Preprint

Article

Enhancing Decarbonation in Solid Waste Management, Wastewater and Contaminated Soil Treatments: The Role of Data Automation and Decision Support Systems

Altmetrics

Downloads

155

Views

59

Comments

0

A peer-reviewed article of this preprint also exists.

This version is not peer-reviewed

Submitted:

17 July 2024

Posted:

18 July 2024

You are already at the latest version

Alerts

Abstract

As global concerns about climate change intensify, the need for effective strategies to reduce carbon emissions has never been more urgent. This paper explores the crucial role of data automation (DA) and decision support systems (DSS) in enhancing decarbonation efforts within the realms of solid waste management (SWM), wastewater treatment (WWT), and contaminated soil remediation (CSR). Specifically, the paper provides: (i) an overview of the carbon footprint (CFP) in relation to environmental management (EM) and the role of DA and DSS in decarbonization; (ii) DA case studies in areas of SWM, WWT, and CSR; (iii) 3. life cycle assessment (LCA) based DSS case studies in areas of SWM, WWT, and CSR; (iv) multi-criteria decision analysis (MCDA) based DSS case studies in areas of SWM, WWT, and CSR; and (v) optimal contractual delivery methods based DSS case studies in EM practices. The analysis disclosed that adoption of DA and DSS in SWM, WWT, and CSR holds significant potential for decarbonizing these EM processes. By optimizing operations, enhancing resource efficiency, and integrating renewable energy sources, these technologies contribute to the reduction of GHG emissions and promote sustainable environmental practices. As the demand for more effective and eco-friendly solutions grows, the role of DA and DSS will become increasingly pivotal in achieving global decarbonization goals.

Keywords:

Subject: Environmental and Earth Sciences - Waste Management and Disposal

1. Introduction

1.1. Carbon Footprints (CFPs)

Decarbonation, the reduction of carbon dioxide (CO2) emissions, is a critical aspect of environmental management aimed at mitigating climate change impacts. Traditional approaches in solid waste management (SWM), wastewater treatment (WWT), and contaminated soil remediation (CSR) often rely on manual data collection and analysis, which are prone to inefficiencies and inaccuracies. This paper highlights how data automation and decision support systems (DSS) can revolutionize these processes, providing real-time, accurate insights that enhance decision-making and operational effectiveness.

The environmental impacts of inadequate SWM, WWT, and CSR include greenhouse gas emissions, water pollution, and loss of biodiversity. Economically, these issues can lead to increased healthcare costs, reduced property values, and significant cleanup expenses.

The GHGs generated by WWT plants can be divided into two parts: direct- and indirect-carbon emissions [1,2]. Direct CO2 emissions usually refer to onsite CH4 and N2O emissions, which are usually generated by microbial metabolic activities throughout the processes of WWT and sludge treatment/disposal. The N2O is estimated to contribute about 23-43% of GHG emissions during the biological nitrogen removal process [3]. Indirect CO2 emissions mainly stem from the consumption of energy and resources and is estimated to produce 14-36% of total emissions from a WWT plant.

In a study by Sweetapple et al. [4], it was reported that the direct emissions of CH4 and N2O from the wastewater sector were over 5% of the global non-CO2 GHG emissions in 2005 and is expected to increase to about 22% by 2030. Although the quantity of N2O emissions is less than that of CH4 emissions, N2O emissions usually have much higher impact (546 g CO2e/m3) than CH4 (284 g CO2e/m3) emissions [5]. In addition, Zhang et al. [6] have indicated that the carbon footprint (CFP) due to the direct gaseous emissions (CH4 and N2O) plays an important role, especially for those WWT plants with high influent concentrations of pollutants.

The consumption of electricity and chemicals in running a typical WWT plant is very high. It is estimated that about 3-4% of the total global electricity consumption is attributed to running of the aeration system, lifting pumps, and sludge dewatering units within a the WWT [7,8]. Chemicals are consumed in removing the phosphorus, dewatering of sludge or being utilized as carbon sources for denitrification.

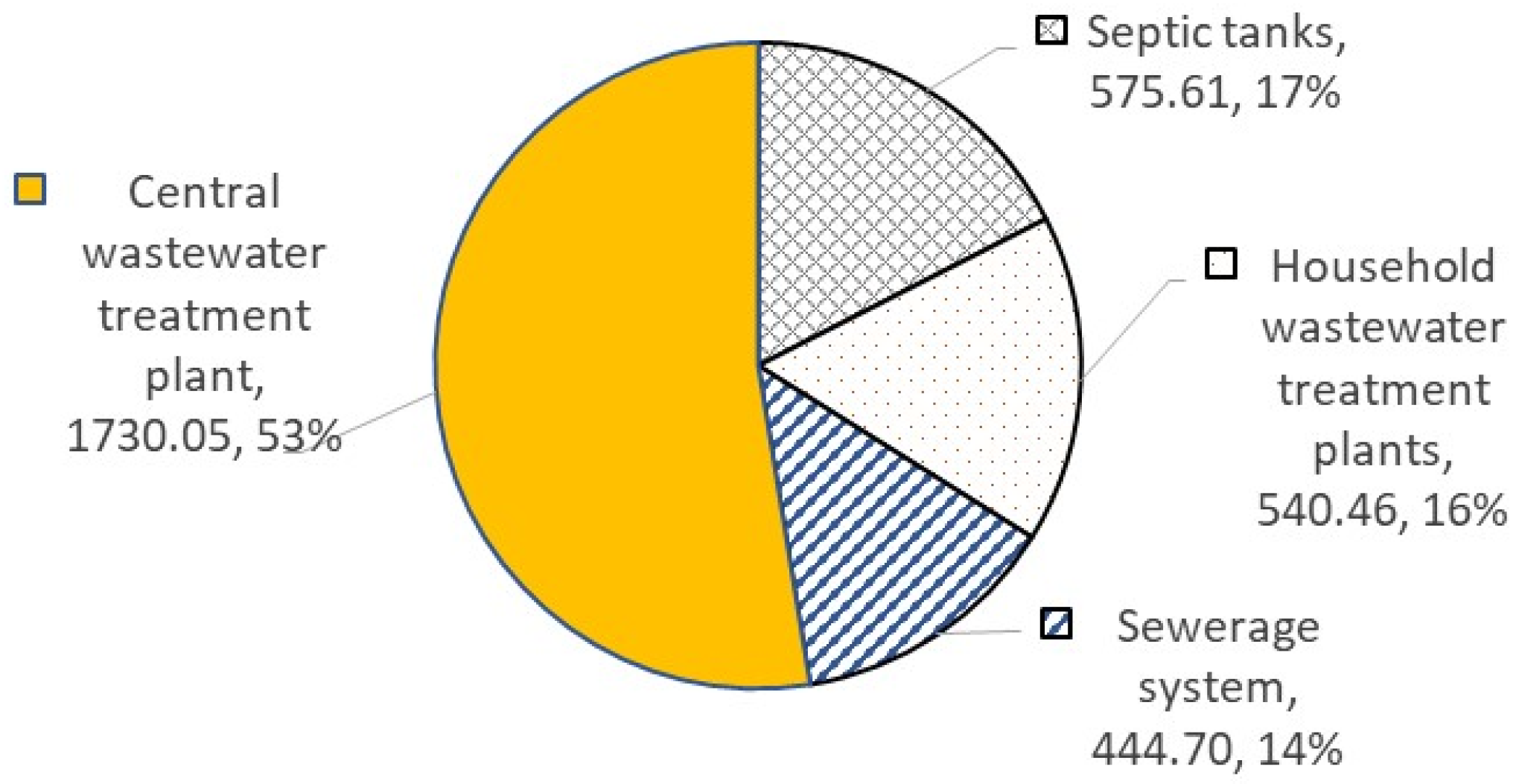

In a study by Zawartka et al. [9], the total CFP for all stages of each element within the system of a central wastewater treatment plant (CWWT), septic tank (ST), household wastewater treatment (HHWWT) plants, and sewerage system (SW) (Figure 1) was estimated at 3,290.82 kg CO2e/functional unit with percent contributions as 53, 17, 16, and 14% for CWWT, ST, HHWWT, and SW, respectively.

Therefore, reducing these direct and indirect emissions from WWT plants could assist in reducing tackling GHG by implementing advanced technologies, such as carbon capture to improve energy recovery by digestion, and biological treatment to improve effluent quality.

The estimated CFP of four CSR technologies (excavation and landfilling, soil washing, electro-kinetics, and phytoremediation) for a contaminated soil with heavy metals (lead, arsenic, and thallium) in Italy is shown in Figure 2 (data from Vocciante et al. [10]). The CFP over a period of 100 years was normalized per m3 of contaminated soil and the analysis considered each process from cradle-to-grave with reclamation potential of the site. The results indicated that phytoremediation (total CPF = 7.94 Kg CO2e/m3) was the best option followed by soil washing (total CPF = 44.64 Kg CO2e/m3), and electro-kinetics (total CPF=301.73 Kg CO2e/m3). Excavation and landfilling produced the highest CFP (total CPF=11,436.51 Kg CO2 eq./m3) and was considered the least favored technology.

Therefore, effective decarbonation strategies in the WWT and CSR are essential to mitigate environmental damage and economic losses.

