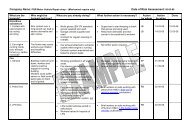

Example: Risk assessment in a warehouse - Forktruck Solutions Ltd.

Example: Risk assessment in a warehouse - Forktruck Solutions Ltd.

Example: Risk assessment in a warehouse - Forktruck Solutions Ltd.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

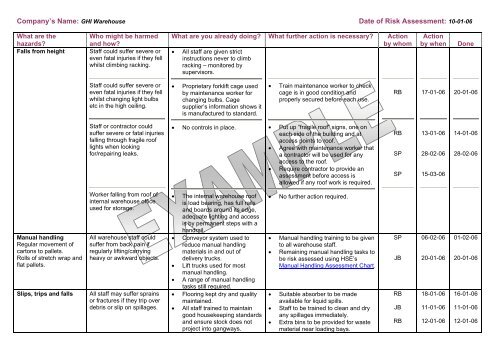

Company’s Name: GHI Warehouse Date of <strong>Risk</strong> Assessment: 10-01-06<br />

What are the<br />

hazards<br />

Falls from height<br />

Who might be harmed<br />

and how<br />

Staff could suffer severe or<br />

even fatal <strong>in</strong>juries if they fell<br />

whilst climb<strong>in</strong>g rack<strong>in</strong>g.<br />

What are you already do<strong>in</strong>g What further action is necessary Action<br />

