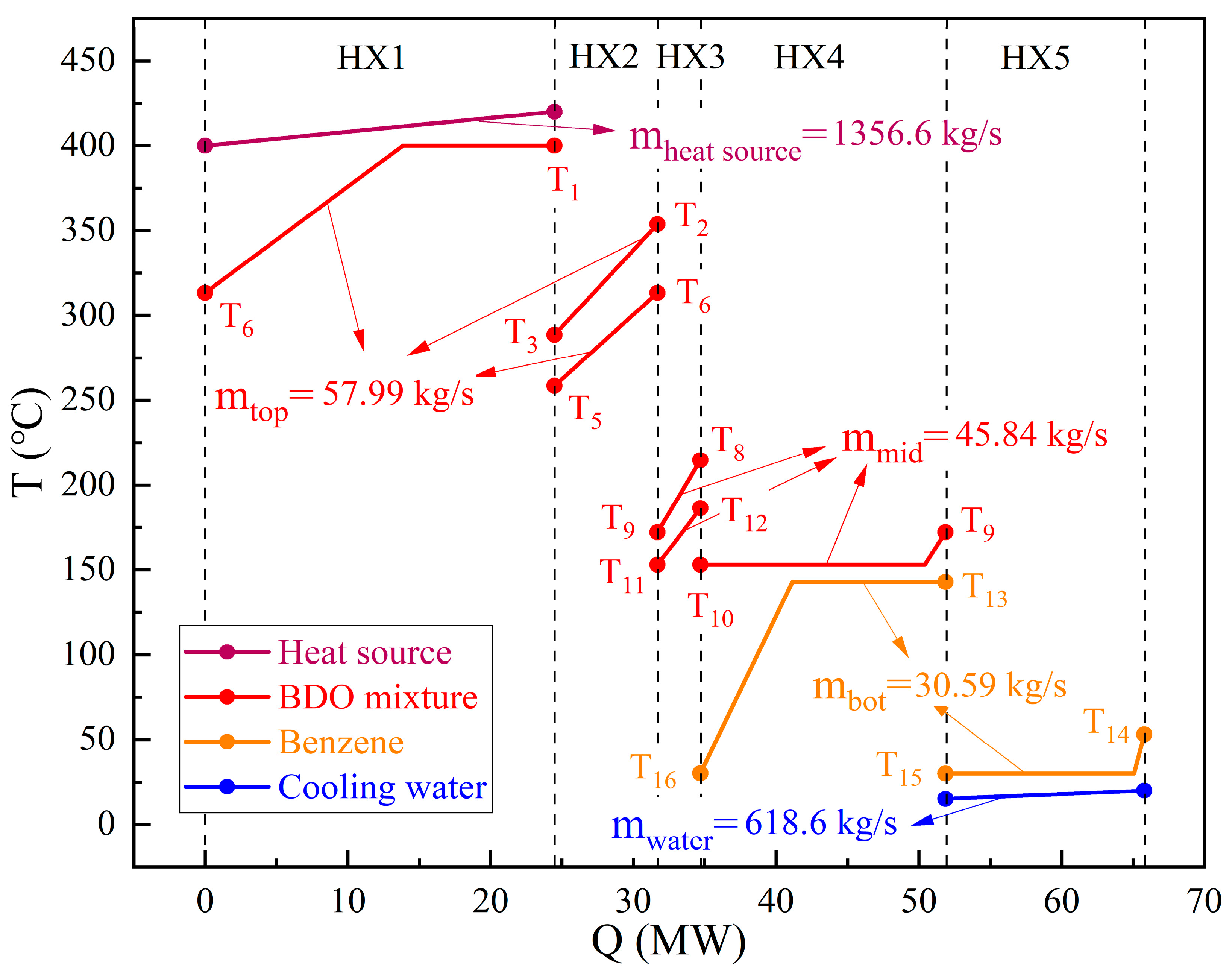

4.1.3. T-Q Diagram

Figure 8 illustrates the T-Q diagram at the optimum condition. The dotted lines distinguish different heat exchangers. The heat transfer temperature difference takes place at the pinch point for HX1, HX4 and HX5, while it occurs at the high temperature BDO mixture outlet for HX2 and HX3. The heat transfer temperature differences are 11.31, 29.97, 19.28, 10 and 10.26 °C for HX1-HX5, respectively. Notably, of 10 °C is the minimum heat transfer temperature difference in all the HXs. The heat transfer temperature differences in HX1, HX2, HX3 and HX5 are higher than . The heat transfer in HX1-HX5 is 24.472, 7.216, 3.012, 17.443 and 13.942 MW, respectively.

