Preprint

Article

Integrating Building Information Modeling (BIM) and Life Cycle Cost Analysis (LCCA) to Evaluate the Economic Benefits of Designing Aging-in-Place Homes at the Conceptual Stage

Altmetrics

Downloads

105

Views

36

Comments

0

A peer-reviewed article of this preprint also exists.

This version is not peer-reviewed

Submitted:

09 May 2024

Posted:

13 May 2024

You are already at the latest version

Alerts

Abstract

This paper presents a methodology for the integration of Building Information Modeling (BIM) and Life Cycle Cost Analysis (LCCA) to assess the economic implications of designing aging-in-place (AIP) homes at the conceptual stage. With the global increase in the aging population, there is an increased demand for housing solutions tailored to the needs of elderly individuals. Focusing on the importance of the early phase of design, this study aims to improve the process of making efficient decisions by providing a comprehensive assessment of the life cycle costs associated with AIP homes. The study introduces a semi-automated model for the economic evaluation of AIP homes, enabling the estimation of costs throughout the houses’ entire life cycle, from design and construction to operation, maintenance, and eventual renovation or disposal. The said model facilitates the exploration of the long-term economic feasibility of design’s related decisions with an emphasis on the importance of considering the life cycle costs early during the design process to optimize the functionality and economic viability. By investing in accessible and universal design features upfront, the initial costs for modifications can lead to long-term savings by reducing the need for extensive retrofits. The model can easily do comparison between different design alternatives in terms of their lifecycle costs, allowing designers to assess the financial impact of using important features in their design such as wider doorways, accessible bathrooms, and elevators. Overall, this study provides valuable insights for designers and homeowners about the economic aspects of designing AIP homes as a support for efficient decision-making during the early stages of the design process.

Keywords:

Subject: Engineering - Architecture, Building and Construction

1. Introduction

Presently, Canada is navigating through a profound demographic transition, anticipating that by 2031, almost 25% of its population will fall into the age group of 65 years and older. This demographic shift poses challenges for the healthcare system, as individuals aged 65 and older represent 19% of the population, which already account for almost half (47%) of healthcare spending (NIA, 2022). A national survey conducted by the National Institute on Ageing (NIA) in collaboration with TELUS Health in year 2020 has revealed a noteworthy shift in Canadians’ perspectives on aging, post-COVID-19. The survey indicates that 60% of the Canadian population and 70% of older Canadians have reconsidered moving to long-term care or retirement homes. A vast number of Canadians, almost 91%, and nearly 100% of older Canadians express the desire to age in their own homes. AIP is emphasized for its benefits in providing comfort, familiarity, and enhanced well-being for seniors, minimizing the stress associated with major life changes (Koeppel, 2022). Housing plays a pivotal role in AIP, as architectural space is intimately connected to human existence (Wu and Handziuk, 2013). In the absence of an initial design aligned with AIP requirements, existing homes may require substantial renovations, incurring significant costs and potentially affecting resale value if not executed with aesthetic consideration. For example, the need for widening doorways would cost between $20,000 and $40,000, depending on the home’s architecture, the cost of installing an elevator ranges from $80,000 to $100,000, bathroom refurbishments would cost around $20,000 to $30,000, while the cost of a kitchen overhauls is between $40,000 and $80,000, underscores the financial impact of retrofitting. It is important to note that these costs are based on the year 2022, which would be much higher in future years. Proactively integrating these considerations during the conceptual design phase can substantially mitigate these costs (Jermyn, 2022). The strategic integration of AIP requirements during the conceptual design stage holds the potential to significantly reduce the costs associated with retrofitting and modifying of a house over the long run. This proactive approach minimizes the need for extensive retrofitting later, as the home is originally structured to accommodate potential mobility challenges and accessibility requirements. Consequently, the costs correlated with retrofitting, which can be substantial, are mitigated. Investing in thoughtful AIP design during the conceptual phase not only enhances the overall functionality of the space but also serves as a prudent economic strategy, offering a cost-effective alternative to reactive modifications that may become necessary in the absence of such foresight. LCCA is a method for evaluating the total cost of owning, operating, and maintaining an asset or system throughout its entire lifespan. Adopting LCCA into the overall cost estimation helps in selecting the best option between projects with similar applications but with varying cost parameters throughout their life cycle (Younis et al., 2018; Guo et al., 2019). LCCA becomes particularly pertinent in the context of AIP design by helping designers implement systematic and comprehensive evaluations of the economic implications associated with various design alternatives. It allows for the prediction and evaluation of the long-term costs linked to different AIP features and modifications, and accordingly identifies the cost-effective design solution(s) that contribute to both the immediate and long-term economic sustainability. LCCA enables the comparison of different design alternatives, allowing designers to make informed choices that optimize both the functionality and economic feasibility of assets. Younis et al., (2018) emphasized the importance of employing LCCA during the initial phases of design. This early application allows for refinement and improvement in the design, ultimately aiming to minimize project’s future costs. This study explores the integration of LCCA and Building Information Modeling (BIM) in the context of AIP design at the conceptual design stage by introducing a novel plugin developed and inherited into Autodesk Revit as BIM tool. This integrated approach offers architects and stakeholders a robust analytical tool that would enhance the efficiency of making important decisions early during the design stage. The overarching goal is to create adaptive, sustainable, and economically feasible living environments for the aging population. The developed model via its unique plugin facilitates the execution of comprehensive LCCA for AIP designs and allows for the comparison of various design alternatives in an automatic manner. Incorporating LCCA into BIM for AIP homes (AIPHs), through this innovative algorithm (plugin), allows for holistic assessments of the construction costs and the long-term financial implications for design decisions. This approach considers numerous factors, such as maintenance, adaptability, and energy efficiency, and redefines the design of AIPH by merging the economic sustainability with advanced digital modeling. The integration of LCCA and BIM supports real-time design adjustments, making homes more adaptable as residents age, and therefore, reduces the need for expensive future modifications, which will offer financial ease for residents over the long term. Ultimately, this approach ensures that homes are not only functional and attractive but also financially sustainable over their life. This study extends from the authors’ prior research, Rostamiasl and Jrade (2022), which concentrated on the integration of BIM, Universal Design (UD), and AIP design requirements during the conceptual design stage. It is important to note that in this current study, the term “building” is broadly applied, particularly in the cases related to the energy analysis, LCA and LCCA. While the term “house” is specifically referenced to the design for aging and serves as the focus of the case project used to test the developed model.

2. Literature Review

LCCA is a methodology employed to assess the financial aspects of a project throughout its service life and plays a central role in estimating future expenses starting from the design stage onward. It encompasses the total cost of an asset throughout its life cycle, including investment, construction, operation, maintenance, rehabilitation, and the residual value at the end of service life. LCCA offers a way to optimize design alternatives, ensuring financially sound decision-making early in a project’s design stage. This method strikes a balance between initial and future costs (such as operating, maintenance, repair, or replacement costs), ultimately aiming to reduce the overall project cost (Huang et al., 2018). BIM concept serves as a valuable method for managing project’s information, which facilitates the evaluation of the Life Cycle Cost (LCC) while creating project’s models at the various stages of its design. BIM speeds up the process of estimating the costs with fewer mistakes, less errors and simplified decision-making procedures. This streamlined approach contributes to improve the structure’s performance over its lifespan. Moreover, BIM facilitates the utilization of visual tools and specific information about various components and activities, enhancing LCC results for effective use by decision-makers (Zoghi & Kim, 2020). One of the most significant tasks facilitated by BIM is the execution of the Quantity Takeoff (QTO) process (Valinejadshoubi, et al., 2024), which is one of the most important items needed to conduct the LCCA.