by whom<br />

• All staff are given strict<br />

<strong>in</strong>structions never to climb<br />

rack<strong>in</strong>g – monitored by<br />

supervisors.<br />

Action<br />

by when<br />

Done<br />

Staff could suffer severe or<br />

even fatal <strong>in</strong>juries if they fell<br />

whilst chang<strong>in</strong>g light bulbs<br />

etc <strong>in</strong> the high ceil<strong>in</strong>g.<br />

• Proprietary forklift cage used<br />

by ma<strong>in</strong>tenance worker for<br />

chang<strong>in</strong>g bulbs. Cage<br />

supplier’s <strong>in</strong>formation shows it<br />

is manufactured to standard.<br />

• Tra<strong>in</strong> ma<strong>in</strong>tenance worker to check<br />

cage is <strong>in</strong> good condition and<br />

properly secured before each use.<br />

RB<br />

17-01-06<br />

20-01-06<br />

Staff or contractor could<br />

suffer severe or fatal <strong>in</strong>juries<br />

fall<strong>in</strong>g through fragile roof<br />

lights when look<strong>in</strong>g<br />

for/repair<strong>in</strong>g leaks.<br />

• No controls <strong>in</strong> place.<br />

• Put up “fragile roof” signs, one on<br />

each side of the build<strong>in</strong>g and at<br />

access po<strong>in</strong>ts to roof.<br />

• Agree with ma<strong>in</strong>tenance worker that<br />

a contractor will be used for any<br />

access to the roof.<br />

• Require contractor to provide an<br />

<strong>assessment</strong> before access is<br />

allowed if any roof work is required.<br />

RB<br />

SP<br />

SP<br />

13-01-06<br />

28-02-06<br />

15-03-06<br />

14-01-06<br />

28-02-06<br />

Manual handl<strong>in</strong>g<br />

Regular movement of<br />

cartons to pallets.<br />

Rolls of stretch wrap and<br />

flat pallets.<br />

Slips, trips and falls<br />

Worker fall<strong>in</strong>g from roof of<br />

<strong>in</strong>ternal <strong>warehouse</strong> office<br />

used for storage.<br />

All <strong>warehouse</strong> staff could<br />

suffer from back pa<strong>in</strong> if<br />

regularly lift<strong>in</strong>g/carry<strong>in</strong>g<br />

heavy or awkward objects.<br />

All staff may suffer spra<strong>in</strong>s<br />

or fractures if they trip over<br />

debris or slip on spillages.<br />

• The <strong>in</strong>ternal <strong>warehouse</strong> roof<br />

is load bear<strong>in</strong>g, has full rails<br />

and boards around its edge,<br />

adequate light<strong>in</strong>g and access<br />

is by permanent steps with a<br />

handrail.<br />

• Conveyor system used to<br />

reduce manual handl<strong>in</strong>g<br />

materials <strong>in</strong> and out of<br />

delivery trucks.<br />

• Lift trucks used for most<br />

manual handl<strong>in</strong>g.<br />

• A range of manual handl<strong>in</strong>g<br />

tasks still required.<br />

• Floor<strong>in</strong>g kept dry and quality<br />

ma<strong>in</strong>ta<strong>in</strong>ed.<br />

• All staff tra<strong>in</strong>ed to ma<strong>in</strong>ta<strong>in</strong><br />

good housekeep<strong>in</strong>g standards<br />

and ensure stock does not<br />

project <strong>in</strong>to gangways.<br />

• No further action required.<br />

• Manual handl<strong>in</strong>g tra<strong>in</strong><strong>in</strong>g to be given<br />

to all <strong>warehouse</strong> staff.<br />

• Rema<strong>in</strong><strong>in</strong>g manual handl<strong>in</strong>g tasks to<br />

