Pressure Vessels

(4243 products)Pressure Vessel Heads

1000 INR (Approx.)/Piece

MOQ100 Kilograms/Kilograms

Main Domestic MarketAll India

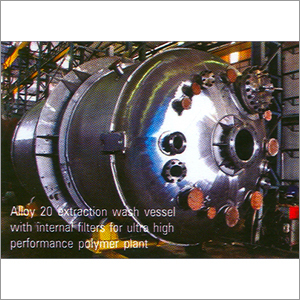

Extraction Wash Vessel

Price: 200000.00 INR/Unit

MOQ1 Unit/Units

Supply Ability10 Per Week

Delivery Time4-5 Week

Packaging DetailsPacking in corrugated box, shrink wrapping and wooden crates available.

Dipesh Engineering Works

Mumbai

Trusted Seller

Trusted Seller23 Years

Super Premium

Super PremiumGrey Ss Vertical Pressure Vessels

Price: 1000000 INR/Unit

MOQ1 Unit/Units

Product TypeSS Vertical Pressure Vessels

UsageIndustrial

SizeDifferent available

United Engineers & Consultants

Pune

Super Seller

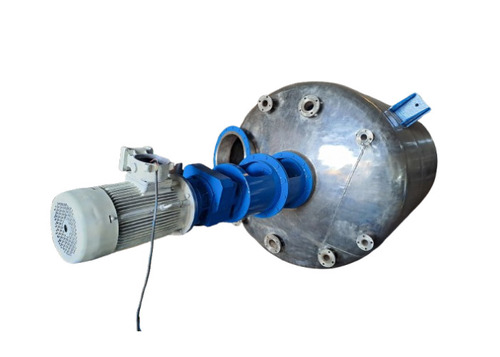

Super SellerSaturation Vessel - Color: Blue

Price: 400000 INR/Unit

MOQ1 Unit/Units

Product TypeSaturation Vessel

ColorBlue

Filter TypeCartridge

Sliver Reactor Vessel

Price Trend: 500000.00 - 5000000.00 INR/Unit

MOQ1 , Unit/Units

ColorSliver

Product TypeReactor Vessel

Usageindustrial

Insulated milk storage Tank

Price: 224000.00 INR/Unit

MOQ1 Unit/Units

Product TypeTank

MaterialSS

Capacity500-15000 :Litre Liter/day

Ved Engineering

Noida

Trusted Seller

Trusted Seller12 Years

Super Seller

Super SellerFrp Mixed Bed Vessels - Application: Industrial

Price Trend: 40000.00 - 200000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypePressure Vessel

ApplicationIndustrial

ColorWhite

Shalin Composites (india) Private Limited

Palghar

Vertical Pressure Vessel By Ambica Boiler

Product DescriptionWe manufacture any type of Vertical Pressure Vessel in stainless steel and mild steel and also any kind of SS and MS fabrication like storage tanks, coulumns etc. Our range of Vertical Pressure Vessels are available at industrial leading prices

Frp Vessels - Color: Silver

Price: 150.00 INR/Kilograms

MOQ10 Ton/Tons

Product TypeFRP Vessels

Height500-800 Millimeter (mm)

ColorSilver

Deep Enterprise

Ahmedabad

Trusted Seller

Trusted Seller14 Years

Super Seller

Super SellerFrp Surge Suppression Vessel - Application: Industrial

Price Trend: 15000.00 - 150000.00 INR/Piece

MOQ1 Piece/Pieces

TypeSurge Suppression Vessel

ApplicationIndustrial

MaterialFRP

Shalin Composites (india) Private Limited

Vasai

Pressure Vessels By P-Square Technologies

Price: 25000 INR/Unit

MOQ1 Unit/Units

Payment TermsCash Advance (CA)

Supply Ability1 Per Week

Delivery Time3-2 Week

Pressure Vessels By Jd Engineering

MOQ1 Piece/Pieces

Payment TermsCash Against Delivery (CAD), Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Cheque

Supply Ability10 Per Week

Delivery Time10 Days

Jd Engineering

Ghaziabad

Trusted Seller

Trusted Seller11 Years

Super Seller

Super SellerWhite Cryogenic Pressure Vessels

Price: 21,00,000 INR/Unit

MOQ1 Unit/Units

ColorWhite

Size1000 L

UsageIndustrial

Abhijit Enterprises

Pune

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerLow Pressure Ammonia Receivers

Price: 800000 INR/Piece

MOQ1 Piece/Pieces

Main Domestic MarketAll India

Metalex Cryogenics Ltd.