According to Altaf et al., (2020), the integration of LCC and BIM mitigates potential conflicts and errors in the cost-estimating process. Early integration of BIM and LCCA during the project’s design has the potential to minimize the operation, repair, and maintenance costs (Altaf, et al., 2020) as the early design stage has a significant impact on the performance of a building during its life span (Kovacic & Zoller, 2015). Designers and investors require an efficient tool to predict the LCC during the initial design phases of facilities. This tool should help in estimating, not only, the construction costs but also the life cycle operating costs, savings and benefits. Emphasizing the life cycle costs over the construction costs would facilitate the process of making more informed decisions (Muller et al., 2019; Kneifel, 2010). Various studies have explored the integration of LCCA with Building Information Modeling (BIM) and have demonstrated promising outcomes. For instance, Kehily et al., (2013) investigated the feasibility of utilizing the data extracted from BIM models to conduct comprehensive LCC calculations, which was achieved by employing a cost-estimating tool in their approach. Jalaei et al., (2015) conducted a study that integrated a Decision Support System (DSS) with Building Information Modeling (BIM). They aimed to assess the feasibility of combining BIM, DSS, and Life Cycle Cost Analysis (LCCA). They developed a DSS to optimize the selection of sustainable materials during the conceptual design phase. Subsequently, design alternatives recommended by the DSS were evaluated within an integrated environment that merged the concepts of BIM and LCCA methods. Their integrated approach allowed for the analysis of the operational costs of the entire building. Santos et al., (2020) assessed the benefits of integrating BIM and LCC by incorporating an external database for LCCA into a BIM environment. The findings indicated that this integration played a significant role in promoting sustainability during the initial stages of projects. Ansah et al., (2020) stated that the integration of BIM and LCC is a practical approach for assessing the advantages of implementing façade systems with improved environmental impacts. Rad et al., (2021) introduced an LCCA framework that was designed for the use during the conceptual design stage of buildings. The framework aimed to enhance resilience and to optimize construction costs by developing a plugin within BIM tools. The plugin facilitates the selection of resilient components at the early stages of design. Viscuso et al., (2022) devised a model’s framework that integrates BIM, LCC and Life Cycle Assessment (LCA). Interoperability was achieved through Dynamo, linking BIM models, which were generated in Autodesk Revit, with the LCA tool (One-Click LCA). This integration can be spanned over various stages of a project, with the aim to deliver more sustainable designs that are aligned with LEED protocols. The framework extended its consideration to the economic aspects by employing LCCA to attain optimal cost solutions at every stage of a project. Shin and Cho (2015) developed an Excel spreadsheet-based framework that allowed for the implementation of LCA and LCCA by obtaining necessary information from BIM models to select appropriate design alternatives. Juan and Hsing (2017) developed three design proposals that target different service lives (30 years, 50 years, and 100 years), based on the building’s expected life, and used BIM technology to simulate the life cycle cost and design performance, built on scenario analysis of a building’s renovation over its life cycle. Le et al., (2020) developed a BIM-integrated RDBMS (Relational Database Management System) for compiling and organizing the required data and information from BIM models to compute buildings’ LCC. The system integrated BIM authoring program (tool), a database management system, a spreadsheet system, and a visual programming interface to perform building LCCA. Lee et al., (2020) proposed a method for preparing preliminary cost estimates based on BIM’s levels 1 & 2 of details and the actual construction cost data to support the decision-making early in the design phase. Rashed et al., (2019) proposed a method that combines the capabilities of BIM and energy simulations with LCC through a case study that can be used by facility managers or building design teams to select the most cost-effective assembly of building’s envelope.

Furthermore, building upon the comprehensive review of the literature, it is evident that the early stages of design play a critical role in minimizing the environmental footprint of buildings. As highlighted by Anton and Díaz (2014) and Yang et al. (2018), this phase offers the greatest flexibility for improvements, whereas the opportunities for changes diminish and the cost of implementing alterations escalates rapidly as projects progress. Therefore, a strategic approach to make efficient design decisions during the initial stages is imperative for achieving the sustainability outcomes

Estimating the cost of embodied carbon emissions in buildings primarily focuses on assessing the carbon outputs across all the stages of a building’s life, including material extraction, processing, construction, operation, and end-of-life phases (Dixit et al., 2012). The primary aim is to quantify the carbon emissions in carbon equivalent units to measure the building’s total environmental impact. The process comprises the calculation of the embodied carbon, which includes emissions from materials’ production to construction, and the operational carbon, which consists of emissions during the building’s use. Effective strategies for reducing embodied carbon involve using low-carbon materials, optimizing building design to minimize material usage, and improving the recycling and reusing of materials. Methods for estimating these emissions have evolved, focusing on life cycle assessments (LCAs) that account for all related activities and processes to provide a comprehensive carbon footprint of building projects (Akbarnezhad & Nadoushani, 2014; Akbarnezhad & Xiao, 2017). A study by Schmidt et al., ( 2020) used a comprehensive approach to estimate the cost of embodied carbon emissions in the construction and maintenance of a building through its life cycle. It involved quantifying the life-cycle of greenhouse gas (GHG) emissions, for both operational and embodied, of a building and then applying economic evaluation techniques to those emissions. This process accounted for initial construction emissions, recurring emissions from materials that need replacement, and operational emissions over the building’s lifecycle. The financial implications were estimated by multiplying these emissions by the current market price of carbon and then employing income methods (capitalization and discounted cash flow) to assess their economic value over time. Similarly, Sun & Park, (2020) used BIM to estimate the cost of embodied carbon emissions for tunnel’s construction, integrating CO2 emission factors of materials and equipment into a 3D model in Autodesk Revit. These emissions were converted to costs using the EU emissions trading system prices, enabling an economic analysis of the construction process. Their approach provided a method to assess and manage the environmental and financial impacts of construction projects. Both studies aimed to embed environmental costs into the evaluation of projects to achieve better decision-making in construction.

Robati et al., (2021) employed a Carbon Value Engineering (CO2VE) framework for estimating the cost of embodied carbon emissions during the design of buildings. The approach integrated the reduction of embodied carbon and capital costs by using a detailed Bill of Quantities to assess initial designs by applying the Pareto Principle to focus on key impact areas and proposing alternative materials and structural systems to reduce both the costs and emissions. The effectiveness of their framework was demonstrated through its application to an 18-storey building in Sydney, where significant savings in carbon emissions and construction costs were attained by optimizing the design and material selection. Langston et al., (2018) developed a method to estimate embodied carbon emissions costs by analyzing new-build versus refurbished projects using hybrid input-output analysis and LCA, to assess the embodied carbon and link it to construction costs, demonstrating that refurbished projects typically exhibit lower embodied carbon and costs per square meter compared to new-builds. The study highlighted the economic and environmental advantages of refurbishment over new construction.

Several studies, such as Llatas, et al., (2020) and Nwodo & Anumba, (2019) have been proposed to assess the environmental impact and cost of construction projects by translating the embodied carbon into a monetary value. Schmidt, et al., (2018) advocated for the implementation of a carbon tax applied to the lifecycle carbon emissions of buildings. This strategy aimed to effectively communicate greenhouse gas (GHG) emissions to stakeholders and to provide incentives for reducing emissions.

Despite of the extensive body of research on the integration of BIM, LCA and LCCA, a notable gap exists in the reviewed literature. To the authors’ knowledge, there is a scarcity of studies that specifically concentrate on this integration within the context of AIP design during the conceptual design stage. This gap underscores the need for a dedicated exploration of how BIM and LCCA can be synergized to address the unique requirements of AIP design within the early phases of conceptualization. In addition to quantifying the environmental impact of buildings in terms of carbon emissions, guiding efforts to reduce carbon footprints in the construction industry. The main challenges include the standardization of measurement methods and the improvement of data’s quality to ensure consistency and reliability in the estimates. This gap underscores the need for a dedicated exploration of how BIM, LCA and LCCA can be synergized to address the unique requirements of AIP design at the early stages of projects. Considering the requirements of the aging population, LCCA within a BIM environment facilitates the implementation of a comprehensive evaluation of the economic implications associated with the different design alternatives for AIP. This approach not only helps optimizing the construction costs but also enables decision-makers to gauge the long-term financial feasibility and sustainability of AIP homes. The streamlined integration of BIM and LCCA at the conceptual design stage can guide designers and stakeholders toward making informed decisions that prioritize both the well-being of aging residents and the economic efficiency of AIP designs, thus addressing the identified gaps in the existing literature and contributing to the advancement of AIP-focused designing practices.

3. Development Methodology

The adopted BIM-LCCA integration method introduces a novel approach through the development of a semi-automated model and the creation of a tailored plug-in within BIM tool (i.e., Autodesk Revit). This innovative process streamlines the assessment of LCCA for AIP homes, specifically by addressing the significant influence of AIP requirements on future modification and alteration costs. By accounting for all types of costs, starting from initial, through operational, repairs and maintenance, major replacements, and ending by salvage/resale, from the early design phase, the integrated framework ensures comprehensive cost considerations.