be risk assessed us<strong>in</strong>g HSE’s<br />

Manual Handl<strong>in</strong>g Assessment Chart.<br />

• Suitable absorber to be made<br />

available for liquid spills.<br />

• Staff to be tra<strong>in</strong>ed to clean and dry<br />

any spillages immediately.<br />

• Extra b<strong>in</strong>s to be provided for waste<br />

material near load<strong>in</strong>g bays.<br />

SP<br />

JB<br />

RB<br />

JB<br />

RB<br />

06-02-06<br />

20-01-06<br />

18-01-06<br />

11-01-06<br />

12-01-06<br />

01-02-06<br />

20-01-06<br />

16-01-06<br />

11-01-06<br />

12-01-06

Fall<strong>in</strong>g objects<br />

From rack<strong>in</strong>g and dur<strong>in</strong>g<br />

movement<br />

Operation of lift trucks<br />

A member of staff or any<br />

other person <strong>in</strong> the<br />

<strong>warehouse</strong> may suffer<br />

serious <strong>in</strong>jury if struck by a<br />

fall<strong>in</strong>g object.<br />

Injuries such as fractures or<br />

at worse fatalities can be<br />

caused as a result of:<br />

• the vehicle crash<strong>in</strong>g <strong>in</strong>to<br />

other vehicles and/or<br />

other objects;<br />

• staff and visitors be<strong>in</strong>g<br />

hit by lift trucks;<br />

• objects fall<strong>in</strong>g from lift<br />

trucks on to staff and<br />

visitors;<br />

• lift trucks toppl<strong>in</strong>g over;<br />

• people fall<strong>in</strong>g from the<br />

vehicle or parts of the<br />

vehicle, and<br />

• be<strong>in</strong>g crushed by the<br />

mast.<br />

• Cleaner empties b<strong>in</strong>s and<br />

removes loose debris daily.<br />

• Pallets stored safely <strong>in</strong><br />

designated area.<br />

• Protective non-slip footwear<br />

supplied and worn.<br />

• Rack<strong>in</strong>g is designed to be<br />

suitable for the loads carried<br />

and has not been modified.<br />

• Staff report any damage to<br />

rack<strong>in</strong>g immediately.<br />

• System <strong>in</strong> place to make sure<br />

defective pallets withdrawn<br />

from use immediately.<br />

• Protective footwear used by<br />

all enter<strong>in</strong>g <strong>warehouse</strong>.<br />

• Protective gloves provide to<br />

handle pallets.<br />

• All operators tra<strong>in</strong>ed and<br />

competent for use of the lift<br />

truck.<br />

• Trucks serviced regularly and<br />

exam<strong>in</strong>ed by suppliers every<br />

six months.<br />

• Drivers <strong>in</strong>structed to keep<br />

keys with them at all times.<br />

• System <strong>in</strong> place for refresher<br />

tra<strong>in</strong><strong>in</strong>g of drivers.<br />

• Gangways and aisles of<br />

sufficient space to enable lift<br />

trucks to load and unload<br />

from the rack<strong>in</strong>g safely.<br />

• System <strong>in</strong> place to keep<br />

vehicles and pedestrians<br />

separated.<br />

• Access to <strong>warehouse</strong><br />

restricted to staff.<br />

• Floor condition ma<strong>in</strong>ta<strong>in</strong>ed on<br />

a regular basis, housekeep<strong>in</strong>g<br />

standards ma<strong>in</strong>ta<strong>in</strong>ed by<br />

cleaner and workforce.<br />

• Warn<strong>in</strong>g signs located around<br />

the traffic route.<br />

• Trucks have seat belts and<br />

• Sign fixed to rack<strong>in</strong>g stat<strong>in</strong>g<br />

maximum loads/configuration.<br />

• Supervisor to ensure truck drivers<br />

check trucks each day before<br />

start<strong>in</strong>g.<br />

• Separate pedestrian entrance(s)<br />

with protective barrier rail to be<br />

provided next to roller-shutter doors.<br />

• Housekeep<strong>in</strong>g standards and floor<br />

condition to be covered by a<br />

monthly <strong>in</strong>spection by manager and<br />

brief record kept.<br />

• Strict requirement that only<br />

competent drivers may operate lift<br />

trucks to be expla<strong>in</strong>ed to all staff.<br />

Discipl<strong>in</strong>ary action to be taken<br />

aga<strong>in</strong>st anyone <strong>in</strong>volved <strong>in</strong> break<strong>in</strong>g<br />

this rule.<br />

RB 14-07-06<br />

JB 10-01-06<br />

RB 20-06-06<br />

SP 27-01-06<br />

SP 23-01-06<br />

10-01-06<br />

27-01-06<br />

23-01-06

Traffic movements<br />

(deliveries etc)<br />

Mach<strong>in</strong>ery<br />

Stretch-wrap mach<strong>in</strong>e<br />

Injuries such as fractures or<br />

at worse fatalities can be<br />

<strong>in</strong>curred by<br />

• staff and visitors be<strong>in</strong>g<br />

hit by vehicle;<br />

• people fall<strong>in</strong>g from a<br />

vehicle or parts of a<br />

vehicle; and<br />

• objects fall<strong>in</strong>g from<br />

vehicle on to staff and<br />

visitors.<br />

All staff us<strong>in</strong>g the mach<strong>in</strong>e.<br />

Mov<strong>in</strong>g parts can trap parts<br />

of the body (e.g.<br />

f<strong>in</strong>gers/hand/arm) caus<strong>in</strong>g<br />

crush <strong>in</strong>juries. The whole<br />

body may also get trapped<br />

between mov<strong>in</strong>g pallet load<br />

and fixed structure.<br />

Staff can also cut<br />

themselves on sharp edges<br />

or scald themselves on hot<br />

parts.<br />

roll cages.<br />

• Floor and traffic routes<br />

suitable for the vehicles us<strong>in</strong>g<br />

them.<br />

• Vehicle routes kept free of<br />

obstructions (with spillages<br />

be<strong>in</strong>g cleaned up promptly).<br />

• Park<strong>in</strong>g of cars and vans only<br />

allowed <strong>in</strong> marked spaces<br />

well away from external<br />

delivery/dispatch area.<br />

• Outside area gritted when<br />

frosty, snow cleared.<br />

• Sensible speed limits<br />

imposed and adhered to.<br />

• Adequate signage to warn of<br />

hazards<br />

• Revers<strong>in</strong>g of delivery vehicles<br />

should be avoided unless<br />

absolutely necessary.<br />

• Any revers<strong>in</strong>g that is<br />

necessary should be<br />

overseen by a tra<strong>in</strong>ed<br />

revers<strong>in</strong>g assistant<br />

(Banksman).<br />

• Only standard palletised loads<br />

wrapped.<br />

• Mach<strong>in</strong>e is relatively new and<br />

<strong>in</strong>structions show it meets the<br />

relevant guard<strong>in</strong>g standard.<br />

• Emergency stop button<br />

provided.<br />

• Fixed guards on mov<strong>in</strong>g parts<br />

• Mechanical parts ma<strong>in</strong>ta<strong>in</strong>ed<br />

regularly.<br />

• Staff tra<strong>in</strong>ed to use correctly.<br />

• Anyone work<strong>in</strong>g <strong>in</strong> the vic<strong>in</strong>ity of<br />