4.1.4. Entropy Generation

Figure 9 exhibits the percentage of entropy generated by each component at the maximum . The largest exergy destruction takes place in HX4, which accounts for more than 30% of the total irreversible losses. This is mainly due to the large heat transfer temperature difference in the subcooled region of HX4. The cold side benzene rises from subcooled state at 30.21 °C to saturated liquid state at 143 °C, while the hot side BDO mixture remains in the binary phase state of 153 °C. The entropy generation in T3 ranks the second largest on account of the large enthalpy drop (i.e., exergy drop) during expansion. The irreversible loss in P3 accounts for merely 0.1%, which is much less than that of P1 and P2. The reason is that the mass flow rate through P3 ( 30.59 kg/s) is remarkably lower than that of P1 ( 57.99 kg/s) and P2 ( 45.84 kg/s).

4.1.5. Exergy Efficiency

Figure 10 graphs the variation of with and . Similar to Figure 3, the area of the curved surface representing pentane and R141b is smaller than that of benzene, toluene and cyclohexane due to the narrower range. Benzene and toluene have very close exergy efficiencies, and pentane has the lowest . Given , drops monotonously as elevates. The optimal is obtained at the lowest of 153 °C for different bottom ORC fluids, which is the same as that of .

Figure 11 shows the cross section of the above three-dimensional diagram corresponding to of 153 °C. All the curves first climbs marginally, and then go down considerably. The peak value of each curve is achieved when is 172 °C. The maximum is 74.14% for benzene, which indicates that the TORC system has the highest degree of thermodynamic perfection when benzene is adopted. It is worth pointing out that the maximum thermal and exergy efficiencies correspond to the same middle ORC condensation temperatures of 153 °C, but different MHX outlet temperatures.

4.2. Economic Assessment

Benzene is exemplified in this section due to its highest and . The economic calculation is based on the parameters in Table 5.

4.2.1. Design of HXs

Heat Transfer Research Inc (HTRI) technology has been used by companies worldwide for decades to design, operate, and maintain HXs and fired heaters. The acclaimed Xchanger Suite® software is applied in this section as it is considered the most advanced available for the design, rating, and simulation of HXs [49].

The most widely used shell-and-tube HXs are exemplified. The hot and cold fluids are located in the shell and tube sides, respectively. Double tube passes with the tube outer diameter of 19 mm and the tube pitch of 25 mm are employed, which are frequent in industrial production. The ratio of the tube length and the shell inner diameter is limited to 4-10, and the over-design area above 10% is ensured in the design process. The introduction of rod baffles can remarkably increase the flow rate while reducing the vibration and the flow resistance of the shell side fluid. The shell side fluid makes an axial flow parallel to the tube bundle, which facilitates uniform vortices along the tube length and on the heat transfer surfaces. The vortices are good for improving the parallel flow heat transfer. In consequence, rod baffles are exploited in HX1-HX5.

The physical parameters of the BDO mixture can be derived from Aspen Plus by importing a mass fraction of 26.5% biphenyl and 73.5% diphenyl oxide. Then the parameters like density, heat capacity, thermal conductivity and dynamic viscosity can be imported from Aspen Plus into Xchanger Suite. As the fouling resistances of organic heat carriers for industrial use, solvent vapor, refrigerant liquid, and cooling water below 52 °C are all 17.6×10-5 m2·K/W according to GB/T 151-2014 [51], the fouling resistances of BDO mixture, benzene and water in this work are taken as 17.6×10-5 m2·K/W. 420 °C industrial flue gas is exemplified as heat source, and its fouling resistance is 176.1×10-5 m2·K/W [52]. The dominating composition of flue gas is air and its physical parameters can be invoked from REFPROP 8.0 [53]. Table 7 provides the design data of different HXs and Figure 12 portrays the schemes.

4.2.2. Material Selection and Initial Investment

Choice of construction materials is a compromise between the conflicting goals of performance and capital cost. Multiple factors need to be considered, including mechanical properties (mainly strength), oxidation resistance, heat resistance, and corrosion resistance, etc [53]. The operating temperatures of HX1 and T1 reach 400 °C, which imposes stringent requirements for materials. Although stainless steel is somewhat more expensive than carbon steel, its various properties and lifespan in the range of 400 to 500 °C are superior to those of carbon steel [53,54,55]. In view of this, HX1 and T1 are manufactured in stainless steel and carbon steel for the remaining equipment. Table 8 indexes the selected impact factors of the devices [29,53].

The power generated by T1 (), T2 () and T3 () is 4.059 MW, 2.990 MW and 3.069 MW, respectively. and the mass of benzene () are 38064.6-39262.9 kg and 16572.6-17094.3 kg according to Section 3.2.2. For the sake of sufficient charge mass and reliable results, and are taken as 40000 kg and 18000 kg, respectively. As is 2.2 $/kg and is 0.92 $/kg [57], the total cost of the two fluids is 10.46×104 $.

Table 9 summarizes the first cost of each component. The total cost of the TORC system is 2087.17×104 $. The cost of T1 accounts for the largest proportion, followed by T3 and T2. The three turbines occupy more than three quarters and the five HXs account for nearly one fifth of the total investment. It can be calculated that LEC is 0.0284 $/kWh, which is lower than that of the indicators obtained by the previous TORC studies [4,5].