The framework for integrating BIM and LCCA comprises four distinct and sequential phases. Phase 1, focuses on collecting and storing data related to aging-in-place requirements and the anticipated retrofitting costs for improved accessibility. This data is then stored in a dedicated database, which is subsequently linked to a BIM tool (i.e., Autodesk Revit) through C# coding. Within Autodesk Revit, novel plug-ins are developed to facilitate the retrieval of data needed for LCCA, LCA, AIP prerequisites, and energy analysis. Phase 2, consists of creating detailed 3D models that include materials quantity take-off and integrating it with RSMeans cost data. Concurrently, preparations are made for the model to interface with the energy analysis and LCA tools. Phase 3, focuses on analyzing and simulating energy usage, extracting vital data about the energy consumption and associated costs, and conducting an LCA to calculate the embodied carbon. These results are subsequently integrated into the LCCA module to contribute in the calculation of both the initial and operational costs. Finally, Phase 4, focuses on developing the LCCA plugin, which autonomously receives data from the energy analysis and LCA plugins, RSMeans cost data, and user inputs. The sophisticated design of this plugin facilitates the implementation of scenario and sensitivity analysis and therefore generating detailed reports, charts, and visual representations. These resources are tailored to provide designers and owners with the necessary insights for making optimal decisions throughout the design process. Figure 1 illustrates the framework of the integrated model.

3.1. Phase 1- Data Collection and Integration

During this initial phase, a systematic review of the relevant literature and standards related to AIP requirements is conducted. Data pertaining to AIP requirements, with a specific focus on accessibility features and anticipated retrofitting costs for AIP considerations, is meticulously compiled. Subsequently, a relational database is designed by utilizing MySQL and a cloud server to ensure efficient data retrieval and manipulation whenever needed. To establish the connectivity, C# coding and PHP programming are employed to create a bidirectional link between the database and the selected BIM tool (i.e., Autodesk Revit). Several plugins are developed in this phase, which include: 1) an AIP requirements plugin, to facilitate the integration of specific design considerations into the BIM model; 2) an Energy Analysis plugin that extracts detailed energy consumption data with cost implications and seamlessly transferring this information to the LCCA plugin; 3) an LCA plugin that calculates the model’s embodied carbon and transfers it to the LCCA plugin along with the associated carbon cost; and 4) an LCCA plugin, which is equipped with functionalities to retrieve and process data from the connected database while accepting input parameters related to design alternatives, cost data, and AIP features.

3.2. Phase 2 – Creation of BIM 3D Model

During this phase, a detailed 3D model is created, serving as a cornerstone for the comprehensive evaluation of AIP home designs. This intricate modeling process extends beyond the architectural aspects to encompass specific AIP requirements as identified in Phase – 1, to ensure a holistic representation. The BIM 3D model will be the basis for all the subsequent calculations, analysis and integration of LCCA. Concurrently, a detailed materials’ quantity take-off is executed. Quantity can be measured from BIM models by extracting geometric data and semantic properties of each building element called BIM-based Quantity Takeoff (QTO) (Valinejadshoubi, et al., 2024). This phase also incorporates RSMeans cost data to estimate the construction costs, encompassing the costs of materials, equipments and labour, contractor costs, and O&P (Overhead and profit) establishing the initial cost based on the MasterFormat and Uniformat divisions for all the building elements. During this stage, the cloud server engages in a bi-directional interaction with the plug-ins to facilitate the import and export of data to and from the database. Once the design is finalized, which incorporates all the geometric and non-geometric components, an analytical model is generated so it would be exported to DesignBuilder (energy analysis tool) to calculate the total annual energy consumption and embodied carbon for the 3D model. Initially, zones and spaces are identified, followed by adjustments such as location and orientation. The model is exported to DesignBuilder as a gbXML file, which is done in two ways: i) via the DesignBuilder add-in in Autodesk Revit; or ii) directly from the export option in the File tab of Autodesk Revit. When using the DesignBuilder add-in, the setting toolbar icon is located on the analysis menu. The general tab remains at its default setting, while the merge tab allows for subsequent modifications in Autodesk Revit after transferring the model. In this instance, the merge tab remains unchecked. Finally, the “Use rooms/space volumes” and “Complex with mullions and shading surface” options are selected to generate the gbXML file. This interrelation is essential to predict and evaluate the energy consumption and embodied carbon aspects of the design, contributing to a more comprehensive LCCA. The meticulous coordination of these elements in Phase – 2 set the stage for a well-informed and integrated approach to the design of AIP home’s, where design, cost, LCA and energy considerations are intricately interwoven to enhance the overall project outcomes.

3.3. Phase 3 – Energy Analysis, LCA and Simulation

In this third phase, the focus shifts to energy analysis, LCA and simulation, given the significant impact of energy consumption costs on the overall operational costs and embodied carbon cost on the initial cost. The process starts by extracting detailed information about the building geometry from the 3D BIM model. This extracted information is then exported in the form of a gbXML file to facilitate the integration into the designated tool. This study elected to use DesignBuilder as the energy analysis and LCA tool due to its robust features and capabilities that align with the objectives of this research. With its user-friendly interface and advanced simulation capabilities, DesignBuilder enables accurate modeling and assessment of the energy consumption and embodied carbon of buildings.

Upon exporting the gbXML file to DesignBuilder, the building geometry undergoes assessment for any inconsistencies. Presently, there are no specific guidelines for verifying the geometric data, aside from the software’s message indicating the number of buildings, blocks, and zones post-transfer to DesignBuilder (Elnabawi, 2020). In this investigation, successful exportation of the house geometry is evidenced in Figure 2. For this study, the default heating and cooling systems are established, and a Fan Coil Unit (4 Pipe) with default settings is implemented for the HVAC system. The occupancy load is set for three occupants, utilizing the default occupancy schedule for residential spaces. Heating and cooling setpoint temperatures are configured at 18°C and 25°C, respectively. For additional accuracy, walls and roofs were restructured similar to the 3D BIM model’s walls and roofs’ properties. Windows are centrally positioned on each façade, and the properties of these selected windows are detailed in Table 1. Furthermore, shading is not considered in the base model and for simplicity, the influence of window’s frames is excluded from consideration in this study.

The foremost essential step in ensuring accurate energy simulation is to identify the location and select the appropriate weather file. DesignBuilder provides access to a wide range of weather files based on EnergyPlus, a widely known and used energy simulation engine. Users can select the relevant weather file correlated with their project’s location to ensure accurate simulation results that account for the local climate conditions. Then, all the relevant parameters and adjustments are incorporated to ensure a comprehensive and accurate simulation. Toward the end, the simulation process generates detailed results, encompassing the annual energy consumption of the building and the related costs. These results are stored in a dedicated database and will be used during the LCCA process. This integration ensures that the insights gleaned from the energy analysis, including operational costs, are automatically incorporated into the broader framework of LCCA. In this study, most of the adjustments are made within the DesignBuilder environment to ensure high accuracy.