1.2. Role of Data Automation and Decision Support Systems (DSS) in Decarbonization

The integration of data automation and decision support systems (DSS) into environmental management processes can significantly aid in decarbonizing SWM, WWT, and CSR. By leveraging advanced technologies, these systems streamline operations, enhance efficiency, and reduce GHG emissions across these critical environmental sectors.

In SWM, data automation and DSS play a crucial role in optimizing the collection, transportation, and processing of solid waste. Automated systems use real-time data from sensors and GPS technology to optimize waste collection routes, minimizing fuel consumption and reducing emissions from collection vehicles. For instance, smart bins equipped with sensors can signal when they are full, allowing for dynamic route adjustments that prevent unnecessary trips. DSS can further enhance this process by analyzing data on waste generation patterns, helping municipalities plan more efficient collection schedules and implement targeted recycling programs. By predicting waste volumes and types, DSS can also assist in optimizing the operations of waste processing facilities, such as recycling centers and incinerators, to ensure they run at maximum efficiency, thereby reducing energy consumption and associated emissions.

In WWT, data automation and DSS contribute to energy efficiency and reduced CFPs by optimizing treatment processes. Automated monitoring systems track key parameters such as flow rates, chemical concentrations, and microbial activity in real-time. This data enables precise control of treatment processes, reducing the need for excessive chemical use and minimizing energy consumption. DSS can analyze historical and real-time data to predict system performance and identify areas for improvement. For example, these systems can recommend operational adjustments to aeration processes, which are typically energy-intensive, to ensure they are running efficiently. By predicting inflow patterns, DSS can also help in managing peak loads, thereby preventing overloading of the system and reducing the risk of untreated wastewater discharge. Moreover, DSS can support the integration of renewable energy sources, such as biogas produced from sludge digestion, into the energy supply of wastewater treatment plants. This not only reduces reliance on fossil fuels but also promotes a circular economy approach, where waste products are converted into valuable resources.

In CSR, data automation and DSS are essential for the effective remediation of contaminated soils, as they facilitate accurate site assessment and optimized remediation strategies. Automated systems collect data from soil samples, monitoring wells, and other sources to assess contamination levels and distribution. This data is then fed into DSS, which use advanced modeling techniques to predict the spread of contaminants and evaluate the effectiveness of different remediation methods. DSS can recommend the most suitable remediation techniques based on site-specific conditions, such as soil type, contamination level, and local environmental regulations. This ensures that the chosen method is not only effective in removing contaminants but also energy-efficient and low in carbon emissions. For instance, bioremediation techniques, which use microorganisms to degrade pollutants, can be optimized to enhance their efficiency and reduce the need for energy-intensive mechanical interventions. Furthermore, DSS can facilitate the monitoring and management of remediation projects by providing real-time updates and predictive analytics. This allows for proactive adjustments to the remediation strategy, minimizing delays and reducing the overall environmental impact of the remediation activities.

2. Data Automation in Environmental Management

Data automation involves using technology to collect, process, and analyze data with minimal human intervention. In environmental management, this encompasses the use of sensors, remote monitoring systems, and automated reporting tools. The convergence of Internet of Things (IoT), Artificial Intelligence (AI), and blockchain technologies offers exciting possibilities for sustainable environmental management in SWM, WWT, and CSR.

2.1. Solid Waste Management (SWM)

In a study by Hannan et al. [11], the information communication technology tools (IoT and AI) were used to assist in the separation, collection, transportation, and disposal of different types of waste. In another study by Khoa et al. [12], an AI tool was used to estimate the amount of waste collected in waste bins and to optimize the distance between bins to enhance waste collection efficiency. Also, in a study by Kassou et al. [13], the IoT-based applications were integrated with blockchain technology to create a framework for improving the management of hospital waste and wastewater. Furthermore, in a study by Jiang et al. [14], several IoT tools were used to aid the decision-makers to examine the consumption patterns of city residents according to the type of discharged waste. In a study by Senthilkumar et al. [15], an air quality monitoring system using fog computing based IoT was demonstrated. The sensor module, the fog computing device, and the IoT cloud platform were integrated to evaluate the effectiveness of the monitoring system.

Moreover, AI-powered systems can analyze waste streams and guide sorting processes for increased efficiency and material recovery. Blockchain technology can ensure transparency and traceability throughout the recycling chain, boosting consumer confidence in recycled products. In a study by Sheng et al. [16], the AI enabled classification of wastes in smart collection bins (e.g., plastic, metal, paper, or general waste). Then, the data received via the Long-Range communication protocol, object detection, and waste classification were utilized in the TensorFlow framework using a pre-trained object detection model. In another study by Kang et al. [17], the smart management of e-waste was demonstrated by using level sensors in smart collection boxes and a mobile application connected to a cloud database and Wi-Fi module. The mobile application guides users to the nearest e-waste collection box on campus based on their current location using Global Positioning System (GPS).

Also, Seker [18] developed a real-time smart, cost-effective waste collection system that employs IoT with technologies like radio frequency identification (RFID), GIS, and ground penetrating radar systems (GPRS). It is effective for municipal waste collection and transportation and has the goal of reducing environmental pollution.

In a recent study by Zhou et al. [19], a novel image recognition system was introduced called Deep MW for the purpose of sorting medical waste. Deep MW utilizes a Convolutional Neural Network (CNN) as its underlying architecture. The system aims to enhance the ease, accuracy, and efficiency of medical waste sorting and recycling processes, while also reducing the risk of occupational exposure for workers in medical waste facilities.

Furthermore, geo-environmental engineering can incorporate real-time data to optimize landfill operations, such as methane capture and leachate management; hence operating a smarter landfills. AI can analyze data to predict potential environmental impacts and identify areas for improvement. In a study by Gopikumar et al. [20], the IoT technology was used to managed landfill leachate and feed a fuzzy control system real-time data, such as turbidity, suspended solids, dissolved oxygen, and chemical oxygen demand collected by sensors. In another study by Mabrouki et al. [21], an intelligent system equipped with different sensors for CO, CO2, NO2, CH4, and H2S measurements using an Arduino Uno card and IoTs module was used to monitor landfill biogas to prevent potential hazardous emissions.

2.2. Wastewater Treatment (WWT)

Recently, Li et al. [22] provided a comprehensive review on the use of AI applied to WWT plants based on the visualization of bibliometric tools. They have highlighted the importance of Machine Learning (ML) algorithms, such as Convolutional Neural Networks (CNN) and Long Short-Term Memory (LSTM), in predicting process parameters, enhancing material performance, and optimizing energy utilization. Also, they have pointed out that AI applied to WWT plants is still in its primary stage, and with the rapid development of AI, significant technical innovation in WWT can be anticipated soon.

In a study by Chen et al. [23], a Convolutional Neural Network (CNN) framework for collecting near-infrared data to monitor water quality, which provided technical support for agricultural irrigation, water recycling, and water resources protection was developed. Also, Geng et al. [24] designed a Cross-Coupled Attention Recurrent Neural Network (CCA-RNN) that could accurately predict the changes in total nitrogen in WWT plants.

In another study by Yaqub et al. [25], a Long Short-Term Memory (LSTM)-based neural network (NN) for predicting the removal of total phosphorus, ammonia nitrogen, and total nitrogen in a membrane bioreactor after data visualization was established. Also, Xu et al. [26] developed a sensor based on LSTM for monitoring and predicting key performance parameters of the two-stage anaerobic-oxic process in WWT, demonstrating high-resolution automatic measurements and effective prediction of key performance in biological WWT. Zhang et al. [27] established a multi-source data-driven delayed water quality index detection model based on the LSTM-NN algorithm, achieving the monitoring of water quality parameters in WWT plants.

In addition, an Advanced real time-Instrumentation, Control, and Automation (Art-ICA) controllers were developed and their performance, energy consumption and GHG emissions of several full-scale WWT plants were evaluated [28,29,30,31]. This process used three feedback controllers, where each one regulates either the total suspended solids (TSS) in the biological treatment tank, the concentration of nitrates (NO3-N) at the end of the denitrification zone and the concentration of ammonium (NH4-N) in the last aerated tank, close to predefined set-points. Each controller works by simultaneously performing a real-time adaptation of the three actuators, namely, the sludge surplus pump, the internal recycling pump and the external air supply [29].

Furthermore, the art-ICA has already been proven in a pilot plant configured for biological nutrient removal (BNR) process treating domestic wastewater of Bilbao (Spain) ([28,32] and in two full-scale WWT plants at Galindo-Bilbao and Mekolalde (Spain) [29,30]. The implementation of art-ICA in these two facilities revealed that the nitrogen emissions in the treated water reduced from 12-15 to 8-10 mg N/l, which corresponds to a reduction of nitrogen discharges by about 25-30%. Furthermore, the electricity used for aeration was reduced after art-ICA implementation, saving 13-20% of energy consumption [29,30].

