Safety Guidelines - ChyComm

Department of Chemical and Biomolecular Engineering Graduate Student Safety Guide

Made by Chemical Hygiene Committee (ChyComm)

According to the Office of Environmental Health and Safety:

"Laboratory operations involve the use of hazardous chemicals and equipment, which may pose health hazards and physical hazards to laboratory personnel. These hazards can be managed or minimized through appropriate facilities, protocols and knowledgeable personnel, the foundations of practicing safe science. Regulations which address these issues are intended to formalize existing protocols and training practices. These protocols, practices and regulatory issues regarding research are routinely practiced and addressed in the private sector. Thus implementation, while legally mandated, enhances the academic experience of our students and prepares them to recognize regulatory aspects of research operations at OSU and elsewhere. All faculty, staff and lab personnel have responsibilities to ensure a safe environment for academic research."

Without a safe lab practice, experimentation could result in very serious injury or other issues. The only person that can keep you safe is you.

Table of contents

- Basic Lab Protocols

- Lab Safety on Traditional Side

- Lab Safety on Bio-side

- Available Sources

1. Basic Lab Protocol

1.1 Personal Protective Equipment (PPE)

- PPE should not be considered as a reliable safety measurement. They should only be considered after all the engineering and administrative controls are implemented. This is the last line of defense.

- The recommended lab attire includes pants, short-sleeved shirt, safety goggles, lab coats and gloves, regardless of the season.

- Material selection of gloves should be based upon the MSDS of the working chemicals.

- PPE is not to be worn outside the lab area or comes into contact with door handles and elevators buttons.

1.2 Food and Drinks

- No food or drinks are allowed in the laboratory area.

- All food and drinks are to be consumed inside the office with both doors closed or in the designated dining area on each floor.

- Food and drink should not be disposed in the trash cans inside the working area.

1.3 Proper Fume Hood Practice

- Keep the sash closed as much as possible at all times.

- All fume hood equipment and chemicals should be at least 6” away from the edge of the hood.

- Fume hood is not to be used for storage.

- Do not put your body inside the hood during normal operation.

- Contact the building manager if you run into any issue with the hood.

1.4 Fire related safety

- Make sure that you are aware of all the exits, fire alarms, fire-extinguisher locations, safety shower, building evacuation procedure and trained in using a fire extinguisher etc.

- Shut the door behind you while evacuating.

- Keep solvents in flammable liquid storage cabinets and combustibles away from open flame area.

- Remember ‘RACE’ while dealing with a “fire situation”:

R: Rescue/remove all occupants

A: Activate fire alarm

C: Confine the fire by closing doors

E: Evacuate/Extinguish

5. While dealing with fire extinguisher, remember “PASS”

P: Pull the pin

A: Aim extinguisher nozzle at the base of the fire

S: Squeeze the trigger while holding the extinguisher upright

S: Sweep the extinguisher from side to side; cover the fire with spray

In case of fire, keep infectious wastes in an autoclave, incubator or refrigerator for containment.

1.5 Other Recommended Practices

- Always utilize a buddy system when running an experiment.

- Collect tools and organize the working area before the end of the day.

- Properly clean and dispose any trash by the end of the day.

- When in doubt, ask your co-worker and safety office for best practices.

- Keep the office doors closed at all time. This will prevent theft and contain chemical spills. Offices are designed to have a positive pressure over the laboratory area. With the doors closed, a gas leak will be less likely to enter the office.