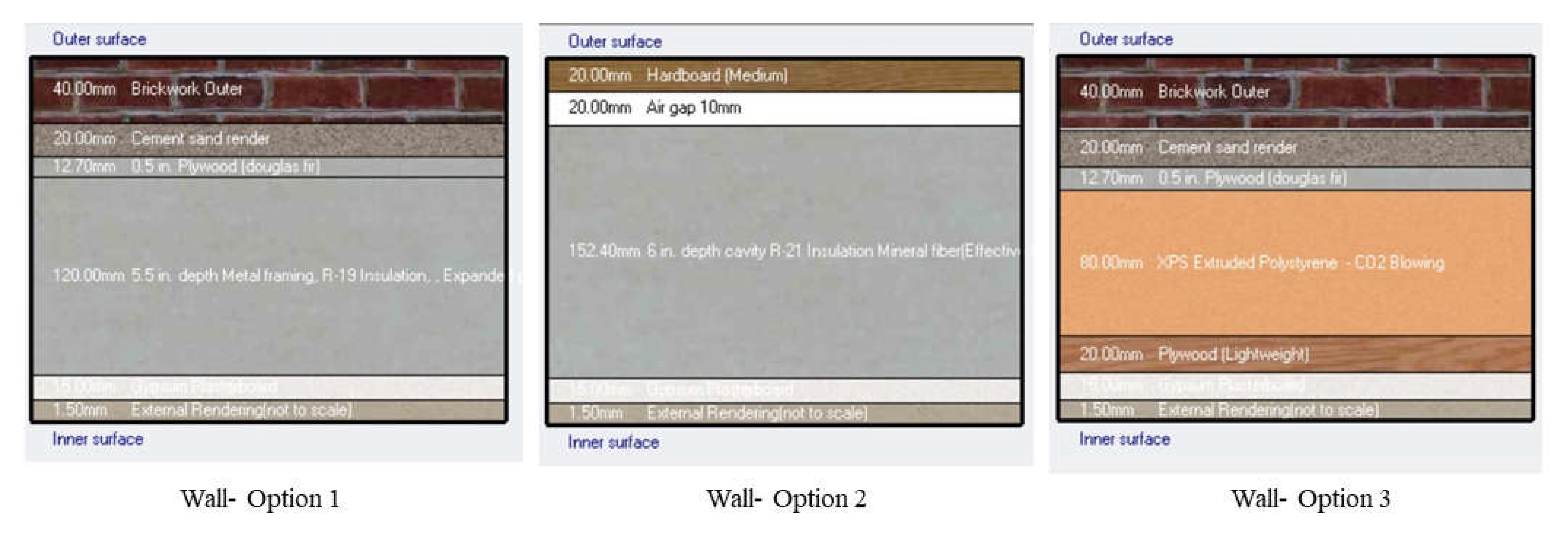

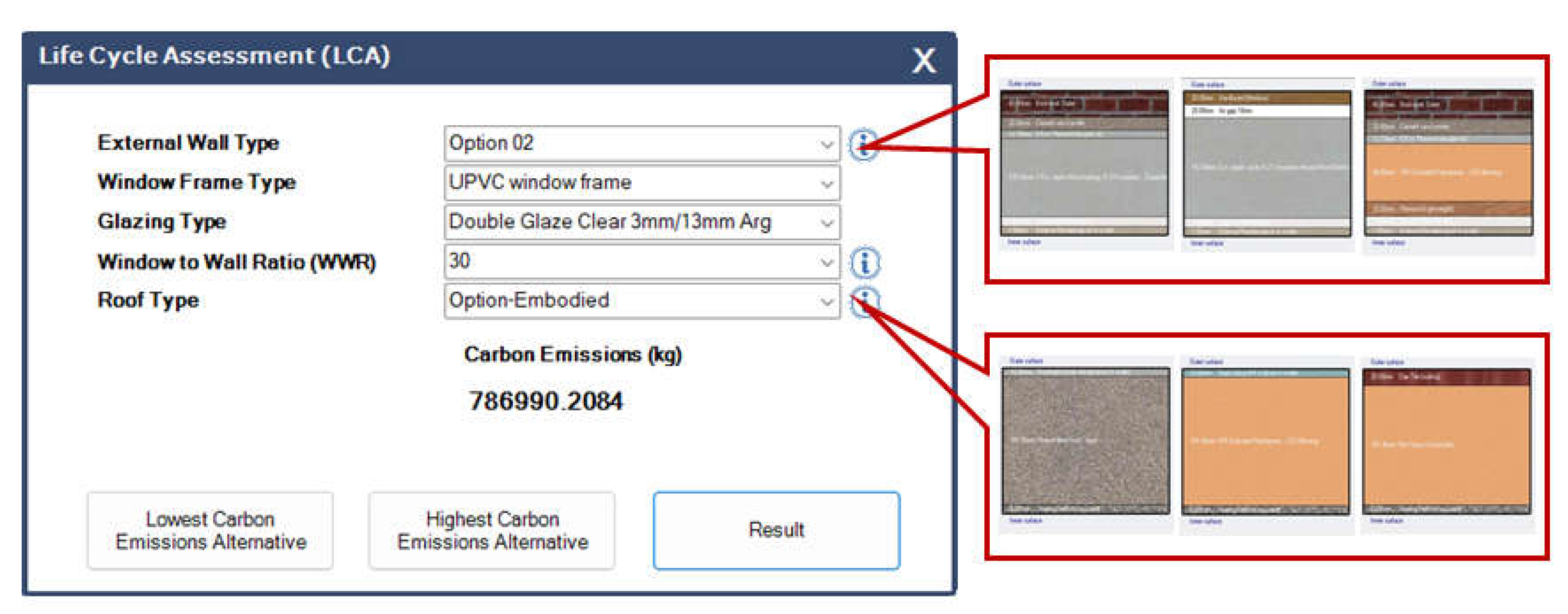

The next step is to conduct a life cycle assessment (LCA) to generate the embodied carbon. The same model that is used for the energy analysis with all its parameters and adjustments is used to conduct the LCA. The primary focus of this study in relation to the LCA is on the envelope components of residential buildings, specifically the walls, roofs, and windows as these components play a critical role in the overall energy consumption and environmental impact of buildings. The scope of this study involves the production stage of building materials (including raw material extraction and manufacturing), which is defined as cradle to gate. The assessment of the embodied carbon within this scope involves the quantification of the embodied carbon associated with the extracting, processing, and manufacturing processes. By analyzing the embodied carbon, this study seeks to identify the chances for reducing carbon emissions and promoting environmentally sustainable building practices. This analysis generates valuable insights into the environmental impact of residential building’s envelopes and supports the decision-making process aimed at mitigating carbon emissions and promoting the adoption of low-carbon building’s materials and construction practices. The study aims to contribute to the development of more sustainable and eco-friendly houses especially for the aging population. To achieve this goal, an optimization analysis is conducted using different variables as shown in Table 2. Figure 3 and Figure 4 show the selected walls and roofs respectively.

The scope of this study is limited to optimizing the embodied carbon of a building envelope, therefore, it is assumed that interior items, which include interior walls, finishes, ceiling, equipment, furniture, fixtures, and furnishings will remain the same for each generated alternative. Optimization usually requires running a significant number of simulations. The setting considered for the optimization algorithm in this study is 100 simulations with a population size of 20 as recommended by the DesignBuilder tool. Open-Beagle is used as the optimization engine. Maximum population size is set at 50, Tournament size at 2, Crossover rate of 1, and Individual mutation probability of 0.4. Upon generating the optimization analysis and generating the results, all data is stored in the external database that will be used later in BIM tool to help designers select different variables. By selecting variables the associated embodied carbon value in (kg) is provided to the designer through the LCA plugin. The plug-in is able to recommend the best and worst combination of variables in term of embodied carbon emission.

The value of the embodied carbon emission is transferred to the LCCA plug-in along with the associated costs to compile the carbon cost, which is added to the initial cost. Carbon pricing is gaining momentum globally. In Canada, the federal government implemented a coordinated nationwide carbon price, beginning at $20 per tonne of carbon dioxide equivalent emissions (tCO2e) in 2019 and rising to $80 per tonne as of April 1, 2024. All provinces and territories in Canada must maintain a carbon price of at least $80 per tCO2e in 2024 (Government of Canada, 2024).

3.4. Phase 4 – LCCA Integration

In this phase, the developed LCCA plugin will automatically receive data inputs from the AIP, LCA, and energy analysis plugins, ensuring real-time and accurate integration. It will also bring in RSMeans cost data and user inputs, forming a complete dataset for thorough LCCA. The plugin is designed to explore various design alternatives and their economic impacts through scenario analyses. Also, it has the ability to conduct sensitivity analysis to identify the most sensitive parameters and to check how the model responds to changes in the input constraints. The integrated model then produces a detailed LCCA by considering the design, construction, operation, and maintenance costs. These results are visually presented and analyzed to identify the cost-effective design’s option, empowering designers and owners to make informed decisions. Ultimately, the plugin produces detailed reports that summarize the results of the LCCA, sensitivity analysis, and scenario analysis by offering accessible insights for the decision-making processes. This phase commences by gathering essential user-defined data, including unit cost, project location, study period, and interest rate. Next, it calculates the initial cost that incorporates the capital investment for land acquisition, designer fees, construction costs, and carbon cost of the house 3D model. The evaluation of the cost data starts by acquiring the land cost, which is provided by the user, while designer fees, construction costs, and carbon cost are retrieved from the database that has been established in Phase – 2, with the model’s flexibility, users can change the input values. Operation costs are automatically sourced from the energy analysis plug-in, as outlined in Phase – 3. Additionally, minor maintenance costs, integral to the operational costs, are computed as a percentage of the construction cost. While the default value, as per the literature reviews, is set at 2% of the construction cost, however, users have the flexibility to input alternative values.