In another study by Vieira et al. [31], the raw wastewater, nitrous oxide emissions, energy consumption and water discharges were quantified in two independent trains operated under different operational modes, conventional operation and art-ICA control. The implementation of the art-ICA strategy improved the effluent quality and reduced the operational costs, resulting in a better performance of these WWT plants. The art-ICA controllers activation led to a reduction of 54% and 7-10% of the total nitrogen effluent and in the specific energy consumption, respectively. Moreover, process control with art-ICA did not have a negative impact on the N2O emissions of the plants and contributed to lower global warming potential (GWP) by the facilities. The lower indirect CO2 production due to lower energy consumption contributes to the observation that art-ICA control is environmentally preferable to conventional control systems.

In another study by Moldovan and Nuca [32], a Supervisory Control and Data Acquisition (SCADA) and an automated system were implemented in the WWT systems and the results have indicated that the maintenance costs have reduced by 30-40%, the increase energy efficiency have increased by 20%, and the reject water quality (BOD, COD, ammonia, nitrogen, chloride, and hydrogen sulphide) was in compliance with the environmental regulations. Also, Oduah and Ogunye [33] developed a low-cost, smart, remote sensing septic tank that can be used onsite to prevent sewage overflow. It uses an ultrasonic sensor for detection and monitoring the wastewater level in the septic tank and a Global System for Mobile Communication (GSM) module to send Short Message Service (SMS) alerts to the users, avoiding spills of contaminants that can cause health problems.

Moreover, Porro [34] with several partners, have developed the N2ORisk-DSS, which uses AI to combine expert knowledge on N2O and ML to quickly diagnose the WWT process and N2O emissions, propose mitigation actions, and ultimately eliminate N2O. Also, a commercial product such as Siemens gPROMS digital twin has been developed and used to reduce and remove CO2, CH4, and N2O emissions, which account for 57% of all emissions from the WWT process (https://smartwatermagazine.com/news/siemens/siemens-digital-twin-set-drive-worlds-first-carbon-neutral-wastewater-treatment-plant).

In a study by Khan et al. [35], a system composed of wireless sensor networks, a GSM module for notifications in case of emergency, an Arduino Uno R3 microcontroller, and an IoT-based cloud server was developed to monitor water quality for an industrial effluent treatment plant.

Soleimani et al. [36] applied Artificial Neural Network (ANN) to optimize process conditions such as crossflow velocity, influent temperature, and pH value, obtaining the maximum permeate flux with the minimum fouling resistance.

In summary, the use of AI can provide decision-makers with new and effective ways to save energy, reduce emissions, and lower costs. In recent years, research has explored the application of AI in optimizing energy costs in WWT. For example, Wang et al. [37] used real operational data from a WWT plant in China as a dataset, an ANN to develop a process model, estimating material costs, and all-inclusive cost calculations and the results showed that this model could reduce total energy and material costs by 10%-15%. In another recent study by Adibimanesh et al. [38], a hybrid model using an ML algorithm used for various incineration systems in European WWT plants, resulting in a 6% reduction in total energy consumption. In addition, Wang et al. [39], developed a feature engineering automatic framework based on variation sliding layers (VSL) to precisely control the air demand of aeration tanks in WWT plants, and the results demonstrated that using VSL in classic ML, deep learning, and ensemble learning could significantly improve the efficiency of aeration intelligent control in WWT plants by 16.12% compared to conventional aeration control of preset dissolved oxygen (DO) and feedback to the blower.

2.3. Contaminated Soil Remediation (CSR)

AI-driven sensor systems, AI and IoT can be efficiently used to detect contamination levels and track the progress of remediation efforts. This data helps in optimizing the use of remediation techniques, minimizing energy usage, and reducing emissions associated with soil treatment. Popescu et al. [40] provided a comprehensive review to the recent advancements in using AI, sensors and IOTs for environmental pollution monitoring, considering the complexities of predicting and tracking pollution changes due to the dynamic nature of the environment. In another study by Davis et al. [41], sensing measurements linked to a digital twin computation platform [42] were successful in providing subsurface mapping processes spatially and temporally and continuous estimates of degradation rates for management decisions. The multiple sensors targeting parameters, such as major gasses (O2, CO2, and CH4), and temperature, relevant to the subsurface biodegradation processes, at a petroleum contaminated site, were used.

In another study by Vasudevan and Baskaran [43], an innovative unmanned surface vehicle (USV) based on the IoT and sensors was developed to monitor subsurface water. The system is efficient, with low investment and reduced energy consumption.

Mohamed [44] used time domain electrometry (TDR) to monitor the changes in subsurface soil moisture content, aqueous and non-aqueous solute concentrations by using eigen-decomposition and Fourier spectral analysis [45,46,47,48,49,50], and neuro-fuzzy logic [51] to analyze the reflected signals and predict the subsurface pollutant concentrations.

Sivavec et al. [52] developed an automated system to monitor the pollutants and control the pump and treat activities during the remediation of in-situ contaminated soils. The system consisted of a sensor, to sense pollutants in the contaminated aqueous composition, and a monitor, to receive information concerning the contaminant from the sensor, and to consequently control the pump and treat system during the treatment process. The monitor is situated at a location remote from the pump and treat system.

The challenges and considerations that need to be addressed for successful implementation of data-based automation systems include:

- the vast amount of data collected by IoT devices raises concerns about security and privacy. Robust data governance frameworks are needed to ensure data protection and prevent misuse;

- implementing these technologies requires significant investment in sensor networks, AI software, and blockchain infrastructure. Public-private partnerships and innovative financing models are crucial for wider adoption;

- integrating these complex technologies necessitates a skilled workforce capable of managing, analyzing, and maintaining the systems. Training programs and capacity building are essential;

- ensuring compatibility between different IoT devices, AI platforms, and blockchain systems is vital for seamless data exchange and system integration; and

- AI algorithms need to be designed with fairness and transparency in mind to avoid bias in waste management decisions.

The preceding highlights that integration of IoT, AI, and blockchain technologies within geo-environmental engineering holds immense promise for achieving sustainable environmental management practices. However, addressing the preceding challenges is crucial for realizing this potential and ensuring responsible and equitable implementation.

3. Decision Support Systems

The DSS have been used to (i) support SWM, considering criteria such as waste reduction, recycling, and disposal options [53]; (ii) identify the most sustainable options for water and WWT, considering criteria such as treatment efficiency, energy consumption, and social acceptance [54,55,56,57,58]; and (iii) help selecting the most sustainable CSR technologies [59,60,61,62,63,64,65,66].

For example, for predicting groundwater level (GWL) using input variables (groundwater extraction rate, E; rainfall rate, R; and river flow rate, P), Feng et al. [67] evaluated various traditional and deep machine learning (DML) algorithms that included convolutional neural network (CNN), recurrent neural network (RNN), support vector machine (SVM), decision tree (DT), random forest (RF), and generative adversarial network (GAN). The analysis indicated that the CNN algorithm achieved the highest accuracy in GWL prediction and provided superior performance among all the evaluated algorithms because of its robustness against noise and variability, scalability for handling large datasets with multiple input variables, parallelization capabilities for fast processing, and above all autonomous learning capability that resulted in fewer outlier predictions.

Also, for optimizing the green and sustainable remediation (GSR) implementation for CSR, with alignment to the sustainability goals, a variety of DSS tools were used [64,65,66,68,69,70], and number of issues have been included in the DSS to account for the transition towards GSR such as (i) stakeholder involvement ([71,72,73]; and (ii) sustainable evaluation indicators and techniques [74,75,76,77,78].

For DSS to effectively support the environmental management objectives, they must address the following considerations:

a) sustainability metrics by defining and quantifying indicators representing environmental (e.g., resource depletion, biodiversity impacts), social (e.g., community well-being, equity considerations), economic (e.g., lifecycle costs, long-term value), and technical (e.g., effectiveness, resilience) factors;

b) trade-offs by acknowledging and explicitly handling the potential trade-offs between sustainability dimensions. For example, a highly effective environmental management technology might be very energy intensive;

c) uncertainty by accounting for uncertainties in data, model parameters, and long-term outcomes, particularly those related to climate change impacts; and

d) stakeholder involvement by facilitating transparency and incorporating diverse perspectives from regulators, communities, developers, and technical experts throughout the modeling process.

A variety of modeling approaches that have been recognized as potentially effective instruments in environmental decision making, includes:

a) Life Cycle Assessment (LCA), which evaluates environmental impacts over a technology or process's entire lifespan [9,79,80];

b) Cost-Benefit Analysis (CBA), which assesses the economic feasibility of environmental management strategies, factoring in social and environmental externalities [66]; and

c) Risk-Based Decision Making (RDM), which evaluates the potential health impact via a hazard index [64,65,81] or by equating in monetary terms the cost of the damage caused by the cost of managing an affected site [66] or by incorporating the likelihood and severity of potential risks into the evaluation process [61,82,83]; and

d) Multi-Criteria Decision Analysis (MCDA), which balances multiple, sometimes conflicting, objectives using weighting systems and stakeholder input [62,84,85].

However, development of an integrated methodology that accounts for the complex decision-making process will overcome the inherit limitations present in the traditional methodologies and have a robust capacity to use various types of data, available information, and disputes between relevant stakeholders.