2. Lab Safety on Traditional Side

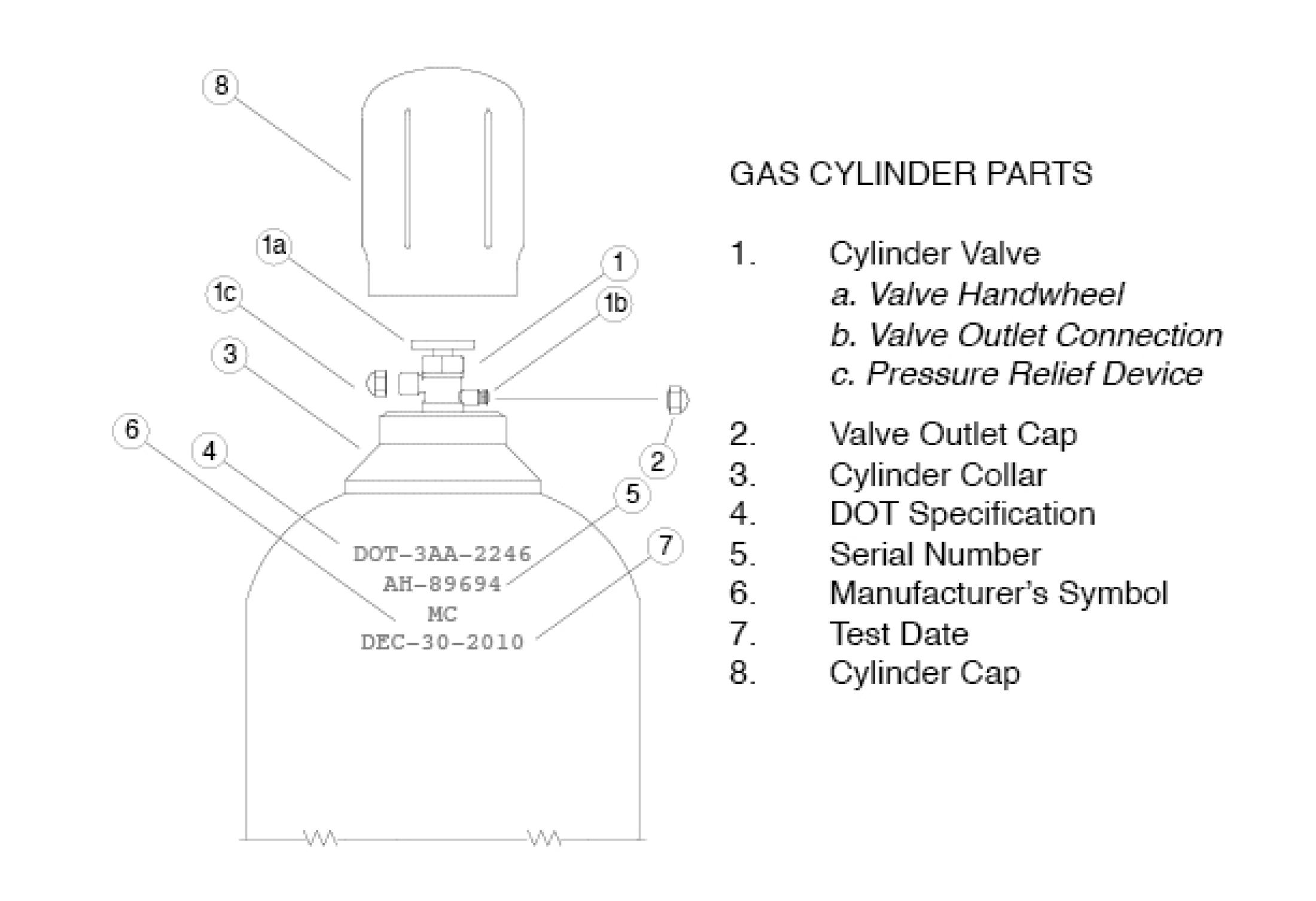

2.1 Cylinder Safety

Compressed gas cylinders of various sizes are used regularly in CBEC. Cylinders can be ordered through OSU gas warehouse and delivered to your lab. The number of cylinders in a lab should be minimized for safety, and also to save money (labs are charged a monthly rent for each cylinder, in addition to the initial cost of the gas inside). Empty cylinders can be returned to the designated rack in the loading dock for pick up (shown in the photo below). Most labs keep an inventory of what cylinders are present and when they are returned, but procedures may vary from group to group.

Gas cylinder safety:

- Make sure all the gas cylinders are capped and individually chained in the vertical position when not in use. Gang-chaining, or chaining a group of cylinders with a single chain, is a safety violation. Also, each cylinder must be chained to 2 secure points (i.e. you can’t chain a cylinder to a single hook).