Throughout the lifecycle of a building, its various components may experience wear and tear, necessitating periodic repairs and replacements. Factors such as aging deterioration and technological advancements can further drive the need for these interventions. This study places particular emphasis on the future modifications for a home that are required to align with the aging-in-place requirements, which encompass a range of accessibility and safety features tailored to accommodate the needs of elderly occupants. The decision to focus on these modifications stems from the recognition that failing to address aging-in-place considerations during the initial design phase can lead to significant retrofitting costs and potential disruptions to occupants’ lives. To provide a comprehensive understanding of these anticipated modifications and their associated costs, relevant literature was thoroughly reviewed (Jermyn, 2022; Trout & Smith, 2023). The findings of reviewing the literature, including cost breakdowns, are presented in Table 3, shedding light on the financial implications of incorporating aging-in-place features into residential designs. Certain prices were initially denominated in US dollars and were subsequently converted to Canadian dollars for consistency and ease of comparison. The conversion was conducted using the city indexes from the RSMeans website. To obtain the costs in Canadian dollars, the specified Canadian city index was divided by the national average index to do the cost conversion. Then those values were rounded to facilitate the calculations. It is important to note that these prices are anchored in the collected data from the year 2022. Thus, to accurately project future costs, adjustments must be made to reflect the year of occurrence. This adjustment can be achieved through Equation - 1.

Where (F) is the forecasted cost; (P) is the past/current cost; (i) is the inflation rate; and (t) is the number of time periods between the known and forecasted year.

Salvage value, as defined, represents the residual worth of a product at the end of its designated lifespan. Every building has a finite lifespan, with its salvage value ultimately diminishing to zero by the end of that period. However, in this study, resale value is considered as well. This decision allows for greater flexibility and provides a more dynamic and realistic perspective into the analysis, reflecting the potential financial returns that can be realized upon the sale of the property though users retain the option to utilize salvage value if preferred.

The Present Worth Method (PWM) is utilized to adjust all costs incurred at various stages throughout the building’s life cycle to their present values. PWM converts all cash flows to an equivalent single sum at time zero. This adjustment will be made by using different equations. For recurrent costs such as annual operating costs, and minor maintenance costs, Equation – 2 is inherited in the developed model. These recurring costs are treated as a uniform series in the cashflows, ensuring a comprehensive assessment of their present value over the building’s life cycle.

Where (PW) is the equivalent present worth; (A) is the annual magnitude of the uniform series; (i) = MARR (Minimum Attractive Rate of Return) per year; and (t) is the study period.

For non-recurrent costs such as major replacements and salvage value, which occur as a single cost over different time periods, Equation – 3 is incorporated into the developed model.

Where PW is the present worth; (F) is future cost; (i = MARR); and (t) is the number of time periods between the occurrence and initial.

After calculating all the costs including the initial costs, operational costs, maintenance costs, replacement/modifications costs, and salvage/resale value, their summation is presented with all the details in tables and cashflow diagram formats to be used for comparative analysis. The alternative with the highest present worth serves as the favoured recommendation, denoting superior economic viability amidst the array of options. To compute the present worth value through the summation of costs, it is imperative to recognize the polarity of values. Operational costs and similar expenditures are represented as negative values since they entail an outflow of funds over time. Conversely, positive values denote inflows or returns, such as salvage value. By integrating these opposing financial implications, the net present value encapsulates the cumulative impact of costs and returns over the building’s lifecycle.

The model performs sensitivity and scenario analyses based on various alternatives. In sensitivity analysis, charts and graphs are automatically generated to assist designers and owners in identifying the most sensitive parameters that need more attention due to their influence of the overall life cycle costs. The model can compare up to four different alternatives simultaneously, which are presented in the form of tables and graphs. The graphical tool offers a high level of clarity and simplicity, allowing designers to easily compare options during the conceptual design stage, which is a novel feature of the developed model.

4. Model Testing and Results

To evaluate the effectiveness of the developed model, testing is conducted on a two-story house situated in Ottawa, Ontario, Canada as illustrated in Figure 5. The house is modeled with two different interior designs to compare their functionalities. The first design, Alternative 1, is conventional, lacking the considerations of aging-in-place requirements. The second design, Alternative 2, integrates aging-in-place features, such as wider doors and hallways, the installation of an elevator, and modifications to the bathroom and kitchen for enhanced accessibility. Both alternatives comprise three bedrooms, a living room, a kitchen, three bathrooms, and an attached garage. Utilizing Autodesk Revit© as the chosen BIM tool, a comprehensive 3D design model is constructed for the house, encompassing all the geometric and non-geometric elements, including walls, doors, windows, floors, stairs, and cabinets. The total area for both models is 185.28 square meters, with a floor height of 2.7 meters. After completing the project and conducting the energy analysis and LCA based on the described methodology, the results are stored in the database and are considered by designers to select the best alternatives based on the users’ needs. Figure 6 shows the developed LCA plug-in and associated features. In this plugin, designer can select different alternatives for the variables. Upon selecting the result button, the carbon emission value in kilograms is generated. Additionally, designers have the option to select alternatives with either the highest or lowest carbon emission values. The final results are automatically exported to the database so it will be used by LCCA plugin.

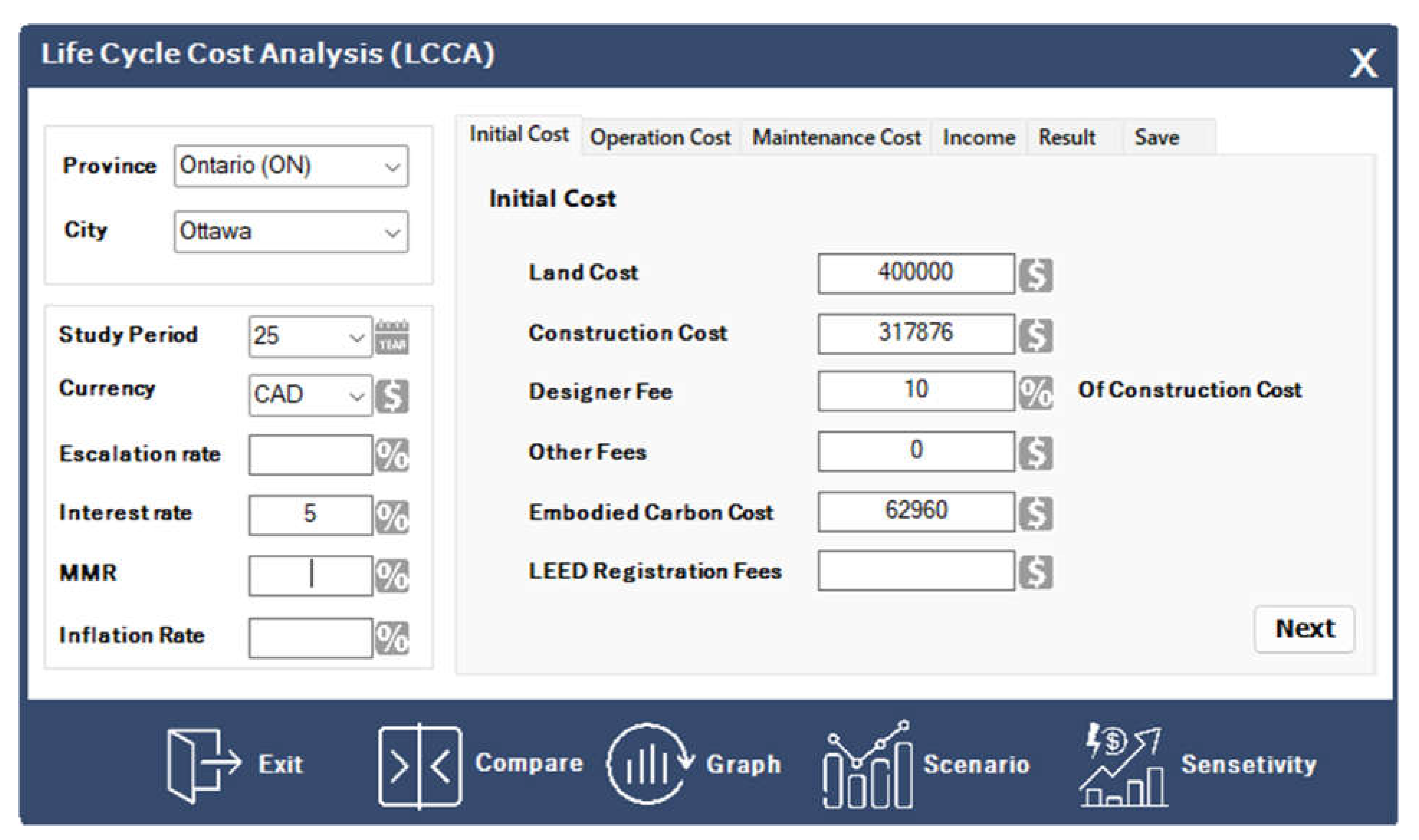

Upon activating the Life Cycle Cost Analysis (LCCA) plug-in, a user-friendly interface is presented, guiding the user to input essential data, including the study period and the prevailing rate (MARR) as a percentage. The default values of the study period and the rate are assumed to be 25 years and 5%, respectively, in this study, however, users can modify these values if they need. The plug-in ensures meticulous data entry to guarantee the accuracy of the LCCA results. In cases where fields are left empty, the plug-in prompts users to fill in all the required information, thereby minimizing the risk of inaccuracies in the analysis.