3.1. Life Cycle Assessment (LCA)

LCA has become a powerful tool for geo-environmental engineers in their quest to achieve a zero-CFP [79,86,87]. It allows for a comprehensive evaluation of the environmental impacts of a product, service, or process throughout its entire lifespan, from cradle (raw material extraction) to grave (disposal or end-of-life). It is very detailed with numerous footprint indicators, such as the CO2-, water- or energy- footprint. In addition, social- and economic-footprints have also been developed, but are still rarely used [88]. By understanding these impacts, engineers can make informed decisions about material selection, construction practices, remediation techniques, and other aspects of their projects, aiming to minimize the overall environmental burden.

The significant benefits of using LCA in geo-environmental engineering include: (i) pinpoint specific phases or activities with the highest CFP, allowing for targeted reduction efforts; (ii) evaluate the environmental impact of different material choices, construction methods, or remediation techniques to inform sustainable decision-making; (iii) transparent communication of LCA results can demonstrate commitment to sustainability and build trust with stakeholders; and (iv) LCA can help in meeting environmental regulations and standards related to greenhouse gas emissions and resource use.

3.1.1. Solid Waste Management (SWM)

In a study by Hong et al. [89], the environmental and economic impacts of the three medical waste disposal scenarios (i.e., pyrolysis, chemical disinfection, and steam sterilization) were quantified via an LCA coupled with life cycle costing (LCC). The results (Figure 3; data from Hong et al. [89]) showed that steam sterilization exhibit the highest CFP (3.73×103 kg CO2e) followed by pyrolysis (1.26×103 kg CO2e) and chemical disinfection (8.00×102 kg CO2e) because of the differences in energy consumption. The CFP main contributors are: (i) for steam sterilization, electricity (26.1%) and diesel (66.7%); (ii) for pyrolysis, electricity (23.8%), diesel (36.1%) and sodium hydroxide (29.9%); and (iii) for chemical disinfection, electricity (66%) and lime (11%).

In addition, from an economic viewpoint, the economic burden contributing factors are: (i) for steam sterilization, electricity and diesel (39%), and labor, and human health protection (69.1 %); (ii) for pyrolysis, sodium hydroxide, electricity and active carbon (43.3%), and labor, human health protection, and investment (18.4%); and (iii) for chemical disinfection, electricity, chlorine and landfill (27.5%), and investment, labor, and human health protection (66%). However, the chemical disinfection showed the highest net profit (220.13 USD/t) followed by pyrolysis (189.96 USD/t) and steam sterilization (28.66 USD/t). Therefore, a balance between the achieving sustainability goals and economic benefit must be realized in choosing the best technology for the treatment of this medical waste.

3.1.2. Wastewater Treatment (WWT)

Recently, several LCA methodologies such as IMPACT World+ [90], ReCiPe [91], and LIME 2 [92] have been applied to WWT plants [93,94,95]. For instance, the LCA studies were conducted to: (i) evaluate all the elements of a wastewater treatment system [96,97]; (ii) evaluate the negative influence of septic tanks on the soil and water environment [98,99,100,101]; (iii) assess alternatives for a city’s water-wastewater service system [102]; (iv) select a sustainable sewerage servicing systems and technologies [103]; (v) assess the vertical and horizontal flow in constructed wetlands [104]; and (vi) evaluate the system of wastewater collection, transport and treatment [9].

Studies suggest that operation related stages, including WWT, sludge treatment, and sludge disposal, are the main contributors to the environmental impact of conventional WWT plants ( >90%) [105,106]. Of the four processes related to a conventional WWT plants (i.e., construction, operation, sludge treatment and disposal, and emissions to air), the environmental impact of the operational process was most significant, being 85–97% of the total impact among all seven impact categories considered. Also, in a study by Limphitakphong et al. [107], the LCA of WWT plants in three impact categories (climate change, eutrophication, and acidification) showed that eutrophication accounted for over 90% of the total environmental impact. Therefore, it is important to assess effluent water quality thoroughly when comparing WWT options with different effluent qualities.

In addition, in a study by Lorenzo-Toja et al. [97], the environmental efficiency of multiple units in 47 WWT plants located in different regions of Spain and operated for 4 years was analyzed using LCA and data envelop analysis (DEA). The results suggested that (i) for most of the facilities, the efficiency standards tended to remain constant through time; (ii) significant differences were detected among plants with different legislation thresholds for their effluent withdrawal; (iii) WWT plants discharging to non-sensitive water bodies appeared to be able to attain efficiency values near the benchmark, whereas facilities with stricter thresholds (i.e. sensitive water bodies) resisted to achieve those values, especially in the case of the smaller plants; and (iv) the use of the slacks-based measure of efficiency (SBM) model for one single year of operation is a good proxy for the evaluation of the environmental efficiency of these systems.

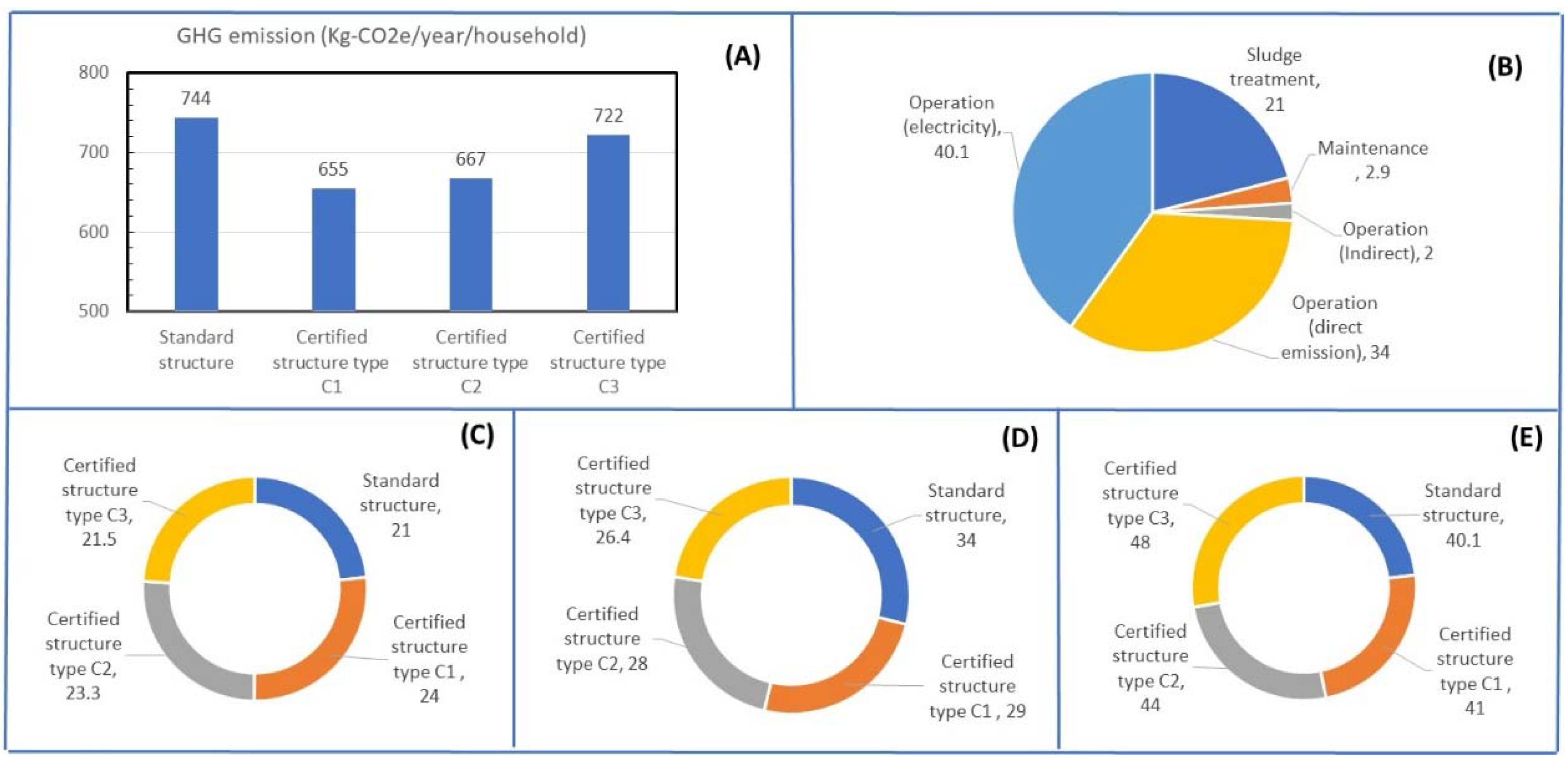

Also, in a study by Mishima et al. [108], the environmental load from the septic systems in Japan was evaluated using LCA and the results have shown that the mean environmental load of the effluent during the operation stage was 37.6%, and the operation stage accounts for over 99% of the involved eutrophication, biological toxicity, and toxic chemicals, which are strongly related to the quality of the effluent. The septic systems used in the LCA consisted of the sedimentation tank, anaerobic tank, aerobic tank, clarification tank, and disinfection tank. These systems were further classified into: (a) standard-structure type (S) as per the Japanese specification and effluent water quality of BOD = 20 mg/l; and (b) certified structure types (C1-C3) which are freely designed and manufactured by septic system manufacturers and certified with the authorized effluent water quality based on the treatment performance test. The effluent water quality standards are BOD=20 mg/l and T-N=20 mg/l for C1, BOD=10 mg/l, and T-N 20 mg/l for C2, and BOD=10 mg/l, T-N= 10 mg/l, and T-P = 1 mg/l for C3. The average total volumes of these septic tanks are 2.95, 2.10, 2.74, 2.89 m3 for S, C1, C2, C3, respectively.