5. Comparison with a Cascade ORC Using the BDO Mixture

A BDO cycle bottomed by a benzene cycle is depicted in Figure 13 as a reference to determine whether the proposed TORC can boost efficiency and drive down cost compared with the cascade ORC. The conditions of cold and heat source are identical to those in Fig 1, as well as the equipment efficiencies. T4 inlet temperature () and bottom cycle condensation temperature () are respectively 400 °C and 30 °C. Figure 14 presents the variations of the cascade efficiencies. The maximum thermal and exergy efficiencies are respectively 39.84% and 74.14% at the lowest of 153 °C. Table 10 reports the thermodynamic parameters for cascade ORC at the optimum condition.

Table 11 and Table 12 lists the HX design parameters and initial cost. HX6 and T4 are made of stainless steel due to the 400 °C operation temperature, and the others are carbon steel. The power generated by T4 and T5 is 7.056 MW and 3.297 MW, respectively. is 36196.2-37335.7 kg and is 16572.6-16918.2 kg theoretically. In the same vein, and are taken as 38000 kg and 18000 kg, respectively. The total cost of the two fluids is 10.02×104 $ and the overall cost of the cascade ORC system is 2210.19×104 $. It can be calculated that LEC is 0.0308 $/kWh, which is higher than that of the TORC system.

6. Conclusions

This paper proposes a high-temperature TORC system using the near-azeotropic mixture BDO as the top and middle ORC working fluid, and common organic fluids for the bottom ORC. Thermodynamic and economic studies of the system show that:

- (1)

- The optimum thermodynamic property is achieved when benzene is adopted as the bottom ORC fluid. Given the top ORC evaporation and bottom ORC condensation temperatures, both the system thermal and exergy efficiencies decrease with the increment in middle ORC condensation temperature (). It indicates that a smaller temperature difference in the bottom ORC is more beneficial to the overall thermodynamic performance.

- (2)

- In the case of accurate calculation of different HX pressure drops, the maximum thermal efficiency () of 40.86% is obtained at the MHX outlet temperature () of 257 °C and the lowest available of 153 °C. The highest exergy efficiency () of 74.14% is achieved at of 172 °C and of 153 °C. HX4 accounts for the largest entropy generation (30%) on account of the huge heat transfer irreversible loss between the BDO mixture and benzene, followed by T3 and HX1.

- (3)

- Given the total net power output of 10 MW, the investment cost of the TORC system is 2087.17×104 $. The three turbines accounts for more than 75% and the five HXs occupy nearly 20% of the total investment. The levelized energy cost (LEC) is 0.0284 $/kWh, which is appreciably lower than that of the existing TORC systems.

- (4)

- The TORC outperforms the BDO misture-based cascade ORC by 1.02% in thermal efficiency, while saving the LEC by 0.0024 $/kWh. It demonstrates that the TORC is more favorable under the condition of 400 °C heat source.

| Nomenclature | HTRI | Heat Transfer Research Inc | |

| heat exchanger area, m2 | HX | heat exchanger | |

| coefficient | LEC | levelized electricity cost | |

| cost, $ / coefficient | LNG | Liquefied Natural Gas | |

| specific heat, J/kg·K | MHX | mixing heat exchanger | |

| exergy, kW | ORC | organic Rankine cycle | |

| correction factor | P | pump | |

| pressure factor | T | turbine | |

| temperature factor | TORC | triple organic Rankine cycle | |

| enthalpy, kJ/kg | |||

| annual loan interest rate | Subscript | ||

| coefficient | 0,1,2… | number | |

| mass flow rate, kg/s | ambient | ||

| price, $/kg | basic | ||

| pressure, kPa | the bare module | ||

| heat, W | bottom ORC | ||

| entropy, kJ/K | equivalent hot side temperature | ||

| entropy, kJ/(kg·K) | exergy | ||

| temperature, °C | life time | ||

| time, h | middle ORC | ||

| specific volume, m3/kg | minimum | ||

| work, kWh | net power output | ||

| device efficiency, % | operation and maintenance | ||

| efficiency, % | operation | ||

| density, kg/m3 | isentropic | ||

| saturated liquid | |||

| Abbreviation | saturated vapor | ||

| BDO | Biphenyl / diphenyl oxide | turbine | |

| CEPCI | Chemical Engineering | thermal | |

| Plant Cost Index | top ORC | ||

| CRF | Capital recovery factor | total | |

| G | generator | ||

Acknowledgments

This study was sponsored by National Natural Science Foundation of China (52206008), Fundamental Research Funds for the Central Universities of China (JZ2022HGTB0266), Science and Technology Major Project of Anhui Province (202003a05020025), DONGFANG ELECTRIC Dongfang Boiler Group CO., LTD.