In developing the integrated model, many tables were established to house crucial information, including detailed quantity take-off, user-entered data, energy consumption metrics, embodied carbon and associated cost and more. Microsoft Excel and MySQL were utilized as external databases to effectively store and manage this data. For the initial analysis phase, focusing on the initial cost, users are guided to enter specific information such as land cost, designer fees, and additional charges. The Quantity Take-Off (QTO) for each building element is exported to an external database, which is used to estimate the construction costs by using RSMeans cost database to retrieve the unit cost of materials and necessary labor rates for all elements. This construction cost is then automatically fetched from the database and integrated into the LCCA plug-in. The user retains the freedom to adjust the data obtained from the database as needed. Additionally, designer fees can be retrieved from the same database or be inputted by the user as illustrated in Figure 7.

In this study, the land cost was calculated using various local realtor applications to obtain the average land cost at the proposed project’s location, which remains consistent for both alternatives. Based on RSMeans cost data, the construction cost, including contractor fees, was found to be $317,876 for Alternative 1 and $368,410 for Alternative 2. The initial cost of Alternative 2 showed an increase in the construction cost because of the inclusion of aging-in-place requirements. An entrance ramp, wider doors, an elevator, a walk-in bathtub and an upgraded kitchen were considered for Alternative 2 as being parts of the AIP requirements. Additionally, the designer fee is assumed to be 10% of the construction cost. In addition, the carbon cost is calculated and incorporated into the plugin automatically.

Moving to the next step, which is dedicated to calculating the operating costs, data is sourced from the energy analysis plug-in, with DesignBuilder serving as the chosen energy analysis tool in this study. The 3D BIM models are exported and transferred to DesignBuilder as gbXML file formats for simulating their energy consumption. Subsequently, the outcomes contain the annual energy consumption, which are stored in the external database and seamlessly retrieved by the LCCA plug-in. Users are afforded flexibility in the parameters’ input, including energy unit cost and annual minor maintenance or repair costs as percentages as shown in Figure 8. The annual cost for minor maintenance and/or repairs can be estimated based on historical data or expert judgment with a default value of 2% of the construction cost in this study. The plug-in efficiently computes the annual utility cost and stores it in the database to be used in the life cycle cost calculation of the project. In this study, Alternative 1 exhibits an annual total energy consumption of 38,150 kW, while Alternative 2, with the addition of an elevator, shows a higher consumption of 45,300 kW annually. Continuing to the subsequent step, which delves into the major replacement costs. Over the projects’ life cycle, components may necessitate their replacement or significant repairs due to aging and deterioration. Particularly, if Aging-in-Place (AIP) requirements were not integrated during the conceptual design phase, subsequent modifications and retrofitting become imperative to align with AIP concepts. Users are empowered to select the elements to be replaced from a drop-down menu or manually input the desired elements, their associated costs and the required year for replacement. Associated costs are sourced from RSMeans cost database. The plug-in diligently computes all the replacement costs and their corresponding present values. Routine maintenance costs such as painting and shingle replacement were not considered in both alternatives, since they are assumed to be the same. For Alternative 1, which lacks the aging-in-place requirements, future modifications are accounted for as seen in Figure 9.

The subsequent step is dedicated to entering the revenue, encompassing details such as potential rent value, salvage value, or resale value as pictured in Figure 10. The resale value could potentially be equal to or greater than the construction cost, depending on various factors such as market conditions, property appreciation, and demand for the property. Unlike salvage value, which typically represents the value of the asset after its useful life, resale value refers to the amount that could be obtained from selling the asset at any time during its life cycle. Although in some cases, particularly in areas with rising property values or high demand, the resale value of a property could indeed exceed its construction cost, in this study the resale value is assumed to not exceed the construction cost. The inputs in this step contribute to the life cycle cost based on the present worth. Upon selecting the Result button, the plug-in promptly computes all the incurred costs, including the initial cost, repair and maintenance cost, operational cost, and salvage/resale value. The summation is presented in detailed tables, encapsulating the project’s life cycle cost. The plug-in generates a comprehensive cashflow in a tabulated format delineating all the parameters, their respective present worths, and the net present value (NPV) as seen in Figure 11. For additional clarity, users can visualize the cashflow diagram, enhancing their understanding of the financial implications as shown in Figure 12. Figure 13 and Figure 14 showcase the plug-ins automatic execution of scenario analysis and sensitivity analysis. Notably, the plug-in is equipped to save and compare up to four alternatives, facilitating a streamlined and efficient decision-making process as illustrated in Figure 15. The plug-in facilitates the preservation, printing, and sharing of all the generated results. This feature facilitates the documentation, communication, collaboration, transparency, and archiving of findings, enhancing the decision-making and knowledge sharing among stakeholders.

5. Discussion, Limitations and Future Works

The integration of BIM, LCA and LCCA presents a promising approach to facilitate the economic and environmental impact evaluation associated with AIP homes. In response to the growing global aging population, there is an increasing demand for housing solutions that cater to the needs of elderly residents while promoting independence and comfort. This study focuses on the early stage of design, due to its importance, with the aim to provide architects and stakeholders with valuable insights into the economic implications of designing AIP homes, and introduces a novel approach to integrate BIM and LCCA concepts for evaluating the life cycle costs associated with AIP homes. Through the development of a semi-automated integrated model and the creation of tailored plugins within Autodesk Revit, the methodology facilitates data integration and analysis. The integration process involves the incorporation of detailed BIM information, including design specifications and material quantifications, with cost data obtained from external databases based on RSMeans cost data. By considering all the costs associated with design, construction, operation, maintenance, and eventual disposal or renovation, the developed model provides decision-support information that optimizes both functionality and economic sustainability. Furthermore, the model allows doing scenario and sensitivity analyses by facilitating the exploration of various design alternatives and their economic implications. The developed model was tested by using an actual case project that consist of a two-story house to be built in Ottawa, Ontario, Canada, where the results yield valuable insights. Alternative 1 represents a conventional design approach while Alternative 2 incorporates AIP requirements. After evaluating the model’s output and conducting a comparative analysis, it is evident that Alternative 1 presents a lower initial cost when compared to Alternative 2. The inclusion of aging-in-place features in Alternative 2 necessitates additional upfront investments to accommodate modifications such as wider doors, elevator installation, and bathroom and kitchen enhancements. Consequently, Alternative 2 demonstrates higher energy consumption and operational costs attributable to the installation and operation of an elevator. Although Alternative 1 may boast lower operational costs initially, Alternative 2 provides valuable insights into long-term operational considerations, particularly concerning aging-in-place accommodations. This comparison underscores the significance of proactive design interventions in optimizing both initial and long-term costs while addressing the evolving needs of occupants.