For the LCA, the following four life-cycle stages of the septic systems were considered: (i) manufacturing, including the fabrication of the septic systems’ components; (ii) installation which involves transportation from the factory to the installation site; (iii) operation which includes operation, maintenance, sludge treatment, and effluent discharge. Items such as material consumption, electricity consumption, direct GHG emissions, and indirect GHG emissions were considered in the operational process. The COD, T-N, total phosphorus (T-P), and ammonium nitrogen (NH4–N) in the effluent were calculated for the effluent discharge, and the quality of the gray water influent was assumed to be: BOD, COD, T-N (100% as NH4–N), and T-P of 145, 65, 10, and 1.5 mg/L, respectively. The average amount of sludge generated was assumed to be 1.2 L/p/d; and (iv) disposal whereby at the end of the life cycle the septic tank components would be incinerated, and the residues would be landfilled.

The functional unit was assumed to be 1-year use of a five population equivalents (PE) septic system by one household, and the lifespan of a septic system was assumed to be 40 years. Throughout the life cycle of the septic system, 10 impact categories were considered: climate change, eutrophication, biological toxicity, toxic chemicals, urban area air pollution, acidification, ozone layer destruction, photochemical oxidant, resources depletion, and waste.

The unit GHG emissions from the septic systems were assumed to be: (i) 2,477 (for S), 1,984 (for C1), and 1,044 (for C2 and C3) g-CH4/person/year; and (ii) 71.7 (for S), 54.5 (for C1), 123.2 (for C2 and C3) g-N2O/person/year.

Also, the LCA was estimated using the impact assessment model LIME2 [92] and the ecotoxicity estimation model [108]. The results (Figure 4) indicated that the total GHG emissions during operation of the standard structure is the highest (744 Kg-CO2e/year/household) followed by certified structures C3 (722), C2 (667) and C1 (655), respectively. For the standard structure, the GHG emissions are distributed (Figure 4B), from the highest to the lowest, as electricity (40.1%), direct emissions (CH4 and N2O) (34%), sludge treatment (21%), maintenance (2.9%), and indirect (2%). The GHG contribution due to sludge treatment was in deceasing order C1 (24%), C2 (23.3%), C3 (21.5) and Standard (21%). However, for the direct emissions, the GHG emissions were 34, 29, 28, 26.4% for standard, C1, C2, and C3, respectively. The GHG emissions due to electricity were 48, 44, 41and 40.1% for C3, C2, C1, and standard, respectively. Therefore, the contribution of electricity consumption was the highest among all types of the septic systems, followed by the direct emissions of the systems (CH4 and N2O) and the sludge treatment process; hence optimal control during operation is needed to reduce GHG emissions.

For the LCA, of the analyzed 10 impact categories, the major contributors to the environmental impact were GHG, eutrophication, biological toxicity, and air pollution. For the standard structure, the LCA impact categories were in decreasing order GHG (35%), eutrophication (23%), biological toxicity (17%), and air pollution (12%); whilst, for the certified structure C3, GHG (41%), eutrophication (29%), biological toxicity (8%), and air pollution (16%). The LCA have also indicated that both operation (about 30%) and disposal, due to landfill space requirement, (60-65%) stages have the major impacts. To reduce the impact of landfill disposal, implementation of nature-based solutions (NbS) (biodegradation, phytoextraction, phytovolatilization, and revegetation) is highly recommended [109,110,111,112,113].

In another study by Khan et al. [80], an LCA was employed to compare the CFP of three treatment processes, incineration, mechanical recycling and chemical recycling of a functional unit of 1 ton of re-pulping waste reject. Using biomass-based heat sources, the generated CFPs were 560, 740, and 1900 kg CO2e/t of waste for chemical recycling, mechanical recycling, and incineration scenario, respectively. However, using natural gas-based heat sources, the generated CFPs were 290, 430, and 960 kg CO2e/t of waste for chemical recycling, mechanical recycling, and incineration, respectively. Therefore, the chemical recycling would be the best option with using natural gas as the energy source. It is to be noted that it is useful to conduct uncertainty analysis to evaluate the impact of the assumptions used in the LCA.

In addition to identifying the environmental impacts from WWT plants via LCA, the trade-off of the new integration of existing technologies in terms of cost and environmental impact can be assessed [114]. In a study by Meneses et al. [115], the technologies adopted for more stringent effluent standards from WWT plants (such as, 10-15 mg N/l and 1-2 mg P/l by EU Urban Waste Water Directive) could improve effluent quality; however, it may require additional energy consumption, utilization of more chemical reagents, and production of more sludge. In another study by Hauck et al. [116], a 16% reduction in marine eutrophication was obtained; however, the GHG impacts increased by 9% from the traditional operation of the Dokhaven WWT plant, The Netherlands, because of the increasing use of electricity. The results also indicated that the trade-off between effluent quality and other environmental impacts should not be neglected when applying advanced technologies.

3.1.3. Contaminated Soil Remediation (CSR)

In a study by Cappuyns [117], the environmental impacts of two contaminated sites by mineral oil, and one site by mineral oil and BTEX (Benzene, Toluene, Ethylbenzene, and Xylene), were quantified by means of the BATNEEC (Best Available Technology Not Entailing Excessive Costs) methodology, which uses a multicriteria analysis considering environmental, technical and financial aspects. The CFPs were calculated by a methodology based on the principles of LCA (REC; Risk reduction, Environmental merit and Costs), and an environmental merit index (E) was determined based on interviewing a panel of environmental experts. The CFPs were calculated by using three methods:

a) the Soil Remediation Tool (SRT) [118], which allows users to estimate sustainability metrics for various CSR technologies such as excavation, soil vapor extraction, pump and treat, enhanced in situ biodegradation, thermal treatment, in situ chemical oxidation, permeable reactive barrier, long-term monitoring, and monitored natural attenuation;

b) the SiteWise tool [119], which considers variety of remedial actions such as site investigation, construction, operation and monitoring; and

c) Tauw CO2 calculator [120,121], which considers different CSR options (in-situ and ex-situ), and the possibility of using renewable energy sources to decrease the overall environmental impacts of a CSR operation.

The results showed that the CFP of soil excavation, as a CSR option, was mainly attributed to the transport of soil (30.1-55.4%), while the excavation activities themselves (6.1-10.6%) and the in-situ treatment of the groundwater (1.6-3.7%) were of secondary importance, and the pumping of the groundwater had a negligible (0.2-0.3%) contribution. Transport of the equipment and personnel to the site only had a marginal contribution to the total CO2 emissions.

Therefore, optimization of these tools, taking into account new developments in the field of CSR, such as the use of more accurate screening tools to delineate the extent of the contamination, the use of innovative (sustainable) CSR technologies or the use renewable energy sources, will further improve the environmental impacts assessment of CSR activities [10,117].

In another study by Amponsah et al. [122], the GHG emissions (CO2e) from six ex-situ CSR technologies, including excavation and land disposal, excavation and incineration, thermal desorption, soil vapor extraction, bioremediation, and soil washing were evaluated. The results showed (i) a large variation in the GHG emissions of treated soil varying from 3.1 × 10−7 t to 8.2 t CO2e/m3; (ii) incineration had the highest mean GHG emissions (0.7 t CO2e/m3) and thermal desorption the lowest (0.07 t CO2e/m3); (iii) a large variation range of GHG emissions from the excavation and disposal, and excavation and incineration technologies, varying from 3.1 × 10−7 t to 8.2 t CO2e/m3 of treated soil. This information provides the decision makers with new prospects for choosing the most sustainable CSR technology via green practices throughout the remedial stages (investigation, design, construction, operation, and monitoring).

In another study by Huysegoms et al. [76], LCA, to assess the impacts linked to the remediation works, and Cost-Benefit Analysis (CBA) were used to assess the CSR technologies (excavation of contaminated soils and off-site thermal treatment). Both the soil and the groundwater at the site were contaminated by poly-aromatic hydrocarbons (PAH) and cyanide. The results from the LCA were monetized using a Stepwise 2006 technique, that can be fully implemented in the LCA-SimaPro software to provide users with values on three overall safeguard subjects (human well-being, biodiversity and resource productivity), which are linked to the sustainability three pillars (people, planet, profit), and Ecovalue 08 technique, that used to monetized endpoint impact based on market valuations of resource depletion and individual Willingness To Pay (WTP) estimates for environmental quality. The results from the Stepwise 2006 are expressed in terms of Quality Adjusted Life Years (QALY) for human well-being, Biodiversity Adjusted Hectare Years (BAHY) for biodiversity and euros for resource productivity. The use of such monetization analysis is not a routine process for site remediation evaluation [86].