mov<strong>in</strong>g vehicles should be given<br />

high visibility cloth<strong>in</strong>g and tra<strong>in</strong><strong>in</strong>g.<br />

• Area around mach<strong>in</strong>e to be kept<br />

unobstructed at all times.<br />

• Area around mach<strong>in</strong>e to be<br />

<strong>in</strong>dicated by use of mark<strong>in</strong>gs <strong>in</strong><br />

fluorescent orange-red.<br />

• Weekly check on guard<strong>in</strong>g and<br />

condition of mach<strong>in</strong>e.<br />

SP 20-01-06 20-01-06<br />

JB 18-01-06 18-01-06<br />

RB 28-04-06<br />

JB 18-01-06 18-01-06<br />

Conveyor belt for<br />

unload<strong>in</strong>g from lorries<br />

As above, particularly where<br />

the belt meets rollers.<br />

• Guards provided for mov<strong>in</strong>g<br />

parts.<br />

• Conveyor <strong>in</strong>structions show it<br />

meets guard<strong>in</strong>g standards.<br />

• Emergency stop button<br />

• Weekly check on guard<strong>in</strong>g and<br />

condition of conveyor.<br />

JB<br />

18-01-06<br />

18-01-06

Portable electrical<br />

equipment<br />

Mess room: Industrial<br />

cleaner, kettle and<br />

heater.<br />

Fire<br />

• Bulk storage of<br />

easily burnt<br />

materials.<br />

• Ignited through<br />

electrical fault,<br />

smok<strong>in</strong>g materials,<br />

battery recharg<strong>in</strong>g<br />

etc.<br />

Hazardous substances<br />

Vehicle exhaust fumes<br />

All staff could <strong>in</strong>cur<br />

potentially fatal electrical<br />

shocks or burns if they use<br />

faulty electrical equipment.<br />

If trapped <strong>in</strong> the <strong>warehouse</strong><br />

all staff and visitors could<br />

suffer from smoke <strong>in</strong>halation<br />

or burns which could<br />

potentially kill.<br />

The fumes may cause staff<br />

eye irritation and respiratory<br />

irritation.<br />

provided.<br />

• Regular ma<strong>in</strong>tenance.<br />

• Fixed electrical <strong>in</strong>stallations<br />

are ma<strong>in</strong>ta<strong>in</strong>ed to a suitable<br />

standard and <strong>in</strong>spected every<br />

five years.<br />

• Build<strong>in</strong>g designed with fireresist<strong>in</strong>g<br />

materials.<br />

• Exits and fire exits marked<br />

and kept clear.<br />

• Fire ext<strong>in</strong>guishers located<br />

throughout <strong>warehouse</strong>.<br />

• Access to all exits and fire<br />

ext<strong>in</strong>guishers kept clear at all<br />

times.<br />

• Fire detection and alarm<br />

system <strong>in</strong> place.<br />

• Fire evacuation procedures<br />

displayed at each fire alarm<br />

po<strong>in</strong>t.<br />

• Ma<strong>in</strong>tenance contracts for<br />

ext<strong>in</strong>guishers and<br />

detection/alarm system.<br />

• Fire drill and tra<strong>in</strong><strong>in</strong>g <strong>in</strong> use of<br />

ext<strong>in</strong>guishers held once a<br />

year.<br />

• Smok<strong>in</strong>g prohibited <strong>in</strong> the<br />

<strong>warehouse</strong>.<br />

• Cleaner ensures no debris left<br />

around <strong>warehouse</strong>.<br />

• All staff tra<strong>in</strong>ed <strong>in</strong> good<br />

housekeep<strong>in</strong>g dur<strong>in</strong>g<br />

<strong>in</strong>duction.<br />

• Number of vehicles deliver<strong>in</strong>g<br />

materials is relatively low and<br />

exposure very limited this<br />

prevents build-up of fumes.<br />

• Drivers not allowed to leave<br />

vehicles eng<strong>in</strong>es runn<strong>in</strong>g <strong>in</strong><br />

