Waterstop-RX TechData.pdf - masco.net

Waterstop-RX TechData.pdf - masco.net

Waterstop-RX TechData.pdf - masco.net

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DESCRIPTION<br />

Expanding Concrete Joint <strong>Waterstop</strong><br />

<strong>Waterstop</strong>-<strong>RX</strong> is a sodium bentonite based waterstop designed to stop water infiltration through cast-in-place concrete construction<br />

joints by expanding upon contact with water to form a positive seal against the concrete. The key to <strong>Waterstop</strong>-<strong>RX</strong>’s effectiveness is<br />

its high sodium bentonite content which provides superior expansion to seal and fill voids and cracks in the concrete. <strong>Waterstop</strong>-<strong>RX</strong><br />

is an active bentonite/butyl-rubber based waterstop that is designed to replace passive PVC/Rubber dumbbell waterstops, thereby<br />

eliminating the requirement of special pieces, split-forming and seam welding.<br />

<strong>Waterstop</strong>-<strong>RX</strong> has been successfully tested by independent testing firms to over 200 feet (60 meters) of hydrostatic water pressure,<br />

under both continuous immersion and wet/dry cycling.<br />

<strong>Waterstop</strong>-<strong>RX</strong> is available in three sizes and shapes (see Product Table). <strong>Waterstop</strong>-<strong>RX</strong> 101 is produced in a rectangular shape<br />

measuring 1” x 3/4” (25 x 19 mm). <strong>Waterstop</strong>-<strong>RX</strong> 101T is produced in a trapezoidal shape measuring 1-1/4” x 1/2” (31 x 12 mm) with<br />

a reinforcing plastic scrim embedded in the top surface for high tensile strength. The patented trapezoidal shape distributes the<br />

expansive force over a greater area and allows the concrete to flow more readily over the product during placement. <strong>Waterstop</strong>-<strong>RX</strong><br />

102 is produced in a half-circle (Crescent) shape measuring 3/4” x 3/8” (19 x 9 mm).<br />

Though <strong>Waterstop</strong>-<strong>RX</strong> possesses good resistance to many chemicals, the waterstop is not intended to be used as the primary joint<br />

sealant for chemical containment vessels. Consult manufacturer for guidance regarding chemical compatibility for secondary<br />

chemical containment applications. Additionally, <strong>Waterstop</strong>-<strong>RX</strong> is not an expansion joint sealant. Expansion joints require an<br />

expansion joint product provided by others.<br />

T<br />

E<br />

C<br />

H<br />

D<br />

A<br />

T<br />

A<br />

APPLICATIONS<br />

Applications include both vertical and horizontal<br />

non-moving concrete construction joints, new to<br />

existing concrete construction, irregular surfaces, and<br />

around through-wall pe<strong>net</strong>rations, such as plumbing<br />

and utility pipes. Additionally <strong>Waterstop</strong>-<strong>RX</strong> can seal<br />

around concrete pilings and steel H-piles passing<br />

through the slab. <strong>Waterstop</strong>-<strong>RX</strong> works in both<br />

continuous hydrostatic and intermittent hydrostatic<br />

conditions.<br />

<strong>Waterstop</strong>-<strong>RX</strong> products are designed for reinforced<br />

structural concrete with a minimum of 3,000 psi<br />

compressive strength. <strong>RX</strong>-101 and <strong>RX</strong>-101T are<br />

designed for concrete 8” (200 mm) thick or greater<br />

with two rows of reinforcing steel. <strong>RX</strong>-102 is designed<br />

for vertical concrete 6” (150 mm) thick or greater; and<br />

horizontal concrete no less than 4” (100 mm) thick.<br />

<strong>RX</strong>-102 should be used in concrete with one row of<br />

steel reinforcement, concrete curbs, planter walls,<br />

fountains, and lightweight structural concrete.<br />

<strong>Waterstop</strong>-<strong>RX</strong> is a reliable, cost-effective means<br />