The LCA analysis reported by Huysegoms et al. [76] showed that the impact categories that mostly contribute to the environmental impact of the adopted CSR technologies are energy consumption, climate change, and formation of particulate matter, where the off-site treatment, and transportation contributed about 70%, and 10%, respectively, of the total impact. The minimum and maximum monetized values of the environmental impact parameters for the proposed remedial method were 17,758 and 259,996 EU2015, respectively, with impact category contributions in a decreasing order as abiotic depletion (44.6%), global warming (26.64%), human toxicity (19.91%), eutrophication (5.44%), acidification (3.26%), and photochemical oxidation (0.13%). Based on the CBA, the NPV contribution of the remedial work, externality, and site restoration to the total NPV were estimated at 63.54%, 29,72%, and 6.73%, respectively. However, since the pollution source has been removed, the NPV of the positive health impact was estimated at 48.28% of the total NPV, indicating that the project is not socially profitable in the short term (30 years) because of the limited health benefits of the remediation and the large cost of transport of soil to off-site treatment facilities (39.74% of the total NPV).

From the preceding analysis, it can be seen that the social CBA is a method that can be used to address all negative and positive impacts of a remediation; whilst, the LCA provides an in-depth, extensive and substantiated view on the environmental impacts, negative and positive, of the remediation project. Therefore, combining both methods would be an important step; however, the LCA needs to be monetized. The analysis showed that the resultant costs of CO2/t are 44-euro for the CBA, 83-euro for LCA with Stepwise 2006 technique, and 11 to 222-euro for LCA with Ecovalue 08 technique. It is worth noting such differences are attributed to the type of impacts covered in each method. The LCA with monetization gives a more extensive view on the environmental effects, including eutrophication and acidification, whilst, social CBA addresses air pollutants from the remediation works, monitoring and transportation, meaning that the use of monetized LCA is a more appropriate and comprehensive method due to inclusion of variety of environmental impacts.

Recently, in a study by Ashkanani et al. [123], the LCA of thirteen (13) distinct CSR technologies for heavy polyaromatic hydrocarbons (PAH)-contaminated soils was evaluated based on nine well-defined LCA criteria, each assigned an LCA score ranging from 1 (indicating the lowest environmental impact, very low category, VL) to 5 (the highest impact, very high category, VH). And to rank these technologies, a sub-categories were assigned as low (L), medium (M), and high (H) for scores of 2, 3, and 4, respectively. The thirteen CSR technologies were grouped into: (i) physico-chemical (sheet pile wall, pumping (P), dual phase extraction (DPE), soil vapor extraction (SVE), chemical oxidation (S-ISCO), passive soil vapor extraction (PSVE)); (ii) thermal (thermal desorption (ISTD), steam enhanced extraction, thermal resistivity - ERH); and (iii) biological (stimulation reductive dechlorination process (SRD), excavation plus off site treatment, soil mixing with micro-scale (ZVI), natural attenuation (NA)). The nine environmental criteria considered in the LCA were resource consumption, CO2 emission, toxicity, waste, energy consumption, carbon footprint (CFP), cost planning and construction, initial capital cost, and ongoing operating cost.

The results shown in Figure 5 (data from Ashkanani et al. [123]) indicate that the thermal technologies have the highest CFPs, total LCA and LCCA impacts. The biological treatments have low to moderate LCA impact (Figure 5B) but have higher economic costs in comparison with the physico-chemical treatments (Figure 5C). The rankings of these technologies are shown in Table 1 with specific rankings to each criterion considered in the LCA. Therefore, for choosing the appropriate technology, a balance must be made between the economic cost and achieving sustainability goals.

The vital challenges of using LCA in geo-environmental engineering include: (i) consistent and reliable data on material production, energy consumption, and emissions across different regions and sectors can be challenging to find; (ii) modeling complex systems and accurately assessing indirect impacts can require specialized expertise and software; and (iii) life cycle inventory data and impact assessment methods may carry uncertainties, requiring careful interpretation and sensitivity analysis.

The crucial considerations of using LCA in assessing geo-environmental engineering projects include: (i) clearly define the specific processes and activities included in the assessment, whether it's a single construction project, a specific remediation technique, or the entire life cycle of a piece of infrastructure; (ii) quantify the energy, materials, water, and other resources consumed at each stage of the life cycle, as well as the emissions and waste generated; (iii) assess the environmental impacts of these inputs and outputs using various categories like climate change, resource depletion, human health, and ecosystem quality; and (iv) analyze the results to identify hotspots with the highest environmental impact and explore alternative materials, design strategies, or management practices to reduce those impacts.

In addition, it is recommended to [117]: (i) first step, an initial ranking of soil remediation techniques based on more qualitative site-specific criteria is required. The ranking can be done using a BATNEEC analysis [75], which is based on the principles of a multicriteria analysis; and (ii) second step, a quantitative assessments using LCA and related techniques may be of value for an in-depth analysis.

3.2. Multi-Criteria Decision Analysis

Researchers used the Multi-Criteria Decision Analysis (MCDA) in the area of sustainable waste management applications [124] to: (i) investigate optimal decision making among various alternative waste management strategies (e.g., landfill disposal, incineration, recycling, reuse, etc.); (ii) explore possible technologies (e.g., mass incineration, pyrolysis, gasification, plasma incineration in cement kilns, etc.); and (iii) determine the optimal location of a waste management facility (e.g., landfill, waste treatment facility, recycling facility, etc.). for example, the MCDA has been used to integrate multi-attributive and multi-dimensional indices in a holistic manner [62,84,85].

3.2.1. Solid Waste Management (SWM)

In a study by Demircan and Yetilmezsoy [57], four different smart SWM strategies, which combine different sustainable waste management strategies and smart waste management technologies, were evaluated using a hybrid fuzzy AHP-TOPSIS approach that can support local authorities in determining sustainable SWM strategies in smart cities. The four SWMs were: (i) integrating informal recyclable waste collection into a formal smart system (SWM1); (ii) a pay as you throw application leveraging blockchain technology (SWM2); (iii) Internet-of-Things (IoT)-based community composting (SWM3); and (iv) preventing illegal sewage discharge by utilizing IoT (SWM4).

The four main criteria used were (i) environmental criteria (with 5 sub-criteria: less atmospheric emissions, less soil pollution, less surface water pollution, energy recovery, and natural resources recovery); (ii) technical criteria ( with 3 sub-criteria: operational feasibility, innovativeness, and need for qualified personnel); (iii) economic criteria (with 4 sub-criteria: maintenance costs, transportation costs, operational costs, and initial investment costs); and (iv) social criteria (with 3 sub-criteria: increased awareness on sustainable cities, increased quality of life in the city, and new employment opportunities).

The composite weight vector for the environmental criteria was found to be: WEnvironmental criteria = (0.42, 0.27, 0.27, 0.04, 0.00), meaning that the order of importance of the five sub-criteria was determined to be: less atmospheric emissions > less soil pollution/ less surface water pollution > energy recovery > natural resources recovery. Therefore, the less atmospheric emissions is highly important than soil and surface water pollutions, which came the second. The energy recovery and recovery of natural resources were not important within the environmental criterion. The composite weight vector for the technical criteria was found to be: WTech = (0.64, 0.36, 0.00), meaning that the order of importance of the three sub-criteria was determined to be: operational feasibility > innovativeness > need for qualified personnel. Therefore, operational feasibility was the most important criterion among the technical criteria and the need for qualified personnel was unimportant.

The composite weight vector for the economic criteria was found to be: WEcon = (0.56, 0.30, 0.14, 0.00), meaning that the order of importance of the four sub-criteria was determined to be: initial investment costs > operational costs > maintenance costs > transportation costs. Therefore, the initial investment cost criterion is very important compared to other economic criteria and the transportation cost is unmeaningful. The composite weight vector for the social criteria was calculated as follows: WSocial = (0.53, 0.46, 0.01), meaning that the ranking of the three sub-criteria was: increased awareness on sustainable cities > increased quality of life in the city > new employment opportunities. Therefore, the new employment opportunities criterion was rather insignificant compared to the other two criteria.

Therefore, the overall ranking of the proposed smart SWM strategy alternatives according to the closeness coefficients (values are given in the respective parentheses) was SWM2 (0.458) > SWM3 (0.453) > SWM4 (0.452) > SWM1 (0.440). This means that the application pays as you throw (SWM2), which uses blockchain technology, had the best performance among the proposed smart sustainable SWMs. Among the two strategies with very close closeness coefficients, IoT-based community composting (SWM3) was slightly ahead of IoT-based illegal sewage discharge prevention (SWM4) by only 0.001. The strategy of integrating illegal waste collection workers into a formal smart system (SWM1) came in last as the least favorite. In addition, the analysis of the sub-criteria revealed that authorities should give due consideration to operational feasibility (0.64), initial investment costs (0.56) and increased awareness (0.53) before implementing such strategies.

3.2.2. Contaminated Soil Remediation (CSR)

Recently, new MCDA approaches based on health risk assessment (HRA), GIS, fuzzy set theory and Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) have been used to evaluate the optimal CSR technologies [59,64,65,66,125,126,127,128,129,130,131,132,133,134].

In a study by Li et al. [135], a combination of weights based TOPSIS model, following a MCDA approach, was used to evaluate both the measures and indices over the entire life cycle of a contaminated site management from site investigation to land reuse in China. Generally, projects would have several Best Management Practices (BMP) indices, which are defined by the ASTM as strategies incorporating GSR principles into remediation or management at a specific site to balance the key elements of sustainability [136]. In this study case, the project had 44 BMP indices (10 for environmental, 12 social, 8 economics, and 14 technology), and 108 BMPs incorporated in the five processes (site investigation, strategy design, remediation implementation, efficacy validation and land reuse).