References

- Dumont, O.; Frate, G.F.; Pillai, A.; Lecompte, S.; De paepe, M.; Lemort, V. Carnot battery technology: A state-of-the-art review. J. Energy Storage. 2020, 32, 101756. [Google Scholar] [CrossRef]

- Prabhu, E. Solar Trough Organic Rankine Electricity System (STORES) Stage 1: Power Plant Optimization and Economics. November 2000 - May 2005. United States: N. p. 2006. [CrossRef]

- Mahmoud, M.; Mohammed, H.; Saleh, A. Oil and Gas Refining and Marketing Companies; Patent Issued for Power Generation Using Independent Triple Organic Rankine Cycles from Waste Heat in Integrated Crude Oil Refining and Aromatics Facilities. SA, 19178021.2 (October 7, 2020). https://patentimages.storage.googleapis.com/0f/8f/f1/04c69a73bd2aee/EP3553287B1.pdf.

- Zhang, Y.F.; Gong, L.; Hung, T.C. Innovative arrangements of multiple organic Rankine cycles to effectively generate power from the medium-to-low grade of heat source. Appl. Therm. Eng. 2021, 193, 116960. [Google Scholar] [CrossRef]

- Yu, H.; Lu, X.L.; Zhang, W.; Zhang, J. Thermodynamic and Techno-economic Analysis of a Triple-pressure Organic Rankine Cycle: Comparison with Dual-pressure and Single-pressure ORCs. Acta Geologica Sinica (English Edition). 2021, 95, 1857–1869. [Google Scholar] [CrossRef]

- García, R.F.; Carril, J.C.; Gomez, J.; Gomezet, M.R. Power Plant Based on Three Series Rankine Cycles Combined with a Direct Expander Using LNG Cold as Heat Sink. Energy. Convers. Manage. 2015, 101, 285–294. [Google Scholar] [CrossRef]

- Zhang, M.G.; Zhao, L.J.; Xiong, Z. Optimization and analyses of organic Rankine cycle combined system utilizing cold energy of LNG and industrial waste heat. CIESC J 2014, 65, 3144–3151. [Google Scholar] [CrossRef]

- Ma, G.G.; Lu, H.F.; Cui, G.B.; Huang, K. Multi-Stage Rankine Cycle (MSRC) Model for LNG Cold-Energy Power Generation System. Energy 2018, 165, 678–688. [Google Scholar] [CrossRef]

- Han, F.H.; Wang, Z.; Ji, Y.L.; Lia, W.H.; Sundénc, B. Energy Analysis and Multi-Objective Optimization of Waste Heat and Cold Energy Recovery Process in LNG-Fueled Vessels Based on a Triple Organic Rankine Cycle. Energy. Convers. Manage. 2019, 195, 561–572. [Google Scholar] [CrossRef]

- Dai, X.Y.; An, Q.S.; Shi, L. Experiment research for the thermal stability of isobutene and isopentane. J. Eng. Therm. 2013, 34, 1416–1419, https://www.researchgate.net/publication/289013198_Experiment_research_for_the_thermal_stability_of_ isobutene_and_isopentane. [Google Scholar]

- Therminol® VP-1 by application.

- https://www.therminol.com/applications/organic-rankine-cycle#_ga. [Accessed on 5 August 2023].

- Therminol® VP-1 Heat Transfer Fluid. https://www.therminol.com/product/71093459?pn=Therminol-VP-1-Heat-Transfer-Fluid. [Accessed on 5 August 2023].

- Vishwakarma, S.; Debnath, B.K.; Debnath, K. Comparative analysis of absorber tubes of parabolic trough solar collector using Therminol VP-1 as heat transfer fluid, Lect. N. Mech. Eng. 2020; pp. 1227–40. [CrossRef]

- Bronicki, L.Y. The Ormat Rankine Power Unit. In: 7th Intersociety Energy Conversion Engineering Conference, San Diego, USA, 1972; pp. 327–334.

- Bombarda, P.; Invernizzi, C. Binary Liquid Metal-Organic Rankine Cycle for Small Power Distributed High Efficiency Systems. Proc IMechE Part A: J Power and Energy 2014, 229, 192–209. [Google Scholar] [CrossRef]

- Vescovo, R.; Spagnoli, E. High temperature orc systems. Energy Procedia 2017, 129, 82–89. [Google Scholar] [CrossRef]

- Vescovo, R. High temperature organic rankine cycle (ht-orc) for cogeneration of.

- steam and power, in: AIP Conference Proceedings. vol. 2191, AIP Publishing LLC. 2019, p, 020153. [CrossRef]

- Sampedro, E.O.; Védie, L. Wet to dry cycles for high temperature waste heat valorisation using a diphenyl-biphenyl oxide mixture, in: 6th International Seminar on ORC Power Systems. Munich Germany, 11-13 October, 2021; pp. 1–10. [CrossRef]

- Li, P.C.; Li, J. High-temperature Direct Vapor Generation Organic Rankine Cycle in the Concentrated Solar Power Application. 6th International Seminar on ORC Power Systems, October 11-13, 2021; Munich, Germany.