- Never leave a cylinder unsecured.

- Always use a cart to transport gas cylinders, and only transport cylinders when they are capped.

- Cylinders should be capped when not in use. Do not leave a regulator on a cylinder with no line attached. And always vent lines and ensure cylinders are closed before removing regulators.

- Incompatible (i.e. oxidizers and flammable) gas cylinders should not be stored together. Additionally, cylinders should not be stored near heat sources, as it may cause pressure build up and lead to a gas release or explosion. When possible, toxic/harmful gases should be stored in ventilated cylinder cabinets.

- Use the correct regulator. Every cylinder has specific CGA#. The CGA number can be found on the cylinder and should match the number on the regulator. For example, CO2 cylinder has CGA320 requirement. Hence, a regulator with CGA320 reading should be used. Regulators for flammable gas cylinders have notches on the nut that connects the regulator to the cylinder, these nuts are tightened counterclockwise.

- There is an EHS Training Module called “Compressed Gas Cylinder Safety” which provides more information on safely using gas cylinders in the lab. This can be accessed by logging into the EHS Safety Training Portal.

2.2 Chemical Waste Handling

2.2.1 Waste Segregation and Storage

- Waste should be segregated and stored so as to keep incompatible materials apart (i.e. acids, bases, and flammables should be kept separately).

- Many labs have designated areas where waste should be stored until proper disposal (typically labeled as satellite waste collection areas).

- Bottles should only be filled 2/3 of the way full before being disposed.

- Bottles must be properly labeled. The label should contain contact information (name, phone number), storage location, and a general description of waste type being stored. An inventory of each waste deposit into the bottle should also be kept with the bottle, and an additional copy elsewhere (in case of a release so that the contents can be properly identified).

- Nalgene and glass bottles are both appropriate for waste storage containers.

2.2.2 Disposal of Empty Chemical Containers

When a chemical is used up, the empty container should be properly cleaned before disposal. Typically, triple rinsing is sufficient for many materials. The label should be removed or crossed out. Plastic containers can then be placed in the trash. Glass can be disposed of with general glassware disposal (which can be discarded at the same time as hazardous waste). Custodial services may also pick up glass bottles if left in the hallway outside the laboratory door (indicate they are cleaned and for disposal).

2.2.3 Options for Waste Disposal

- EHS may be contacted for a waste pickup via the website log in after clicking on “Hazardous Waste Request” and logging on. This is shown in the figure below.

- Copies of proper logs of all waste are required. Waste that can be disposed includes chemical waste, sharps waste, battery waste, and glass.

- In many cases, waste disposal may be a responsibility of the Safety Officer with a group, so contacting this person first is usually an important step for your lab.

2.3 Chemical Hygiene Plan and Standard Operating Procedures

- The Chemical Hygiene Plan (CHP) will contain a lot of information that will be useful to you in getting acquainted with your new lab space. Some highlights of the information it contains are:

- Updated chemical inventory with location of each chemical

- Standard Operating Procedures (SOPs)

- Standard Operating Procedures contain pertinent information describing the safe use and operation of:

- Hazardous chemicals that are used in your lab

- Various procedures that take place in your lab (experiments, measurements, synthesis, etc.)

- This information will include things like required Personal Protective Equipment (PPE), which engineering controls to use, waste disposal instructions, and exposure limits.

- Ask your group safety representative where your lab’s CHP is located! If you come across a procedure or chemical that does not have an accompanying SOP that you think should, we encourage you to talk to your group safety representative and help construct a SOP for it.

2.4 Building Emergency Action Plan

A Building Emergency Action Plan (BEAP) specifies the procedure building occupants should take in the event of an emergency. Examples of emergencies include:

- Fire

- Chemical Spills

- Severe Weather

- Medical Emergencies

The BEAP is specifically tailored to each building. If an emergency occurs in CBEC, some important things to keep in mind are:

- If an alarm sounds, immediately evacuate the building

- Use the nearest stairwell to exit, DO NOT USE THE ELEVATORS

- Go to the pre-determined location specified in the BEAP

- Visit BEAP for more info.