The 44 BMPs indices were:

a) the 10 environment indices included ecological restoration; air pollution; greenhouse gas emissions; soil change; ecological impact; water pollution; resource consumption; waste generation; green measures; and residual risk;

b) the 8 economic indices comprised direct and indirect costs; land value; direct and indirect benefits; protection of the environmental investments; innovations in investments and financing; and economic uncertainty;

c) the 12 societal indices consisted of health and safety; community disturbance; public acceptance and participation; information disclosure/sharing; social equity and justice; policy compliance; regional suitability; employment opportunities; ecological culture; examine index (performance appraisal by the government on site and project managers); system construction; and publicity and education; and

d) the 14 technology indices covered remediation time, effect, sustainability, and position (on-site or off-site, in-situ or ex-situ); technical innovation, availability, maturity, feasibility, and operation; emergency management; directory management; land safe utilization; and capacity building.

The results indicated that the proposed sustainable CSR of the different sites vary widely due to the applications of different BMPs. Notably, the BMPs affect sustainability throughout the site management processes (site investigation with quality assurance sampling, strategy design with resilience to climate change, implementation of remedial measures for treatment and reuse of cleaned soils and water, efficacy validation for reduction in residual risks, and land reuse with implementation of sustainable capping/covering systems). The results also indicated that when considering the whole-life cycle management, the environmental dimensions were found to be the controlling parameters over the social dimensions in both the strategy design and the remedial implementation processes.

Furthermore, the results indicated that the level of importance of the four categories during the whole life-cycle management of a contaminated site were ranked in descending order as environmental (0.3866) > economics (0.2427) > technology (0.2139) > social (0.1568). This outcome is not surprising because of the mandatory regulations on secondary pollution prevention in China. The social aspects showed the lowest impact on sustainability performance because public engagement in the decision-making process of CSR in China is frequently disregarded (Li et al., 2018). Both economics and technology categories had almost equal importance in view of nurturing sustainable management decisions.

Notably, while the choice of a practicable technology is principally determined by the economic factors, it will directly affect the CFP as well as other environmental impacts of a remediation project. More importantly: (i) the sensitivity analysis of the TOPSIS method showed that the random variations of indices' weights did not result in significant changes of the sustainable remedial measures of the evaluated sites, indicating that the method could provide a robust outcome that would help the decision makers in reaching a sustainable decision; and (ii) the MCDA analysis would enable the stakeholders to adopt optimal BMPs for risk control to enhance the expected sustainable remedial measures for the contaminated site managements as well as future redevelopments of the sites.

In the environmental category, residual risk, GHG emissions, ecological impact, water pollution, and resource consumption indices had the highest impact on the environmental sustainability (more than 50%). It is worth noting that: (i) the residual risk index showed the highest influence on the environmental sustainability with 12.96% contribution, indicating that remedial measures to remove the existing pollutants from contaminated soils had more important weights than that for air, ecology, water and resource caused by implementation of the remediation process; and (ii) soil change index, with 9.5% contribution to the environmental sustainability, is a significant parameter that needs to be considered in the choice of a specific remedial measure (i.e., limiting any adverse impacts on the properties (physical, chemical, biological, and overall quality) of the treated soils.

Within the social category, the main contributing indices to the social sustainability were health and safety (22.45%), public participation (12%), and public acceptance (9.5%), indicating the importance of the public perceptions and feedback as well as the conflict resolutions among different stakeholders during the whole decision-making process. Also, it is to be noted that: (i) the performance appraisal index strongly contributed with 8.1% to the social sustainability, indicating the positive role of regulatory agencies of including the social aspects in the government performance appraisal of remedial projects; and (ii) the information disclosure/knowledge sharing showed the lowest contribution with 1.66%, indicating the current inefficiency that needs to be mitigated with more focus in developing future management approaches to enhance public information disclosure and dissemination of information.

Within the economic category, the direct cost contributed to the economic sustainability by 18.95%. Also, the direct cost together with the environmental protection investment, investment and financing innovation, land value, and economic uncertainty contributed to the economic sustainability by 72.22%. However, the indirect cost contributed with 7.87%, which is the lowest in the economic category could be attributed to the difficulty in quantifying it in monetary terms (e.g., calculating the health damage cost caused by exposure to pollutants).

Within the technical category, remediation time, and remediation effect contributed to the technological sustainability by about 11.40%, which is the highest, because of the implicit specification in any remedial project. Other indices such as technical innovation, technical availability, technical maturity, and technical operability had a combined contribution of 29.09% to the technical sustainability. In addition, based on regional policies, new indices including directory management, capacity building, land safe utilization, and system construction had contribution ranging from 5.53 to 8.05%, indicating the clear potential in enhancing the technical sustainability. It is worth noting that the remediation location (i.e., in-situ or ex-situ) had the lowest contribution (3.46%), which is less than the average (7.15%), to the technical sustainability. However, in-situ remediation would be preferable over ex-situ because the latter may pose secondary pollution risk and additional economic costs.

Furthermore, the sustainability of the risk management approaches applied to the eleven sites in China varies widely (Figure 6; data from Li et al. [135]). Based on this analysis, the capping plus natural attenuation plus institutional control scored the highest values (0.9345 and 0.8219) because of the adopted risk management measures (i.e., elimination of secondary pollution, reduction of treatment cost, and no direct treatment), which is basically a containment method that is not feasible for the long-term due to potential leakage and pollution of the surroundings. However, other remedial technologies that used different treatment techniques showed low sustainability scores ranging from 0.3534 to 0.6559. The authors (Li et al. [135]) have attributed the lower scores to: (i) the cleanup projects were implemented prior to introduction of the GSR policies; (ii) the implemented treatment technologies imposed level of disturbance to the local environment, presence of sensitive receptors in the area; and (iii) the high level of social concerns, resulting in a lower-than-expected scores in the environmental, social, economic and technical sustainability.

These results could be due to limitations in this method of analysis, which include: (i) subjective nature of the links between BMPs and the evaluation indices, which depends on feedback from site stakeholders (e.g. managers, experts and technicians); (ii) health and environmental risks to pollution generally expand over years to decades, which would require more data that is difficult to track and collect over such a sustained period; and (iii) the specific nature of the indicators used in the model are specifically based on the Chinses culture. Therefore, more research in needed to overcome the subjectivity of the links between BMPs and the evaluation indices, the long-term reliability of data for evaluating the health and environmental risks, and development of a universal set of indicators that are independent of the culture sensitivities.

3.2.3. Optimal Contractual Delivery Method

The process of sustainability integration into project portfolio management (PPM) has been challenging and complex [137,138] due to [139]: (i) the environmental and social sustainability goals are multifaceted, complex, and lack clear solutions [140]; and (ii) the project management sustainability goals as well as the longer-term corporate goals and may extend beyond the delivery horizons of individual projects or shorter-term portfolios [141]. These complications hinder the ability of both project and portfolio managers to align the project portfolio’s short-term goals (e.g., multiple projects’ time, budget, and scope objectives) with longer-term project portfolio and corporate business goals [142].

In a study by Al Nahyan et al. [143], a fuzzy-based multi-criterion decision-making modelling was used to develop the DSS to assist the client in reaching a knowledge-based decision to choose the optimal contractual delivery method (CDM), considering the stakeholders (client or sponsor, government agency, project manager, consultant, and contractor), project requirements, potential elements of risks, investment opportunities, and constraints during the five stages of project delivery (planning, scoping, design, tendering, scheduling, and construction). The study used 11 CDMs, which are Design Bid Build (DBB), Design Build (DB), Performance Based Maintenance Contracts (PBMC), Construction Management at Risk (CMR), Design Build with Warranty (DBW), Design Build Operate Maintain (DBOM), Design Build Finance Operate (DBFO), Build Operate Transfer (BOT), Design Build Finance Operate Maintain (DBFOM), Alliance Contracting (AC), and Build Own Operate (BOO).

The elements and indicators used in the MCDA based DSS and assessed by decision makers were: (i) risk indicators levels (technical, institutional, project management, country’s economic situation, and financial); (ii) constraint indicators (institutional, organizational, performance, and financial); and (iii) opportunities indicators levels (institutional transparency, government policies, and return on investments).

The model results indicated that most of the delivery methods were equally valid when the project risk was minimal. In addition, it was recommended to select DBOM and DB methods of project delivery as the project risk increases beyond 50 percent. However, the conventional delivery method (DBB) was the least recommended if the project’s risk weight exceeds 30%. With equal considerations to the identified factors, the AHP model recommended DB as the best suitable delivery method as compared to DBB and CMR. With such an intricate system, the client can investigate the specifics of various project stages and study the effects of enhancements or deficiencies of the stakeholder entities’ capabilities.