- Li, P.C.; Ye, J.; Li. J.; Wang, Y.D.; Jiang, X.B.; Qian, T.L. Thermodynamic and techno-economic analysis of a direct thermal oil vaporization solar power system. Energy 2023, 282, 128963. [CrossRef]

- Ren, X.; Li, J.; Pei, G.; Li, P.C.; Gong, L. Parametric and Economic Analysis of High-temperature Cascade Organic Rankine Cycle with a Biphenyl and Diphenyl Oxide Mixture. Energy. Convers. Manage. 2023, 276, 116556. [Google Scholar] [CrossRef]

- Li, P.C.; Qian, T.L.; Li, J.; Lin, H.W.; Wang, Y.D.; Pei, G. Thermo-economic analysis of a novel partial cascade organic-steam Rankine cycle. Energy. Convers. Manage. 2023, 283, 116941. [Google Scholar] [CrossRef]

- Dincer I. 1.6 Exergy, in: Comprehensive Energy Systems. Elsevier 2018; pp. 212–264. [CrossRef]

- Gao, G.T.; Li, J.; Li, P.C.; Yang, H.L.; Pei, G.; Ji, J. Design and analysis of an innovative concentrated solar power system using cascade organic Rankine cycle and two-tank water/steam storage. Energy. Convers. Manage. 2021, 237, 114108. [Google Scholar] [CrossRef]

- Önsan, Z.I.; Avci, A.K. Chapter 14 - reactor design for fuel processing, in: Fuel Cells: Technologies for Fuel Processing. Elsevier 2011; pp. 451–516. [CrossRef]

- Mukherjee, R. Practical Thermal Design of Shell-and-Tube Heat Exchangers. Begell House Inc: 2004-01-01.

- EASTMAN. Therminol ® VP-1 heat transfer fluid [EB/OL]. https://www.eastman.com/Literature_Center/T/TF9141.pdf. [Accessed on 5 August 2023].

- Li, J.; Alvi, J.Z.; Pei, G.; Su, Y.H.; Li, P.C.; Gao, G.T. Modelling of organic Rankine cycle efficiency with respect to the equivalent hot side temperature. Energy 2016, 115, 668–83. [Google Scholar] [CrossRef]

- Turton, R.; Bailie, R.C.; Whiting, W.B.; Shaeiwit, J.A. Analysis, synthesis, and design of chemical processes (4th ed.). Prentice Hall PTR, New Jersey 2013.

- Kose, O.; Koc, Y.; Yagli, H. Energy, exergy, economy and environmental (4E) analysis and optimization of single, dual and triple configurations of the power systems: Rankine Cycle/Kalina Cycle, driven by a gas turbine. Energy. Convers. Manage. 2021, 227, 113604. [Google Scholar] [CrossRef]

- Eduardo, J.C.C.; Motta, H.P. Exergoeconomic analysis of a solar-powered/fuel assisted Rankine cycle for power generation. Energy 2015, 88, 555–562. [Google Scholar] [CrossRef]

- Li, P.C.; Cao, Q.; Li, J.; Lin, H.W.; Wang, Y.D.; Gao., G.T. An innovative approach to recovery of fluctuating industrial exhaust heat sources using cascade Rankine cycle and two-stage accumulators. Energy 2021, 228, 120587. [Google Scholar] [CrossRef]

- Cataldo, F.; Mastrullo, R.; Mauro, A.W.; Vanoli, G.P. Fluid selection of organic Rankine cycle for low-temperature waste heat recovery based on thermal optimization. Energy 2014, 72, 159–167. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, C.; Wang, S.K.; Xu, X.X.; Li, Q.B. Thermo-economic comparison of subcritical organic Rankine cycle based on different heat exchanger configurations. Energy 2017, 123, 728–741. [Google Scholar] [CrossRef]

- Zhang, S.J.; Wang, H.X.; Guo, T. Performance comparison and parametric optimization of subcritical Organic Rankine Cycle (ORC) and transcritical power cycle system for low-temperature geothermal power generation. Appl. Energy 2011, 88, 2740–2754. [Google Scholar] [CrossRef]

- Bai, L. Life cycle assessment of electricity generation from low temperature waste heat: the influence of working fluid. NTNU-Norwegian University of Science & Technology 2012.