Pune

Trusted Seller

Trusted Seller14 Years

Super Seller

Super SellerCryogenic Pressure Vessel - Material: Stainless Steel

Price Trend: 1000000.00 - 4500000.00 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

MaterialStainless Steel

ConditionNew

Vishwakarma Engineering

Vadodara

Trusted Seller

Trusted Seller3 Years

Super Seller

Super SellerVacuum Vessel - High-Quality Raw Material, Superior Durability, Versatile Applications

Product DescriptionWe have gained a reputed position in our domain by manufacturing, exporting and supplying a varied variety of Vacuum Vessel in Chandisar, Gujarat, India. With assistance of our diligent professionals, we manufactured the offered products with superior raw material sourced from the leading vendors.

Balaji Engineering

Chandisar

Premium Seller

Premium SellerAtsm Sa 516 Gr.65 Pressuer Vessel - Application: Industrial

Price: 80 INR/Kilograms

MOQ100 Kilograms/Kilograms

ColorGray

SizeSizes Available

Product TypePressuer Vessel

Diamond Alloys Inc

Mumbai

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerJacketed Vessel Application: Industrial

Price Trend: 500000.00 - 2500000.00 INR/Number

MOQ1 Number

Product TypeJacketed Vessel

TypeVessel

ColorGray

Industrial Pressure Vessel

Product Description\015\012\015\012We offer a wide range of Industrial Pressure Vessel, which is precisely designed to hold gases or liquids at a pressure different from the ambient pressure. Our range of Industrial Pressure Vessel is a closed container whose end caps fitted to the cylindrical body known as heads. Kno

Destiny Solution And Engineers

Ahmedabad

Trusted Seller

Trusted Seller6 Years

Premium Seller

Premium SellerStainless Steel Pressure Vessels Usage: Industrial

Price Trend: 100000.00 - 1000000.00 INR/Unit

MOQ1 , Unit/Units

Product TypeStainless Steel Pressure Vessels

UsageIndustrial

MaterialStainless Steel

Prime Advance Polishing System Pvt. Ltd.

Vadodara

Trusted Seller

Trusted Seller16 Years

Super Seller

Super SellerStainless Steel Pressure Vessels Size: Customized By Msm Process Solutions Pvt. Ltd.

Price: 300000 INR/Unit

MOQ5 Unit/Units

Product TypeStainless Steel Pressure Vessels

SizeCustomized

UsageIndustrial

Msm Process Solutions Pvt. Ltd.

Pune

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerHigh Performance Blending Vessels

Price: 1000000 INR

Payment TermsLetter of Credit (L/C), Others, Telegraphic Transfer (T/T)

Main Domestic MarketAll India

Acme Process Systems Pvt. Ltd.

Pune

Trusted Seller

Trusted Seller3 Years

Super Seller

Super SellerPressure Vessel By Utech Projects Pvt. Ltd.

MOQ50-100 Unit/Units

Payment TermsCheque

Supply Ability100 Per Year

Delivery Time2 Months

Utech Projects Pvt. Ltd.

Mumbai

Trusted Seller

Trusted Seller14 Years

Super Seller

Super SellerStainless Steel Chemical Reactor Vessel Application: Industrial

Price: 600000 INR/Unit

MOQ1 Unit/Units

ColorSilver

SizeDifferent Available

ApplicationIndustrial

Ambika Process Equipments

Pune

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerStainless Steel Industrial Reaction Vessels

MOQ10 Unit/Units

SizeDifferent Sizes Available

UsageIndustrial

MaterialStainless Steel

Rotech Engineers

Pune

Trusted Seller

Trusted Seller3 Years

Super Seller

Super SellerPressure Vessel Application: These Are Utilized For Processing Of Liquids

MOQ1 , Unit/Units

Weightmax 10000 Kilograms (kg)

SizeAs per Design Specification

LengthAs per Design Specification Millimeter (mm)

Shree Sarjan Industries Pvt. Ltd.