to stop water infiltration through concrete<br />

cold joints. It can also be used around pipe and<br />

structural pe<strong>net</strong>rations<br />

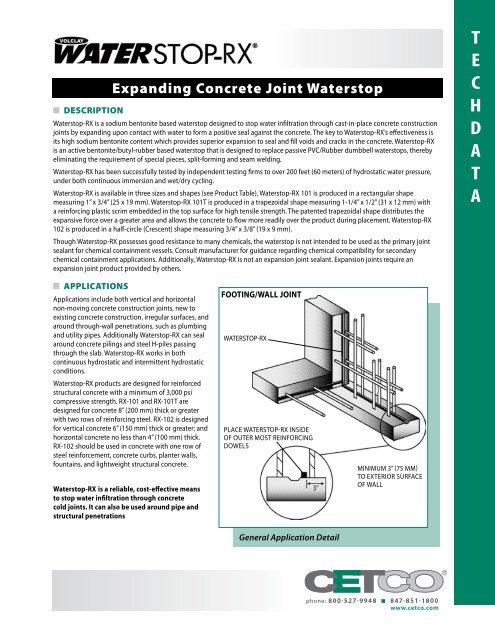

FOOTING/WALL JOINT<br />

WATERSTOP-<strong>RX</strong><br />

Place WATERSTOP-<strong>RX</strong> inside<br />

of outer most reinforcing<br />

dowels<br />

3”<br />

General Application Detail<br />

Minimum 3” (75 mm)<br />

to exterior surface<br />

of wall<br />

phone: 800. 527. 9948 847. 851. 1800<br />

www.cetco.com<br />

1

T<br />

E<br />

C<br />

H<br />

D<br />

A<br />

T<br />

A<br />

WATERSTOP-<strong>RX</strong><br />

INSTALLATION<br />

Surface preparation: Surfaces should be clean and dry. Remove all dirt, rocks, rust or other construction debris. Do not install<br />

<strong>Waterstop</strong>-<strong>RX</strong> in standing water or on an iced substrate.<br />

Adhesive: Apply a continuous bead of CETSEAL along the substrate where <strong>Waterstop</strong>-<strong>RX</strong> will be installed. Assure proper 3” (75<br />

mm) concrete coverage will be maintained. Keep the nozzle tip pressed against the concrete at a 45 o angle during application.<br />

Installation: After applying a continuous bead of CETSEAL, remove release paper, then firmly press the entire length of<br />

<strong>Waterstop</strong>-<strong>RX</strong> onto the adhesive. For vertical and overhead applications, firmly press a minimum of 15 seconds to assure<br />

adhesion. For best results apply <strong>Waterstop</strong>-<strong>RX</strong> within 30 minutes of adhesive installation. <strong>Waterstop</strong> must be placed into adhesive<br />

prior to CETSEAL skinning over and curing. CETSEAL may be applied to damp surfaces, but not in standing water.<br />

Tightly butt coil ends together to form a continuous waterstop - do not overlap coil ends. Place in maximum practical lengths to<br />

minimize coil end joints. Where required, cut coils with a sharp knife or utility blade to fit coil ends together. Make horizontal to<br />

vertical transitions by abutting product coil sections together, no special accessory pieces are required.<br />

At structural and pipe pe<strong>net</strong>rations, cut into strips to fit around the pe<strong>net</strong>ration. Apply to adhesive and abut coil ends together.<br />

On irregular surfaces such as stone or rough concrete, make sure waterstop remains in direct contact with the substrate along the<br />

entire installation. There should not be any air gap between the waterstop and the substrate.<br />

2<br />

LIMITATIONS<br />

<strong>Waterstop</strong>-<strong>RX</strong> is not a self-adhering product. CETSEAL is required to secure <strong>Waterstop</strong>-<strong>RX</strong> to concrete, metal, or PVC (Pipe)<br />

surfaces. Mechanical fasteners should not be used to secure waterstop alone, but may be used in conjunction with CETSEAL. Do<br />

not use any other adhesive or construction sealant, except CETSEAL, to secure <strong>Waterstop</strong>-<strong>RX</strong>.<br />