- Ding, Y.; Liu, C.; Zhang, C.; Xu, X.X.; Li, Q.B.; Mao, L.F. Exergoenvironmental model of Organic Rankine Cycle system including the manufacture and leakage of working fluid. Energy 2018, 145, 52–64. [Google Scholar] [CrossRef]

- Sohrabi, A.; Behbahaninia, A.; Sayadi, S. Thermodynamic optimization and comparative economic analysis of four organic Rankine cycle configurations with a zeotropic mixture. Energy. Convers. Manage. 2021, 250, 114872. [Google Scholar] [CrossRef]

- Astolfi, M. Techno-economic Optimization of Low Temperature CSP Systems Based on ORC with Screw Expanders. Energy Procedia. 2015, 69, 1100–1112. [Google Scholar] [CrossRef]

- Li, Y.R.; Du, M.T.; Wu, C.M.; Wu, S.Y.; Liu, C.; Xu, J.L. Economical evaluation and optimization of subcritical organic Rankine cycle based on temperature matching analysis. Energy 2014, 68, 238–247. [Google Scholar] [CrossRef]

- Gao, G.T.; Li, J.; Li, P.C.; Cao, J.Y.; Pei, G.; Dabwan, Y.N. Design of steam condensation temperature for an innovative solar thermal power generation system using cascade Rankine cycle and two-stage accumulators. Energy. Convers. Manage. 2019, 184, 389–401. [Google Scholar] [CrossRef]

- Wang, X.; Tian, H.; Shu, G. Part-Load Performance Prediction and Operation Strategy Design of Organic Rankine Cycles with a Medium Cycle Used for Recovering Waste Heat from Gaseous Fuel Engines. Energies 2016, 9. [CrossRef]

- Eduardo, L.M.; Ángel, M.G.; Helen, L.; Raúl, L.; Teresa, L.; Mauricio, S. Comparative Thermodynamic Analysis of the Performance of an Organic Rankine Cycle Using Different Working Fluids. Energies, 2022, 15.

- Wang, K.; He, Y.L. Thermodynamic analysis and optimization of a molten salt solar power tower integrated with a recompression supercritical CO2 Brayton cycle based on integrated modeling. Energy. Convers. Manage. 2017, 135, 336–350. [Google Scholar] [CrossRef]

- Jun, L.P.; Qin, N.W.P.; Shen, H.B.; Hsion, L.C.; Loong, L.H. Paving a way toward circular economy for oil and gas industry: A conceptual modelling of re-refining process through solvent extraction and hydrofinishing pathway. J Clean Prod 2022, 380, 134839. [Google Scholar] [CrossRef]

- El-Emam, R.S.; Dincer, I. Exergy and exergoeconomic analyses and optimization of geothermal organic Rankine cycle. Appl. Therm. Eng. 2013, 59, 1–2. [Google Scholar] [CrossRef]

- Fernandez, F.J.; Prieto, M.M.; Suarez-Ramon, I. Thermodynamic analysis of high-temperature regenerative organic Rankine cycles using siloxanes as working fluids. Energy 2011, 36, 5239–5249. [Google Scholar] [CrossRef]

- Drescher, U.; Brüggemann, D. Fluid selection for the organic Rankine cycle in biomass power and heat plants. Appl. Therm. Eng. 2007, 27, 223–238. [Google Scholar] [CrossRef]

- HTRI Software. https://www.htri.net/about. [Accessed 5 August 2023].

- Aspen plus. https://www.aspentech.com/en/products/engineering/aspen-plus. [Accessed 5 August 2023].

- Fouling resistance of industrial fluids. National Standard of the People’s Republic of China. GB/T 151-2014. pp. 212–213.

- Lemmon, E.W; Huber, ML; McLinden, M.O. Refprop 8.0. NIST Standard reference database 23, version 8.0.

- Smith, R. Appendix B: Materials of Construction, In: Chemical Process Design and Integration, 2nd Edition. 2016, pp. 853–860.

- Stainless Steel vs Carbon Steel – Comparison – Pros and Cons. https://material-properties.org/stainless-steel-vs-carbon-steel-comparison-pros-and-cons/. [Accessed 22 October 2023].

- CARBON STEEL VS STAINLESS STEEL: WHAT IS THE DIFFERENCE? https://www.rocheindustry.com/carbon-steel-vs-stainless-steel/#Carbon_Steel_vs_Stainless_Steel_Final_Verdict. [Accessed 22 October 2023].

- REKKAS-VENTIRIS, GEORGIOS. Archimede Concentrated Solar Power Plant Dynamic Simulation: Control systems. Heat Transfer Fluids and Thermal Energy Storage 2018.

- Benzene Price. https://www.echemi.com/productsInformation/pid_Seven2868-benzene.html. [Accessed 5 August 2023].

Figure 1.

Schematic diagram of the TORC.

Figure 2.

T-s diagram of the TORC.

Figure 3.

Variations of TORC thermal efficiency with and .

Figure 5.

Variations of subcycle net power outputs for benzene when 153 °C.

Figure 6.

Variations of subcycle thermal efficiencies for benzene when 153 °C.

Figure 7.

Variations of subcycle mass flow rates for benzene when 153 °C.

Figure 8.

T-Q diagram at the optimal condition.

Figure 9.