Vadodara

Industrial Flash Steam Separators

Price Trend: 3000.00 - 15000.00 INR/Piece

MOQ50 Piece/Pieces

Supply Ability1 Per Month

Delivery Time1 Months

Mahavas Precision Controls Private Limited

Pune

Industrial Pressure Vessels By Ascent Machineries & Engg. Services

Price: 1000000 INR/Piece

MOQ1 Piece/Pieces

Supply Ability1 Per Day

Delivery Time1 Week

Ascent Machineries & Engg. Services

Mumbai

Seamless Finish Industrial Pressure Vessel

MOQ5 Piece/Pieces

Payment TermsCash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

Sample PolicyContact us for information regarding our sample policy

Main Domestic MarketMaharashtra

Yantrik Engineers

Pune

Trusted Seller

Trusted Seller7 Years

Super Seller

Super SellerLatest From Pressure Vessels

2000L Mild Steel Pressure Vessels

By:

Sd Engineering Works

FRP Pressure Vessels

By:

Ardis Enviro Solutions

Ready To Ship Pressure Vessels

Pressure Vessel: Introduction

It is necessary to apply pressure to a container in order to store liquids, vapors, or gases at pressures significantly higher or lower than the surrounding atmosphere. They are used in a wide variety of fields, from the petrochemical industry to the oil and gas business to the chemical industry to the food processing industry. Machines like reactors, flash drums, separators, and heat exchangers all make use of pressure vessels.

There is a codified set of rules and regulations that cover every aspect of pressure vessels. The Boiler and Pressure Vessel Code (BPVC) is the most frequently used and acknowledged collection of guidelines for boilers, pressure vessels, and nuclear power plant components.

Pressure Vessel: How Does It Work?

In order for a pressure vessel to perform its intended purpose, it must first achieve the necessary level of pressure for the task at hand similar to how a diving tank must maintain its air pressure. Either directly, through the use of valves and release gauges, or indirectly, through the transfer of heat, they can deliver the pressure.

Temperatures typically exceed 750 degrees Fahrenheit (400 degrees Celsius), and potential pressure levels range anywhere from 15 psi to to 150,000 psi. There is a wide range of capacities available for pressure tanks, ranging from 75 litres (about 20 gallons) to several thousand litres.

Pressure Vessels: Uses, Types

Different types of Pressure Vessels and Their uses

1. Storage Vessels

These are pressure containers that are used to keep liquids, vapours, and gases for a temporary period of time. The container may be put to use later on in a subsequent process to hold fluids, or it may be used to store finished goods like compressed natural gas (CNG) and liquid nitrogen.

3. Packed bed reactor

Cylindrical containers known as packed bed reactors house an immobilised bed of catalyst inside their interior. The reaction occurs on the surface of the solid catalyst as the gaseous or liquid reactants flow out of the vessel in one direction.

The conversion rate of packed bed reactors is high relative to the amount of catalyst used, and there is a greater surface area of contact between the reactant and the catalyst.

Having said that, the cylindrical vessel that houses these reactors needs to be strong enough to withstand the weight of the catalyst bed.

4. Jacked reactors

During a chemical reaction, it is important to keep the temperature of the Pressure Vessels, products, and catalysts at the same level. The contents of the reactor can be cooled or heated by a utility fluid that circulates through the jacket that wraps around the vessel. Examples of such fluids include cooling water and steam.

When designing reactors, one of the most important factors to take into account is the type of the reaction. During a chemical reaction, heat can either be given off referred to as an exothermic reaction or taken in referred to as an endothermic reaction .

It is necessary to either heat or cool the mixture during the reaction in order to create conditions that are favourable for the reaction, which will maximise product conversion and increase efficiency. Additionally, this will help prevent an uncontrolled increase or decrease in temperature during the reaction. Therefore, a reactor with a jacket is something that needs to be considered.

5. Fluidized bed reactor

Additionally, it includes a bed of the catalyst. The solid catalyst is kept in suspension inside the reactor pressure vessel by the high velocities at which the gaseous or liquid reactants move across the bed in these reactors.

This causes the solid catalyst to operate more like a fluid. Because the catalyst is fluidized, it is possible to thoroughly mix the reactants in all directions. As a result, it is possible to achieve high reactant conversion and mass transfer rates as well as a temperature that is uniform throughout the reactor.

6. Spherical pressure vessels

Due to the robust structure of spherical pressure vessels, they are ideally suited for the containment of high-pressure fluids; yet, the fabrication of these vessels is complicated and expensive. Because both the internal and external load are distributed uniformly around the surface of the sphere, there are no weak places in the structure.

They have a lower surface area to volume ratio than the other options. If a pressure vessel of the same volume is going to be manufactured, then fabricating a spherical vessel will require a smaller amount of material than fabricating a cylindrical vessel. Because of its smaller surface area, the spherical vessel will experience a lower rate of heat transfer from the more intensely heated body in comparison to other shapes.

7. Cylindrical Pressure Vessels

A cylindrical shell and a set of heads are the component parts that make up a cylindrical pressure vessel. The body of the pressure vessel is represented by the cylindrical shell. The heads act as end caps or an enclosure for the shell, covering the contents of the vessel that they are attached to.