<strong>Waterstop</strong>-<strong>RX</strong> is not designed, nor intended to function as an expansion joint sealant. For precast concrete applications, contact<br />

manufacturer for product suitability and for any special installation requirements.<br />

<strong>Waterstop</strong>-<strong>RX</strong> products are designed for structural concrete with a minimum of 3,000 psi compressive strength. <strong>Waterstop</strong>-<strong>RX</strong> 101<br />

and <strong>RX</strong>-101T require a minimum of 3” (75 mm) of concrete coverage. <strong>Waterstop</strong>-<strong>RX</strong> 102 requires a minimum concrete coverage of<br />

2” (50 mm). <strong>Waterstop</strong>-<strong>RX</strong> should only be used in applications where the product is completely encapsulated within the concrete.<br />

<strong>Waterstop</strong>-<strong>RX</strong> should not be prehydrated by being subjected to submersion or remain in extended contact with water prior to<br />

encapsulation in concrete. If the product exhibits considerable swell prior to encapsulation in the concrete, it must be replaced<br />

with new material.<br />

In conditions where severe ground water chemical contamination exists, or is expected, consult manufacturer for product<br />

chemical compatibility information.<br />

PACKAGING<br />

<strong>Waterstop</strong>-<strong>RX</strong> is available in corrugated cartons, palletized 36 cartons per pallet. Cartons are color coded for easy product<br />

identification. CETSEAL is packaged separately.<br />

WATERSTOP-<strong>RX</strong> PRODUCT TABLE<br />

PRODUCT SIZE ROLL LENGTH CROSS-SECTION SHAPE UNIT QTY/CARTON MIN CONCRETE<br />

COVERAGE<br />

<strong>RX</strong>-101 1” X 3/4” 16’ 8” ( 5 m) Rectangle 100 LF (30.4 m) 3” (75 mm)<br />

<strong>RX</strong>-101T 1-1/4” X 1/2” 20’ (6 m) Trapezoid with Poly 120 LF (36.5 m) 3” (75 mm)<br />

Scrim Reinforcement<br />

<strong>RX</strong>-102 3/4” x 3/8” 33’ 4” (10 m) Half-Circle 200 LF (60.9 m) 2” (50 mm)<br />

2

WATERSTOP-<strong>RX</strong><br />

5<br />

FAST & EASY<br />

INSTALLATION STEPS<br />

STEP 1<br />

CLEAN<br />

SURFACE<br />

STEP 2<br />

APPLY<br />

ADHESIVE<br />

STEP 3<br />

PLACE<br />

WATERSTOP<br />

REMOVE ALL DIRT AND DEBRIS<br />

APPLY CETSEAL<br />

MIN 3” (75<br />

mm)<br />

REMOVE RELEASE PAPER THEN PRESS<br />

FIRMLY AGAINST CETSEAL. MAINTAIN<br />

MIN. CONCRETE COVERAGE DEPTH<br />

ACCESSORY PRODUCTS<br />

CETSEAL is a multi-purpose, single component polyether moisture<br />

cure adhesive used to secure <strong>Waterstop</strong>-<strong>RX</strong> into position. Apply a<br />

continuous bead of CETSEAL to substrate then install <strong>Waterstop</strong>-<strong>RX</strong><br />