<strong>warehouse</strong>.<br />

• Roller shutter doors and<br />

<strong>warehouse</strong> w<strong>in</strong>dows open<br />

• Manager to arrange and record the<br />

six monthly <strong>in</strong>spection and test<strong>in</strong>g of<br />

portable equipment.<br />

• Instruct staff to report faults<br />

immediately.<br />

• Discussions with <strong>in</strong>surer on the<br />

provision of automatic clos<strong>in</strong>g of<br />

roller-shutter doors l<strong>in</strong>ked to fire<br />

alarm to be decided upon.<br />

• No further action required.<br />

SP 01-05-06<br />

JB 13-01-06 13-01-06<br />

SP 25-08-06

where practicable to assist<br />

ventilation.<br />

Bleach and clean<strong>in</strong>g<br />

fluids<br />

Direct sk<strong>in</strong> contact could<br />

lead to the cleaner gett<strong>in</strong>g<br />

sk<strong>in</strong> irritation. The vapour<br />

may cause the cleaner to<br />

have eye irritation or<br />

breath<strong>in</strong>g difficulties.<br />

• Cleaner made aware of safe<br />

procedures. Rubber gloves<br />

used.<br />

• First aid facilities (<strong>in</strong>c. eye<br />

wash) are readily available.<br />

• Investigate availability of safer<br />

alternatives for cleaner.<br />

RB<br />

17-02-06<br />

28-02-06<br />

Recharg<strong>in</strong>g of fork lift<br />

truck batteries –<br />

potential explosion by<br />

release of hydrogen,<br />

spillage of acid<br />

Light<strong>in</strong>g<br />

Hygiene/comfort<br />

Burns or fractures from<br />

material ejected could affect<br />

any worker nearby at the<br />

time.<br />

Poor light<strong>in</strong>g is likely to<br />

result <strong>in</strong> higher levels of<br />

work error and accidents.<br />

All staff could suffer varied<br />

discomfort eg be<strong>in</strong>g too<br />

hot/cold.<br />

• Batteries charged <strong>in</strong><br />

designated bay that is well<br />

ventilated. Safe system of<br />

work used which <strong>in</strong>cludes<br />

provision and use of goggles<br />

and gloves. Potential sources<br />

of ignition controlled<br />

• Good quality light<strong>in</strong>g provided<br />

throughout the <strong>warehouse</strong>.<br />

• Stack<strong>in</strong>g of materials <strong>in</strong><br />

<strong>warehouse</strong> on top of rack<strong>in</strong>g<br />

is restricted <strong>in</strong> order to avoid<br />

block<strong>in</strong>g light and creat<strong>in</strong>g<br />

shadows.<br />

• Cleaner checks that light units<br />

are operat<strong>in</strong>g and are<br />

replaced by electrician when<br />

necessary.<br />

• Floodlight<strong>in</strong>g <strong>in</strong> the external<br />

area.<br />

• Heated mess room provided<br />

with hot and cold water and<br />

water for beverages.<br />

• Area kept clean.<br />

• Lockers available for staff’<br />

belong<strong>in</strong>gs.<br />

• Toilets a short walk away,<br />

cleaned daily.<br />

• Supervisor to monitor and ensure<br />

protective equipment is be<strong>in</strong>g worn.<br />

• No further action required.<br />

• No further action required.<br />

JB<br />

13-01-06<br />

13-01-06<br />

Review Date: 26-02-07