In terms of maintenance and replacement costs, it becomes evident that while both alternatives incur maintenance and replacement costs over their respective life cycles, the nature and magnitude of these expenses vary significantly. Alternative 1 without explicit consideration of aging-in-place requirements during the conceptual stage, may initially appear to have lower maintenance costs. However, as the building ages and the need for accessibility modifications arises, Alternative 1 necessitates extensive retrofitting and alterations. These post-construction modifications can incur substantially higher costs compared to integrating aging-in-place features from the outset. Conversely, Alternative 2, which integrates aging-in-place requirements into the initial design phase, anticipates and accommodates future accessibility needs proactively and minimizes the need for post-construction modifications and retrofitting. Consequently, while Alternative 2 may entail higher upfront investments, it ultimately offers lower long-term maintenance and replacement costs due to its inherent adaptability and readiness for aging-in-place living. In summary, while Alternative 1 may appear cost-effective in the short term, its susceptibility to higher modification and alteration expenses over time renders it less economically viable compared to Alternative 2, which prioritizes proactive integration of aging-in-place features to mitigate future maintenance expenditures. Both alternatives may exhibit differences in salvage or resale values, influenced by factors such as market conditions, depreciation rates, and the degree of adaptation to aging-in-place principles. However, future resale values for Alternative 2, with its integrated aging-in-place features, could be influenced by the growing demand for accessible and adaptable housing options. Overall, while Alternative 1 may present lower upfront costs, Alternative 2 offers enhanced functionality and adaptability for aging residents, potentially mitigating long-term costs associated with retrofitting and accessibility modifications. After comparing the NPV of both Alternatives as depicted in Figure 15, it can be concluded that Alternative 2 is more favorable. Its higher NPV suggests the benefit of integrating AIP requirements early in the design process. The LCCA provides valuable insights into the trade-offs between initial investments and long-term operational and maintenance considerations, empowering stakeholders to make informed decisions based on their priorities and objectives.

While this study provides a solid foundation for integrating BIM, LCA and LCCA in the design process of AIP homes, there are several avenues for future research and enhancement. First, incorporating stochastic modeling techniques to consider inflation and residual values of assets could enhance the accuracy of cost estimations. Additionally, developing a simple system dynamics model of aging population could provide valuable insights into the demand for AIP homes in the coming years. Moreover, while this study utilized the present worth method and uniform series of cash flows, future research could explore alternative LCCA methods such as the annual worth method or future worth method. Additionally, incorporating different forms of cash flows such as gradient series or geometric series warrants investigation in subsequent studies.

While this study presents a comprehensive framework for integrating BIM and LCCA in the design of AIP homes, there are several limitations to acknowledge. First, the accuracy of the LCCA heavily relies on the quality of input data. Any inaccuracies or uncertainties in the data, such as construction costs, evaluation of energy consumption, and maintenance expenses, could impact the reliability of the results. Moreover, the developed integrated model and associated plugins are based on certain assumptions and simplifications, which may not have fully captured the complexity of real-world scenarios. Additionally, the scope of this study is limited to the economic evaluation of AIP homes, overlooking other important factors such as social, environmental, and health-related considerations. Future research will aim to incorporate a more holistic approach that considers a broader range of criteria to support the design decision-making related to AIP homes.

6. Conclusion

In conclusion, this paper presented a comprehensive methodology for integrating BIM and LCCA to support the design of AIP homes. The four-phases approach, starts with data collection and integration, progressing through 3D modeling, quantity take-off, energy analysis, and LCA simulation, and resulting in the automated LCCA, establishes a robust framework for designers and stakeholders. The integration of real-time data from aging-in-place requirements, LCA and energy analysis plugins ensures accuracy and immediacy in design-related decisions. The LCCA plugin, designed for scenario and sensitivity analyses, contributes to identifying economically viable design alternatives. The integrated model produces a detailed LCCA by considering various cost components and design factors. The ability to compare different options would aid designers and owners in selecting the most optimal design alternative. By addressing the unique requirements of AIP design in the conceptual stage, this methodology not only enhances the functionality and adaptability of homes but also provides a cost-effective and sustainable approach to accommodate the evolving needs of an aging population. The development of a dedicated plugin for Autodesk Revit represents a technological advancement, showcasing the potential for innovative solutions in the design of housing. This research contributes to the growing body of knowledge on the integration of BIM and LCCA, particularly within the context of AIP design, filling a notable gap in the existing literature. Moving forward, this methodology holds promise for advancing the field of design and fostering the creation of adaptive, sustainable, and economically feasible living environments for an aging society.

References

- Akbarnezhad, A., & Nadoushani, Z. S. M. (2014). Estimating the Costs, Energy Use and Carbon Emissions of Concrete Recycling Using Building Information Modelling. ISARC Proceedings, 385–392.

- Akbarnezhad, A. , & Xiao, J. (2017). Estimation and minimization of embodied carbon of buildings: A review. Buildings, 7(1), 5–5.

- Altaf, M. , Alaloul, W. S., Musarat, M. A., Bukhari, H., Saad, S., & Ammad, S. (2020). BIM Implication of Life Cycle Cost Analysis in Construction Project: A Systematic Review. 2020 Second International Sustainability and Resilience Conference: Technology and Innovation in Building Designs (51154),1–7. [CrossRef]

- Ansah, M. K. , Chen, X., Yang, H., Lu, L., & Lam, P. T. I. (2020). An integrated life cycle assessment of different façade systems for a typical residential building in Ghana. Sustainable Cities and Society, 53, 101974. [CrossRef]

- Anton, L. _A., Díaz, J., (2014). Integration of life cycle assessment in a BIM environment. Procedia Engineering 85, 26e32. [CrossRef]

- Dixit, M. K. , Fernández-Solís, J. L., Lavy, S., & Culp, C. H. (2012). Need for an embodied energy measurement protocol for buildings: A review paper. Renewable and Sustainable Energy Reviews, 16(6), 3730–3743. [CrossRef]

- Elnabawi, M. H. (2020). Building Information Modeling-Based Building Energy Modeling: Investigation of Interoperability and Simulation Results. Frontiers in Built Environment, 6. [CrossRef]

- Government of Canada. (2024). Carbon Tax. Retrieved from British Colombia Government website: https://www2.gov.bc.ca/gov/content/environment/climate-change/clean-economy/carbon-tax. Retrieved on April, 23, 2024.

- Guo, F. , Gregory, J., Kirchain, R., Probabilistic (2019), life-cycle cost analysis of pavements based on simulation optimization, Transp. Res. Rec. 2673, 389–396. https:// doi.org/10.1177/0361198119838984.

- Huang, L. , Liu, Y., Krigsvoll, G., Johansen, F., (2018), Life cycle assessment and life cycle cost of university dormitories in the southeast China: case study of the university town of Fuzhou, J. Clean. Prod. [CrossRef]

- Jalaei, F., Jrade, A., Nassiri, M., (2015). Integrating decision support system (DSS) and building information modeling (BIM) to optimize the selection of sustainable building components, J. Inform. Technol. Construct. 20 (2015) 399–420. https: //www.itcon.org/paper/2015/25.

- Jermyn, D., (2022) “Do you want to age in place? This is what renovations could cost,” THE GLOBE AND MAIL, October 2022.

- Juan, Yi-Kai & Hsing, Nai-Pin. (2017). BIM-Based Approach to Simulate Building Adaptive Performance and Life Cycle Costs for an Open Building Design. Applied Sciences (Switzerland). 7. 10.3390/app7080837.

- Kehily, D. , Woods, T., & McDonnell, F. (2013). Linking Effective Whole Life Cycle Cost Data Requirements to Parametric Building Information Models Using BIM Technologies. International Journal of 3-D Information Modeling (IJ3DIM), 2(4), 1–11. [CrossRef]

- Kneifel, J., (2010). Life-cycle carbon and cost analysis of energy efficiency measures in new commercial buildings, Energy Buildi. 42, 333–340. [CrossRef]

- Koeppel, K., (2022), “What Is Aging in Place and How Is It Beneficial?,” November 2022. [Online]. Available: https://aging.com/best-mobility-scooters/what-is-aging-in-place-and-how-is-it-beneficial/. [Accessed 05 07 2023].

- Kovacic, I., Zoller, V., (2015). Building life cycle optimization tools for early design phases, Energy 92 (2015) 409–419. [CrossRef]

- Langston, C. , Chan, E. H. W., & Yung, E. H. K. (2018). Hybrid Input-Output Analysis of Embodied Carbon and Construction Cost Differences between New-Build and Refurbished Projects. Sustainability, 10(9), Article 9. [CrossRef]

- Le, H. T. T. , Likhitruangsilp V., and N. Yabuki, (2020). “A BIM-Integrated Relational Database Management System for Evaluating Building Life-Cycle Costs”, Eng. J., vol. 24, no. 2, pp. 75-86, Mar. 2020.

- Lee, Jaewook & Yang, Hyuncheul & Lim, Jinkang & Hong, Taehoon & Kim, Jimin & Jeong, Kwangbok. (2020). BIM-based preliminary estimation method considering the life cycle cost for decision-making in the early design phase. Journal of Asian Architecture and Building Engineering. 19. 1-16. 10.1080/13467581.2020.1748635.