Entropy generation in the TORC on the use of benzene.

Figure 10.

Variations of TORC exergy efficiency with and .

Figure 11.

Variations of TORC exergy efficiency with when 153 °C.

Figure 12.

Schemes of the shell and tube HXs.

Figure 13.

Schematic diagram of the cascade ORC.

Figure 14.

Variations of the cascade ORC thermal and exergy efficiencies with .

Table 1.

Allowable pressure drop.

| Intel pressure (MPa) | < 0.1 | 0.1-0.17 | 0.17-1.1 | 1.1-3.1 | 3.1-8.1 |

| Allowable pressure drop (MPa) | p/10 | 0.005-0.035 | 0.035 | 0.035-0.18 | 0.07-0.5 |

Table 2.

Definition of the entropy generation in different components.

| Equipment | Equation |

|---|---|

| T1 | |

| T2 | |

| T3 | ) |

| HX1 | |

| HX2 | |

| HX3 | |

| HX4 | |

| HX5 | |

| MHX | |

| P1 | |

| P2 | |

| P3 |

Table 3.

Values of constants for pumps.

| 3.4771 | 0.135 | 0.1438 | 1.89 | 1.35 | -0.3935 | 0.3957 | -0.00226 | 1.6 | 1 |

Table 4.

Specific parameters for calculation.

| Parameters | Design Value |

|---|---|

| Net power output of TORC system [21,41], | 10 MW |

| ORC turbine efficiency [19,32], | 0.85 |

| Pump efficiency [42,43], | 0.8 |

| Generator efficiency [30,34], | 0.95 |

| Efficiencies of HX2 and HX3 [30,35], | 0.7 |

| Minimum heat transfer temperature difference [19,20], | 10 °C |

| Evaporation temperature of the top ORC [21], | 400 °C |

| Condensation temperature of the bottom ORC [20], | 30 °C |

| Ambient temperature [21,44], | 15 °C |

| CEPCI in 2001 [22] | 397 |

| CEPCI in 2020 [45] | 600.6 |

| Interest rate [35], | 5 % |

| Annual operating time [5,46], | 7000 h |

| System life time [34,35], | 20 years |

Table 5.

Thermodynamic parameters at the optimum condition when the bottom cycle fluid is benzene.

| (°C) | (kPa) | (kJ/kg) | (kJ·kg-1·K-1) | |

|---|---|---|---|---|

| 1 | 400 | 1090 | 1005.77 | 4.5671 |

| 2 | 353.73 | 105.69 | 932.08 | 4.5879 |

| 3 | 288.49 | 100.69 | 807.64 | 4.3513 |

| 4 | 257 | 100.69 | 457.78 | 3.6941 |

| 5 | 258.52 | 1160 | 459.32 | 3.7004 |

| 6 | 313.23 | 1125 | 583.76 | 3.9230 |

| 7 | 257 | 100.69 | 751.76 | 4.2489 |

| 8 | 214.62 | 6.33 | 683.11 | 4.2739 |

| 9 | 172.27 | 5.70 | 617.41 | 4.1222 |

| 10 | 153 | 5.13 | 243.32 | 3.2450 |

| 11 | 152.99 | 105.69 | 243.45 | 3.2450 |

| 12 | 186.39 | 100.69 | 309.14 | 3.3934 |

| 13 | 143 | 503.67 | 469.98 | 1.1532 |

| 14 | 53.41 | 17.61 | 364.65 | 1.2116 |

| 15 | 30 | 15.92 | -91.39 | -0.2784 |

| 16 | 30.21 | 538.67 | -90.64 | -0.2779 |

Table 6.

Results of the parameters corresponds to the maximum .

| Top ORC | Middle ORC | Bottom ORC | TORC | |

|---|---|---|---|---|

| (kg/s) | 57.99 | 45.84 | 30.59 | —— |

| (MW) | 4.27 | 3.15 | 3.23 | 10.65 |

| (MW) | 0.089 | 0.006 | 0.023 | 0.118 |

| (MW) | 3.97 | 2.98 | 3.05 | 10 |

| (MW) | 24.47 | 20.29 | 17.15 | 24.47 |

| (%) | 16.22 | 14.71 | 17.76 | 40.86 |

| (%) | 28.95 | 33.19 | 67.17 | 72.94 |

Table 7.