- You should also take the BEAP online module in EHS online training. This is a required training module for all users of CBEC facilities.

3. Lab Safety on Bio-side

3.1 Biosafety Level 1 (BSL1)

Biosafety level 1 (BSL1) is suitable for work that involves well characterized agents that are not known to consistently cause disease in immunocompetent adults. These materials should also not pose environmental risks. Work can typically be conducted on open bench tops using standard microbiological practices. Special containments equipment or facility design is not necessarily required.

3.1.1 Solid bio-waste should be disposed of in the biohazard boxes with red bags as provided by OSU EHS.

- EHS Supply delivery and waste pick up.

- Waste should be left outside of the laboratory in boxes that have the bags tied and are adequately taped. (Two layers of tape on both the top and bottom lids)

- Waste pickups are scheduled for delivery every Tuesday and Thursday morning (As of Summer 2016) Waste should therefore be left out either Monday or Wednesday evening.

3.1.2 Liquid bio-waste

Liquid bio waste should be contained in the HDPE carboys provided by EHS, adequately capped, wrapped and tied in a red biohazard bag, and put in the boxes as outlined in 3.1.1.

3.1.3 Food

Eating, drinking, smoking, handling contact lenses, applying cosmetics, and storing food for human consumption must not be permitted in laboratory areas. Food must be stored outside the laboratory area in cabinets or refrigerators designated and used for this purpose.

3.2.4 Sharps

Careful management of needles and other sharps are of primary importance. Needles must not be bent, sheared, broken, recapped, removed from disposable syringes, or otherwise manipulated by hand before disposal.

3.2 Biosafety Level 2 (BSL2)

Biosafety Level 2 (BSL2) builds upon the BSL1 protocol and is suitable for work with agents that pose moderate hazards to personnel and the environment. These procedures differ from BSL1 in that all laboratory personnel must have specific training in handling all pathogenic material. Access to the laboratory is more strictly controlled. And all procedures that create aerosols must be performed in applicable BSCs.

- All procedures from BSL1 should be considered a baseline for BSL2.

- You should review your lab’s exposure control plan (ECP) before beginning any laboratory work.

- All BSL2 labs should have an adequately developed ECP with fully documented “Appendix A” per OSU EHS protocol. These plans are developed to outline ways to minimize occupational exposures.

- This material will guide how your lab handles any BSL2 level materials with sections on personal protective equipment, lab coat cleaning, and sample containment.

- BSL2 materials should NEVER be in the public cold rooms (ie: CBEC X37 and X38.)

- Plants or animals not intended for research should not be in BSL2 labs.

- All materials with potential BSL2 exposure should be treated as if it contains a pathogenic agent.

- Needles should NEVER be recapped after use.

- Proper disinfectant should be used (10% bleach & 70% ethanol, 1M NaOH, or equivalent).

- Lab coat/Goggles/Gloves are required in BSL2 designated areas.

- Laboratory personnel must be provided medical surveillance, as appropriate, and offered available immunizations for agents handled or potentially present in the laboratory: Occupational Health Registry.

- Incidents that may result in exposure to infectious materials must be immediately evaluated, treated, and reported to the laboratory supervisor. Medical evaluation, surveillance and treatment should be provided and appropriate records maintained.

- All procedures involving the manipulation of infectious materials that may generate an aerosol should be conducted within a Biosafety BSC or other physical containment devices.

- Access to labs should be strictly controlled. Do not leave the doors propped open or allow unauthorized personnel to enter the lab without direct supervision.

4. Resources

4.1 EHS online training program:

Safety training has to be completed before working in the lab. The specific training program depends on the research group’s requirements. Students should submit the online training certificates to the safety coordinator after completion.

4.3 Chemical Hygiene Committee (ChyComm)

ChyComm is a safety committee organized and run by CBE graduate students with supervision from a faculty representative. For more information, please visit the ChyComm page.