- Llatas, C. , Soust-Verdaguer, B., and Passer, A. (2020). Implementing Life Cycle Sustainability Assessment during design stages in Building Information Modelling: From systematic literature review to a methodological approach, Building and Environment, Vol. [CrossRef]

- Muller, M.F. , Esmanioto, F., Huber, N., Loures, E.R., Canciglieri, O., (2019). A systematic literature review of interoperability in the green Building Information Modeling lifecycle, J. Clean. Prod. [CrossRef]

- NIA, (2022), “Ageing in the Place: Supporting Older Canadians to Live Where They Want,” National Institute on Ageing, Toronto, 2022. Retrieved from https://www.niageing.ca/airp. Access date: December 2023.

- NIA, (2020), “Pandemic Perspectives on Ageing in Canada in Light of COVID-19: Findings from a National Institute on Ageing/TELUS Health National Survey,”.

- Nwodo, M. , and Anumba, C., (2019), “A review of life cycle assessment of buildings using a systematic approach, Building and Environment, Vol. [CrossRef]

- Rad, M. A. H. , Jalaei, F., Golpour, A., Varzande, S. S. H., & Guest, G. (2021). BIM-based approach to conduct Life Cycle Cost Analysis of resilient buildings at the conceptual stage. Automation in Construction, 123, 103480. [CrossRef]

- Rashed, Yussra & Nosair, Ibrahim & Nassar, Khaled & Mashaly, Islam & Ghanem, Meshary. (2019). A BIM-based Life Cycle Cost (LCC) Method to Reduce the Operation Energy Costs in Buildings. 151-158. 10.26868/25222708.2019.210616.

- Robati, M. , Oldfield, P., Akbar Nezhad, A., Carmichael, D., & Kuru, A. (2021). Carbon value engineering: A framework for integrating embodied carbon and cost reduction strategies in building design. Building and Environment, 192, 107620. [CrossRef]

- Rostamiasl, V. and Jrade, A., (2022), “Integrating Universal Design Standards and Building Information Modeling at the Conceptual Design Stage of Buildings,” Open Journal of Civil Engineering, vol. 12, no. 4, pp. 492–523.

- Santos, R. , Costa, A. A., Silvestre, J. D., Vandenbergh, T., & Pyl, L. (2020). BIM-based life cycle assessment and life cycle costing of an office building in Western Europe. Building and Environment, 169, 106568. [CrossRef]

- Schmidt, M. , Crawford, R. H., & Warren-Myers, G. (2020). Integrating life-cycle GHG emissions into a building’s economic evaluation (1). 1(1), 361-378, Article 1. [CrossRef]

- Shin, Y., and Cho, K. (2015). BIM Application to Select Appropriate Design Alternative with Consideration of LCA and LCCA. Mathematical Problems in Engineering Volume 2015. [CrossRef]

- Sun, H. , & Park, Y. (2020). CO(2) Emission Calculation Method during Construction Process for Developing BIM-Based Performance Evaluation System. APPLIED SCIENCES-BASEL, 10(16). [CrossRef]

- Trout, J. and Smith, J., “The Cost of Aging in Place Remodeling,” (2023). [Online]. Available: https://www.retirementliving.com/the-cost-of-aging-in-place-remodeling. [Accessed 07 2023].

- Valinejadshoubi, Mojtaba & Moselhi, Osama & Iordanova, I. & Valdivieso, Fernando & Bagchi, Ashutosh. (2024). Automated system for high-accuracy quantity takeoff using BIM. Automation in Construction. 157. 105155. 10.1016/j.autcon.2023.105155.

- Viscuso, S. , Monticelli, C., Ahmadnia, A., & Zanelli, A. (2022). Integration of life cycle assessment and life cycle costing within a BIM-based environment. Frontiers in Sustainability, 3. [CrossRef]

- Wu, Wei, and Emily Handziuk. (2013) “Use of Building Information Modeling in Aging-in-Place Projects: A Proof of Concept.” Computing in Civil Engineering, 2013, pp. 443–50. [CrossRef]

- Yang, X. , Mingming Hu, Jiangbo Wu, Bin Zhao, (2018) “Building-information-modeling enabled life cycle assessment, a case study on carbon footprint accounting for a residential building in China,” Journal of Cleaner Production, Vol. 183, pp. [CrossRef]

- Younis, A. , Ebead, U., and Judd, S., (2018), Life cycle cost analysis of structural concrete using seawater, recycled concrete aggregate, and GFRP reinforcement, Constr. Build. Mater. [CrossRef]

- Zoghi, M. , & Kim, S. (2020). Dynamic Modeling for Life Cycle Cost Analysis of BIM-Based Construction Waste Management. In Sustainability (Vol. 12, Issue 6). [CrossRef]

Figure 1.

Framework for the Integration of BIM and LCCA.

Figure 2.

House’s Geometry and Zones in DesignBuilder.

Figure 3.

Different wall options selected for the optimization analysis.

Figure 4.

Different roof options selected for the optimization analysis.

Figure 5.

Proposed 3D BIM Model (Alternative 1, Conventional Design).

Figure 6.

Life Cycle Assessment Plug-in.

Figure 7.

Initial Cost and other entries.

Figure 8.

Operational Cost data entry.

Figure 9.

Major Replacement Cost data entry.

Figure 10.

Income Revenue data entry.

Figure 11.

LCCA Results.

Figure 12.

LCCA results (Cashflow and NPV).

Figure 13.

Scenario Analysis Example.

Figure 14.

Complete Sensitivity Analysis.

Figure 15.

Comparison of Different Alternatives.

Table 1.

Base Model of Windows’ Properties.

| Number of Panes | 1st Pane Glass type | 2nd Pane Glass Type | Window Gas type | Glazing | Window Frame | Frame Width |

|---|---|---|---|---|---|---|

| 2 | Clear 3 mm | Clear 3 mm | 13 mm Air | 30% Glazed | UPVC | 0.04 m |

Table 2.

List of the Optimization Parameters.

| Optimization Parameters | Design Variables | Objectives |

| Wall Materials (Three Alternatives) Roof Materials (Three Alternatives) Window to Wall ratio (Ranging from 20% to 80%) Windo Glazing types (single, doubled and tripled) Window frame Materials (Three Alternatives) |

Embodied carbon Total Energy Consumption |

Table 3.

Modification and Remodeling Costs, (Jermyn, 2022; Trout & Smith, 2023).

| Project’s work item(s) | Price Range to Install* | Average Cost* |

|---|---|---|

| Walk-in Tub or Shower | $5,000 to $20,000 | $12,500 |

| Ramp Installation at Entrance | $1,200 to $2,500 | $1,850 |

| Widen an Entry Door | $300 to $10,000 | $5,150 |

| Stairlift Installation | $4,000 to $27,000 | $15,500 |

| Install Entry Handrails | $1000 to $1,600 | $1,300 |

| Install an Elevator | $45,000 to $100,000 | $72,500 |

| Install Lever Taps on Faucets | $250 to $500 | $375 |

| Widen Hallways w/out Structural Changes | $1,100 to $2,000 | $1,550 |

| Widen Hallways with Structural Changes | $41,000 to $55,000 | $48,000 |

| Replace 10 Windows | $7,500 to $14,500 | $11,000 |

| Remodel Bathroom | $20,000 to $38,500 | $29,250 |

| Kitchen Countertop Height Adjustment | $20,000 to $27,500 | $23,750 |

| Replace the Bathroom floor with a nonslip surface | $9,000 to $37,500 | $46,500 |

| Through-the-Floor Lift (only links two floors) | $30,000 | $30,000 |

| porch lift | $9,000 | $9,000 |

| kitchen Renovation | $40,000 to $80,000 | $60,000 |

*Prices vary by location.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Copyright: This open access article is published under a Creative Commons CC BY 4.0 license, which permit the free download, distribution, and reuse, provided that the author and preprint are cited in any reuse.

Development of a Plug-In to Support Sustainability Assessment in the Decision-Making of a Building Envelope Refurbishment

Bernardette Soust Verdaguer

et al.

,

2023

Sustainable and Energy Saving Model Research for Existing Housing Stocks; Field Study

Hasan Polat

et al.

,

2023

MDPI Initiatives

Important Links

© 2024 MDPI (Basel, Switzerland) unless otherwise stated