The challenges when applying MCDA to evaluate the sustainability of the environmental management projects are:

(i) sustainability itself is a multi-faceted concept. Deciding which environmental, social, and economic factors to include, and how to measure them, can be a significant challenge;

(ii) reliable and comprehensive data on the potential impacts of different remediation options across various sustainability criteria may be limited, especially for social and long-term environmental effects;

(iii) assigning weights to different criteria in MCDA inevitably involves a degree of subjectivity, which can be influenced by stakeholder biases and value judgments;

(iv) stakeholders (regulators, communities, developers, etc.) may have divergent views on the relative importance of different sustainability factors, requiring careful facilitation for consensus;

(v) there is inherent uncertainty surrounding the long-term outcomes of remediation technologies, especially when factoring in issues like climate change and evolving regulations; and

(vi) conveying the complex trade-offs and rationale behind MCDA results to non-technical stakeholders can be challenging and requires clear presentation.

The key considerations when applying MCDA to evaluate the sustainability of the environmental management projects are:

(i) involving stakeholders in the process of identifying and selecting the most relevant sustainability criteria from the outset is crucial. This should include environmental, social, economic, and technical aspects tailored to site-specific concerns;

(ii) defining quantifiable metrics (where possible) for each criterion is essential to ensure objective comparisons. This may involve both qualitative and quantitative indicators;

(iii) choosing a weighting method that reflects stakeholder preferences while maintaining transparency. Common methods include ranking, pairwise comparisons, and the Analytic Hierarchy Process (AHP);

(iv) performing sensitivity analysis to understand how changes in weights or input data might affect the overall ranking of remediation options. This adds robustness to the decision process;

(v) using techniques like Monte Carlo simulations to explicitly incorporate uncertainty into the analysis, providing a range of potential outcomes rather than single point estimates; and

(vi) Facilitating ongoing communication with stakeholders throughout the MCDA process to build trust, address concerns, and ensure that diverse perspectives are considered.

Despite its challenges, MCDA is a valuable tool for guiding sustainable decision-making for environmental management projects. By carefully considering these factors, practitioners can increase the likelihood of successful, sustainable outcomes that align with the needs and values of all stakeholders. Here's how to address some of the issues: (i) developing standardized sustainability metrics and data collection protocols can improve consistency across contaminated site assessments; (ii) consulting specialized experts in areas like LCA, social impact assessment, and risk modeling can help ensure the quality of the analysis; and (iii) clearly documenting all assumptions, methodologies, and data sources used in the MCDA process increases its defensibility and acceptance.

4. Conclusion

The adoption of data automation and DSS in SWM, WWT, and CSR holds significant potential for decarbonizing these EM processes. By optimizing operations, enhancing resource efficiency, and integrating renewable energy sources, these technologies contribute to the reduction of GHG emissions and promote sustainable environmental practices. As the demand for more effective and eco-friendly solutions grows, the role of DA and DSS will become increasingly pivotal in achieving global decarbonization goals.

The study hypothesized that moving towards a zero- carbon footprint (CFP), geo-environmental engineers must consider the following key areas:

1) integration of data automation and DSS into environmental management processes can significantly aid in decarbonizing SWM, WWT, and CSR. By leveraging advanced technologies, these systems streamline operations, enhance efficiency, and reduce GHG emissions across these critical environmental sectors. Continued research and development are improving data availability, modeling tools, and methodologies. Collaboration between engineers, sensors’ developers, DSS experts, and AI software developers is crucial for advancing the integration process in the industry.

2) achieving a zero-CFP in SWM requires a comprehensive approach. Collaborating across the industry, implementing best practices, and continuously seeking innovative solutions are key aspects. By reducing waste generation, promoting reuse and recycling, exploring low-carbon disposal options, and engaging communities, the geo-environmental engineering profession can take decisive steps towards a more sustainable future.

3) achieving carbon neutrality in CSR necessitates a multifaceted approach. Embracing innovative low-energy techniques, optimizing existing methods, exploring sustainable materials and waste management practices, and continuously seeking further advancements are all crucial steps. Additionally, collaboration between engineers, scientists, policymakers, and the public is essential to develop and implement effective solutions for a cleaner and more sustainable future.

4) transitioning towards energy-efficient operations requires a multi-pronged approach that involves investment in new technologies, adoption of best practices, and collaboration across the industry. Additionally, data collection and analysis are crucial for accurately measuring energy consumption and identifying areas for improvement. By continuously seeking innovative solutions and embracing a sustainability mindset, the geo-environmental engineering profession can move towards a zero-carbon future.

5) achieving economic feasibility alongside sustainable environmental goals requires a multifaceted approach. By employing careful LCA and life cycle costing (LCC), fostering innovation, exploring alternative financing methods, and demonstrating the economic advantages of sustainable practices, the geo-environmental engineering industry can successfully navigate this crucial aspect of the journey towards a zero-carbon future.

References

- Metcalf and Eddy. Wastewater Engineering: Treatment and Reuse, 4th ed.; McGraw-Hill: New York, NY, USA, 2014. [Google Scholar]

- Chai, C.; Zhang, D.; Yu, Y.; Feng, Y.; Wong, M.S. Carbon footprint analyses of mainstream wastewater treatment technologies under different sludge treatment scenarios in China. Water, 2015, 7, 918–938. [Google Scholar] [CrossRef]

- Corominas, L.; Alsina, X.F.; Snip, L.; Vanrolleghem, P. Comparison of different modeling approaches to better evaluate greenhouse gas emissions from whole wastewater treatment plants. Biotechnol. Bioeng. 2012, 109, 2854–2863. [Google Scholar] [CrossRef] [PubMed]

- Sweetapple, C.; Fu, G.; Butler, D. Identifying sensitive sources and key control handles for the reduction of greenhouse gas emissions from wastewater treatment, Water Res. , 2014, 62, 249–259. [Google Scholar] [CrossRef]

- Sweetapple, C.; Fu, G.; Butler, D. Identifying key sources of uncertainty in the modelling of greenhouse gas emissions from wastewater treatment, Water Res., 2013, 47(13) 4652-4665. [CrossRef]

- Zhang, Y.; Zhang, C.; Qiu, Y.; Li, B.; Pang, H.; Xue, Y.; Liu, Y.; Yuan, Z.; Huang, X. Wastewater treatment technology selection under various influent conditions and effluent standards based on life cycle assessment, Resour. Conserv. Recycl., 2020, 154. [CrossRef]

- McCarty, P.L.; Bae, J.; Kim, J. Domestic wastewater treatment as a net energy producer–can this be achieved? Environ. Sci. Technol. 2011, 45(17), 7100–7106. [Google Scholar] [CrossRef] [PubMed]

- Hao, X.; Liu, R.; Huang, X. Evaluation of the potential for operating carbon neutral WWTPs in China, Water Res. 2015, 87, 424-431. [CrossRef]

- Zawartka, P.; Burchart-Korol, D.; Blaut, A. Model of Carbon Footprint Assessment for the Life Cycle of the System of Wastewater Collection, Transport and Treatment. Scientific Reports (2020) 10:5799. [CrossRef]

- Vocciante, M.; D'Auris, A. de F.; Franchi, E.; Petruzzelli, G.; Ferro, S., CO2 footprint analysis of consolidated and innovative technologies in remediation activities. Journal of Cleaner Production, 2021. [CrossRef]

- Hannan, M.A.; Al Mamuna, M.D.A.; Hussain, A.; Basri, H.; Begum, R.A. A review on technologies and their usage in solid waste monitoring and management systems: Issues and challenges. Waste Manag. 2015, 43, 509–523. [Google Scholar] [CrossRef] [PubMed]

- Khoa, T.A.; Phuc, C.H.; Lam, P.D.; Nhu, L.M.B.; Trong, N.M.; Phuong, N.T.H.; Dung, N.V.; Tan-Y, N.; Nguyen, H.N.; Duc, D.N.M. Waste management system using iot-based machine learning in university. Wirel. Commun. Mob. Comput. 2020, 2020, 6138637. [Google Scholar] [CrossRef]

- Kassou, M.; Bourekkadi, S.; Khoulji, S.; Slimani, K.; Chikri, H.; Kerkeb, M.L. Blockchain-based medical and water waste management conception. E3S Web Conf. 2021, 234, 00070. [Google Scholar] [CrossRef]

- Jiang, P.; Van Fan, Y.; Zhou, J.; Zheng, M.; Liu, X.; Klemeš, J.J. Data-driven analytical framework for waste-dumping behavior analysis to facilitate policy regulations. Waste Manag. 2020, 103, 285–295. [Google Scholar] [CrossRef] [PubMed]

- Senthilkumar, R.; Venkatakrishnan, P.; Balaji, N. Intelligent based novel embedded system based iot enabled air pollution monitoring system. Microprocess. Microsyst. 2020, 77, 103172. [Google Scholar] [CrossRef]

- Sheng, T.J.; Islam, M.S.; Misran, N.; Baharuddin, M.H.; Arshad, H.; Islam, M.D.R.; Chowdhury, M.E.H.; Rmili, H.; Islam, M.T. An internet of things based smart waste management system using lora and tensorflow deep learning model. IEEE Access, 2020, 8, 148793–148811. [Google Scholar] [CrossRef]

- Kang, K.D.; Kang, H.; Ilankoon, I.M.S.K.; Chong, C.Y. Electronic waste collection systems using internet of things (IoT): Household electronic waste management in Malaysia. J. Clean. Prod. 2020, 252, 119801. [Google Scholar] [CrossRef]