before CETSEAL skins over and cures. Adhesive yield will vary with<br />

use, substrate and application.<br />

LIMITED WARRANTY<br />

Specifications and other information contained herein supersedes all<br />

previously printed matter and are subject to change without notice.<br />

All goods sold by seller are warranted to be free from defects in<br />

material and workmanship. The foregoing warranty is in lieu of and<br />

excludes all other warranties not expressly set forth herein, whether<br />

expressed or implied by operation of law or otherwise, including but<br />

not limited to any implied warranties of merchantability or fitness.<br />

Seller shall not be liable for incidental or consequential losses,<br />

damages or expenses, directly or indirectly arising for the sale,<br />

handling or use of goods, or from any other case relating thereto,<br />

and seller’s liability hereunder in any case is expressly limited to the<br />

replacement (in the form originally shipped) of goods not complying<br />

with the agreement or at seller’s election, to the repayment of,<br />

or crediting buyer with, an amount equal to the purchase price<br />

of such goods, whether such claims are for breach of warranty or<br />

negligence.<br />

Any claim by buyer with reference to the goods sold hereunder<br />

for any cause shall be deemed waived by buyer unless submitted<br />

to seller in writing within thirty (30) days from the date buyer<br />

discovered or should of discovered, any claimed breach.<br />

Materials should be inspected and tested by purchaser prior to<br />

their use if product quality is subject to verification after shipment.<br />

Performance guarantees are normally supplied by the applicator.<br />

<strong>Waterstop</strong>-<strong>RX</strong> is not an expansion joint material nor should it be<br />

used as such. Watertightness of expansion joints is the responsibility<br />

of others.<br />

3<br />

T<br />

E<br />

C<br />

H<br />

D<br />

A<br />

T<br />

A<br />

STEP 4<br />

BUTT COIL<br />

ENDS<br />

TIGHTLY BUTT COIL ENDS TO FORM<br />

A CONTINUOUS WATERSTOP. DO NOT<br />

OVERLAP COIL ENDS<br />

TYPICAL PROPERTIES<br />

PROPERTY TEST METHOD VALUE<br />

Hydrostatic Head Independent Test 231 Ft. (70 m)<br />

Resistance<br />

Wet / Dry Cycling Independent Test No Effect<br />

(25 Cycles @ 231 ft)<br />

Adhesion to Concrete<br />

Using CETSEAL<br />

Independent Test Excellent<br />

STEP 5<br />

POUR<br />

CONCRETE<br />

Concrete<br />

<strong>Waterstop</strong>-<strong>RX</strong><br />

POUR AND VIBRATE CONCRETE<br />

phone: 800. 527. 9948 847. 851. 1800<br />

www.cetco.com<br />

3

T<br />

E<br />

C<br />

H<br />

D<br />

A<br />

T<br />

A<br />

WATERSTOP-<strong>RX</strong><br />

TYPICAL PRODUCT APPLICATIONS<br />

WATERSTOP-<strong>RX</strong>101 and <strong>RX</strong>101T<br />

Vertical and horizontal concrete 8” (200 mm) thick or greater<br />

Concrete with two rows of steel reinforcement<br />

Shotcrete Foundation Walls<br />

High hydrostatic pressures<br />

Tie-back plates and pe<strong>net</strong>rations<br />

INSTALL WATERSTOP-<strong>RX</strong> AT<br />

ALL SLAB POUR JOINTS AND<br />

CONNECT WITH WALL JOINT<br />

INSTALLATION TO FORM<br />

CONTINUOUS WATERSTOP<br />

WATERSTOP-<strong>RX</strong> 102<br />

Vertical concrete 6” (150 mm) thick or greater.<br />

Horizontal concrete 4” (100 mm) thick or greater<br />

Concrete with one row of steel reinforcement<br />

Slabs containing only wire mesh<br />

Fountains / Planter Boxes / Curbs<br />

INSTALL WATERSTOP-<strong>RX</strong><br />

AT ALL WALL POUR JOINTS<br />

REINFORCING STEEL<br />

4<br />

INSTALL WATERSTOP-<strong>RX</strong><br />

AT FOOTING/WALL JOINT<br />

Test Method<br />

INSTALL WATERSTOP-<strong>RX</strong><br />

Typical Value<br />

SLAB JOINT SECTION DETAIL<br />

INSIDE OF OUTER MOST<br />

REINFORCING STEEL<br />

Hydrostatic Pressure Resistance ASTm d 5385 (mod.) 231 ft. (70 m)<br />

Permeability ASTm d 5084