The heads can have a more rounder or flatter contour, depending on your preference. This latter minimises the cylindrical vessel's susceptibility to damage.Because of their adaptability and space efficiency, cylindrical pressure vessels are the most common type of vessel.

They can be manufactured at a far lower cost than spherical vessels can. However, in comparison to spherical pressure vessels, they tend to have a lower strength. In order to obtain the same level of strength as spherical vessels when bearing the same level of internal pressure, their walls often need to be thicker.

8. Boilers

A boiler is a type of heat transfer equipment that can draw its heat from a fuel source, a nuclear power source, or an electrical power source. Boilers are used in a variety of industries, including the chemical, nuclear, and electrical power industries.

The majority of the time, they assume the shape of an enclosed vessel that performs the function of a conduit, allowing heat to travel from the source of heat to the fluid that is being heated.The heating of liquids is the primary function of these various devices.

The fluid's phase will regularly transition from the liquid state, in which it is currently found, to the vapour state, in which it is currently found, inside the boiler. In addition to being used in the generation of electricity, the vapour that is created by the boiler is also put to use in a range of other applications that include heating.

The turbine blades are given a boost in speed by the pressurised steam that is generated by steam boilers. This steam is produced at a higher pressure than is typical. Because of this, the vessel that makes up the boiler needs to have a high degree of strength in order to be able to endure the extremely high pressures and levels of thermal stress that it will be subjected to.

The majority of different kinds of substances experience a weakening of their level of strength as the temperature is raised.

9. Heat Exchangers

Heat exchangers are devices that are used to move heat from one fluid to another or between multiple fluids. They find widespread application in the energy, food processing, bioprocessing industries and pharmaceutical, among others.

The functionality of heat exchanger equipment is reliant on the thermal and flow properties of the fluids that are participating in the heat exchange, as well as the thermal property of the conductive partition for indirect contact heat exchangers.

The difference in temperature between the hot and cold fluids in a heat exchanger causes the materials in the device to be subjected to stress, as does the internal pressure of the device, which contains the fluids.

10. Process Vessels

These vessels are a second subcategory that can be derived from pressure vessels. In commercial environments, these containers are used for a wide variety of processes, including mixing, agitation, decanting, distilling, mass separating, and chemical reactions.

The degree to which there will be a change in pressure inside the process vessel is determined by the process itself as well as the substances that are being changed.

11. Columns for Distillation

As a consequence of this, a mixture of liquids can be sorted into groups according to the particular degrees of volatility that they possess.

Vapours, and Storage and transport of liquids, gases at pressures much greater or lower than ambient pressure requires the use of pressure vessels. Some rules govern the design, building, repair, and testing of pressure vessels; examples are the ASME BPVC and API 510. Safety during operation of the pressure vessel is prioritised during the creation of such rules.

Heat exchangers, boilers, Storage tanks, and process vessels are the various types of pressure vessels. You can find both spherical and cylindrical pressure vessels. In most cases, vessels will be cylindrical in shape, but their tops may be hemispherical, ellipsoidal, or toroidal. A pressure vessel's axis might be either vertical or horizontal.

FAQ: Pressure Vessels

Q. What are pressure vessels used for?

Ans. Pressure vessels designed to maintain a pressure much higher or lower than that of the surrounding environment, in order to store or transport gases or liquids.

Q. What is a reaction vessel used for?

Ans. Reaction vessel is used for holding the components of a reaction.

Q. What is difference between vessel and reactor?

Ans. A vessel is a container for the steam or gases that power a turbine to generate energy, whereas a reactor is the Engine that generates the steam or hot gases.

Manufacturers & Suppliers of Pressure Vessels

Company Name | Member Since |

|---|---|

Dipesh Engineering Works Mumbai, India | 23 Years |

P-Square Technologies Pune, India | 16 Years |

Prime Advance Polishing System Pvt. Ltd. Vadodara, India | 16 Years |

Ascent Machineries & Engg. Services Mumbai, India | 16 Years |

K-Pack Systems Private Limited Bengaluru, India | 15 Years |

Shalin Composites (India) Private Limited Vasai, India | 15 Years |

Pratham Engineering Mira Bhayandar, India | 14 Years |

Deep Enterprise Ahmedabad, India | 14 Years |

Metalex Cryogenics Ltd. Pune, India | 14 Years |

Utech Projects Pvt. Ltd. Mumbai, India | 14 Years |

Popular Products