Design parameters of different HXs.

| HX1 | HX2 | HX3 | HX4 | HX5 | |

|---|---|---|---|---|---|

| Type | BJM | BES | BEM | BEM | BJM |

| Shell side heat transfer coefficient, W/m2·K |

68345 | 311.75 | 223.80 | 247.43 | 1486.3 |

| Tube side heat transfer coefficient, W/m2·K |

1135.3 | 684.35 | 210.49 | 609.96 | 11485 |

| Shell ID, mm | 2100 | 1700 | 1900 | 1900 | 1400 |

| Tube length, m | 16 | 144 | 9 | 10 | 10 |

| Ratio of tube length and shell ID | 7.62 | 88.24 | 4.74 | 5.26 | 7.14 |

| Tube count | 3359 | 2774 | 4972 | 4612 | 2506 |

| Overall heat transfer coefficient, W/m2·K |

611.36 | 181.64 | 91.51 | 152.48 | 819.90 |

| Heat duty, MW | 27.230 | 7.9854 | 3.3410 | 9.2282 | 14.362 |

| Baffle central spacing, mm | 800 | 1000 | 800 | 800 | 1000 |

| Effective mean temperature difference, °C | 16 | 21.9 | 16.2 | 24.7 | 13.3 |

| Area, m2 | 3118.9 | 2291.8 | 2631.4 | 2716.2 | 1475.4 |

| Over design, % | 12.27 | 14.13 | 16.60 | 10.71 | 11.78 |

Table 8.

Values of constants for HXs and turbines.

| HX1 | 2.9 | 1 | 1 |

| HX2 | 1 | 1 | 1 |

| HX3 | 1 | 1 | 1 |

| HX4 | 1 | 1.3 | 1 |

| HX5 | 1 | 1.3 | 1 |

| T1 | 3.2 | 1 | 1 |

| T2 | 1 | 1.3 | 1 |

| T3 | 1 | 1 | 1 |

Table 9.

Investment cost of each component.

| Component | Cost (×104 $) | Component | Cost (×104 $) | Component | Cost (×104 $) |

|---|---|---|---|---|---|

| HX1 | 173.73 | HX2 | 48.58 | HX3 | 53.37 |

| HX4 | 70.89 | HX5 | 46.81 | T1 | 1010.74 |

| T2 | 331.46 | T3 | 259.67 | P1 | 12.10 |

| P2 | 2.92 | P3 | 5.28 | G1 | 24.32 |

| G2 | 18.19 | G3 | 18.65 |

Table 10.

Thermodynamic parameters of the cascade ORC at the optimum condition.

| (°C) | (kPa) | (kJ/kg) | (kJ·kg-1·K-1) | |

|---|---|---|---|---|

| 17 | 400 | 1090 | 1005.77 | 4.5671 |

| 18 | 302.54 | 6.33 | 835.25 | 4.6201 |

| 19 | 203.75 | 5.7 | 665.75 | 4.2270 |

| 20 | 153 | 5.13 | 243.32 | 3.245 |

| 21 | 155.68 | 1160 | 244.83 | 3.2571 |

| 22 | 238.96 | 1125 | 414.33 | 3.6174 |

| 23 | 143 | 503.67 | 469.98 | 1.1532 |

| 24 | 53.03 | 17.61 | 364.23 | 1.2119 |

| 25 | 30 | 15.92 | -91.39 | -0.2784 |

| 26 | 30.21 | 538.67 | -90.79 | -0.2779 |

Table 11.

Design parameters of the HXs in cascade ORC.

| HX6 | HX7 | HX8 | HX9 | |

|---|---|---|---|---|

| Type | BJM | BES | BES | BJM |

| Shell side heat transfer coefficient, W/m2·K |

70939 | 190.63 | 953.18 | 1439.4 |

| Tube side heat transfer coefficient, W/m2·K |

976.58 | 434.62 | 564.03 | 9541.7 |

| Shell ID, mm | 2000 | 1800 | 2100 | 1500 |

| Tube length, m | 14 | 13 | 16 | 8 |

| Ratio of tube length and shell ID | 7 | 7.22 | 7.62 | 5.33 |

| Tube count | 2978 | 2774 | 5246 | 2535 |

| Overall heat transfer coefficient, W/m2·K |

576.69 | 116.22 | 267.68 | 791.08 |

| Heat duty, MW | 26.878 | 7.7654 | 17.345 | 13.718 |

| Baffle central spacing, mm | 800 | 1000 | 800 | 1000 |

| Effective mean temperature difference, °C | 22.0 | 35 | 13.5 | 14.1 |

| Area, m2 | 2427.1 | 2126.3 | 5581.4 | 1382.0 |

| Over design, % | 14.54 | 11.41 | 16.27 | 12.28 |

Table 12.

Investment cost of each component in cascade ORC.

| Component | Cost (×104 $) | Component | Cost (×104 $) | Component | Cost (×104 $) |

|---|---|---|---|---|---|

| HX6 | 146.50 | HX7 | 46.17 | HX8 | 111.42 |

| HX9 | 44.78 | T4 | 1435.81 | T5 | 342.46 |

| P4 | 9.52 | P5 | 5.34 | G4 | 39.17 |

| G5 | 19.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Copyright: This open access article is published under a Creative Commons CC BY 4.0 license, which permit the free download, distribution, and reuse, provided that the author and preprint are cited in any reuse.

MDPI Initiatives

Important Links

© 2024 MDPI (Basel, Switzerland) unless otherwise stated